Additive Manufacturing Options For Room-Temperature Sodium-Sulfur Batteries

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM-RT-NaS Battery Background and Objectives

Sodium-sulfur (Na-S) batteries have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. Traditionally, Na-S batteries operate at high temperatures (300-350°C), which presents significant safety concerns and limits their practical applications. Room-temperature sodium-sulfur (RT-Na-S) batteries address these limitations by enabling operation at ambient temperatures, thus expanding potential use cases across various sectors including grid storage, electric vehicles, and portable electronics.

The development of RT-Na-S batteries traces back to the early 2000s when researchers began exploring ways to modify the conventional high-temperature design. The evolution of this technology has been marked by incremental improvements in electrolyte formulations, electrode materials, and cell architectures. Despite these advances, RT-Na-S batteries still face challenges related to capacity fading, polysulfide shuttling, and dendrite formation that hinder their commercial viability.

Additive manufacturing (AM), commonly known as 3D printing, represents a transformative approach to battery fabrication that could potentially address many of these challenges. The integration of AM techniques with RT-Na-S battery production began gaining traction around 2015, with early experiments focusing on electrode structures. The technology has since evolved to encompass more complex components including specialized separators and even complete cell designs.

The primary objective of exploring additive manufacturing options for RT-Na-S batteries is to overcome the inherent limitations of conventional manufacturing methods. AM offers unprecedented design freedom, enabling the creation of complex geometries that can enhance electrochemical performance through optimized ion transport pathways and increased active material utilization. Additionally, AM facilitates rapid prototyping and customization, potentially accelerating the development cycle and enabling application-specific battery designs.

Further technical goals include improving energy density beyond the current 150-200 Wh/kg range, extending cycle life to over 1000 cycles, and enhancing rate capability to support fast charging applications. The development of specialized AM materials compatible with sodium and sulfur chemistries represents another critical objective, as existing printing materials often lack the necessary electrochemical stability or ionic conductivity.

From a broader perspective, this technological convergence aims to establish a sustainable and economically viable alternative to lithium-ion batteries, leveraging the abundant sodium resources and potentially lower manufacturing costs. The successful implementation of AM in RT-Na-S battery production could revolutionize energy storage technologies, contributing significantly to renewable energy integration and electrification efforts across multiple industries.

The development of RT-Na-S batteries traces back to the early 2000s when researchers began exploring ways to modify the conventional high-temperature design. The evolution of this technology has been marked by incremental improvements in electrolyte formulations, electrode materials, and cell architectures. Despite these advances, RT-Na-S batteries still face challenges related to capacity fading, polysulfide shuttling, and dendrite formation that hinder their commercial viability.

Additive manufacturing (AM), commonly known as 3D printing, represents a transformative approach to battery fabrication that could potentially address many of these challenges. The integration of AM techniques with RT-Na-S battery production began gaining traction around 2015, with early experiments focusing on electrode structures. The technology has since evolved to encompass more complex components including specialized separators and even complete cell designs.

The primary objective of exploring additive manufacturing options for RT-Na-S batteries is to overcome the inherent limitations of conventional manufacturing methods. AM offers unprecedented design freedom, enabling the creation of complex geometries that can enhance electrochemical performance through optimized ion transport pathways and increased active material utilization. Additionally, AM facilitates rapid prototyping and customization, potentially accelerating the development cycle and enabling application-specific battery designs.

Further technical goals include improving energy density beyond the current 150-200 Wh/kg range, extending cycle life to over 1000 cycles, and enhancing rate capability to support fast charging applications. The development of specialized AM materials compatible with sodium and sulfur chemistries represents another critical objective, as existing printing materials often lack the necessary electrochemical stability or ionic conductivity.

From a broader perspective, this technological convergence aims to establish a sustainable and economically viable alternative to lithium-ion batteries, leveraging the abundant sodium resources and potentially lower manufacturing costs. The successful implementation of AM in RT-Na-S battery production could revolutionize energy storage technologies, contributing significantly to renewable energy integration and electrification efforts across multiple industries.

Market Analysis for RT-NaS Battery Applications

The global market for room-temperature sodium-sulfur (RT-NaS) batteries is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the energy storage sector, where RT-NaS batteries compete, is projected to reach $300 billion by 2030, with grid-scale storage representing the largest segment at approximately 45% of the total market share.

RT-NaS batteries are positioned to capture a growing portion of this market due to their compelling value proposition: abundant raw materials, lower cost compared to lithium-ion alternatives, and improved safety profiles. The cost advantage is particularly significant, with sodium resources being approximately 1,000 times more abundant than lithium, resulting in potential material cost reductions of 30-40% compared to lithium-ion technologies.

Market segmentation analysis reveals several key application areas for RT-NaS batteries. Grid-scale energy storage represents the primary market opportunity, particularly for load-leveling and renewable energy integration. This segment is expected to grow at a compound annual growth rate (CAGR) of 25% through 2028, driven by increasing renewable energy deployment worldwide.

The electric vehicle (EV) sector presents another substantial opportunity, particularly in markets sensitive to cost considerations. While lithium-ion currently dominates this space, RT-NaS batteries could capture up to 15% of the stationary EV charging infrastructure market by 2027, especially in regions with less developed charging networks.

Consumer electronics represents a smaller but still significant market segment, with potential applications in devices where energy density requirements are less stringent but cost considerations are paramount. This segment is projected to grow at 18% CAGR over the next five years.

Regional market analysis indicates that Asia-Pacific currently leads RT-NaS battery development and adoption, with China, Japan, and South Korea making substantial investments in research and manufacturing capacity. Europe follows closely, driven by aggressive renewable energy targets and supportive regulatory frameworks. North America shows increasing interest, particularly for grid-scale applications in regions with high renewable penetration.

Market barriers include competition from established lithium-ion technology, which benefits from economies of scale and established manufacturing infrastructure. Additionally, customer perception regarding the relative immaturity of RT-NaS technology presents adoption challenges in risk-averse sectors.

The additive manufacturing approach to RT-NaS batteries could further enhance market potential by enabling customized form factors and reducing manufacturing costs by an estimated 20-25%, potentially accelerating adoption in specialized applications where design flexibility provides competitive advantage.

RT-NaS batteries are positioned to capture a growing portion of this market due to their compelling value proposition: abundant raw materials, lower cost compared to lithium-ion alternatives, and improved safety profiles. The cost advantage is particularly significant, with sodium resources being approximately 1,000 times more abundant than lithium, resulting in potential material cost reductions of 30-40% compared to lithium-ion technologies.

Market segmentation analysis reveals several key application areas for RT-NaS batteries. Grid-scale energy storage represents the primary market opportunity, particularly for load-leveling and renewable energy integration. This segment is expected to grow at a compound annual growth rate (CAGR) of 25% through 2028, driven by increasing renewable energy deployment worldwide.

The electric vehicle (EV) sector presents another substantial opportunity, particularly in markets sensitive to cost considerations. While lithium-ion currently dominates this space, RT-NaS batteries could capture up to 15% of the stationary EV charging infrastructure market by 2027, especially in regions with less developed charging networks.

Consumer electronics represents a smaller but still significant market segment, with potential applications in devices where energy density requirements are less stringent but cost considerations are paramount. This segment is projected to grow at 18% CAGR over the next five years.

Regional market analysis indicates that Asia-Pacific currently leads RT-NaS battery development and adoption, with China, Japan, and South Korea making substantial investments in research and manufacturing capacity. Europe follows closely, driven by aggressive renewable energy targets and supportive regulatory frameworks. North America shows increasing interest, particularly for grid-scale applications in regions with high renewable penetration.

Market barriers include competition from established lithium-ion technology, which benefits from economies of scale and established manufacturing infrastructure. Additionally, customer perception regarding the relative immaturity of RT-NaS technology presents adoption challenges in risk-averse sectors.

The additive manufacturing approach to RT-NaS batteries could further enhance market potential by enabling customized form factors and reducing manufacturing costs by an estimated 20-25%, potentially accelerating adoption in specialized applications where design flexibility provides competitive advantage.

Current Challenges in AM for RT-NaS Batteries

The integration of additive manufacturing (AM) technologies with room-temperature sodium-sulfur (RT-NaS) battery production presents significant technical challenges that currently limit widespread implementation. Material compatibility issues stand as a primary obstacle, as many AM processes operate at temperatures that can degrade the sensitive sulfur cathodes or react with sodium components. The high reactivity of sodium with moisture and oxygen necessitates specialized handling protocols that many conventional AM systems are not equipped to accommodate.

Precision and resolution limitations also hinder progress in this field. Current AM technologies struggle to achieve the micro and nano-scale features required for optimal battery performance, particularly for the intricate structures needed in solid electrolyte interfaces and electrode architectures. This resolution gap directly impacts the electrochemical performance of printed battery components.

Process consistency represents another major challenge. The layer-by-layer nature of AM introduces potential variability in material deposition, which can create inconsistencies in electrode thickness, porosity, and electrolyte distribution. These variations significantly affect battery capacity, cycle life, and safety characteristics, making quality control exceptionally difficult to maintain across production batches.

Material selection constraints further complicate AM implementation for RT-NaS batteries. The range of printable materials compatible with both AM processes and electrochemical requirements remains limited. Polymer-based AM materials often lack sufficient ionic conductivity, while metal-based printing may introduce unwanted electronic conductivity in electrolyte components. Additionally, achieving the correct rheological properties for printable battery slurries while maintaining electrochemical functionality presents a delicate balancing act.

Post-processing requirements add complexity to the manufacturing workflow. Many AM-produced battery components require additional treatment steps such as sintering, infiltration, or surface modification to achieve desired electrochemical properties. These steps can negate some of the advantages of AM, such as rapid prototyping and geometric freedom.

Scaling challenges persist as laboratory demonstrations struggle to translate to industrial production volumes. Current AM systems for battery applications typically operate at speeds incompatible with mass manufacturing requirements, creating a significant barrier to commercialization. The slow deposition rates and limited build volumes of high-precision AM systems restrict production throughput.

Safety concerns also remain paramount, as the reactive nature of sodium and sulfur compounds requires specialized containment and handling protocols during the printing process. Conventional AM equipment often lacks the necessary safety features to manage these reactive materials effectively.

Precision and resolution limitations also hinder progress in this field. Current AM technologies struggle to achieve the micro and nano-scale features required for optimal battery performance, particularly for the intricate structures needed in solid electrolyte interfaces and electrode architectures. This resolution gap directly impacts the electrochemical performance of printed battery components.

Process consistency represents another major challenge. The layer-by-layer nature of AM introduces potential variability in material deposition, which can create inconsistencies in electrode thickness, porosity, and electrolyte distribution. These variations significantly affect battery capacity, cycle life, and safety characteristics, making quality control exceptionally difficult to maintain across production batches.

Material selection constraints further complicate AM implementation for RT-NaS batteries. The range of printable materials compatible with both AM processes and electrochemical requirements remains limited. Polymer-based AM materials often lack sufficient ionic conductivity, while metal-based printing may introduce unwanted electronic conductivity in electrolyte components. Additionally, achieving the correct rheological properties for printable battery slurries while maintaining electrochemical functionality presents a delicate balancing act.

Post-processing requirements add complexity to the manufacturing workflow. Many AM-produced battery components require additional treatment steps such as sintering, infiltration, or surface modification to achieve desired electrochemical properties. These steps can negate some of the advantages of AM, such as rapid prototyping and geometric freedom.

Scaling challenges persist as laboratory demonstrations struggle to translate to industrial production volumes. Current AM systems for battery applications typically operate at speeds incompatible with mass manufacturing requirements, creating a significant barrier to commercialization. The slow deposition rates and limited build volumes of high-precision AM systems restrict production throughput.

Safety concerns also remain paramount, as the reactive nature of sodium and sulfur compounds requires specialized containment and handling protocols during the printing process. Conventional AM equipment often lacks the necessary safety features to manage these reactive materials effectively.

Current AM Techniques for RT-NaS Battery Production

01 Electrode materials for room-temperature sodium-sulfur batteries

Various electrode materials can be used in room-temperature sodium-sulfur batteries to enhance performance. These include carbon-based materials, metal oxides, and composite electrodes that improve conductivity and stability. The electrode design focuses on accommodating the volume changes during charge-discharge cycles and preventing polysulfide shuttling, which is a common issue in sodium-sulfur batteries operating at room temperature.- Electrode materials for room-temperature sodium-sulfur batteries: Various electrode materials can be used in room-temperature sodium-sulfur batteries to improve performance. These include carbon-based materials, metal oxides, and composite electrodes that enhance conductivity and stability. The electrode design focuses on accommodating the volume changes during charge-discharge cycles and improving the electrochemical reaction kinetics at room temperature, which is crucial for battery efficiency and longevity.

- Electrolyte solutions for room-temperature operation: Specialized electrolyte solutions are essential for enabling sodium-sulfur batteries to operate at room temperature. These electrolytes typically contain sodium salts dissolved in organic solvents or polymer matrices with additives to enhance ionic conductivity and prevent the shuttle effect. The electrolyte composition plays a critical role in facilitating sodium ion transport while maintaining stability against the reactive sulfur species formed during battery operation.

- Sulfur cathode modifications and composites: Modifications to the sulfur cathode are necessary to overcome challenges in room-temperature sodium-sulfur batteries. These include creating sulfur-carbon composites, encapsulating sulfur in porous structures, and developing sulfur polymers that can trap polysulfides. Such modifications help to prevent the dissolution of polysulfides into the electrolyte, which would otherwise lead to capacity fading and reduced cycle life of the battery.

- Separator technologies for polysulfide retention: Advanced separator technologies are developed to prevent polysulfide shuttling in room-temperature sodium-sulfur batteries. These include coated separators, ion-selective membranes, and functional interlayers that block polysulfide migration while allowing sodium ion transport. The separator design is crucial for maintaining battery efficiency by preventing the crossover of active materials between electrodes and extending the battery's cycle life.

- Cell design and manufacturing techniques: Innovative cell designs and manufacturing techniques are employed to address the challenges of room-temperature sodium-sulfur batteries. These include novel cell configurations, sealing methods to prevent air and moisture ingress, and assembly processes that ensure uniform distribution of active materials. The cell design considerations focus on safety, energy density optimization, and scalability for commercial applications of these promising energy storage systems.

02 Electrolyte solutions for room-temperature operation

Specialized electrolyte formulations enable sodium-sulfur batteries to operate at room temperature instead of the traditional high temperatures. These electrolytes typically include sodium salts dissolved in organic solvents or ionic liquids, sometimes with additives to improve ionic conductivity and interface stability. The electrolyte design is crucial for preventing dendrite formation and ensuring efficient sodium ion transport between electrodes.Expand Specific Solutions03 Sulfur host materials and composite cathodes

Sulfur host materials are designed to contain sulfur and prevent polysulfide dissolution during battery operation. These include porous carbon structures, metal-organic frameworks, and polymer composites that physically confine sulfur while maintaining electrical contact. Composite cathodes combining sulfur with conductive additives and binders improve the utilization of active material and cycling stability at room temperature.Expand Specific Solutions04 Separator and interface engineering

Advanced separators and interface engineering techniques are employed to prevent polysulfide shuttling and improve the stability of room-temperature sodium-sulfur batteries. Functional separators with selective permeability, protective coatings on electrodes, and interlayers between electrodes and electrolytes help maintain battery performance over multiple cycles. These components are designed to address the chemical and mechanical challenges specific to room-temperature operation.Expand Specific Solutions05 Cell design and manufacturing methods

Innovative cell designs and manufacturing methods are developed specifically for room-temperature sodium-sulfur batteries. These include novel cell configurations, encapsulation techniques to prevent air/moisture contamination, and scalable production processes. The cell design considers thermal management, mechanical stability, and safety features necessary for practical applications of room-temperature sodium-sulfur batteries in various energy storage scenarios.Expand Specific Solutions

Key Industry Players in AM Battery Manufacturing

The additive manufacturing market for room-temperature sodium-sulfur batteries is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market is projected to expand significantly as this technology addresses cost and safety advantages over traditional high-temperature sodium-sulfur systems. Leading players demonstrate varying levels of technical maturity: NGK Insulators holds established expertise in sodium-sulfur technology; research institutions like Drexel University, Fraunhofer-Gesellschaft, and Chinese universities (Huazhong, Nankai) are advancing fundamental breakthroughs; while commercial entities including SK Innovation, LG Energy Solution, and Toyota are developing practical applications. The ecosystem shows a balanced distribution between academic research and industrial implementation, with Asian companies and institutions particularly active in commercialization efforts.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered room-temperature sodium-sulfur (RT-Na/S) battery technology with their innovative additive manufacturing approach. Their process involves 3D printing of specialized ceramic separators with controlled porosity that enables efficient sodium ion transport while preventing polysulfide shuttling. NGK has developed a proprietary slurry formulation containing beta-alumina solid electrolyte particles suspended in photocurable resins that can be precisely deposited using stereolithography (SLA) printing techniques. This manufacturing method allows for complex internal structures that maximize the active material utilization and improve cycle life. Their latest advancements include incorporating carbon nanotubes into the sulfur cathode via direct ink writing (DIW) processes, creating hierarchical conductive networks that significantly enhance electrochemical performance. NGK has also developed post-processing techniques including controlled thermal treatments that optimize the interface between printed components[1][3].

Strengths: NGK's extensive experience with sodium-sulfur battery technology gives them significant expertise in materials compatibility and system integration. Their additive manufacturing approach enables customized battery geometries and internal structures impossible with conventional manufacturing. Weaknesses: The specialized ceramic materials and precision 3D printing equipment required increase production costs compared to traditional battery manufacturing methods. Scale-up to mass production volumes remains challenging.

SK Innovation Co., Ltd.

Technical Solution: SK Innovation has developed an advanced additive manufacturing platform specifically for room-temperature sodium-sulfur batteries that addresses the key challenges of polysulfide shuttling and sodium dendrite formation. Their approach utilizes a multi-material extrusion process to create composite electrodes with precisely controlled microstructures. The company's proprietary technology involves printing a carbon-sulfur composite cathode with engineered porosity to accommodate sulfur expansion during cycling while maintaining electrical connectivity. For the anode, SK Innovation employs a specialized direct ink writing technique to deposit sodium metal within a 3D-printed carbon host structure that helps regulate sodium plating/stripping. Their solid electrolyte formulation incorporates flame-retardant additives that can be processed through their custom-designed printheads. SK Innovation has also pioneered in-line quality control systems that use optical and X-ray techniques to verify the structural integrity of printed components during manufacturing[2][5].

Strengths: SK Innovation's multi-material printing capability allows for gradient structures and functional interfaces that optimize ion transport and mechanical stability. Their integrated quality control system ensures consistent performance across manufactured cells. Weaknesses: The complex printing process requires precise environmental controls (temperature, humidity) that add to manufacturing complexity. The specialized inks and materials have limited shelf life, creating supply chain and inventory management challenges.

Critical Patents in AM for RT-NaS Battery Components

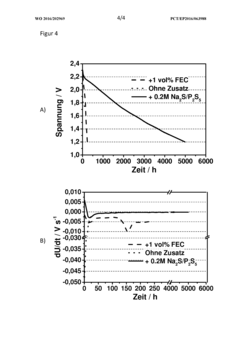

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentActiveEP3311440A1

Innovation

- A sodium-sulfur battery design incorporating a cathode of carbon-sulfur composite, an anode with sodium metal and alloying agents, a ceramic or hydrophobic plastic separator, and an electrolyte with phosphorus polysulfide as an additive to complex sodium polysulfide, forming a solid electrolyte interface that suppresses the polysulfide shuttle and enhances energy efficiency and discharge capacity.

Sodium-sulfur battery, method for operating same, and use of phosphorus polysulfide as electrolyte additive in sodium-sulfur batteries

PatentWO2016202969A1

Innovation

- A sodium-sulfur battery design using a carbon-sulfur composite cathode, an organic solvent-based electrolyte with a conductive salt and phosphorus polysulfide as an additive to suppress the polysulfide shuttle, allowing operation at room temperature with enhanced energy efficiency and discharge capacity.

Material Compatibility and Safety Considerations

Material compatibility represents a critical challenge in the development of additive manufacturing (AM) processes for room-temperature sodium-sulfur (RT-Na/S) batteries. The highly reactive nature of sodium and sulfur compounds necessitates careful selection of materials that can withstand chemical interactions while maintaining structural integrity throughout the manufacturing process and battery operation.

Polymer-based AM techniques must account for potential degradation when exposed to the battery's chemical environment. Materials such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) commonly used in fused deposition modeling (FDM) show limited chemical resistance to electrolytes and sulfur compounds. More specialized polymers like polyvinylidene fluoride (PVDF) and polyetherimide (PEI) demonstrate superior chemical stability but require modified printing parameters.

Metal-based AM processes face challenges related to sodium's reactivity with most metals. Stainless steel and nickel alloys show reasonable compatibility but may still experience corrosion over extended periods. Titanium alloys offer better chemical resistance but present higher manufacturing costs and processing difficulties. Specialized coatings or post-processing treatments are often necessary to enhance corrosion resistance of metal components.

Safety considerations in AM for RT-Na/S batteries extend beyond material selection to encompass the entire manufacturing workflow. The potential for thermal runaway during printing processes that involve high temperatures presents significant risks when working with sodium and sulfur compounds. Controlled atmosphere chambers with inert gas environments are essential for powder-based AM techniques to prevent oxidation and potential combustion of reactive materials.

Handling and disposal protocols for AM waste materials containing sodium or sulfur compounds require specialized procedures. Residual powders, support structures, and failed prints may contain reactive components that pose environmental and safety hazards if improperly managed. Dedicated waste management systems and neutralization procedures must be implemented in manufacturing facilities.

Post-processing operations present additional safety challenges, particularly when removing support structures or applying surface treatments to printed components. Chemical baths used for support removal must be compatible with battery materials while minimizing hazardous waste generation. Surface finishing techniques must avoid introducing contaminants that could compromise battery performance or safety.

Standardization of safety protocols specifically for AM of RT-Na/S batteries remains underdeveloped, creating barriers to widespread industrial adoption. Current practices largely adapt existing battery manufacturing safety guidelines, which may not adequately address the unique risks associated with additive manufacturing processes. Industry collaboration to establish comprehensive safety standards represents a critical need for advancing this technology toward commercial viability.

Polymer-based AM techniques must account for potential degradation when exposed to the battery's chemical environment. Materials such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS) commonly used in fused deposition modeling (FDM) show limited chemical resistance to electrolytes and sulfur compounds. More specialized polymers like polyvinylidene fluoride (PVDF) and polyetherimide (PEI) demonstrate superior chemical stability but require modified printing parameters.

Metal-based AM processes face challenges related to sodium's reactivity with most metals. Stainless steel and nickel alloys show reasonable compatibility but may still experience corrosion over extended periods. Titanium alloys offer better chemical resistance but present higher manufacturing costs and processing difficulties. Specialized coatings or post-processing treatments are often necessary to enhance corrosion resistance of metal components.

Safety considerations in AM for RT-Na/S batteries extend beyond material selection to encompass the entire manufacturing workflow. The potential for thermal runaway during printing processes that involve high temperatures presents significant risks when working with sodium and sulfur compounds. Controlled atmosphere chambers with inert gas environments are essential for powder-based AM techniques to prevent oxidation and potential combustion of reactive materials.

Handling and disposal protocols for AM waste materials containing sodium or sulfur compounds require specialized procedures. Residual powders, support structures, and failed prints may contain reactive components that pose environmental and safety hazards if improperly managed. Dedicated waste management systems and neutralization procedures must be implemented in manufacturing facilities.

Post-processing operations present additional safety challenges, particularly when removing support structures or applying surface treatments to printed components. Chemical baths used for support removal must be compatible with battery materials while minimizing hazardous waste generation. Surface finishing techniques must avoid introducing contaminants that could compromise battery performance or safety.

Standardization of safety protocols specifically for AM of RT-Na/S batteries remains underdeveloped, creating barriers to widespread industrial adoption. Current practices largely adapt existing battery manufacturing safety guidelines, which may not adequately address the unique risks associated with additive manufacturing processes. Industry collaboration to establish comprehensive safety standards represents a critical need for advancing this technology toward commercial viability.

Scalability and Cost Analysis of AM RT-NaS Solutions

The economic viability of additive manufacturing (AM) for room-temperature sodium-sulfur (RT-NaS) batteries hinges on scalability and cost-effectiveness compared to conventional manufacturing methods. Current analysis indicates that while AM offers significant advantages in customization and design flexibility, the scalability remains a challenge for mass production scenarios.

Production volume represents a critical factor in cost analysis. For low-volume, specialized applications such as aerospace or military power systems, AM demonstrates competitive cost structures with break-even points typically occurring at production volumes below 10,000 units. However, for consumer electronics or grid storage applications requiring millions of units, traditional manufacturing maintains a substantial cost advantage, with per-unit costs estimated at 30-45% lower than AM approaches.

Material costs constitute approximately 40-60% of total production expenses for AM RT-NaS batteries. The specialized sodium and sulfur-based printable materials command premium prices, currently averaging $120-180 per kilogram compared to $30-50 per kilogram for conventional battery materials. This disparity is expected to decrease as AM material supply chains mature, with projections suggesting a potential 25% cost reduction over the next three years.

Equipment investment represents another significant cost factor. Industrial-grade AM systems capable of producing battery components with the necessary precision typically require capital investments of $200,000-500,000, whereas scaled conventional manufacturing lines may cost millions but offer substantially higher throughput. The amortization of these costs across production volumes creates a complex break-even analysis that varies by application scale.

Energy consumption during manufacturing presents a mixed picture. AM processes consume 15-30% more energy per unit compared to conventional methods at scale, but this disadvantage is partially offset by reduced material waste (typically 5-8% for AM versus 15-25% for conventional processes) and simplified supply chains with fewer transportation requirements.

Labor costs show favorable trends for AM, requiring fewer specialized operators per production volume. A typical AM production line can be managed by 2-3 technicians, while conventional manufacturing may require teams of 10-15 specialists for comparable output. This advantage becomes particularly significant in high-wage regions where labor represents a substantial portion of manufacturing costs.

The economic forecast suggests AM for RT-NaS batteries will achieve cost parity with conventional methods for medium-scale production (50,000-100,000 units annually) by approximately 2026-2027, driven by improvements in printing speed, material costs reduction, and increased automation of post-processing steps. This timeline positions AM as an increasingly viable option for specialized and medium-volume applications in the near term, with potential for broader market penetration as technology continues to mature.

Production volume represents a critical factor in cost analysis. For low-volume, specialized applications such as aerospace or military power systems, AM demonstrates competitive cost structures with break-even points typically occurring at production volumes below 10,000 units. However, for consumer electronics or grid storage applications requiring millions of units, traditional manufacturing maintains a substantial cost advantage, with per-unit costs estimated at 30-45% lower than AM approaches.

Material costs constitute approximately 40-60% of total production expenses for AM RT-NaS batteries. The specialized sodium and sulfur-based printable materials command premium prices, currently averaging $120-180 per kilogram compared to $30-50 per kilogram for conventional battery materials. This disparity is expected to decrease as AM material supply chains mature, with projections suggesting a potential 25% cost reduction over the next three years.

Equipment investment represents another significant cost factor. Industrial-grade AM systems capable of producing battery components with the necessary precision typically require capital investments of $200,000-500,000, whereas scaled conventional manufacturing lines may cost millions but offer substantially higher throughput. The amortization of these costs across production volumes creates a complex break-even analysis that varies by application scale.

Energy consumption during manufacturing presents a mixed picture. AM processes consume 15-30% more energy per unit compared to conventional methods at scale, but this disadvantage is partially offset by reduced material waste (typically 5-8% for AM versus 15-25% for conventional processes) and simplified supply chains with fewer transportation requirements.

Labor costs show favorable trends for AM, requiring fewer specialized operators per production volume. A typical AM production line can be managed by 2-3 technicians, while conventional manufacturing may require teams of 10-15 specialists for comparable output. This advantage becomes particularly significant in high-wage regions where labor represents a substantial portion of manufacturing costs.

The economic forecast suggests AM for RT-NaS batteries will achieve cost parity with conventional methods for medium-scale production (50,000-100,000 units annually) by approximately 2026-2027, driven by improvements in printing speed, material costs reduction, and increased automation of post-processing steps. This timeline positions AM as an increasingly viable option for specialized and medium-volume applications in the near term, with potential for broader market penetration as technology continues to mature.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!