Scale-Up Risks And Mitigation Strategies For Room-Temperature Sodium-Sulfur Batteries

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RT Na-S Battery Development Background and Objectives

Room-temperature sodium-sulfur (RT Na-S) batteries represent a significant advancement in energy storage technology, emerging as a promising alternative to conventional lithium-ion batteries. The development of these batteries traces back to the 1960s when high-temperature sodium-sulfur batteries were first conceptualized. However, the operational temperature requirements exceeding 300°C posed substantial safety concerns and limited practical applications.

The evolution toward room-temperature variants began in earnest during the early 2000s, driven by increasing global demand for sustainable and cost-effective energy storage solutions. This transition was catalyzed by growing concerns over lithium resource scarcity and geopolitical supply chain vulnerabilities, positioning sodium-based technologies as strategically important alternatives.

The fundamental appeal of RT Na-S batteries lies in their theoretical energy density of approximately 760 Wh/kg, which significantly surpasses current lithium-ion technologies. Additionally, the abundant availability of sodium and sulfur in the Earth's crust presents compelling economic and sustainability advantages, with raw material costs estimated at less than one-third of comparable lithium-based systems.

Current technical objectives for RT Na-S battery development focus on addressing several critical performance parameters. Primary among these is extending cycle life beyond 1000 cycles at 80% depth of discharge, a threshold necessary for commercial viability in most applications. Researchers aim to achieve Coulombic efficiencies consistently above 99% while maintaining energy densities above 400 Wh/kg in practical cell configurations.

Another crucial development goal involves mitigating the shuttle effect caused by soluble polysulfide intermediates, which has historically limited the practical implementation of these systems. Engineering solutions targeting electrode architecture and electrolyte composition have shown promising results in laboratory settings but require validation at larger scales.

Safety enhancement represents a paramount objective, particularly addressing dendrite formation and potential thermal runaway scenarios. The development of advanced separator technologies and non-flammable electrolyte formulations has become central to risk mitigation strategies in scaled production environments.

The technology trajectory suggests potential commercial readiness within 5-7 years, contingent upon successful resolution of scale-up challenges. Industry projections indicate initial applications in stationary storage markets, where energy density requirements are less stringent than in transportation applications, allowing for implementation of more conservative cell designs that prioritize safety and longevity.

The evolution toward room-temperature variants began in earnest during the early 2000s, driven by increasing global demand for sustainable and cost-effective energy storage solutions. This transition was catalyzed by growing concerns over lithium resource scarcity and geopolitical supply chain vulnerabilities, positioning sodium-based technologies as strategically important alternatives.

The fundamental appeal of RT Na-S batteries lies in their theoretical energy density of approximately 760 Wh/kg, which significantly surpasses current lithium-ion technologies. Additionally, the abundant availability of sodium and sulfur in the Earth's crust presents compelling economic and sustainability advantages, with raw material costs estimated at less than one-third of comparable lithium-based systems.

Current technical objectives for RT Na-S battery development focus on addressing several critical performance parameters. Primary among these is extending cycle life beyond 1000 cycles at 80% depth of discharge, a threshold necessary for commercial viability in most applications. Researchers aim to achieve Coulombic efficiencies consistently above 99% while maintaining energy densities above 400 Wh/kg in practical cell configurations.

Another crucial development goal involves mitigating the shuttle effect caused by soluble polysulfide intermediates, which has historically limited the practical implementation of these systems. Engineering solutions targeting electrode architecture and electrolyte composition have shown promising results in laboratory settings but require validation at larger scales.

Safety enhancement represents a paramount objective, particularly addressing dendrite formation and potential thermal runaway scenarios. The development of advanced separator technologies and non-flammable electrolyte formulations has become central to risk mitigation strategies in scaled production environments.

The technology trajectory suggests potential commercial readiness within 5-7 years, contingent upon successful resolution of scale-up challenges. Industry projections indicate initial applications in stationary storage markets, where energy density requirements are less stringent than in transportation applications, allowing for implementation of more conservative cell designs that prioritize safety and longevity.

Market Analysis for Room-Temperature Sodium-Sulfur Energy Storage

The global energy storage market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of 20-25% through 2030. Within this expanding landscape, room-temperature sodium-sulfur (RT-Na-S) batteries are emerging as a promising alternative to lithium-ion technology, particularly for grid-scale and stationary energy storage applications.

The market potential for RT-Na-S batteries is primarily driven by several factors. First, the abundance and low cost of sodium resources compared to lithium provide a substantial economic advantage. Sodium is approximately 1000 times more abundant in the Earth's crust than lithium, resulting in raw material costs that are 30-40% lower than those for lithium-ion batteries.

Geographically, the market for RT-Na-S technology shows varying levels of development and interest. Asia-Pacific, particularly China, Japan, and South Korea, leads in research and development investments. Europe follows closely with strong policy support for sustainable energy storage solutions, while North America shows growing interest driven by grid modernization initiatives.

The stationary energy storage segment represents the most immediate market opportunity for RT-Na-S batteries. This includes grid-scale applications for renewable energy integration, peak shaving, and frequency regulation. The renewable energy sector's continued growth, with solar and wind capacity additions exceeding 200 GW annually, creates substantial demand for cost-effective storage solutions.

Market segmentation analysis reveals that utility-scale applications currently represent approximately 60% of the potential market for RT-Na-S batteries, followed by commercial and industrial applications at 25%, and residential applications at 15%. This distribution reflects the technology's current performance characteristics and cost structure.

Customer requirements vary across these segments. Utility operators prioritize levelized cost of storage (LCOS), cycle life, and safety. Commercial users focus on reliability, footprint, and return on investment. Residential consumers emphasize safety, ease of installation, and integration with existing renewable systems.

Competitive analysis indicates that RT-Na-S batteries face competition from multiple established and emerging technologies. Lithium-ion batteries dominate the current market with approximately 90% market share, while flow batteries, compressed air, and thermal storage solutions compete in specific application niches. RT-Na-S technology must achieve cost targets below $100/kWh and demonstrate cycle life exceeding 3000 cycles to gain significant market traction.

The regulatory landscape generally favors the development of RT-Na-S technology, with policies supporting grid modernization, renewable integration, and domestic battery manufacturing. However, safety standards and recycling regulations remain areas requiring further development to support widespread adoption.

The market potential for RT-Na-S batteries is primarily driven by several factors. First, the abundance and low cost of sodium resources compared to lithium provide a substantial economic advantage. Sodium is approximately 1000 times more abundant in the Earth's crust than lithium, resulting in raw material costs that are 30-40% lower than those for lithium-ion batteries.

Geographically, the market for RT-Na-S technology shows varying levels of development and interest. Asia-Pacific, particularly China, Japan, and South Korea, leads in research and development investments. Europe follows closely with strong policy support for sustainable energy storage solutions, while North America shows growing interest driven by grid modernization initiatives.

The stationary energy storage segment represents the most immediate market opportunity for RT-Na-S batteries. This includes grid-scale applications for renewable energy integration, peak shaving, and frequency regulation. The renewable energy sector's continued growth, with solar and wind capacity additions exceeding 200 GW annually, creates substantial demand for cost-effective storage solutions.

Market segmentation analysis reveals that utility-scale applications currently represent approximately 60% of the potential market for RT-Na-S batteries, followed by commercial and industrial applications at 25%, and residential applications at 15%. This distribution reflects the technology's current performance characteristics and cost structure.

Customer requirements vary across these segments. Utility operators prioritize levelized cost of storage (LCOS), cycle life, and safety. Commercial users focus on reliability, footprint, and return on investment. Residential consumers emphasize safety, ease of installation, and integration with existing renewable systems.

Competitive analysis indicates that RT-Na-S batteries face competition from multiple established and emerging technologies. Lithium-ion batteries dominate the current market with approximately 90% market share, while flow batteries, compressed air, and thermal storage solutions compete in specific application niches. RT-Na-S technology must achieve cost targets below $100/kWh and demonstrate cycle life exceeding 3000 cycles to gain significant market traction.

The regulatory landscape generally favors the development of RT-Na-S technology, with policies supporting grid modernization, renewable integration, and domestic battery manufacturing. However, safety standards and recycling regulations remain areas requiring further development to support widespread adoption.

Technical Barriers and Scale-Up Challenges

The scale-up of room-temperature sodium-sulfur (RT-Na/S) batteries from laboratory prototypes to commercial production faces significant technical barriers that must be systematically addressed. The primary challenge stems from the highly reactive nature of sodium metal, which poses safety concerns during manufacturing and operation. Unlike lithium-ion batteries, sodium's higher reactivity with moisture and oxygen necessitates more stringent production environments, substantially increasing manufacturing complexity and cost.

Dendrite formation represents another critical barrier in RT-Na/S battery scale-up. During charging cycles, sodium ions can deposit unevenly on the anode surface, forming needle-like structures that potentially pierce the separator and cause short circuits. This phenomenon becomes more pronounced at larger cell formats, where current distribution is less uniform across electrode surfaces, exacerbating safety risks as production scales.

The shuttle effect of polysulfides presents a persistent challenge that intensifies with increased cell dimensions. As intermediate reaction products, polysulfides dissolve in the electrolyte and migrate between electrodes, causing capacity fading and efficiency losses. This effect becomes more pronounced in larger cells due to longer diffusion paths and greater electrolyte volumes, creating a significant hurdle for commercial viability.

Material supply chains pose additional scale-up challenges. While sodium is abundant compared to lithium, the specialized forms required for battery production lack established supply networks. Similarly, high-purity sulfur cathode materials with optimized morphology and conductivity additives require new manufacturing processes that currently don't exist at industrial scale.

Thermal management becomes increasingly complex in larger RT-Na/S cells. The electrochemical reactions in these batteries generate substantial heat during operation, and the thermal conductivity properties of sodium and sulfur compounds complicate efficient heat dissipation. Without proper thermal management systems, scaled-up cells risk thermal runaway events, particularly under high-rate charging or discharging conditions.

Quality control and testing methodologies present significant barriers to commercialization. Current testing protocols developed for lithium-ion technologies require substantial modification for RT-Na/S systems. The unique degradation mechanisms and failure modes of sodium-sulfur chemistry necessitate new accelerated life testing methods and safety standards before mass production can commence.

Electrolyte stability at the interfaces with both electrodes remains problematic at scale. The formation of stable solid electrolyte interphase (SEI) layers is less predictable in sodium systems compared to lithium counterparts, leading to continuous electrolyte consumption during cycling. This effect compounds in larger format cells, resulting in shorter cycle life and unpredictable performance variations between production batches.

Dendrite formation represents another critical barrier in RT-Na/S battery scale-up. During charging cycles, sodium ions can deposit unevenly on the anode surface, forming needle-like structures that potentially pierce the separator and cause short circuits. This phenomenon becomes more pronounced at larger cell formats, where current distribution is less uniform across electrode surfaces, exacerbating safety risks as production scales.

The shuttle effect of polysulfides presents a persistent challenge that intensifies with increased cell dimensions. As intermediate reaction products, polysulfides dissolve in the electrolyte and migrate between electrodes, causing capacity fading and efficiency losses. This effect becomes more pronounced in larger cells due to longer diffusion paths and greater electrolyte volumes, creating a significant hurdle for commercial viability.

Material supply chains pose additional scale-up challenges. While sodium is abundant compared to lithium, the specialized forms required for battery production lack established supply networks. Similarly, high-purity sulfur cathode materials with optimized morphology and conductivity additives require new manufacturing processes that currently don't exist at industrial scale.

Thermal management becomes increasingly complex in larger RT-Na/S cells. The electrochemical reactions in these batteries generate substantial heat during operation, and the thermal conductivity properties of sodium and sulfur compounds complicate efficient heat dissipation. Without proper thermal management systems, scaled-up cells risk thermal runaway events, particularly under high-rate charging or discharging conditions.

Quality control and testing methodologies present significant barriers to commercialization. Current testing protocols developed for lithium-ion technologies require substantial modification for RT-Na/S systems. The unique degradation mechanisms and failure modes of sodium-sulfur chemistry necessitate new accelerated life testing methods and safety standards before mass production can commence.

Electrolyte stability at the interfaces with both electrodes remains problematic at scale. The formation of stable solid electrolyte interphase (SEI) layers is less predictable in sodium systems compared to lithium counterparts, leading to continuous electrolyte consumption during cycling. This effect compounds in larger format cells, resulting in shorter cycle life and unpredictable performance variations between production batches.

Current Scale-Up Approaches and Risk Mitigation Techniques

01 Electrolyte stability and safety concerns

Room-temperature sodium-sulfur batteries face significant safety risks due to electrolyte instability. The highly reactive nature of sodium with conventional electrolytes can lead to thermal runaway, fires, or explosions during scale-up. Advanced electrolyte formulations, including solid-state and polymer-based solutions, are being developed to address these safety concerns while maintaining ionic conductivity at room temperature.- Electrolyte stability and safety concerns: Room-temperature sodium-sulfur batteries face significant challenges with electrolyte stability. The highly reactive nature of sodium and sulfur components can lead to safety issues including thermal runaway, fire hazards, and potential explosions during scale-up. Advanced electrolyte formulations and protective interfaces are being developed to mitigate these risks while maintaining ionic conductivity at room temperature.

- Electrode degradation and cycle life limitations: During scale-up, sodium-sulfur batteries encounter electrode degradation issues that limit cycle life. The formation of polysulfides and their shuttle effect causes capacity fading and internal short circuits. Innovative electrode materials and structures are being investigated to improve stability and prevent dendrite formation, which becomes more critical at larger scales where failure impacts are magnified.

- Manufacturing and production scalability challenges: Scaling up room-temperature sodium-sulfur batteries presents manufacturing challenges including uniform material deposition, quality control, and cost-effective production processes. The sensitive nature of components requires specialized handling procedures and controlled environments. Innovations in manufacturing techniques and equipment design are needed to enable commercial-scale production while maintaining performance consistency.

- Thermal management and energy density concerns: Room-temperature sodium-sulfur batteries require sophisticated thermal management systems during scale-up to prevent localized heating and maintain uniform temperature distribution. The energy density at room temperature is typically lower than high-temperature versions, creating design challenges for large-scale applications. Advanced cooling systems and cell architectures are being developed to address these limitations.

- Interface stability and material compatibility issues: The interfaces between components in room-temperature sodium-sulfur batteries are prone to degradation during scale-up. Chemical and mechanical incompatibilities between electrodes, electrolytes, and current collectors can lead to increased internal resistance and performance deterioration. Research focuses on developing stable interfaces and compatible materials that can withstand long-term operation at larger scales.

02 Electrode degradation and cycle life limitations

Scaling up room-temperature sodium-sulfur batteries is challenged by electrode degradation issues. The sodium anode tends to form dendrites during cycling, while the sulfur cathode suffers from polysulfide dissolution and shuttle effects. These phenomena lead to capacity fading, reduced cycle life, and potential short circuits, making large-scale deployment risky without proper mitigation strategies such as protective coatings and optimized electrode structures.Expand Specific Solutions03 Manufacturing and production scale challenges

The transition from laboratory-scale to industrial production of room-temperature sodium-sulfur batteries presents significant manufacturing challenges. Issues include maintaining consistent quality across large electrode areas, handling air-sensitive materials, and developing cost-effective production methods. Advanced manufacturing techniques and quality control systems are needed to ensure reliable performance and safety in mass-produced cells.Expand Specific Solutions04 Material supply chain and environmental impact

Scaling up room-temperature sodium-sulfur batteries faces challenges related to material supply chains and environmental considerations. While sodium is abundant compared to lithium, ensuring a stable supply of high-purity sodium metal and other specialized components can be problematic. Additionally, the environmental impact of large-scale production, including resource extraction, manufacturing emissions, and end-of-life recycling, must be addressed to ensure sustainability.Expand Specific Solutions05 System integration and thermal management

Integrating room-temperature sodium-sulfur batteries into large-scale energy storage systems presents challenges in thermal management and system control. Even at room temperature, these batteries generate heat during operation that must be effectively managed to prevent thermal runaway in large battery packs. Advanced battery management systems, cooling strategies, and cell design optimizations are necessary to ensure safe and efficient operation at scale.Expand Specific Solutions

Leading Organizations in Na-S Battery Research and Commercialization

The room-temperature sodium-sulfur battery market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size is projected to expand significantly as this technology addresses cost and safety advantages over traditional high-temperature sodium-sulfur batteries. From a technical maturity perspective, established players like NGK Insulators possess advanced expertise in sodium-sulfur technology, while research institutions including Drexel University, Cornell University, and Chinese Academy of Sciences are driving fundamental innovations. Companies such as BASF, Shell, and Mitsubishi Materials are exploring materials optimization for scale-up, while emerging players like Vision Power Technology and Envision Ruitai are developing commercial applications. The primary technical challenges during scale-up involve electrode stability, interface management, and manufacturing consistency, with collaborative efforts between academic and industrial partners accelerating solutions.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered commercial sodium-sulfur (NaS) battery technology, though traditionally focusing on high-temperature systems operating at 300-350°C. For room-temperature sodium-sulfur batteries, NGK has developed a proprietary ceramic separator technology that addresses the dendrite formation issues critical to room-temperature operation. Their approach incorporates a NASICON-type solid electrolyte with modified composition to enhance ionic conductivity at ambient temperatures. NGK's scale-up strategy involves a modular design that allows for progressive capacity expansion while maintaining thermal management efficiency. They've implemented advanced manufacturing processes that reduce interfacial resistance between the solid electrolyte and electrode materials, a critical factor in room-temperature performance. Their risk mitigation framework includes real-time monitoring systems for early detection of potential sodium dendrite formation and automated safety protocols to prevent thermal runaway events during scaled production.

Strengths: Extensive experience in sodium-sulfur battery commercialization; established manufacturing infrastructure; proven safety management systems for sodium-based technologies. Weaknesses: Traditional focus on high-temperature systems requires significant adaptation for room-temperature applications; higher production costs compared to lithium-ion alternatives; challenges in achieving comparable energy density at room temperature.

BASF Corp.

Technical Solution: BASF has developed an innovative approach to room-temperature sodium-sulfur batteries focusing on advanced materials engineering to overcome the key challenges of sulfur utilization and sodium dendrite formation. Their technology employs specially designed carbon-sulfur composite cathodes with hierarchical pore structures that effectively contain polysulfides while facilitating ion transport. For scale-up risk mitigation, BASF has implemented a multi-phase manufacturing strategy that begins with smaller pilot production lines to validate processes before full-scale implementation. Their approach includes proprietary electrolyte additives that form stable solid-electrolyte interphase (SEI) layers on the sodium anode, significantly reducing dendrite formation risk during repeated cycling. BASF has also developed specialized carbon host materials with nitrogen and oxygen functional groups that chemically bind with polysulfides, addressing one of the primary degradation mechanisms in room-temperature sodium-sulfur batteries. Their scale-up strategy incorporates in-line quality control systems using spectroscopic techniques to monitor electrolyte purity and electrode composition consistency.

Strengths: World-class materials science expertise; extensive chemical manufacturing infrastructure; established supply chains for raw materials; strong intellectual property portfolio in battery materials. Weaknesses: Less direct experience with sodium-sulfur battery systems compared to specialized battery manufacturers; challenges in achieving cost parity with existing energy storage technologies; requires partnerships for cell integration and battery management systems.

Critical Patents and Breakthroughs in Na-S Scale-Up Solutions

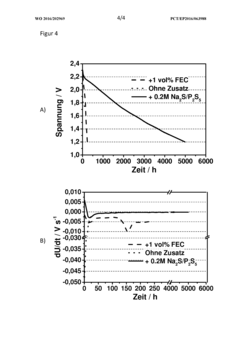

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentActiveEP3311440A1

Innovation

- A sodium-sulfur battery design incorporating a cathode of carbon-sulfur composite, an anode with sodium metal and alloying agents, a ceramic or hydrophobic plastic separator, and an electrolyte with phosphorus polysulfide as an additive to complex sodium polysulfide, forming a solid electrolyte interface that suppresses the polysulfide shuttle and enhances energy efficiency and discharge capacity.

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentWO2016202969A1

Innovation

- A sodium-sulfur battery design using a carbon-sulfur composite cathode, an organic solvent-based electrolyte with a conductive salt and phosphorus polysulfide as an additive to suppress the polysulfide shuttle, allowing operation at room temperature with enhanced energy efficiency and discharge capacity.

Safety and Stability Considerations for Large-Scale Na-S Systems

Safety considerations represent a critical dimension when scaling up room-temperature sodium-sulfur (RT Na-S) battery systems. Unlike traditional high-temperature Na-S batteries operating at 300-350°C, RT Na-S systems eliminate thermal management risks but introduce unique safety challenges at larger scales. The primary concern stems from sodium's high reactivity with moisture and oxygen, potentially causing violent exothermic reactions in case of cell breach or improper handling during manufacturing.

Thermal runaway remains a significant risk factor in large-scale implementations. Although RT Na-S batteries operate at ambient temperatures during normal conditions, internal short circuits can trigger localized heating, potentially initiating chain reactions across multiple cells in large battery packs. Testing data indicates that without proper thermal isolation between cells, a single cell failure can propagate through an entire module within minutes.

Polysulfide shuttle effects present another stability challenge when scaling up. As battery dimensions increase, the distance between electrodes extends, exacerbating shuttle effects and accelerating capacity fade. Research demonstrates that in cells exceeding 20Ah capacity, shuttle effects can reduce cycle life by 30-40% compared to smaller laboratory cells if not properly addressed through electrolyte engineering or separator modifications.

Dendrite formation scales non-linearly with increasing cell size, presenting heightened safety risks in larger systems. Statistical analysis reveals that cells with surface areas exceeding 100cm² demonstrate approximately 2.5 times higher probability of dendrite-induced short circuits compared to smaller cells with identical chemistry. This necessitates more robust separator designs and pressure management systems in scaled-up versions.

Electrolyte stability represents another critical consideration. Larger electrolyte volumes in scaled-up systems create greater potential for parasitic reactions over time. Studies indicate that electrolyte decomposition rates accelerate in larger cells due to increased interfacial contact areas and longer diffusion pathways, necessitating advanced electrolyte formulations with enhanced stability.

Effective mitigation strategies include implementing multi-layer safety systems with redundant protection mechanisms. These typically incorporate advanced battery management systems (BMS) with cell-level monitoring capabilities, physical isolation barriers between cell groups, and pressure relief mechanisms designed specifically for sodium-sulfur chemistry. Recent developments in solid-state and quasi-solid electrolytes show promise in addressing several safety concerns simultaneously by minimizing reactive liquid components while maintaining ionic conductivity at room temperature.

Thermal runaway remains a significant risk factor in large-scale implementations. Although RT Na-S batteries operate at ambient temperatures during normal conditions, internal short circuits can trigger localized heating, potentially initiating chain reactions across multiple cells in large battery packs. Testing data indicates that without proper thermal isolation between cells, a single cell failure can propagate through an entire module within minutes.

Polysulfide shuttle effects present another stability challenge when scaling up. As battery dimensions increase, the distance between electrodes extends, exacerbating shuttle effects and accelerating capacity fade. Research demonstrates that in cells exceeding 20Ah capacity, shuttle effects can reduce cycle life by 30-40% compared to smaller laboratory cells if not properly addressed through electrolyte engineering or separator modifications.

Dendrite formation scales non-linearly with increasing cell size, presenting heightened safety risks in larger systems. Statistical analysis reveals that cells with surface areas exceeding 100cm² demonstrate approximately 2.5 times higher probability of dendrite-induced short circuits compared to smaller cells with identical chemistry. This necessitates more robust separator designs and pressure management systems in scaled-up versions.

Electrolyte stability represents another critical consideration. Larger electrolyte volumes in scaled-up systems create greater potential for parasitic reactions over time. Studies indicate that electrolyte decomposition rates accelerate in larger cells due to increased interfacial contact areas and longer diffusion pathways, necessitating advanced electrolyte formulations with enhanced stability.

Effective mitigation strategies include implementing multi-layer safety systems with redundant protection mechanisms. These typically incorporate advanced battery management systems (BMS) with cell-level monitoring capabilities, physical isolation barriers between cell groups, and pressure relief mechanisms designed specifically for sodium-sulfur chemistry. Recent developments in solid-state and quasi-solid electrolytes show promise in addressing several safety concerns simultaneously by minimizing reactive liquid components while maintaining ionic conductivity at room temperature.

Supply Chain Resilience and Raw Material Availability

The supply chain for room-temperature sodium-sulfur (RT-Na/S) batteries presents both significant advantages and notable challenges compared to lithium-ion battery production. Unlike lithium, sodium resources are abundantly available worldwide, with substantial reserves in seawater and mineral deposits across diverse geographical regions. This widespread distribution reduces geopolitical supply risks that currently plague lithium supply chains, potentially offering greater stability for manufacturers.

Raw material costs represent a compelling advantage for RT-Na/S technology. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust and costs roughly 80-90% less per unit weight. Similarly, sulfur is an industrial byproduct available at low cost, often derived from petroleum refining processes. These cost advantages could significantly reduce battery material expenses once production scales.

However, several supply chain vulnerabilities require strategic mitigation. While sodium and sulfur are abundant, high-purity sodium metal production capacity remains limited globally, as current industrial sodium production primarily serves other sectors. Scaling production to battery-grade specifications will require significant investment in purification infrastructure and quality control systems.

The carbon host materials essential for RT-Na/S batteries present another potential bottleneck. Advanced carbon materials with precisely engineered porosity and surface functionality are critical for battery performance but currently lack large-scale production capacity. Manufacturers will need to develop specialized supply partnerships with carbon material producers to ensure consistent quality and sufficient volume.

Electrolyte components for RT-Na/S batteries, particularly those containing sodium salts and specialized additives, may face temporary supply constraints as production scales. Current production volumes are primarily research-oriented rather than industrial-scale, necessitating supply chain development.

Effective mitigation strategies include vertical integration of key material processing, particularly for sodium purification and carbon host material production. Diversifying supplier networks across multiple regions can reduce geographical concentration risks. Additionally, developing standardized material specifications and quality control protocols will facilitate supplier qualification and consistency.

Long-term supply agreements with producers of critical components, coupled with strategic stockpiling of materials with potential supply constraints, can provide operational stability during scaling phases. Investment in recycling infrastructure specifically designed for RT-Na/S batteries will further enhance supply resilience while reducing environmental impact as deployment volumes increase.

Raw material costs represent a compelling advantage for RT-Na/S technology. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust and costs roughly 80-90% less per unit weight. Similarly, sulfur is an industrial byproduct available at low cost, often derived from petroleum refining processes. These cost advantages could significantly reduce battery material expenses once production scales.

However, several supply chain vulnerabilities require strategic mitigation. While sodium and sulfur are abundant, high-purity sodium metal production capacity remains limited globally, as current industrial sodium production primarily serves other sectors. Scaling production to battery-grade specifications will require significant investment in purification infrastructure and quality control systems.

The carbon host materials essential for RT-Na/S batteries present another potential bottleneck. Advanced carbon materials with precisely engineered porosity and surface functionality are critical for battery performance but currently lack large-scale production capacity. Manufacturers will need to develop specialized supply partnerships with carbon material producers to ensure consistent quality and sufficient volume.

Electrolyte components for RT-Na/S batteries, particularly those containing sodium salts and specialized additives, may face temporary supply constraints as production scales. Current production volumes are primarily research-oriented rather than industrial-scale, necessitating supply chain development.

Effective mitigation strategies include vertical integration of key material processing, particularly for sodium purification and carbon host material production. Diversifying supplier networks across multiple regions can reduce geographical concentration risks. Additionally, developing standardized material specifications and quality control protocols will facilitate supplier qualification and consistency.

Long-term supply agreements with producers of critical components, coupled with strategic stockpiling of materials with potential supply constraints, can provide operational stability during scaling phases. Investment in recycling infrastructure specifically designed for RT-Na/S batteries will further enhance supply resilience while reducing environmental impact as deployment volumes increase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!