Role of AGM Battery in Energy Harvesting Applications

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Background

Absorbed Glass Mat (AGM) batteries have emerged as a crucial component in energy harvesting applications, revolutionizing the way we store and utilize renewable energy. These batteries, first developed in the 1980s for military aircraft, have since found widespread use in various industries due to their unique characteristics and advantages.

AGM batteries are a type of lead-acid battery that uses a special glass mat separator to absorb and immobilize the electrolyte. This design allows for a maintenance-free operation and provides several benefits over traditional flooded lead-acid batteries, including improved safety, higher efficiency, and better performance in extreme conditions.

In the context of energy harvesting applications, AGM batteries play a vital role in addressing the intermittent nature of renewable energy sources. Solar panels, wind turbines, and other energy harvesting systems often generate power inconsistently, necessitating efficient energy storage solutions to ensure a stable and reliable power supply.

The high charge acceptance rate of AGM batteries makes them particularly well-suited for energy harvesting systems. They can quickly absorb and store energy during peak production periods, ensuring minimal energy waste. This characteristic is especially valuable in solar and wind energy applications, where power generation can fluctuate rapidly based on environmental conditions.

AGM batteries also offer excellent deep cycle performance, allowing for repeated charge and discharge cycles without significant degradation. This feature is crucial in energy harvesting applications, where batteries may need to undergo multiple cycles daily to balance energy production and consumption.

The low internal resistance of AGM batteries contributes to their high efficiency in energy storage and delivery. This property minimizes energy losses during charging and discharging processes, maximizing the overall efficiency of the energy harvesting system. Additionally, AGM batteries have a low self-discharge rate, enabling them to retain stored energy for extended periods, which is beneficial in applications with irregular energy production or consumption patterns.

The robust construction and sealed design of AGM batteries make them ideal for use in various environmental conditions. They can operate effectively in a wide range of temperatures and are resistant to vibration and shock, making them suitable for both stationary and mobile energy harvesting applications.

As the demand for renewable energy solutions continues to grow, the role of AGM batteries in energy harvesting applications is becoming increasingly significant. Their ability to efficiently store and deliver energy, combined with their durability and low maintenance requirements, positions them as a key enabler in the transition towards more sustainable energy systems.

AGM batteries are a type of lead-acid battery that uses a special glass mat separator to absorb and immobilize the electrolyte. This design allows for a maintenance-free operation and provides several benefits over traditional flooded lead-acid batteries, including improved safety, higher efficiency, and better performance in extreme conditions.

In the context of energy harvesting applications, AGM batteries play a vital role in addressing the intermittent nature of renewable energy sources. Solar panels, wind turbines, and other energy harvesting systems often generate power inconsistently, necessitating efficient energy storage solutions to ensure a stable and reliable power supply.

The high charge acceptance rate of AGM batteries makes them particularly well-suited for energy harvesting systems. They can quickly absorb and store energy during peak production periods, ensuring minimal energy waste. This characteristic is especially valuable in solar and wind energy applications, where power generation can fluctuate rapidly based on environmental conditions.

AGM batteries also offer excellent deep cycle performance, allowing for repeated charge and discharge cycles without significant degradation. This feature is crucial in energy harvesting applications, where batteries may need to undergo multiple cycles daily to balance energy production and consumption.

The low internal resistance of AGM batteries contributes to their high efficiency in energy storage and delivery. This property minimizes energy losses during charging and discharging processes, maximizing the overall efficiency of the energy harvesting system. Additionally, AGM batteries have a low self-discharge rate, enabling them to retain stored energy for extended periods, which is beneficial in applications with irregular energy production or consumption patterns.

The robust construction and sealed design of AGM batteries make them ideal for use in various environmental conditions. They can operate effectively in a wide range of temperatures and are resistant to vibration and shock, making them suitable for both stationary and mobile energy harvesting applications.

As the demand for renewable energy solutions continues to grow, the role of AGM batteries in energy harvesting applications is becoming increasingly significant. Their ability to efficiently store and deliver energy, combined with their durability and low maintenance requirements, positions them as a key enabler in the transition towards more sustainable energy systems.

Energy Harvesting Market

The energy harvesting market has experienced significant growth in recent years, driven by the increasing demand for sustainable and autonomous power sources across various industries. This market encompasses a wide range of technologies designed to capture and convert ambient energy from sources such as solar, thermal, kinetic, and electromagnetic into usable electrical power. The global energy harvesting market was valued at approximately $460 million in 2020 and is projected to reach $1.2 billion by 2026, growing at a CAGR of around 17% during the forecast period.

One of the key factors driving market growth is the rapid proliferation of Internet of Things (IoT) devices and wireless sensor networks. These applications require long-lasting, maintenance-free power sources, making energy harvesting solutions particularly attractive. The industrial sector has emerged as a major adopter of energy harvesting technologies, utilizing them for condition monitoring, predictive maintenance, and process optimization in manufacturing facilities.

The consumer electronics segment also plays a crucial role in the energy harvesting market, with applications ranging from wearable devices to smart home systems. The automotive industry is another significant contributor, incorporating energy harvesting technologies in vehicles for improved fuel efficiency and powering various sensors and electronic components.

Geographically, North America and Europe currently dominate the energy harvesting market, owing to their advanced technological infrastructure and strong focus on sustainable energy solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing industrialization, government initiatives promoting clean energy, and the rapid adoption of IoT technologies.

The market landscape is characterized by a mix of established players and innovative startups. Key companies in the energy harvesting market include EnOcean GmbH, Texas Instruments, STMicroelectronics, Cymbet Corporation, and Powercast Corporation. These companies are continuously investing in research and development to improve the efficiency and cost-effectiveness of energy harvesting solutions.

Despite the promising growth prospects, the energy harvesting market faces several challenges. These include the relatively low power output of current harvesting technologies, which limits their application in high-power devices, and the need for more efficient energy storage solutions to complement harvesting systems. Additionally, the high initial costs of some energy harvesting technologies can be a barrier to widespread adoption, particularly in price-sensitive markets.

One of the key factors driving market growth is the rapid proliferation of Internet of Things (IoT) devices and wireless sensor networks. These applications require long-lasting, maintenance-free power sources, making energy harvesting solutions particularly attractive. The industrial sector has emerged as a major adopter of energy harvesting technologies, utilizing them for condition monitoring, predictive maintenance, and process optimization in manufacturing facilities.

The consumer electronics segment also plays a crucial role in the energy harvesting market, with applications ranging from wearable devices to smart home systems. The automotive industry is another significant contributor, incorporating energy harvesting technologies in vehicles for improved fuel efficiency and powering various sensors and electronic components.

Geographically, North America and Europe currently dominate the energy harvesting market, owing to their advanced technological infrastructure and strong focus on sustainable energy solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing industrialization, government initiatives promoting clean energy, and the rapid adoption of IoT technologies.

The market landscape is characterized by a mix of established players and innovative startups. Key companies in the energy harvesting market include EnOcean GmbH, Texas Instruments, STMicroelectronics, Cymbet Corporation, and Powercast Corporation. These companies are continuously investing in research and development to improve the efficiency and cost-effectiveness of energy harvesting solutions.

Despite the promising growth prospects, the energy harvesting market faces several challenges. These include the relatively low power output of current harvesting technologies, which limits their application in high-power devices, and the need for more efficient energy storage solutions to complement harvesting systems. Additionally, the high initial costs of some energy harvesting technologies can be a barrier to widespread adoption, particularly in price-sensitive markets.

AGM Battery Challenges

AGM (Absorbent Glass Mat) batteries face several challenges in energy harvesting applications, despite their widespread use in various industries. One of the primary issues is their limited cycle life compared to newer battery technologies. While AGM batteries can typically withstand 300-500 charge-discharge cycles, this may not be sufficient for long-term energy harvesting systems that require frequent cycling.

Another significant challenge is the temperature sensitivity of AGM batteries. Their performance can degrade significantly in extreme temperatures, both hot and cold. This poses problems for energy harvesting applications in outdoor environments or industrial settings with wide temperature fluctuations. The reduced efficiency and capacity at non-optimal temperatures can impact the overall effectiveness of the energy harvesting system.

The self-discharge rate of AGM batteries is also a concern in energy harvesting scenarios. Although lower than traditional lead-acid batteries, AGM batteries still experience some self-discharge over time. This can be problematic in applications where energy is harvested and stored for extended periods before use, potentially leading to energy loss and reduced system efficiency.

Weight and size constraints present another challenge for AGM batteries in energy harvesting applications. While they are more compact than flooded lead-acid batteries, they are still relatively heavy and bulky compared to lithium-ion alternatives. This can limit their use in portable or space-constrained energy harvesting systems, where weight and size are critical factors.

The charging characteristics of AGM batteries can also be challenging in energy harvesting contexts. They require careful voltage regulation during charging to prevent overcharging, which can lead to gassing and reduced battery life. This necessitates more complex charge controllers, potentially increasing system complexity and cost.

Furthermore, AGM batteries have limitations in terms of depth of discharge (DoD). While they can handle deeper discharges than traditional lead-acid batteries, regularly discharging them below 50% can significantly reduce their lifespan. This restriction can be problematic in energy harvesting applications where consistent, deep cycling may be necessary to maximize energy utilization.

Lastly, the environmental impact of AGM batteries poses challenges in terms of sustainability and disposal. Although they are sealed and maintenance-free, they still contain lead and sulfuric acid, which require proper handling and recycling at the end of their life cycle. This aspect becomes increasingly important as environmental regulations tighten and consumers demand more eco-friendly energy storage solutions for harvesting applications.

Another significant challenge is the temperature sensitivity of AGM batteries. Their performance can degrade significantly in extreme temperatures, both hot and cold. This poses problems for energy harvesting applications in outdoor environments or industrial settings with wide temperature fluctuations. The reduced efficiency and capacity at non-optimal temperatures can impact the overall effectiveness of the energy harvesting system.

The self-discharge rate of AGM batteries is also a concern in energy harvesting scenarios. Although lower than traditional lead-acid batteries, AGM batteries still experience some self-discharge over time. This can be problematic in applications where energy is harvested and stored for extended periods before use, potentially leading to energy loss and reduced system efficiency.

Weight and size constraints present another challenge for AGM batteries in energy harvesting applications. While they are more compact than flooded lead-acid batteries, they are still relatively heavy and bulky compared to lithium-ion alternatives. This can limit their use in portable or space-constrained energy harvesting systems, where weight and size are critical factors.

The charging characteristics of AGM batteries can also be challenging in energy harvesting contexts. They require careful voltage regulation during charging to prevent overcharging, which can lead to gassing and reduced battery life. This necessitates more complex charge controllers, potentially increasing system complexity and cost.

Furthermore, AGM batteries have limitations in terms of depth of discharge (DoD). While they can handle deeper discharges than traditional lead-acid batteries, regularly discharging them below 50% can significantly reduce their lifespan. This restriction can be problematic in energy harvesting applications where consistent, deep cycling may be necessary to maximize energy utilization.

Lastly, the environmental impact of AGM batteries poses challenges in terms of sustainability and disposal. Although they are sealed and maintenance-free, they still contain lead and sulfuric acid, which require proper handling and recycling at the end of their life cycle. This aspect becomes increasingly important as environmental regulations tighten and consumers demand more eco-friendly energy storage solutions for harvesting applications.

AGM in Energy Harvesting

01 AGM battery structure and design improvements

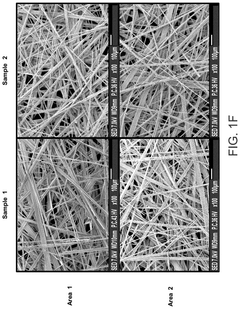

Advancements in AGM battery structure and design focus on enhancing performance and efficiency. These improvements include optimized electrode configurations, innovative separators, and advanced casing designs. Such enhancements aim to increase battery capacity, improve charge acceptance, and extend overall battery life.- AGM battery structure and design: Innovations in the structure and design of AGM (Absorbent Glass Mat) batteries, including improvements in electrode arrangement, separator materials, and overall battery construction to enhance performance and efficiency.

- Electrolyte management in AGM batteries: Advancements in electrolyte management systems for AGM batteries, focusing on optimizing electrolyte distribution, reducing electrolyte loss, and improving overall battery life and performance.

- Thermal management of AGM batteries: Development of thermal management solutions for AGM batteries, including heat dissipation mechanisms and temperature control systems to maintain optimal operating conditions and extend battery lifespan.

- AGM battery monitoring and control systems: Implementation of advanced monitoring and control systems for AGM batteries, incorporating sensors, data analysis, and intelligent management to optimize battery performance, safety, and longevity.

- AGM battery manufacturing processes: Improvements in AGM battery manufacturing processes, including advancements in electrode production, assembly techniques, and quality control measures to enhance battery reliability and consistency.

02 Electrolyte management and absorption techniques

Effective electrolyte management is crucial for AGM battery performance. This includes developing advanced absorption glass mat materials and optimizing electrolyte distribution within the battery. Improved techniques for electrolyte retention and distribution contribute to better battery performance, especially in high-vibration environments.Expand Specific Solutions03 Thermal management and safety features

Innovations in thermal management and safety features for AGM batteries focus on preventing overheating and improving overall battery safety. This includes the development of advanced cooling systems, temperature monitoring devices, and safety venting mechanisms to enhance battery reliability and longevity.Expand Specific Solutions04 Charging and maintenance technologies

Advanced charging and maintenance technologies for AGM batteries aim to optimize battery performance and extend service life. These innovations include smart charging algorithms, automated maintenance systems, and remote monitoring capabilities to ensure proper battery care and prevent premature failure.Expand Specific Solutions05 AGM battery applications and integration

AGM batteries are being integrated into various applications, including automotive, renewable energy storage, and backup power systems. Innovations in this area focus on optimizing battery performance for specific use cases, improving integration with other systems, and developing specialized AGM battery configurations for emerging applications.Expand Specific Solutions

Key AGM Manufacturers

The AGM battery market in energy harvesting applications is in a growth phase, driven by increasing demand for sustainable energy solutions. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, AGM batteries are relatively mature, but ongoing research and development efforts by key players such as Fengfan Co., Ltd., Camel Group Battery Research Institute Co., Ltd., and Stryten Energy LLC are focused on improving performance and efficiency. These companies, along with others like Daramic LLC and FIAMM Energy Technology SpA, are actively contributing to advancements in AGM battery technology for energy harvesting applications, indicating a competitive and innovative landscape.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced AGM battery system specifically designed for energy harvesting applications in vehicles. Their technology utilizes a proprietary electrolyte formulation and electrode design to enhance charge acceptance and cycling performance. The system incorporates intelligent battery management algorithms that optimize energy capture from regenerative braking and other vehicle systems. GM's AGM batteries feature a valve-regulated design that allows for maintenance-free operation and improved safety in automotive environments[1][3]. The company has also implemented advanced manufacturing techniques to increase the consistency and reliability of their AGM batteries, resulting in longer service life and improved performance in energy harvesting scenarios[5].

Strengths: Optimized for automotive applications, high charge acceptance, improved cycling performance, and intelligent energy management. Weaknesses: Potentially higher cost compared to traditional lead-acid batteries, limited to automotive sector applications.

Stryten Energy LLC

Technical Solution: Stryten Energy has developed a range of AGM batteries specifically tailored for energy harvesting applications. Their technology focuses on high-efficiency energy storage and rapid charge acceptance, crucial for capturing intermittent energy from harvesting systems. Stryten's AGM batteries feature advanced lead-carbon electrodes that enhance cycle life and charge acceptance rates[2]. The company has also implemented a proprietary separator technology that improves electrolyte distribution and reduces internal resistance, leading to better overall performance in energy harvesting scenarios[4]. Stryten's batteries are designed with a focus on sustainability, using recycled materials and offering easy end-of-life recycling[6].

Strengths: High charge acceptance rates, improved cycle life, and focus on sustainability. Weaknesses: May have higher upfront costs, potentially limited to specific energy harvesting applications.

AGM Battery Innovations

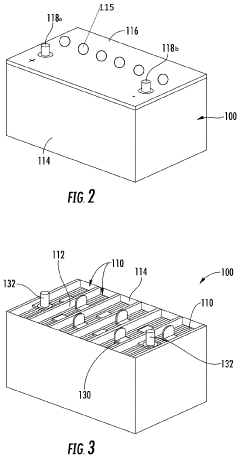

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

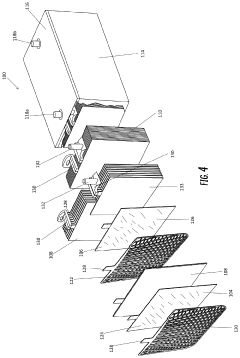

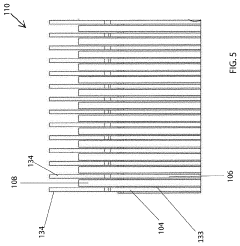

Separators with fibrous mat, lead acid batteries using the same, and methods and systems associated therewith

PatentActiveUS12113237B2

Innovation

- A porous membrane separator with a fibrous mat and ribbed structure is used, incorporating performance-enhancing additives and coatings, increased porosity, and higher silanol group silica to improve retention of active material and reduce electrical resistance, thereby preventing acid stratification and shedding.

AGM Battery Standards

AGM (Absorbent Glass Mat) battery standards play a crucial role in ensuring the quality, safety, and performance of these batteries in energy harvesting applications. These standards provide guidelines for manufacturers, users, and regulatory bodies to maintain consistency and reliability across the industry.

The International Electrotechnical Commission (IEC) has established several standards specifically for AGM batteries. IEC 60896-21 and IEC 60896-22 are key standards that define the methods for testing valve-regulated lead-acid batteries, including AGM types. These standards cover various aspects such as capacity, charge retention, cycle life, and float service life.

The Institute of Electrical and Electronics Engineers (IEEE) has also developed standards relevant to AGM batteries. IEEE 1188 provides recommended practices for the maintenance, testing, and replacement of valve-regulated lead-acid batteries in stationary applications, which is particularly relevant for energy harvesting systems.

In the United States, the Battery Council International (BCI) has established standards for AGM batteries, including specifications for dimensions, terminal configurations, and performance characteristics. These standards ensure compatibility and interchangeability among different manufacturers' products.

For energy harvesting applications, the SAE International (formerly Society of Automotive Engineers) has developed standards such as SAE J2464, which addresses safety and abuse testing of electric vehicle batteries. While not specific to AGM batteries, these standards provide valuable guidelines for battery safety in energy storage systems.

The European Union has implemented the EN 50342 standard series, which covers lead-acid starter batteries. Part 1 of this series includes general requirements and test methods applicable to AGM batteries used in energy harvesting applications.

Compliance with these standards is essential for AGM battery manufacturers to ensure their products meet industry requirements. For energy harvesting system designers, adherence to these standards helps in selecting appropriate batteries that can withstand the specific demands of their applications.

It's important to note that standards are continuously evolving to keep pace with technological advancements. As energy harvesting technologies progress, new standards may emerge or existing ones may be updated to address specific requirements of these applications.

The International Electrotechnical Commission (IEC) has established several standards specifically for AGM batteries. IEC 60896-21 and IEC 60896-22 are key standards that define the methods for testing valve-regulated lead-acid batteries, including AGM types. These standards cover various aspects such as capacity, charge retention, cycle life, and float service life.

The Institute of Electrical and Electronics Engineers (IEEE) has also developed standards relevant to AGM batteries. IEEE 1188 provides recommended practices for the maintenance, testing, and replacement of valve-regulated lead-acid batteries in stationary applications, which is particularly relevant for energy harvesting systems.

In the United States, the Battery Council International (BCI) has established standards for AGM batteries, including specifications for dimensions, terminal configurations, and performance characteristics. These standards ensure compatibility and interchangeability among different manufacturers' products.

For energy harvesting applications, the SAE International (formerly Society of Automotive Engineers) has developed standards such as SAE J2464, which addresses safety and abuse testing of electric vehicle batteries. While not specific to AGM batteries, these standards provide valuable guidelines for battery safety in energy storage systems.

The European Union has implemented the EN 50342 standard series, which covers lead-acid starter batteries. Part 1 of this series includes general requirements and test methods applicable to AGM batteries used in energy harvesting applications.

Compliance with these standards is essential for AGM battery manufacturers to ensure their products meet industry requirements. For energy harvesting system designers, adherence to these standards helps in selecting appropriate batteries that can withstand the specific demands of their applications.

It's important to note that standards are continuously evolving to keep pace with technological advancements. As energy harvesting technologies progress, new standards may emerge or existing ones may be updated to address specific requirements of these applications.

AGM Environmental Impact

The environmental impact of Absorbent Glass Mat (AGM) batteries in energy harvesting applications is a crucial consideration for sustainable technology development. AGM batteries, while offering several advantages in energy storage, also present environmental challenges that need to be addressed.

One of the primary environmental concerns associated with AGM batteries is the use of lead. Although AGM batteries are sealed and considered maintenance-free, they still contain lead, which is a toxic heavy metal. The production and disposal of lead-acid batteries, including AGM types, contribute to environmental pollution if not properly managed. However, it's worth noting that AGM batteries have a higher recycling rate compared to traditional flooded lead-acid batteries, which somewhat mitigates their environmental impact.

The manufacturing process of AGM batteries also has environmental implications. The production of glass mat separators and the assembly of battery components require energy and resources, contributing to carbon emissions and resource depletion. However, compared to some other battery technologies, AGM batteries have a relatively simple manufacturing process, which can potentially reduce the overall environmental footprint.

In terms of operational environmental impact, AGM batteries demonstrate some positive attributes. Their sealed design prevents electrolyte leakage, reducing the risk of soil and water contamination during use. Additionally, AGM batteries have a longer lifespan compared to traditional lead-acid batteries, which means fewer replacements and less frequent disposal, ultimately reducing waste generation over time.

The role of AGM batteries in energy harvesting applications also influences their environmental impact. These batteries are often used in renewable energy systems, such as solar and wind power installations. By enabling efficient energy storage from intermittent renewable sources, AGM batteries indirectly contribute to reducing reliance on fossil fuels and lowering overall carbon emissions.

However, the end-of-life management of AGM batteries remains a significant environmental concern. While these batteries are highly recyclable, with up to 99% of their components being recoverable, the recycling process itself can have environmental impacts if not properly managed. Proper collection, transportation, and recycling infrastructure are essential to minimize the environmental footprint of AGM batteries at the end of their lifecycle.

In conclusion, while AGM batteries offer several environmental benefits, particularly in their application to renewable energy systems, their production and disposal still pose environmental challenges. Continued research and development in battery technology, improved recycling processes, and responsible management practices are crucial to further mitigate the environmental impact of AGM batteries in energy harvesting applications.

One of the primary environmental concerns associated with AGM batteries is the use of lead. Although AGM batteries are sealed and considered maintenance-free, they still contain lead, which is a toxic heavy metal. The production and disposal of lead-acid batteries, including AGM types, contribute to environmental pollution if not properly managed. However, it's worth noting that AGM batteries have a higher recycling rate compared to traditional flooded lead-acid batteries, which somewhat mitigates their environmental impact.

The manufacturing process of AGM batteries also has environmental implications. The production of glass mat separators and the assembly of battery components require energy and resources, contributing to carbon emissions and resource depletion. However, compared to some other battery technologies, AGM batteries have a relatively simple manufacturing process, which can potentially reduce the overall environmental footprint.

In terms of operational environmental impact, AGM batteries demonstrate some positive attributes. Their sealed design prevents electrolyte leakage, reducing the risk of soil and water contamination during use. Additionally, AGM batteries have a longer lifespan compared to traditional lead-acid batteries, which means fewer replacements and less frequent disposal, ultimately reducing waste generation over time.

The role of AGM batteries in energy harvesting applications also influences their environmental impact. These batteries are often used in renewable energy systems, such as solar and wind power installations. By enabling efficient energy storage from intermittent renewable sources, AGM batteries indirectly contribute to reducing reliance on fossil fuels and lowering overall carbon emissions.

However, the end-of-life management of AGM batteries remains a significant environmental concern. While these batteries are highly recyclable, with up to 99% of their components being recoverable, the recycling process itself can have environmental impacts if not properly managed. Proper collection, transportation, and recycling infrastructure are essential to minimize the environmental footprint of AGM batteries at the end of their lifecycle.

In conclusion, while AGM batteries offer several environmental benefits, particularly in their application to renewable energy systems, their production and disposal still pose environmental challenges. Continued research and development in battery technology, improved recycling processes, and responsible management practices are crucial to further mitigate the environmental impact of AGM batteries in energy harvesting applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!