Technical Challenges in Polysilane-Based Device Fabrication

JUL 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Device Evolution and Objectives

Polysilanes have emerged as a promising class of materials for electronic and optoelectronic devices due to their unique properties stemming from their silicon-based backbone structure. The evolution of polysilane-based devices can be traced back to the 1980s when researchers first recognized the potential of these materials for semiconductor applications. Since then, significant progress has been made in understanding their electronic and optical properties, as well as in developing fabrication techniques for polysilane-based devices.

The initial focus of polysilane research was on their photoconductivity and electroluminescence properties, which led to the development of early prototypes of light-emitting devices and photovoltaic cells. As the field progressed, researchers began exploring the use of polysilanes in field-effect transistors, sensors, and memory devices. The unique σ-conjugation along the silicon backbone of polysilanes offers advantages such as high charge carrier mobility and tunable bandgap, making them attractive for a wide range of applications.

One of the key objectives in polysilane device fabrication has been to overcome the challenges associated with processing these materials into thin films and nanostructures. Traditional solution-based methods often resulted in poor film quality and limited control over morphology. Recent advancements in fabrication techniques, such as chemical vapor deposition and electrospinning, have enabled the production of high-quality polysilane films and nanofibers with improved electronic properties.

Another important goal in the field has been to enhance the stability and performance of polysilane-based devices. Early devices suffered from rapid degradation due to the sensitivity of polysilanes to oxygen and moisture. Researchers have been working on developing protective coatings and encapsulation techniques to improve device longevity. Additionally, efforts have been made to optimize the molecular structure of polysilanes through side-chain engineering and copolymerization to enhance their electronic and optical properties.

The current objectives in polysilane device fabrication focus on addressing several key challenges. These include improving the uniformity and reproducibility of polysilane thin films, enhancing charge transport properties through better control of molecular orientation and crystallinity, and developing more efficient doping methods to tune the electronic properties of polysilanes. Furthermore, there is a growing interest in exploring hybrid materials that combine polysilanes with other organic or inorganic semiconductors to create novel device architectures with enhanced functionality.

Looking ahead, the field of polysilane-based devices aims to achieve commercial viability by demonstrating performance metrics comparable to or exceeding those of conventional semiconductor materials. This involves not only improving device efficiency and stability but also scaling up fabrication processes for large-area applications. As research progresses, the ultimate goal is to leverage the unique properties of polysilanes to create a new generation of flexible, lightweight, and cost-effective electronic and optoelectronic devices that can complement or even replace traditional silicon-based technologies in certain applications.

The initial focus of polysilane research was on their photoconductivity and electroluminescence properties, which led to the development of early prototypes of light-emitting devices and photovoltaic cells. As the field progressed, researchers began exploring the use of polysilanes in field-effect transistors, sensors, and memory devices. The unique σ-conjugation along the silicon backbone of polysilanes offers advantages such as high charge carrier mobility and tunable bandgap, making them attractive for a wide range of applications.

One of the key objectives in polysilane device fabrication has been to overcome the challenges associated with processing these materials into thin films and nanostructures. Traditional solution-based methods often resulted in poor film quality and limited control over morphology. Recent advancements in fabrication techniques, such as chemical vapor deposition and electrospinning, have enabled the production of high-quality polysilane films and nanofibers with improved electronic properties.

Another important goal in the field has been to enhance the stability and performance of polysilane-based devices. Early devices suffered from rapid degradation due to the sensitivity of polysilanes to oxygen and moisture. Researchers have been working on developing protective coatings and encapsulation techniques to improve device longevity. Additionally, efforts have been made to optimize the molecular structure of polysilanes through side-chain engineering and copolymerization to enhance their electronic and optical properties.

The current objectives in polysilane device fabrication focus on addressing several key challenges. These include improving the uniformity and reproducibility of polysilane thin films, enhancing charge transport properties through better control of molecular orientation and crystallinity, and developing more efficient doping methods to tune the electronic properties of polysilanes. Furthermore, there is a growing interest in exploring hybrid materials that combine polysilanes with other organic or inorganic semiconductors to create novel device architectures with enhanced functionality.

Looking ahead, the field of polysilane-based devices aims to achieve commercial viability by demonstrating performance metrics comparable to or exceeding those of conventional semiconductor materials. This involves not only improving device efficiency and stability but also scaling up fabrication processes for large-area applications. As research progresses, the ultimate goal is to leverage the unique properties of polysilanes to create a new generation of flexible, lightweight, and cost-effective electronic and optoelectronic devices that can complement or even replace traditional silicon-based technologies in certain applications.

Market Analysis for Polysilane-Based Technologies

The market for polysilane-based technologies is experiencing significant growth, driven by the increasing demand for advanced electronic and optoelectronic devices. Polysilanes, a class of silicon-based polymers, offer unique properties that make them attractive for various applications in the semiconductor industry, photonics, and energy sectors.

In the semiconductor industry, polysilanes are being explored as potential alternatives to traditional silicon-based materials for the fabrication of thin-film transistors and other electronic components. The market for these applications is expected to expand as manufacturers seek more efficient and cost-effective materials for next-generation devices.

The photonics sector represents another promising market for polysilane-based technologies. Polysilanes exhibit excellent photoconductivity and photoluminescence properties, making them suitable for applications in optical sensors, light-emitting diodes (LEDs), and photovoltaic cells. As the demand for high-performance optical devices continues to grow, the market for polysilane-based materials in this sector is projected to increase substantially.

Energy storage and conversion systems also present significant opportunities for polysilane-based technologies. Research into polysilane-based materials for lithium-ion batteries and fuel cells has shown promising results, potentially leading to improved energy density and efficiency. This market segment is expected to see considerable growth as the global focus on renewable energy and electric vehicles intensifies.

The automotive industry is another key market for polysilane-based technologies. With the increasing adoption of electric and autonomous vehicles, there is a growing demand for advanced sensors and electronic components. Polysilanes' unique properties make them suitable for various automotive applications, including lightweight materials for improved fuel efficiency and advanced display technologies.

Despite the promising market potential, challenges remain in the widespread adoption of polysilane-based technologies. These include the need for improved manufacturing processes, enhanced material stability, and reduced production costs. Overcoming these hurdles will be crucial for the market to reach its full potential.

Geographically, Asia-Pacific is expected to be the fastest-growing market for polysilane-based technologies, driven by the region's strong presence in the electronics and semiconductor industries. North America and Europe are also anticipated to see significant growth, particularly in the areas of advanced materials research and development.

As the market for polysilane-based technologies continues to evolve, collaborations between academic institutions, research organizations, and industry players will be essential in driving innovation and commercialization. The successful development and implementation of these technologies have the potential to revolutionize various industries and create new market opportunities in the coming years.

In the semiconductor industry, polysilanes are being explored as potential alternatives to traditional silicon-based materials for the fabrication of thin-film transistors and other electronic components. The market for these applications is expected to expand as manufacturers seek more efficient and cost-effective materials for next-generation devices.

The photonics sector represents another promising market for polysilane-based technologies. Polysilanes exhibit excellent photoconductivity and photoluminescence properties, making them suitable for applications in optical sensors, light-emitting diodes (LEDs), and photovoltaic cells. As the demand for high-performance optical devices continues to grow, the market for polysilane-based materials in this sector is projected to increase substantially.

Energy storage and conversion systems also present significant opportunities for polysilane-based technologies. Research into polysilane-based materials for lithium-ion batteries and fuel cells has shown promising results, potentially leading to improved energy density and efficiency. This market segment is expected to see considerable growth as the global focus on renewable energy and electric vehicles intensifies.

The automotive industry is another key market for polysilane-based technologies. With the increasing adoption of electric and autonomous vehicles, there is a growing demand for advanced sensors and electronic components. Polysilanes' unique properties make them suitable for various automotive applications, including lightweight materials for improved fuel efficiency and advanced display technologies.

Despite the promising market potential, challenges remain in the widespread adoption of polysilane-based technologies. These include the need for improved manufacturing processes, enhanced material stability, and reduced production costs. Overcoming these hurdles will be crucial for the market to reach its full potential.

Geographically, Asia-Pacific is expected to be the fastest-growing market for polysilane-based technologies, driven by the region's strong presence in the electronics and semiconductor industries. North America and Europe are also anticipated to see significant growth, particularly in the areas of advanced materials research and development.

As the market for polysilane-based technologies continues to evolve, collaborations between academic institutions, research organizations, and industry players will be essential in driving innovation and commercialization. The successful development and implementation of these technologies have the potential to revolutionize various industries and create new market opportunities in the coming years.

Current Challenges in Polysilane Device Fabrication

Polysilane-based devices have shown great promise in various applications, including optoelectronics, photonics, and sensors. However, their widespread adoption and commercialization face several significant challenges in the fabrication process. These challenges stem from the unique properties of polysilanes and the complexities involved in their processing and integration into functional devices.

One of the primary challenges in polysilane device fabrication is the control of molecular weight and polydispersity. The electrical and optical properties of polysilanes are highly dependent on their chain length and distribution. Achieving precise control over these parameters during synthesis and processing is crucial for consistent device performance. Current synthetic methods often result in broad molecular weight distributions, leading to variations in device characteristics and reduced reproducibility.

The stability of polysilanes presents another significant hurdle. These materials are susceptible to degradation when exposed to UV light, oxygen, and elevated temperatures. This sensitivity complicates both the fabrication process and the long-term stability of the resulting devices. Developing effective encapsulation techniques and incorporating stabilizing additives are ongoing areas of research to address this challenge.

Thin film formation and patterning of polysilanes pose additional difficulties. Unlike many conventional semiconductors, polysilanes often exhibit poor adhesion to substrates and tend to form non-uniform films. This can lead to issues with device integration and performance consistency. Moreover, traditional photolithographic techniques used for patterning are often incompatible with polysilanes due to their photosensitivity, necessitating the development of alternative patterning methods.

The interface between polysilanes and other materials in multilayer device structures is another critical concern. Achieving good electrical contact and efficient charge transfer across interfaces is essential for device functionality. However, the unique surface properties of polysilanes can lead to poor interfacial interactions, resulting in high contact resistance and reduced device efficiency.

Doping of polysilanes to control their electrical properties is also challenging. Unlike traditional semiconductors, the incorporation of dopants into the polysilane backbone can significantly alter its structure and properties. Finding effective doping strategies that enhance conductivity without compromising the material's desirable characteristics remains an active area of research.

Lastly, the scalability of polysilane device fabrication processes presents a significant barrier to commercialization. Many current fabrication techniques are limited to small-scale laboratory production. Developing scalable, cost-effective manufacturing processes that maintain material quality and device performance is crucial for the transition of polysilane-based devices from research to commercial applications.

One of the primary challenges in polysilane device fabrication is the control of molecular weight and polydispersity. The electrical and optical properties of polysilanes are highly dependent on their chain length and distribution. Achieving precise control over these parameters during synthesis and processing is crucial for consistent device performance. Current synthetic methods often result in broad molecular weight distributions, leading to variations in device characteristics and reduced reproducibility.

The stability of polysilanes presents another significant hurdle. These materials are susceptible to degradation when exposed to UV light, oxygen, and elevated temperatures. This sensitivity complicates both the fabrication process and the long-term stability of the resulting devices. Developing effective encapsulation techniques and incorporating stabilizing additives are ongoing areas of research to address this challenge.

Thin film formation and patterning of polysilanes pose additional difficulties. Unlike many conventional semiconductors, polysilanes often exhibit poor adhesion to substrates and tend to form non-uniform films. This can lead to issues with device integration and performance consistency. Moreover, traditional photolithographic techniques used for patterning are often incompatible with polysilanes due to their photosensitivity, necessitating the development of alternative patterning methods.

The interface between polysilanes and other materials in multilayer device structures is another critical concern. Achieving good electrical contact and efficient charge transfer across interfaces is essential for device functionality. However, the unique surface properties of polysilanes can lead to poor interfacial interactions, resulting in high contact resistance and reduced device efficiency.

Doping of polysilanes to control their electrical properties is also challenging. Unlike traditional semiconductors, the incorporation of dopants into the polysilane backbone can significantly alter its structure and properties. Finding effective doping strategies that enhance conductivity without compromising the material's desirable characteristics remains an active area of research.

Lastly, the scalability of polysilane device fabrication processes presents a significant barrier to commercialization. Many current fabrication techniques are limited to small-scale laboratory production. Developing scalable, cost-effective manufacturing processes that maintain material quality and device performance is crucial for the transition of polysilane-based devices from research to commercial applications.

Existing Fabrication Techniques for Polysilane Devices

01 Synthesis and processing of polysilanes

Challenges in synthesizing and processing polysilanes for device fabrication include controlling molecular weight, achieving desired purity, and optimizing deposition techniques. Proper synthesis and processing are crucial for obtaining the desired electronic and optical properties in polysilane-based devices.- Synthesis and processing of polysilane materials: Challenges in synthesizing and processing polysilane materials for device fabrication include controlling molecular weight, achieving desired purity, and optimizing film formation techniques. These factors significantly impact the electrical and optical properties of the resulting devices.

- Deposition and patterning techniques: Fabrication of polysilane-based devices faces challenges in developing suitable deposition methods and patterning techniques. This includes optimizing spin-coating, vapor deposition, and lithography processes to achieve uniform and well-defined polysilane structures.

- Stability and degradation issues: Polysilane-based devices are susceptible to degradation under various environmental conditions, including exposure to light, heat, and oxygen. Addressing these stability issues is crucial for improving device performance and longevity.

- Integration with other materials and structures: Fabrication challenges arise when integrating polysilane-based components with other materials and structures in complex devices. This includes ensuring compatibility with substrates, electrodes, and other functional layers while maintaining desired device characteristics.

- Doping and modification of polysilanes: Controlling the electronic properties of polysilane-based devices through doping and chemical modification presents challenges in achieving desired conductivity and charge transport characteristics. Developing effective doping methods and identifying suitable dopants are critical for optimizing device performance.

02 Thin film formation and patterning

Fabricating uniform and stable thin films of polysilanes is challenging due to their sensitivity to oxygen and moisture. Developing effective patterning techniques, such as photolithography or etching, while maintaining the integrity of the polysilane structure is crucial for device fabrication.Expand Specific Solutions03 Doping and charge carrier control

Controlling the electronic properties of polysilanes through doping is essential for device performance. Challenges include achieving uniform doping, maintaining stability of dopants, and optimizing charge carrier mobility and concentration for specific device applications.Expand Specific Solutions04 Interface engineering and device integration

Fabricating polysilane-based devices requires careful consideration of interfaces between the polysilane layer and other device components. Challenges include minimizing interfacial defects, optimizing charge injection and extraction, and ensuring compatibility with other materials used in the device structure.Expand Specific Solutions05 Stability and degradation prevention

Polysilanes are susceptible to degradation under various environmental conditions, including light exposure and oxidation. Developing effective encapsulation techniques and improving the inherent stability of polysilanes are crucial challenges in fabricating long-lasting and reliable polysilane-based devices.Expand Specific Solutions

Key Players in Polysilane Research and Industry

The polysilane-based device fabrication market is in its early growth stage, characterized by ongoing research and development efforts. While the market size remains relatively small, it shows promising potential for expansion due to the unique properties of polysilanes. The technology's maturity is still evolving, with companies like Wacker Chemie AG, JSR Corp., and Evonik Operations GmbH leading the way in advancing polysilane-based materials. These firms are investing in R&D to overcome technical challenges and improve device performance. Other players such as Kaneka Corp. and Dow Silicones Corp. are also contributing to the field, focusing on specialized applications and process improvements. As the technology progresses, we can expect increased competition and market growth in the coming years.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced polysilane synthesis techniques, focusing on controlled molecular weight distribution and enhanced thermal stability. Their approach involves using catalytic dehydrocoupling of primary silanes to produce high-purity polysilanes with tailored properties[1]. The company has also implemented novel purification methods to remove trace metal impurities, which is crucial for semiconductor applications. Wacker's polysilanes exhibit improved resistance to oxidation and UV degradation, addressing key challenges in device fabrication[2]. They have successfully integrated these materials into thin-film transistors, demonstrating enhanced charge carrier mobility compared to conventional silicon-based devices[3].

Strengths: High-purity polysilanes with controlled properties, improved thermal and UV stability. Weaknesses: Potentially higher production costs, limited scalability for large-area electronics.

JSR Corp.

Technical Solution: JSR Corp. has pioneered a novel approach to polysilane-based device fabrication, focusing on photopatternable polysilanes for microelectronics. Their proprietary technology involves the synthesis of photo-sensitive polysilanes that can be directly patterned using UV light, eliminating the need for traditional photoresists[4]. This process significantly reduces the number of steps in device fabrication, potentially lowering costs and improving yield. JSR has also developed specialized coating techniques to ensure uniform polysilane film deposition, addressing issues of thickness control and surface roughness that often plague polysilane-based devices[5]. Their materials have shown promise in organic light-emitting diodes (OLEDs) and flexible electronics, demonstrating improved charge transport properties and mechanical flexibility[6].

Strengths: Simplified fabrication process, direct photopatterning capability, suitable for flexible electronics. Weaknesses: Limited to specific types of devices, potential issues with long-term stability under varied environmental conditions.

Breakthrough Patents in Polysilane Device Manufacturing

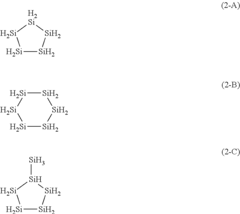

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane production process

PatentInactiveUS20110158886A1

Innovation

- A polysilane production process using a binuclear metal complex catalyst at room temperature and 1 atm to polymerize silane compounds, eliminating the need for large-scale equipment and enabling efficient polysilane synthesis under mild conditions.

Environmental Impact of Polysilane Production

The production of polysilanes, while offering significant potential for advanced electronic and optoelectronic applications, raises important environmental concerns that must be addressed. The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals, which can have substantial environmental implications if not properly managed.

One of the primary environmental concerns is the energy consumption associated with polysilane production. The high-temperature conditions often required for synthesis contribute to increased carbon emissions, particularly if the energy source is not renewable. This aspect of production aligns with broader discussions on the carbon footprint of advanced materials manufacturing and the need for more sustainable energy practices in the semiconductor industry.

Chemical waste management presents another significant challenge. The synthesis of polysilanes frequently involves the use of chlorosilanes and other reactive precursors, which can generate toxic by-products and waste streams. Proper handling, treatment, and disposal of these materials are crucial to prevent soil and water contamination. Additionally, the potential for accidental releases during production or transportation poses risks to local ecosystems and human health.

The use of solvents in polysilane synthesis and processing is also a point of environmental concern. Many of these solvents are volatile organic compounds (VOCs) that can contribute to air pollution and ozone depletion if released into the atmosphere. Efforts to develop greener solvent alternatives or solvent-free processes are ongoing but remain challenging due to the specific chemical requirements of polysilane synthesis.

Resource depletion is another environmental consideration, particularly regarding the silicon feedstock used in polysilane production. While silicon is abundant, the high-purity grade required for electronic applications necessitates energy-intensive refining processes. This raises questions about the long-term sustainability of polysilane production, especially as demand for silicon-based materials continues to grow across various industries.

Water usage in polysilane production and subsequent device fabrication processes also merits attention. The semiconductor industry is known for its high water consumption, and polysilane-based technologies may contribute to this trend. Implementing water recycling systems and developing less water-intensive processes are crucial steps towards reducing the environmental footprint of polysilane production.

As the field of polysilane-based devices advances, there is a growing emphasis on developing more environmentally friendly synthesis methods and production processes. This includes exploring room-temperature synthesis routes, investigating bio-inspired polymerization techniques, and implementing closed-loop manufacturing systems to minimize waste and resource consumption. These efforts align with broader sustainability goals in the electronics industry and reflect an increasing awareness of the need to balance technological progress with environmental stewardship.

One of the primary environmental concerns is the energy consumption associated with polysilane production. The high-temperature conditions often required for synthesis contribute to increased carbon emissions, particularly if the energy source is not renewable. This aspect of production aligns with broader discussions on the carbon footprint of advanced materials manufacturing and the need for more sustainable energy practices in the semiconductor industry.

Chemical waste management presents another significant challenge. The synthesis of polysilanes frequently involves the use of chlorosilanes and other reactive precursors, which can generate toxic by-products and waste streams. Proper handling, treatment, and disposal of these materials are crucial to prevent soil and water contamination. Additionally, the potential for accidental releases during production or transportation poses risks to local ecosystems and human health.

The use of solvents in polysilane synthesis and processing is also a point of environmental concern. Many of these solvents are volatile organic compounds (VOCs) that can contribute to air pollution and ozone depletion if released into the atmosphere. Efforts to develop greener solvent alternatives or solvent-free processes are ongoing but remain challenging due to the specific chemical requirements of polysilane synthesis.

Resource depletion is another environmental consideration, particularly regarding the silicon feedstock used in polysilane production. While silicon is abundant, the high-purity grade required for electronic applications necessitates energy-intensive refining processes. This raises questions about the long-term sustainability of polysilane production, especially as demand for silicon-based materials continues to grow across various industries.

Water usage in polysilane production and subsequent device fabrication processes also merits attention. The semiconductor industry is known for its high water consumption, and polysilane-based technologies may contribute to this trend. Implementing water recycling systems and developing less water-intensive processes are crucial steps towards reducing the environmental footprint of polysilane production.

As the field of polysilane-based devices advances, there is a growing emphasis on developing more environmentally friendly synthesis methods and production processes. This includes exploring room-temperature synthesis routes, investigating bio-inspired polymerization techniques, and implementing closed-loop manufacturing systems to minimize waste and resource consumption. These efforts align with broader sustainability goals in the electronics industry and reflect an increasing awareness of the need to balance technological progress with environmental stewardship.

Scalability Issues in Polysilane Device Fabrication

Scalability issues present significant challenges in the fabrication of polysilane-based devices, hindering their widespread adoption and commercial viability. As the demand for larger and more complex polysilane devices increases, manufacturers face numerous obstacles in scaling up production processes while maintaining device performance and reliability.

One of the primary scalability issues is the difficulty in achieving uniform film thickness and composition across larger substrate areas. Polysilane deposition techniques, such as spin-coating or chemical vapor deposition, often result in thickness variations and compositional inhomogeneities when applied to larger substrates. These inconsistencies can lead to performance disparities and reduced yield rates in device production.

Another critical challenge is the control of molecular weight distribution and chain length in polysilane synthesis as production scales increase. Maintaining precise control over these parameters becomes increasingly difficult in larger batch sizes, potentially affecting the electrical and optical properties of the resulting devices. This variability can lead to inconsistent device performance and reliability issues in scaled-up production.

The integration of polysilane materials with other device components and substrates also poses scalability challenges. As device architectures become more complex and diverse, ensuring proper adhesion, interface quality, and compatibility between polysilane layers and other materials becomes more challenging at larger scales. This can result in increased defect rates and reduced device longevity.

Furthermore, the stability and degradation of polysilane materials under various environmental conditions remain concerns for large-scale device fabrication. Exposure to heat, light, and atmospheric contaminants during extended processing times can lead to material degradation, affecting device performance and long-term reliability. Developing effective encapsulation and protection strategies that are scalable and cost-effective is crucial for addressing this issue.

The cost-effectiveness of polysilane-based device fabrication at larger scales is another significant challenge. As production volumes increase, optimizing material utilization, reducing waste, and improving process efficiency become critical factors in maintaining economic viability. Balancing these considerations with the need for high-quality, consistent device performance requires innovative approaches to process design and optimization.

Addressing these scalability issues requires a multifaceted approach, combining advancements in materials science, process engineering, and device design. Developing novel deposition techniques, improving precursor synthesis methods, and enhancing process control systems are essential steps towards overcoming these challenges. Additionally, exploring alternative device architectures and fabrication strategies that are inherently more scalable may provide new avenues for advancing polysilane-based technologies.

One of the primary scalability issues is the difficulty in achieving uniform film thickness and composition across larger substrate areas. Polysilane deposition techniques, such as spin-coating or chemical vapor deposition, often result in thickness variations and compositional inhomogeneities when applied to larger substrates. These inconsistencies can lead to performance disparities and reduced yield rates in device production.

Another critical challenge is the control of molecular weight distribution and chain length in polysilane synthesis as production scales increase. Maintaining precise control over these parameters becomes increasingly difficult in larger batch sizes, potentially affecting the electrical and optical properties of the resulting devices. This variability can lead to inconsistent device performance and reliability issues in scaled-up production.

The integration of polysilane materials with other device components and substrates also poses scalability challenges. As device architectures become more complex and diverse, ensuring proper adhesion, interface quality, and compatibility between polysilane layers and other materials becomes more challenging at larger scales. This can result in increased defect rates and reduced device longevity.

Furthermore, the stability and degradation of polysilane materials under various environmental conditions remain concerns for large-scale device fabrication. Exposure to heat, light, and atmospheric contaminants during extended processing times can lead to material degradation, affecting device performance and long-term reliability. Developing effective encapsulation and protection strategies that are scalable and cost-effective is crucial for addressing this issue.

The cost-effectiveness of polysilane-based device fabrication at larger scales is another significant challenge. As production volumes increase, optimizing material utilization, reducing waste, and improving process efficiency become critical factors in maintaining economic viability. Balancing these considerations with the need for high-quality, consistent device performance requires innovative approaches to process design and optimization.

Addressing these scalability issues requires a multifaceted approach, combining advancements in materials science, process engineering, and device design. Developing novel deposition techniques, improving precursor synthesis methods, and enhancing process control systems are essential steps towards overcoming these challenges. Additionally, exploring alternative device architectures and fabrication strategies that are inherently more scalable may provide new avenues for advancing polysilane-based technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!