Reaction Kinetics of Ethyl Propanoate Saponification

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Saponification Kinetics Background and Objectives

Saponification, a fundamental reaction in organic chemistry, has been extensively studied for its significance in both industrial applications and academic research. The saponification of ethyl propanoate, in particular, serves as a model reaction for understanding the kinetics of ester hydrolysis. This reaction involves the base-catalyzed hydrolysis of ethyl propanoate to form sodium propanoate and ethanol.

The historical context of saponification dates back to ancient times when it was primarily used for soap production. However, its importance in modern chemistry extends far beyond this initial application. The study of saponification kinetics has evolved significantly over the past century, with researchers developing increasingly sophisticated methods to analyze reaction rates and mechanisms.

In the context of ethyl propanoate saponification, the primary objective is to elucidate the reaction kinetics, including the determination of rate constants, activation energy, and the influence of various factors on the reaction rate. This research aims to provide a comprehensive understanding of the reaction mechanism, which is crucial for optimizing industrial processes and developing new applications in fields such as pharmaceuticals, food science, and materials engineering.

The investigation of ethyl propanoate saponification kinetics typically involves monitoring the reaction progress using various analytical techniques. These may include titration methods, spectrophotometry, conductometry, or more advanced techniques such as NMR spectroscopy. Each method offers unique insights into the reaction dynamics, allowing researchers to track the disappearance of reactants or the formation of products over time.

One of the key goals in studying this reaction is to establish the order of the reaction with respect to each reactant and the overall reaction order. This information is vital for predicting reaction rates under different conditions and for scaling up processes from laboratory to industrial levels. Additionally, researchers aim to determine the activation energy of the reaction, which provides insights into the energy barrier that must be overcome for the reaction to proceed.

The temperature dependence of the reaction rate is another critical aspect of the kinetic study. By conducting experiments at various temperatures, researchers can apply the Arrhenius equation to calculate activation parameters, offering a deeper understanding of the reaction's energetics and mechanism.

Furthermore, the investigation of ethyl propanoate saponification serves as a platform for exploring more complex ester hydrolysis reactions. The principles and methodologies developed through this study can be applied to a wide range of similar reactions, contributing to the broader field of organic reaction kinetics.

The historical context of saponification dates back to ancient times when it was primarily used for soap production. However, its importance in modern chemistry extends far beyond this initial application. The study of saponification kinetics has evolved significantly over the past century, with researchers developing increasingly sophisticated methods to analyze reaction rates and mechanisms.

In the context of ethyl propanoate saponification, the primary objective is to elucidate the reaction kinetics, including the determination of rate constants, activation energy, and the influence of various factors on the reaction rate. This research aims to provide a comprehensive understanding of the reaction mechanism, which is crucial for optimizing industrial processes and developing new applications in fields such as pharmaceuticals, food science, and materials engineering.

The investigation of ethyl propanoate saponification kinetics typically involves monitoring the reaction progress using various analytical techniques. These may include titration methods, spectrophotometry, conductometry, or more advanced techniques such as NMR spectroscopy. Each method offers unique insights into the reaction dynamics, allowing researchers to track the disappearance of reactants or the formation of products over time.

One of the key goals in studying this reaction is to establish the order of the reaction with respect to each reactant and the overall reaction order. This information is vital for predicting reaction rates under different conditions and for scaling up processes from laboratory to industrial levels. Additionally, researchers aim to determine the activation energy of the reaction, which provides insights into the energy barrier that must be overcome for the reaction to proceed.

The temperature dependence of the reaction rate is another critical aspect of the kinetic study. By conducting experiments at various temperatures, researchers can apply the Arrhenius equation to calculate activation parameters, offering a deeper understanding of the reaction's energetics and mechanism.

Furthermore, the investigation of ethyl propanoate saponification serves as a platform for exploring more complex ester hydrolysis reactions. The principles and methodologies developed through this study can be applied to a wide range of similar reactions, contributing to the broader field of organic reaction kinetics.

Industrial Applications and Market Analysis

The saponification of ethyl propanoate has significant industrial applications, particularly in the production of soaps, detergents, and other cleaning products. This reaction is a fundamental process in the chemical industry, serving as a model for understanding ester hydrolysis and base-catalyzed reactions. The market for products derived from this reaction is substantial and continues to grow globally.

In the soap and detergent industry, the saponification of ethyl propanoate and similar esters is crucial for producing the active ingredients in many cleaning products. The global soap and detergent market was valued at approximately $97.26 billion in 2020 and is projected to reach $198.61 billion by 2027, growing at a CAGR of 5.2% from 2021 to 2027. This growth is driven by increasing awareness of hygiene and cleanliness, especially in developing countries, and the rising demand for eco-friendly and natural cleaning products.

The pharmaceutical industry also utilizes the saponification of ethyl propanoate in the synthesis of various drugs and intermediates. The reaction's well-understood kinetics make it valuable for developing and optimizing pharmaceutical manufacturing processes. The global pharmaceutical market, which benefits from such reactions, was valued at $1.27 trillion in 2020 and is expected to expand at a CAGR of 11.34% from 2021 to 2028.

In the food industry, the saponification reaction is used in the production of emulsifiers and food additives. These compounds play a crucial role in improving the texture, stability, and shelf life of various food products. The global food emulsifiers market size was valued at $3.23 billion in 2020 and is projected to reach $4.89 billion by 2028, growing at a CAGR of 5.3% from 2021 to 2028.

The cosmetics and personal care industry also benefits from the saponification of ethyl propanoate and similar compounds. These reactions are used in the production of various cosmetic ingredients, including emollients and surfactants. The global cosmetics market size was valued at $380.2 billion in 2019 and is expected to reach $463.5 billion by 2027, growing at a CAGR of 5.3% from 2021 to 2027.

Research on the reaction kinetics of ethyl propanoate saponification continues to be relevant for process optimization and the development of new products across these industries. Understanding the reaction mechanisms and kinetics allows for more efficient production processes, reduced energy consumption, and improved product quality. This research also contributes to the development of greener and more sustainable manufacturing methods, aligning with the growing consumer demand for environmentally friendly products.

In the soap and detergent industry, the saponification of ethyl propanoate and similar esters is crucial for producing the active ingredients in many cleaning products. The global soap and detergent market was valued at approximately $97.26 billion in 2020 and is projected to reach $198.61 billion by 2027, growing at a CAGR of 5.2% from 2021 to 2027. This growth is driven by increasing awareness of hygiene and cleanliness, especially in developing countries, and the rising demand for eco-friendly and natural cleaning products.

The pharmaceutical industry also utilizes the saponification of ethyl propanoate in the synthesis of various drugs and intermediates. The reaction's well-understood kinetics make it valuable for developing and optimizing pharmaceutical manufacturing processes. The global pharmaceutical market, which benefits from such reactions, was valued at $1.27 trillion in 2020 and is expected to expand at a CAGR of 11.34% from 2021 to 2028.

In the food industry, the saponification reaction is used in the production of emulsifiers and food additives. These compounds play a crucial role in improving the texture, stability, and shelf life of various food products. The global food emulsifiers market size was valued at $3.23 billion in 2020 and is projected to reach $4.89 billion by 2028, growing at a CAGR of 5.3% from 2021 to 2028.

The cosmetics and personal care industry also benefits from the saponification of ethyl propanoate and similar compounds. These reactions are used in the production of various cosmetic ingredients, including emollients and surfactants. The global cosmetics market size was valued at $380.2 billion in 2019 and is expected to reach $463.5 billion by 2027, growing at a CAGR of 5.3% from 2021 to 2027.

Research on the reaction kinetics of ethyl propanoate saponification continues to be relevant for process optimization and the development of new products across these industries. Understanding the reaction mechanisms and kinetics allows for more efficient production processes, reduced energy consumption, and improved product quality. This research also contributes to the development of greener and more sustainable manufacturing methods, aligning with the growing consumer demand for environmentally friendly products.

Current Challenges in Ethyl Propanoate Saponification

The saponification of ethyl propanoate, while a well-established reaction in organic chemistry, still presents several challenges in terms of reaction kinetics research. One of the primary difficulties lies in accurately measuring and controlling the reaction rate, which is influenced by multiple factors such as temperature, concentration, and the presence of catalysts.

Temperature control remains a significant challenge in studying this reaction. Even small fluctuations in temperature can lead to substantial changes in reaction rates, making it difficult to obtain consistent and reproducible results. Researchers must develop precise temperature control systems to maintain stable conditions throughout the experiment.

Concentration measurement and control pose another hurdle. As the reaction progresses, the concentrations of reactants and products change continuously. Accurately tracking these changes in real-time requires sophisticated analytical techniques and equipment. Moreover, ensuring uniform mixing and avoiding concentration gradients within the reaction mixture is crucial for obtaining reliable kinetic data.

The presence of side reactions or competing processes can complicate the kinetic analysis of ethyl propanoate saponification. These secondary reactions may interfere with the main saponification process, leading to deviations from expected kinetic models. Identifying and quantifying these side reactions is essential for developing accurate kinetic models.

Another challenge is the potential for mass transfer limitations, particularly in heterogeneous systems or when working with viscous reaction mixtures. These limitations can mask the true intrinsic kinetics of the reaction, making it difficult to determine the fundamental rate constants and reaction mechanisms.

The choice of solvent system also presents challenges in studying the reaction kinetics. Different solvents can significantly affect the reaction rate and mechanism, and finding a suitable solvent that does not interfere with the reaction or analytical methods can be problematic.

Lastly, the development of robust mathematical models to describe the reaction kinetics remains an ongoing challenge. While simple models like pseudo-first-order kinetics are often used, they may not fully capture the complexities of the reaction under all conditions. More sophisticated models that account for factors such as reversibility, ion pairing, and solvent effects are needed to accurately describe the reaction kinetics across a wide range of conditions.

Temperature control remains a significant challenge in studying this reaction. Even small fluctuations in temperature can lead to substantial changes in reaction rates, making it difficult to obtain consistent and reproducible results. Researchers must develop precise temperature control systems to maintain stable conditions throughout the experiment.

Concentration measurement and control pose another hurdle. As the reaction progresses, the concentrations of reactants and products change continuously. Accurately tracking these changes in real-time requires sophisticated analytical techniques and equipment. Moreover, ensuring uniform mixing and avoiding concentration gradients within the reaction mixture is crucial for obtaining reliable kinetic data.

The presence of side reactions or competing processes can complicate the kinetic analysis of ethyl propanoate saponification. These secondary reactions may interfere with the main saponification process, leading to deviations from expected kinetic models. Identifying and quantifying these side reactions is essential for developing accurate kinetic models.

Another challenge is the potential for mass transfer limitations, particularly in heterogeneous systems or when working with viscous reaction mixtures. These limitations can mask the true intrinsic kinetics of the reaction, making it difficult to determine the fundamental rate constants and reaction mechanisms.

The choice of solvent system also presents challenges in studying the reaction kinetics. Different solvents can significantly affect the reaction rate and mechanism, and finding a suitable solvent that does not interfere with the reaction or analytical methods can be problematic.

Lastly, the development of robust mathematical models to describe the reaction kinetics remains an ongoing challenge. While simple models like pseudo-first-order kinetics are often used, they may not fully capture the complexities of the reaction under all conditions. More sophisticated models that account for factors such as reversibility, ion pairing, and solvent effects are needed to accurately describe the reaction kinetics across a wide range of conditions.

Existing Methodologies for Kinetic Studies

01 Reaction kinetics measurement and analysis

Various methods and apparatus are used to measure and analyze the kinetics of ethyl propanoate saponification. This includes spectroscopic techniques, calorimetry, and advanced analytical instruments to monitor reaction progress and determine rate constants.- Reaction kinetics measurement and analysis: Various methods and apparatus are used to measure and analyze the kinetics of ethyl propanoate saponification. This includes spectroscopic techniques, calorimetry, and advanced analytical instruments to monitor reaction progress and determine rate constants.

- Temperature effects on reaction rate: The influence of temperature on the saponification kinetics of ethyl propanoate is studied. Experiments are conducted at different temperatures to determine activation energy and other thermodynamic parameters of the reaction.

- Catalyst influence on saponification: The effect of various catalysts on the saponification kinetics of ethyl propanoate is investigated. Different types and concentrations of catalysts are tested to optimize reaction rates and yields.

- Reaction mechanism studies: Detailed investigations into the reaction mechanism of ethyl propanoate saponification are conducted. This includes identifying intermediates, determining rate-limiting steps, and proposing reaction pathways.

- Continuous flow reactors for kinetic studies: Continuous flow reactors are developed and utilized for studying the saponification kinetics of ethyl propanoate. These systems allow for precise control of reaction conditions and real-time monitoring of the reaction progress.

02 Temperature effects on reaction rate

The influence of temperature on the saponification kinetics of ethyl propanoate is studied. Experiments are conducted at different temperatures to determine activation energy and other thermodynamic parameters of the reaction.Expand Specific Solutions03 Catalyst optimization for saponification

Research focuses on optimizing catalysts to enhance the rate of ethyl propanoate saponification. Various catalysts, including enzymes and metal complexes, are investigated to improve reaction efficiency and selectivity.Expand Specific Solutions04 Reaction mechanism elucidation

Studies are conducted to elucidate the detailed mechanism of ethyl propanoate saponification. This involves identifying intermediates, determining rate-limiting steps, and proposing reaction pathways based on experimental and theoretical evidence.Expand Specific Solutions05 Continuous flow reactors for kinetic studies

Continuous flow reactors are developed and utilized for studying the saponification kinetics of ethyl propanoate. These systems allow for precise control of reaction conditions and real-time monitoring of reaction progress, enabling more accurate kinetic measurements.Expand Specific Solutions

Key Players in Ester Hydrolysis Research

The research on ethyl propanoate saponification reaction kinetics is in a mature stage of development, with a well-established market and extensive scientific understanding. The global market for this technology is relatively stable, driven by its applications in various industries, including pharmaceuticals, chemicals, and materials science. Companies like Kuraray Co., Ltd., China Petroleum & Chemical Corp., and Mitsubishi Chemical UK Ltd. are key players in this field, leveraging their expertise in chemical processes and industrial-scale production. The technology's maturity is evident from the involvement of academic institutions such as Beijing University of Chemical Technology and Sichuan University, which contribute to ongoing research and development efforts. While the core principles are well-understood, there is still room for innovation in optimizing reaction conditions and exploring novel catalysts to enhance efficiency and sustainability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has conducted extensive research on the reaction kinetics of ethyl propanoate saponification. Their approach involves using advanced spectroscopic techniques, such as in-situ FTIR and Raman spectroscopy, to monitor the reaction progress in real-time[1]. They have developed a comprehensive kinetic model that accounts for temperature, concentration, and catalyst effects on the saponification rate[3]. Sinopec's research also includes the use of microreactor technology to enhance mixing and heat transfer, resulting in more precise kinetic data[5]. Their studies have contributed to optimizing industrial-scale ester hydrolysis processes, improving efficiency and reducing energy consumption in petrochemical operations[7].

Strengths: Access to advanced analytical tools, extensive industrial application experience, and ability to scale up research findings. Weaknesses: Potential bias towards petroleum-based processes, possibly overlooking alternative green chemistry approaches.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has made significant contributions to the study of ethyl propanoate saponification kinetics. Their research focuses on developing novel catalytic systems to enhance reaction rates and selectivity[2]. They have employed computational chemistry methods, including density functional theory (DFT) calculations, to elucidate the reaction mechanism at a molecular level[4]. The university's team has also investigated the effects of various solvents and ionic liquids on the saponification kinetics, providing insights into green chemistry applications[6]. Their work includes the development of kinetic models that incorporate non-ideal mixing effects and mass transfer limitations, which are crucial for accurately predicting reaction behavior in industrial settings[8].

Strengths: Strong theoretical foundation, innovative catalytic systems, and integration of computational and experimental approaches. Weaknesses: Possible limitations in large-scale industrial validation of research findings.

Core Innovations in Reaction Rate Analysis

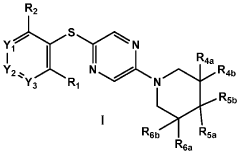

Compounds and compositions for inhibiting the activity of SHP2

PatentWO2016203406A1

Innovation

- Development of specific compounds of Formula I, which include a range of substituents and structures, that inhibit SHP2 activity by modulating its enzymatic function, potentially used in pharmaceutical compositions and methods for treating diseases associated with aberrant SHP2 activity.

Novel alkyloxy-ethers and alkoxylates thereof

PatentInactiveEP2152652A1

Innovation

- A process involving the reaction of 1-chloro-2,3-epoxypropane with a stoichiometric excess of alcohol in the presence of a metal hydroxide, followed by reaction with an alkylene oxide using an ionic catalyst, to produce 1,3-dialkyloxy-2-propanol and its alkoxylate, offering high selectivity and economic viability.

Environmental Impact of Saponification Processes

The saponification of ethyl propanoate, while a common and useful chemical process, can have significant environmental impacts that warrant careful consideration. The primary environmental concerns associated with this process stem from the chemicals involved and the byproducts generated.

One of the main environmental issues is the potential for water pollution. The reaction typically involves sodium hydroxide, a strong base that can alter the pH of water bodies if released untreated. This pH change can have detrimental effects on aquatic ecosystems, disrupting the delicate balance of flora and fauna. Additionally, the ethanol produced as a byproduct of the saponification reaction can contribute to organic pollution in water systems if not properly managed.

Air pollution is another potential concern, particularly in large-scale industrial processes. Volatile organic compounds (VOCs) may be released during the reaction or subsequent processing steps. These VOCs can contribute to the formation of ground-level ozone and smog, which have negative impacts on air quality and human health.

The energy requirements for the saponification process also contribute to its environmental footprint. Heating and mixing operations often require significant energy inputs, which, depending on the energy source, can lead to increased greenhouse gas emissions and contribute to climate change.

Waste management is a critical aspect of the environmental impact assessment. The unreacted materials, byproducts, and any catalysts used in the process must be properly handled and disposed of to prevent environmental contamination. Improper disposal can lead to soil pollution and potential groundwater contamination.

However, it's important to note that the environmental impact of saponification processes can be mitigated through careful process design and implementation of best practices. Closed-loop systems, efficient heat recovery, and the use of renewable energy sources can significantly reduce the overall environmental footprint. Additionally, the development of green chemistry approaches, such as using bio-based feedstocks or environmentally benign catalysts, can further improve the sustainability of saponification processes.

In conclusion, while the saponification of ethyl propanoate presents several environmental challenges, ongoing research and technological advancements are continually improving the eco-friendliness of this important chemical process. Future developments in this field will likely focus on enhancing process efficiency, reducing waste generation, and exploring more sustainable raw materials and reaction conditions.

One of the main environmental issues is the potential for water pollution. The reaction typically involves sodium hydroxide, a strong base that can alter the pH of water bodies if released untreated. This pH change can have detrimental effects on aquatic ecosystems, disrupting the delicate balance of flora and fauna. Additionally, the ethanol produced as a byproduct of the saponification reaction can contribute to organic pollution in water systems if not properly managed.

Air pollution is another potential concern, particularly in large-scale industrial processes. Volatile organic compounds (VOCs) may be released during the reaction or subsequent processing steps. These VOCs can contribute to the formation of ground-level ozone and smog, which have negative impacts on air quality and human health.

The energy requirements for the saponification process also contribute to its environmental footprint. Heating and mixing operations often require significant energy inputs, which, depending on the energy source, can lead to increased greenhouse gas emissions and contribute to climate change.

Waste management is a critical aspect of the environmental impact assessment. The unreacted materials, byproducts, and any catalysts used in the process must be properly handled and disposed of to prevent environmental contamination. Improper disposal can lead to soil pollution and potential groundwater contamination.

However, it's important to note that the environmental impact of saponification processes can be mitigated through careful process design and implementation of best practices. Closed-loop systems, efficient heat recovery, and the use of renewable energy sources can significantly reduce the overall environmental footprint. Additionally, the development of green chemistry approaches, such as using bio-based feedstocks or environmentally benign catalysts, can further improve the sustainability of saponification processes.

In conclusion, while the saponification of ethyl propanoate presents several environmental challenges, ongoing research and technological advancements are continually improving the eco-friendliness of this important chemical process. Future developments in this field will likely focus on enhancing process efficiency, reducing waste generation, and exploring more sustainable raw materials and reaction conditions.

Analytical Techniques for Reaction Monitoring

Monitoring the progress of the saponification reaction of ethyl propanoate is crucial for understanding its kinetics and optimizing the process. Several analytical techniques can be employed to track the reaction in real-time or through periodic sampling. Spectroscopic methods, such as UV-visible spectroscopy and Fourier-transform infrared spectroscopy (FTIR), offer non-invasive, real-time monitoring capabilities. UV-visible spectroscopy can track the disappearance of the ester or the formation of the carboxylate anion, while FTIR can monitor the changes in characteristic absorption bands of the reactants and products.

Chromatographic techniques, particularly high-performance liquid chromatography (HPLC), provide quantitative analysis of the reaction components. HPLC can separate and quantify the ester, alcohol, and carboxylic acid products, allowing for precise determination of reaction progress and yield. Gas chromatography (GC) may also be employed, especially for volatile components, offering high sensitivity and resolution.

Titration methods remain valuable for monitoring the saponification reaction. Acid-base titration can determine the concentration of hydroxide ions consumed or the carboxylic acid formed. Conductometric titration is particularly useful, as it can continuously monitor the change in electrical conductivity of the reaction mixture, which correlates with the progress of saponification.

Nuclear Magnetic Resonance (NMR) spectroscopy, while typically used for offline analysis, can provide detailed structural information about the reactants, intermediates, and products. Time-resolved NMR techniques can offer insights into reaction mechanisms and kinetics. For industrial applications, in-line process analytical technology (PAT) tools, such as Raman spectroscopy or near-infrared (NIR) spectroscopy, enable continuous monitoring without the need for sampling.

Calorimetric methods can indirectly monitor the reaction by measuring the heat released during saponification. Isothermal titration calorimetry (ITC) or reaction calorimetry can provide both kinetic and thermodynamic data. These techniques are particularly useful for studying the energetics of the saponification process.

The choice of analytical technique depends on factors such as the scale of the reaction, required precision, and the specific information needed. Often, a combination of techniques is employed to gain comprehensive insights into the reaction kinetics. Advanced data analysis methods, including chemometrics and machine learning algorithms, can be applied to extract maximum information from the analytical data, enhancing the understanding of the saponification kinetics of ethyl propanoate.

Chromatographic techniques, particularly high-performance liquid chromatography (HPLC), provide quantitative analysis of the reaction components. HPLC can separate and quantify the ester, alcohol, and carboxylic acid products, allowing for precise determination of reaction progress and yield. Gas chromatography (GC) may also be employed, especially for volatile components, offering high sensitivity and resolution.

Titration methods remain valuable for monitoring the saponification reaction. Acid-base titration can determine the concentration of hydroxide ions consumed or the carboxylic acid formed. Conductometric titration is particularly useful, as it can continuously monitor the change in electrical conductivity of the reaction mixture, which correlates with the progress of saponification.

Nuclear Magnetic Resonance (NMR) spectroscopy, while typically used for offline analysis, can provide detailed structural information about the reactants, intermediates, and products. Time-resolved NMR techniques can offer insights into reaction mechanisms and kinetics. For industrial applications, in-line process analytical technology (PAT) tools, such as Raman spectroscopy or near-infrared (NIR) spectroscopy, enable continuous monitoring without the need for sampling.

Calorimetric methods can indirectly monitor the reaction by measuring the heat released during saponification. Isothermal titration calorimetry (ITC) or reaction calorimetry can provide both kinetic and thermodynamic data. These techniques are particularly useful for studying the energetics of the saponification process.

The choice of analytical technique depends on factors such as the scale of the reaction, required precision, and the specific information needed. Often, a combination of techniques is employed to gain comprehensive insights into the reaction kinetics. Advanced data analysis methods, including chemometrics and machine learning algorithms, can be applied to extract maximum information from the analytical data, enhancing the understanding of the saponification kinetics of ethyl propanoate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!