Temperature Resilience Testing Of Room-Temperature Sodium-Sulfur Batteries

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RT-NaS Battery Temperature Resilience Background & Objectives

Room-temperature sodium-sulfur (RT-NaS) batteries represent a significant advancement in energy storage technology, evolving from traditional high-temperature sodium-sulfur batteries that operate at approximately 300-350°C. The development of RT-NaS batteries began in the early 2000s, with researchers seeking to harness the advantages of sodium-sulfur chemistry while eliminating the safety concerns and complex thermal management systems associated with high operating temperatures.

The technological evolution of RT-NaS batteries has been driven by the increasing global demand for sustainable and cost-effective energy storage solutions. Unlike lithium-ion batteries, which rely on relatively scarce and geographically concentrated lithium resources, sodium-sulfur batteries utilize sodium, the sixth most abundant element in the Earth's crust. This abundance translates to potentially lower material costs and reduced geopolitical supply chain risks.

Recent advancements in electrode materials, electrolytes, and cell designs have significantly improved the performance of RT-NaS batteries, making them increasingly viable for grid-scale energy storage applications. However, temperature resilience remains a critical challenge that must be addressed before widespread commercial deployment can be realized.

The primary objective of temperature resilience testing for RT-NaS batteries is to evaluate their performance, safety, and longevity across a wide range of operating temperatures. While these batteries operate at "room temperature" (typically 20-30°C), real-world applications often involve exposure to temperature fluctuations that can significantly impact battery performance and degradation mechanisms.

Specifically, temperature resilience testing aims to characterize how RT-NaS batteries respond to both high-temperature conditions (potentially exceeding 50°C in hot climates or during rapid charging) and low-temperature environments (below 0°C in cold regions or outdoor installations). These tests seek to identify potential failure modes, including capacity fade, increased internal resistance, dendrite formation, and electrolyte degradation that may be accelerated or triggered by temperature variations.

Furthermore, the testing objectives include establishing standardized protocols for evaluating temperature-dependent performance metrics, which will facilitate meaningful comparisons between different RT-NaS battery designs and technologies. This standardization is essential for accelerating the development cycle and enabling informed decision-making by potential adopters of this emerging technology.

The ultimate goal of temperature resilience research is to develop RT-NaS batteries that maintain consistent performance, safety, and longevity across the full range of temperatures encountered in their intended applications, from grid-scale energy storage to potentially electric vehicles and portable electronics in the future.

The technological evolution of RT-NaS batteries has been driven by the increasing global demand for sustainable and cost-effective energy storage solutions. Unlike lithium-ion batteries, which rely on relatively scarce and geographically concentrated lithium resources, sodium-sulfur batteries utilize sodium, the sixth most abundant element in the Earth's crust. This abundance translates to potentially lower material costs and reduced geopolitical supply chain risks.

Recent advancements in electrode materials, electrolytes, and cell designs have significantly improved the performance of RT-NaS batteries, making them increasingly viable for grid-scale energy storage applications. However, temperature resilience remains a critical challenge that must be addressed before widespread commercial deployment can be realized.

The primary objective of temperature resilience testing for RT-NaS batteries is to evaluate their performance, safety, and longevity across a wide range of operating temperatures. While these batteries operate at "room temperature" (typically 20-30°C), real-world applications often involve exposure to temperature fluctuations that can significantly impact battery performance and degradation mechanisms.

Specifically, temperature resilience testing aims to characterize how RT-NaS batteries respond to both high-temperature conditions (potentially exceeding 50°C in hot climates or during rapid charging) and low-temperature environments (below 0°C in cold regions or outdoor installations). These tests seek to identify potential failure modes, including capacity fade, increased internal resistance, dendrite formation, and electrolyte degradation that may be accelerated or triggered by temperature variations.

Furthermore, the testing objectives include establishing standardized protocols for evaluating temperature-dependent performance metrics, which will facilitate meaningful comparisons between different RT-NaS battery designs and technologies. This standardization is essential for accelerating the development cycle and enabling informed decision-making by potential adopters of this emerging technology.

The ultimate goal of temperature resilience research is to develop RT-NaS batteries that maintain consistent performance, safety, and longevity across the full range of temperatures encountered in their intended applications, from grid-scale energy storage to potentially electric vehicles and portable electronics in the future.

Market Analysis for Temperature-Resilient Energy Storage

The global energy storage market is experiencing significant growth, with a projected value of $546 billion by 2035, driven by the increasing integration of renewable energy sources and the need for grid stability. Within this expanding sector, temperature-resilient energy storage solutions represent a critical and rapidly growing segment. Room-temperature sodium-sulfur (RT-Na-S) batteries are emerging as a particularly promising technology due to their potential cost advantages over lithium-ion alternatives and reduced reliance on critical raw materials.

Market demand for temperature-resilient energy storage is being fueled by several key factors. Utility companies are increasingly seeking solutions that can operate reliably across diverse climate conditions, from extreme cold to intense heat, without significant performance degradation. This is especially relevant as climate change intensifies weather extremes globally. Additionally, the renewable energy sector requires storage technologies that can maintain consistent performance despite fluctuating environmental conditions at solar and wind installations.

The industrial sector represents another substantial market, with manufacturing facilities, data centers, and telecommunications infrastructure requiring uninterrupted power supply regardless of ambient temperature variations. The electric vehicle market is also showing interest in temperature-resilient battery technologies that can maintain range and performance across seasonal changes.

Geographically, regions with extreme temperature variations such as the Middle East, Northern Europe, and parts of North America and Asia are showing the strongest demand growth for temperature-resilient energy storage. These markets value the operational stability and reduced maintenance costs associated with batteries that can withstand temperature fluctuations without requiring expensive thermal management systems.

Current market analysis indicates that temperature resilience is becoming a key differentiator in energy storage procurement decisions. Organizations are increasingly willing to pay premium prices for storage solutions that demonstrate superior performance across wider temperature ranges, recognizing the long-term operational savings and reliability benefits.

The market for RT-Na-S batteries specifically is projected to grow at a compound annual growth rate of 24% through 2030, outpacing several other emerging battery technologies. This growth is supported by increasing R&D investments from both private companies and government initiatives focused on developing next-generation energy storage solutions that address temperature resilience challenges while maintaining competitive costs and environmental sustainability.

Market demand for temperature-resilient energy storage is being fueled by several key factors. Utility companies are increasingly seeking solutions that can operate reliably across diverse climate conditions, from extreme cold to intense heat, without significant performance degradation. This is especially relevant as climate change intensifies weather extremes globally. Additionally, the renewable energy sector requires storage technologies that can maintain consistent performance despite fluctuating environmental conditions at solar and wind installations.

The industrial sector represents another substantial market, with manufacturing facilities, data centers, and telecommunications infrastructure requiring uninterrupted power supply regardless of ambient temperature variations. The electric vehicle market is also showing interest in temperature-resilient battery technologies that can maintain range and performance across seasonal changes.

Geographically, regions with extreme temperature variations such as the Middle East, Northern Europe, and parts of North America and Asia are showing the strongest demand growth for temperature-resilient energy storage. These markets value the operational stability and reduced maintenance costs associated with batteries that can withstand temperature fluctuations without requiring expensive thermal management systems.

Current market analysis indicates that temperature resilience is becoming a key differentiator in energy storage procurement decisions. Organizations are increasingly willing to pay premium prices for storage solutions that demonstrate superior performance across wider temperature ranges, recognizing the long-term operational savings and reliability benefits.

The market for RT-Na-S batteries specifically is projected to grow at a compound annual growth rate of 24% through 2030, outpacing several other emerging battery technologies. This growth is supported by increasing R&D investments from both private companies and government initiatives focused on developing next-generation energy storage solutions that address temperature resilience challenges while maintaining competitive costs and environmental sustainability.

Current Challenges in RT-NaS Battery Temperature Performance

Room-temperature sodium-sulfur (RT-NaS) batteries face significant temperature-related challenges that impede their widespread commercial adoption. Unlike traditional high-temperature sodium-sulfur batteries operating at 300-350°C, RT-NaS batteries aim to function effectively at ambient temperatures (20-40°C). However, current RT-NaS systems exhibit substantial performance degradation when exposed to temperature fluctuations commonly encountered in real-world applications.

The primary challenge stems from the sodium polysulfide shuttle effect, which intensifies at elevated temperatures. As temperature increases, the solubility of sodium polysulfides in the electrolyte increases dramatically, accelerating their migration between electrodes. This shuttle effect leads to active material loss, self-discharge, and rapid capacity fading. Testing protocols must accurately quantify this temperature-dependent degradation mechanism to develop effective mitigation strategies.

Electrolyte stability presents another critical challenge in temperature resilience testing. Most current electrolytes for RT-NaS batteries demonstrate narrow electrochemical stability windows that contract further at higher temperatures. This instability triggers parasitic reactions at electrode-electrolyte interfaces, forming resistive layers that impede ion transport. Comprehensive testing methodologies must evaluate electrolyte decomposition rates across various temperature profiles to identify formulations with broader thermal stability.

The solid-electrolyte interphase (SEI) formation on sodium metal anodes exhibits high temperature sensitivity, creating significant testing complexities. At lower temperatures, SEI layers tend to be more brittle and prone to cracking during sodium plating/stripping cycles, while higher temperatures accelerate SEI growth but may produce less protective layers. Current testing protocols struggle to characterize these temperature-dependent SEI dynamics accurately.

Mechanical integrity of electrode materials under thermal cycling represents another substantial challenge. Sodium sulfur compounds undergo volumetric changes during charge-discharge cycles that are exacerbated by temperature fluctuations. These thermal expansion mismatches between active materials, conductive additives, and binders lead to mechanical stress, particle isolation, and eventual electrode pulverization. Testing methodologies must effectively capture these thermomechanical degradation mechanisms.

Finally, safety testing under temperature extremes remains underdeveloped for RT-NaS systems. Unlike lithium-ion batteries with established thermal runaway testing protocols, RT-NaS batteries lack standardized safety evaluation methods that account for their unique failure modes, particularly the potential for sodium metal reactivity and sulfur evolution at elevated temperatures. Developing robust safety testing frameworks that accurately predict real-world thermal risks represents a significant challenge for the field.

The primary challenge stems from the sodium polysulfide shuttle effect, which intensifies at elevated temperatures. As temperature increases, the solubility of sodium polysulfides in the electrolyte increases dramatically, accelerating their migration between electrodes. This shuttle effect leads to active material loss, self-discharge, and rapid capacity fading. Testing protocols must accurately quantify this temperature-dependent degradation mechanism to develop effective mitigation strategies.

Electrolyte stability presents another critical challenge in temperature resilience testing. Most current electrolytes for RT-NaS batteries demonstrate narrow electrochemical stability windows that contract further at higher temperatures. This instability triggers parasitic reactions at electrode-electrolyte interfaces, forming resistive layers that impede ion transport. Comprehensive testing methodologies must evaluate electrolyte decomposition rates across various temperature profiles to identify formulations with broader thermal stability.

The solid-electrolyte interphase (SEI) formation on sodium metal anodes exhibits high temperature sensitivity, creating significant testing complexities. At lower temperatures, SEI layers tend to be more brittle and prone to cracking during sodium plating/stripping cycles, while higher temperatures accelerate SEI growth but may produce less protective layers. Current testing protocols struggle to characterize these temperature-dependent SEI dynamics accurately.

Mechanical integrity of electrode materials under thermal cycling represents another substantial challenge. Sodium sulfur compounds undergo volumetric changes during charge-discharge cycles that are exacerbated by temperature fluctuations. These thermal expansion mismatches between active materials, conductive additives, and binders lead to mechanical stress, particle isolation, and eventual electrode pulverization. Testing methodologies must effectively capture these thermomechanical degradation mechanisms.

Finally, safety testing under temperature extremes remains underdeveloped for RT-NaS systems. Unlike lithium-ion batteries with established thermal runaway testing protocols, RT-NaS batteries lack standardized safety evaluation methods that account for their unique failure modes, particularly the potential for sodium metal reactivity and sulfur evolution at elevated temperatures. Developing robust safety testing frameworks that accurately predict real-world thermal risks represents a significant challenge for the field.

Current Temperature Testing Methodologies for RT-NaS Batteries

01 Electrolyte modifications for room-temperature operation

Various electrolyte modifications can enable sodium-sulfur batteries to operate at room temperature while maintaining temperature resilience. These include using solid polymer electrolytes, gel electrolytes, or ionic liquid-based electrolytes that remain stable across a wide temperature range. These modified electrolytes help prevent the typical high-temperature requirements of traditional sodium-sulfur batteries while maintaining ionic conductivity and electrochemical stability.- Electrolyte modifications for room-temperature sodium-sulfur batteries: Various electrolyte modifications can enhance the temperature resilience of room-temperature sodium-sulfur batteries. These include using polymer electrolytes, gel electrolytes, or solid-state electrolytes that maintain stability across a wide temperature range. Modified electrolytes can prevent sodium polysulfide dissolution and shuttle effect, which are common issues affecting battery performance at room temperature. These electrolyte systems also improve the interface stability between electrodes and electrolyte at varying temperatures.

- Sulfur cathode engineering for temperature stability: Engineering the sulfur cathode structure can significantly improve the temperature resilience of room-temperature sodium-sulfur batteries. Approaches include using carbon-sulfur composites, sulfur-polymer composites, or encapsulating sulfur in porous materials to prevent polysulfide dissolution at varying temperatures. Advanced cathode designs incorporate conductive additives that maintain electrical connectivity even during temperature fluctuations, ensuring consistent performance across a wide temperature range.

- Sodium anode protection strategies for temperature variation: Protecting the sodium metal anode is crucial for maintaining battery performance across temperature variations. Strategies include using protective coatings, artificial solid electrolyte interphases (SEI), or sodium alloys that remain stable at different temperatures. These protection methods prevent unwanted side reactions between the sodium anode and electrolyte, reducing dendrite formation and improving cycling stability under temperature fluctuations.

- Advanced cell design for thermal management: Innovative cell designs can enhance the temperature resilience of room-temperature sodium-sulfur batteries. These designs incorporate thermal management systems, insulation layers, or phase-change materials that help maintain optimal operating temperatures. Some designs feature specialized separators that prevent thermal runaway and ensure safety across a wide temperature range. The cell architecture may also include pressure regulation mechanisms to accommodate volume changes during temperature fluctuations.

- Additives and interface engineering for temperature resilience: Various additives and interface engineering approaches can improve the temperature resilience of room-temperature sodium-sulfur batteries. Functional additives in the electrolyte can stabilize the electrode-electrolyte interface across different temperatures. Interface engineering techniques, such as creating artificial protective layers or using functional separators, help maintain ion transport pathways despite temperature changes. These approaches minimize resistance increases at low temperatures and prevent degradation at elevated temperatures.

02 Advanced electrode materials for temperature stability

Specialized electrode materials can enhance the temperature resilience of room-temperature sodium-sulfur batteries. These include carbon-based materials with hierarchical pore structures, metal sulfides, and composite electrodes that can accommodate volume changes during cycling at various temperatures. These materials help maintain structural integrity and electrochemical performance across a wide temperature range.Expand Specific Solutions03 Protective coatings and interfaces for thermal stability

Implementing protective coatings and engineered interfaces can significantly improve the temperature resilience of room-temperature sodium-sulfur batteries. These include ceramic coatings, polymer layers, and composite interfaces that prevent side reactions between electrodes and electrolytes at varying temperatures. Such protective measures help maintain battery performance and safety across fluctuating environmental conditions.Expand Specific Solutions04 Novel cell designs for temperature fluctuation management

Innovative cell architectures can be employed to manage temperature fluctuations in room-temperature sodium-sulfur batteries. These designs include thermal management systems, insulation layers, and structural modifications that help maintain optimal operating conditions despite external temperature changes. Such designs contribute to improved battery safety, longevity, and performance consistency across varying environments.Expand Specific Solutions05 Additives and dopants for enhanced temperature performance

Various additives and dopants can be incorporated into room-temperature sodium-sulfur batteries to enhance their temperature resilience. These include flame retardants, thermal stabilizers, and performance-enhancing compounds that maintain electrochemical stability across a wide temperature range. Such additives help prevent capacity fading, improve cycling stability, and enhance safety under varying thermal conditions.Expand Specific Solutions

Leading Organizations in RT-NaS Battery Development

Room-temperature sodium-sulfur (RT-Na-S) battery technology is currently in the early growth phase of its industry lifecycle, with a projected market size reaching approximately $400 million by 2027, growing at a CAGR of 30%. The competitive landscape features established players like NGK Insulators, which pioneered high-temperature Na-S batteries, now pivoting to room-temperature variants. Research institutions including Drexel University, Zhejiang University, and the Shanghai Institute of Ceramics are advancing fundamental technology, while commercial entities such as LG Energy Solution, SK Innovation, and BASF are developing practical applications. The technology maturity remains at TRL 4-6, with key challenges in temperature resilience testing being addressed through collaborative efforts between academic institutions and industry leaders like Sumitomo Chemical and State Grid Shanghai Municipal Electric Power Co.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered room-temperature sodium-sulfur (RT-Na/S) battery technology with their proprietary ceramic electrolyte system. Their temperature resilience testing protocol involves subjecting batteries to thermal cycling between -20°C and 60°C while monitoring capacity retention and internal resistance changes. NGK's approach incorporates a specialized carbon-sulfur composite cathode structure that maintains stability during temperature fluctuations, preventing sulfur dissolution and polysulfide shuttle effects. The company has developed a unique solid electrolyte interface (SEI) layer modification technique that remains functional across wide temperature ranges, addressing a key failure point in traditional Na/S systems. Their testing methodology includes accelerated aging tests at elevated temperatures (up to 80°C) to predict long-term performance degradation patterns and establish temperature-dependent performance models for grid storage applications.

Strengths: Industry-leading expertise in ceramic electrolytes with proven commercial deployment experience in grid-scale applications. Established manufacturing infrastructure for sodium-sulfur technology. Weaknesses: Higher production costs compared to lithium-ion alternatives, and their room-temperature variants still face challenges with energy density limitations at extreme temperature conditions.

Drexel University

Technical Solution: Drexel University has developed an innovative approach to temperature resilience testing for room-temperature sodium-sulfur batteries focusing on advanced electrode materials and electrolyte formulations. Their research team employs a multi-faceted testing protocol that evaluates battery performance across temperature ranges from -40°C to 70°C with particular attention to the structural stability of sulfur cathodes. Drexel's technology utilizes a hierarchical carbon framework with tailored porosity to encapsulate sulfur and trap polysulfides, maintaining electrochemical performance even during temperature fluctuations. Their testing methodology incorporates in-situ X-ray diffraction and impedance spectroscopy to monitor phase changes and interfacial resistance variations during thermal cycling. The university has pioneered a novel electrolyte system containing flame-retardant additives that enhances safety while maintaining ionic conductivity across broad temperature ranges, addressing a critical challenge for room-temperature Na/S batteries.

Strengths: Cutting-edge research capabilities with advanced characterization techniques that provide fundamental understanding of failure mechanisms during temperature variations. Strong academic publication record demonstrating scientific leadership in the field. Weaknesses: Limited industrial-scale manufacturing experience and longer timeline required for commercialization compared to established industry players.

Critical Patents in RT-NaS Temperature Resilience Technology

Stable room-temperature sodium-sulfur battery

PatentWO2017152171A1

Innovation

- A sodium-ion conducting battery design featuring a microporous and mesoporous carbon-sulfur composite cathode and a liquid carbonate electrolyte with an ionic liquid tethered to silica nanoparticles, which stabilizes the sodium anode and confines sulfur within the carbon pores, enabling a solid-state electrochemical reaction and preventing the formation of soluble polysulfides.

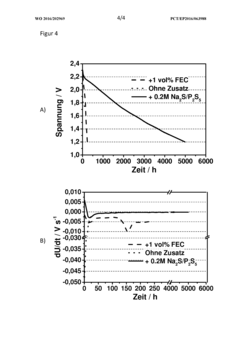

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentWO2016202969A1

Innovation

- A sodium-sulfur battery design using a carbon-sulfur composite cathode, an organic solvent-based electrolyte with a conductive salt and phosphorus polysulfide as an additive to suppress the polysulfide shuttle, allowing operation at room temperature with enhanced energy efficiency and discharge capacity.

Safety Standards and Compliance for Sodium-Based Batteries

The development of room-temperature sodium-sulfur (RT-Na/S) batteries necessitates comprehensive safety standards and compliance frameworks to ensure their safe deployment in various applications. Unlike traditional high-temperature sodium-sulfur batteries operating at 300-350°C, RT-Na/S batteries present unique safety challenges that require specialized regulatory approaches.

Current international safety standards for sodium-based batteries remain in developmental stages, with organizations like the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) working to establish specific guidelines. The IEC 62660 series, while primarily focused on lithium-ion batteries, provides a foundational framework that is being adapted for sodium-based technologies, particularly addressing thermal runaway risks under temperature fluctuations.

Temperature resilience testing forms a critical component of these emerging standards, requiring RT-Na/S batteries to demonstrate stability across operational temperature ranges (-20°C to 60°C) and during extreme conditions. Standard test protocols typically include thermal cycling, thermal shock testing, and accelerated aging under varied temperature conditions to evaluate degradation mechanisms and safety thresholds.

Regulatory bodies in major markets have begun incorporating sodium battery technologies into their compliance frameworks. The UN Transportation Testing requirements (UN 38.3) have been updated to include provisions for sodium-based batteries, addressing concerns about reactivity during transport. Similarly, the European Battery Directive is expanding its scope to encompass sodium battery chemistries, with particular emphasis on temperature-related safety parameters.

Industry-specific standards are also emerging, with automotive applications following modified versions of SAE J2929 and ISO 12405 standards, adapted specifically for sodium battery technologies. These standards emphasize temperature abuse testing protocols that simulate real-world conditions, including rapid temperature fluctuations and extended exposure to extreme environments.

Compliance testing methodologies for RT-Na/S batteries focus heavily on thermal management systems, requiring demonstration of fail-safe mechanisms during temperature excursions. These include controlled cell venting, thermal propagation prevention, and system-level thermal management validation. Manufacturers must document temperature-related failure modes and implement appropriate mitigation strategies to achieve certification.

Looking forward, the harmonization of global safety standards for sodium-based batteries represents a significant challenge. Industry consortia and international standards organizations are collaborating to develop unified testing protocols that address the unique temperature-related behaviors of RT-Na/S batteries while ensuring consistent safety requirements across different regulatory jurisdictions.

Current international safety standards for sodium-based batteries remain in developmental stages, with organizations like the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) working to establish specific guidelines. The IEC 62660 series, while primarily focused on lithium-ion batteries, provides a foundational framework that is being adapted for sodium-based technologies, particularly addressing thermal runaway risks under temperature fluctuations.

Temperature resilience testing forms a critical component of these emerging standards, requiring RT-Na/S batteries to demonstrate stability across operational temperature ranges (-20°C to 60°C) and during extreme conditions. Standard test protocols typically include thermal cycling, thermal shock testing, and accelerated aging under varied temperature conditions to evaluate degradation mechanisms and safety thresholds.

Regulatory bodies in major markets have begun incorporating sodium battery technologies into their compliance frameworks. The UN Transportation Testing requirements (UN 38.3) have been updated to include provisions for sodium-based batteries, addressing concerns about reactivity during transport. Similarly, the European Battery Directive is expanding its scope to encompass sodium battery chemistries, with particular emphasis on temperature-related safety parameters.

Industry-specific standards are also emerging, with automotive applications following modified versions of SAE J2929 and ISO 12405 standards, adapted specifically for sodium battery technologies. These standards emphasize temperature abuse testing protocols that simulate real-world conditions, including rapid temperature fluctuations and extended exposure to extreme environments.

Compliance testing methodologies for RT-Na/S batteries focus heavily on thermal management systems, requiring demonstration of fail-safe mechanisms during temperature excursions. These include controlled cell venting, thermal propagation prevention, and system-level thermal management validation. Manufacturers must document temperature-related failure modes and implement appropriate mitigation strategies to achieve certification.

Looking forward, the harmonization of global safety standards for sodium-based batteries represents a significant challenge. Industry consortia and international standards organizations are collaborating to develop unified testing protocols that address the unique temperature-related behaviors of RT-Na/S batteries while ensuring consistent safety requirements across different regulatory jurisdictions.

Environmental Impact of RT-NaS Battery Materials

The environmental footprint of Room-Temperature Sodium-Sulfur (RT-NaS) battery materials presents significant considerations for sustainable energy storage development. Unlike traditional high-temperature NaS batteries operating at 300-350°C, RT-NaS batteries utilize materials that function effectively at ambient temperatures, potentially reducing operational energy requirements and associated emissions.

Sodium and sulfur, the primary active materials in RT-NaS batteries, offer environmental advantages compared to lithium-ion alternatives. Sodium is abundantly available in seawater and terrestrial deposits, requiring less intensive extraction processes than lithium mining. This abundance translates to reduced land disruption, water usage, and energy consumption during raw material acquisition phases.

Sulfur, predominantly sourced as a byproduct from petroleum refining and natural gas processing, represents a recycling opportunity for industrial waste streams. The utilization of sulfur in battery applications provides a value-added pathway for materials that might otherwise require disposal, creating a positive environmental feedback loop within industrial ecosystems.

However, RT-NaS battery production involves several environmentally challenging components. The carbon-based materials used as electrolyte additives and conductive agents often derive from fossil fuel sources. Additionally, the production of specialized separators and current collectors may involve energy-intensive manufacturing processes and potentially toxic chemical treatments.

The temperature resilience testing of these batteries introduces further environmental considerations. Accelerated aging tests under various temperature conditions require controlled environmental chambers that consume significant energy. The disposal of tested batteries containing reactive sodium compounds necessitates specialized handling protocols to prevent soil and water contamination.

End-of-life management presents both challenges and opportunities. The reactive nature of sodium requires careful decommissioning procedures, yet the theoretical recyclability of both sodium and sulfur components exceeds 90% under optimal recovery conditions. Developing efficient recycling pathways remains crucial for minimizing the cumulative environmental impact of RT-NaS technology deployment.

Life cycle assessments comparing RT-NaS batteries to conventional lithium-ion technologies suggest potential carbon footprint reductions of 25-30%, primarily due to the abundance and lower processing requirements of sodium-based materials. However, these advantages must be balanced against performance characteristics, including cycle life and energy density, to determine true environmental benefit per unit of energy stored and delivered.

Sodium and sulfur, the primary active materials in RT-NaS batteries, offer environmental advantages compared to lithium-ion alternatives. Sodium is abundantly available in seawater and terrestrial deposits, requiring less intensive extraction processes than lithium mining. This abundance translates to reduced land disruption, water usage, and energy consumption during raw material acquisition phases.

Sulfur, predominantly sourced as a byproduct from petroleum refining and natural gas processing, represents a recycling opportunity for industrial waste streams. The utilization of sulfur in battery applications provides a value-added pathway for materials that might otherwise require disposal, creating a positive environmental feedback loop within industrial ecosystems.

However, RT-NaS battery production involves several environmentally challenging components. The carbon-based materials used as electrolyte additives and conductive agents often derive from fossil fuel sources. Additionally, the production of specialized separators and current collectors may involve energy-intensive manufacturing processes and potentially toxic chemical treatments.

The temperature resilience testing of these batteries introduces further environmental considerations. Accelerated aging tests under various temperature conditions require controlled environmental chambers that consume significant energy. The disposal of tested batteries containing reactive sodium compounds necessitates specialized handling protocols to prevent soil and water contamination.

End-of-life management presents both challenges and opportunities. The reactive nature of sodium requires careful decommissioning procedures, yet the theoretical recyclability of both sodium and sulfur components exceeds 90% under optimal recovery conditions. Developing efficient recycling pathways remains crucial for minimizing the cumulative environmental impact of RT-NaS technology deployment.

Life cycle assessments comparing RT-NaS batteries to conventional lithium-ion technologies suggest potential carbon footprint reductions of 25-30%, primarily due to the abundance and lower processing requirements of sodium-based materials. However, these advantages must be balanced against performance characteristics, including cycle life and energy density, to determine true environmental benefit per unit of energy stored and delivered.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!