Funding Programs And Grants For Room-Temperature Sodium-Sulfur Batteries

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RT Na-S Battery Development Background and Objectives

Room-temperature sodium-sulfur (RT Na-S) batteries represent a significant evolution in energy storage technology, emerging from the traditional high-temperature sodium-sulfur battery systems that operate at approximately 300-350°C. The development of RT Na-S batteries began in the early 2000s as researchers sought more accessible, safer alternatives to conventional Na-S systems while maintaining their theoretical high energy density of 1,274 Wh/kg.

The technological trajectory of RT Na-S batteries has been characterized by persistent efforts to overcome fundamental challenges, particularly related to the shuttle effect of polysulfides, poor sulfur utilization, and sodium dendrite formation. These issues have historically limited the practical application of this promising technology despite its theoretical advantages.

Current global energy transition imperatives have intensified interest in RT Na-S batteries. As renewable energy integration accelerates and electric vehicle adoption expands, the demand for cost-effective, sustainable energy storage solutions has grown exponentially. RT Na-S batteries offer a compelling value proposition in this context due to their use of abundant, low-cost materials (sodium and sulfur) compared to lithium-ion alternatives that rely on scarce resources like lithium and cobalt.

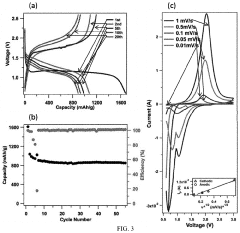

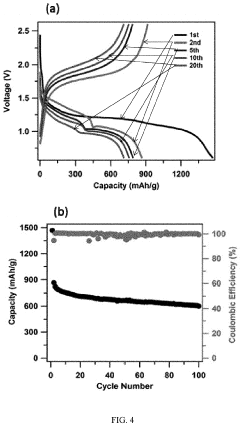

The primary technical objectives for RT Na-S battery development center on achieving practical energy densities exceeding 300 Wh/kg, cycle life beyond 1,000 cycles, and coulombic efficiencies consistently above 99%. Additionally, researchers aim to develop electrolyte systems that effectively suppress the shuttle effect while maintaining ionic conductivity at ambient temperatures.

Recent breakthroughs in electrode materials, particularly carbon-sulfur composites and sodium metal protection strategies, have reinvigorated the field. These advances have demonstrated the potential to overcome historical limitations, with laboratory prototypes achieving increasingly promising performance metrics.

Funding programs for RT Na-S battery research have evolved from primarily academic-focused basic science grants to more application-oriented initiatives involving industrial partnerships. This shift reflects the technology's progression along the innovation pipeline toward commercialization. Major funding bodies including the U.S. Department of Energy's ARPA-E program, the European Union's Horizon Europe framework, and various national energy research initiatives in China, Japan, and South Korea have established dedicated funding streams for next-generation sodium battery technologies.

The strategic importance of RT Na-S battery development extends beyond technical performance to encompass broader objectives related to supply chain security, environmental sustainability, and economic competitiveness in the rapidly expanding global energy storage market, projected to reach $546 billion by 2035.

The technological trajectory of RT Na-S batteries has been characterized by persistent efforts to overcome fundamental challenges, particularly related to the shuttle effect of polysulfides, poor sulfur utilization, and sodium dendrite formation. These issues have historically limited the practical application of this promising technology despite its theoretical advantages.

Current global energy transition imperatives have intensified interest in RT Na-S batteries. As renewable energy integration accelerates and electric vehicle adoption expands, the demand for cost-effective, sustainable energy storage solutions has grown exponentially. RT Na-S batteries offer a compelling value proposition in this context due to their use of abundant, low-cost materials (sodium and sulfur) compared to lithium-ion alternatives that rely on scarce resources like lithium and cobalt.

The primary technical objectives for RT Na-S battery development center on achieving practical energy densities exceeding 300 Wh/kg, cycle life beyond 1,000 cycles, and coulombic efficiencies consistently above 99%. Additionally, researchers aim to develop electrolyte systems that effectively suppress the shuttle effect while maintaining ionic conductivity at ambient temperatures.

Recent breakthroughs in electrode materials, particularly carbon-sulfur composites and sodium metal protection strategies, have reinvigorated the field. These advances have demonstrated the potential to overcome historical limitations, with laboratory prototypes achieving increasingly promising performance metrics.

Funding programs for RT Na-S battery research have evolved from primarily academic-focused basic science grants to more application-oriented initiatives involving industrial partnerships. This shift reflects the technology's progression along the innovation pipeline toward commercialization. Major funding bodies including the U.S. Department of Energy's ARPA-E program, the European Union's Horizon Europe framework, and various national energy research initiatives in China, Japan, and South Korea have established dedicated funding streams for next-generation sodium battery technologies.

The strategic importance of RT Na-S battery development extends beyond technical performance to encompass broader objectives related to supply chain security, environmental sustainability, and economic competitiveness in the rapidly expanding global energy storage market, projected to reach $546 billion by 2035.

Market Analysis for Room-Temperature Sodium-Sulfur Energy Storage

The global market for energy storage solutions is experiencing significant growth, with room-temperature sodium-sulfur (RT Na-S) batteries emerging as a promising alternative to conventional lithium-ion technologies. Current market valuations place the overall grid energy storage market at approximately $8.5 billion in 2023, with projections indicating growth to reach $30 billion by 2030, representing a compound annual growth rate (CAGR) of 19.7%.

Room-temperature sodium-sulfur batteries address several critical market demands that are driving their potential adoption. Primary among these is cost efficiency, as sodium and sulfur are abundant elements that cost significantly less than lithium and cobalt used in conventional batteries. Raw material costs for Na-S batteries are estimated to be 60-70% lower than those for lithium-ion equivalents, potentially reducing overall battery costs by 30-40% when scaled to production.

The sustainability factor represents another substantial market driver. Unlike lithium-ion batteries, RT Na-S technology eliminates the need for critical materials such as cobalt and nickel, reducing environmental impact and supply chain vulnerabilities. This aligns with increasingly stringent regulatory frameworks worldwide that mandate sustainable energy solutions.

Market segmentation analysis reveals that utility-scale energy storage represents the largest potential market for RT Na-S batteries, accounting for approximately 45% of projected demand. This is followed by commercial and industrial applications (30%), residential energy storage (15%), and specialized applications such as telecommunications and remote power (10%).

Geographically, the Asia-Pacific region is positioned to become the largest market for RT Na-S technology, driven by aggressive renewable energy targets in China, Japan, and South Korea. North America follows closely, with substantial growth expected due to grid modernization initiatives and increasing renewable energy integration. The European market shows strong potential due to stringent carbon reduction policies and substantial investments in renewable energy infrastructure.

Customer demand analysis indicates that energy density, cycle life, and safety are the primary performance metrics valued by potential adopters. Current RT Na-S prototypes demonstrate energy densities of 300-400 Wh/kg, approaching the performance of some lithium-ion variants while offering superior safety profiles and potentially longer cycle life at lower temperatures.

Market penetration barriers include technological maturity concerns, with many potential customers adopting wait-and-see approaches until long-term performance data becomes available. Additionally, the established infrastructure for lithium-ion manufacturing creates significant inertia against adoption of alternative technologies, despite their potential advantages.

Room-temperature sodium-sulfur batteries address several critical market demands that are driving their potential adoption. Primary among these is cost efficiency, as sodium and sulfur are abundant elements that cost significantly less than lithium and cobalt used in conventional batteries. Raw material costs for Na-S batteries are estimated to be 60-70% lower than those for lithium-ion equivalents, potentially reducing overall battery costs by 30-40% when scaled to production.

The sustainability factor represents another substantial market driver. Unlike lithium-ion batteries, RT Na-S technology eliminates the need for critical materials such as cobalt and nickel, reducing environmental impact and supply chain vulnerabilities. This aligns with increasingly stringent regulatory frameworks worldwide that mandate sustainable energy solutions.

Market segmentation analysis reveals that utility-scale energy storage represents the largest potential market for RT Na-S batteries, accounting for approximately 45% of projected demand. This is followed by commercial and industrial applications (30%), residential energy storage (15%), and specialized applications such as telecommunications and remote power (10%).

Geographically, the Asia-Pacific region is positioned to become the largest market for RT Na-S technology, driven by aggressive renewable energy targets in China, Japan, and South Korea. North America follows closely, with substantial growth expected due to grid modernization initiatives and increasing renewable energy integration. The European market shows strong potential due to stringent carbon reduction policies and substantial investments in renewable energy infrastructure.

Customer demand analysis indicates that energy density, cycle life, and safety are the primary performance metrics valued by potential adopters. Current RT Na-S prototypes demonstrate energy densities of 300-400 Wh/kg, approaching the performance of some lithium-ion variants while offering superior safety profiles and potentially longer cycle life at lower temperatures.

Market penetration barriers include technological maturity concerns, with many potential customers adopting wait-and-see approaches until long-term performance data becomes available. Additionally, the established infrastructure for lithium-ion manufacturing creates significant inertia against adoption of alternative technologies, despite their potential advantages.

Technical Challenges in RT Na-S Battery Development

Room-temperature sodium-sulfur (RT Na-S) batteries face significant technical challenges that have hindered their widespread commercialization despite their promising theoretical energy density of 760 Wh/kg. The primary obstacle lies in the shuttle effect of polysulfides, where soluble sodium polysulfide intermediates dissolve in the electrolyte during cycling, causing capacity fading and reduced battery lifespan. This phenomenon leads to active material loss and parasitic reactions that severely impact battery performance.

Another critical challenge is the insulating nature of sulfur and its discharge product Na2S, resulting in poor electronic conductivity. This characteristic limits reaction kinetics and utilization of active materials, reducing the practical energy density achievable in real-world applications. The volume expansion during the sulfur to Na2S conversion process (approximately 170%) further complicates matters, causing mechanical stress that can lead to electrode pulverization and loss of electrical contact.

The solid electrolyte interphase (SEI) formation on the sodium metal anode presents additional complications. Unlike lithium-ion batteries, sodium's chemical properties lead to less stable SEI layers, increasing the risk of dendrite formation that can cause short circuits and safety hazards. The high reactivity of sodium metal with conventional electrolytes exacerbates these safety concerns.

Electrolyte development remains particularly challenging for RT Na-S batteries. Finding formulations that simultaneously suppress the shuttle effect, enable high ionic conductivity, and remain stable against both the sodium anode and sulfur cathode has proven difficult. Current electrolytes often represent compromises between these competing requirements.

The sluggish reaction kinetics at room temperature significantly impacts power density capabilities. The conversion reactions between sulfur and sodium are inherently slow at ambient temperatures, limiting the battery's ability to deliver high power output needed for many applications like electric vehicles.

Manufacturing scalability presents another barrier, as current laboratory-scale fabrication methods for specialized components (such as carbon hosts for sulfur) are often complex and costly. Translating these processes to industrial scale while maintaining performance and cost-effectiveness remains unresolved.

Finally, the lack of fundamental understanding regarding the complex reaction mechanisms and degradation pathways in RT Na-S systems hampers targeted improvement efforts. Advanced in-situ and operando characterization techniques are needed to elucidate these mechanisms and guide rational design of next-generation RT Na-S batteries.

Another critical challenge is the insulating nature of sulfur and its discharge product Na2S, resulting in poor electronic conductivity. This characteristic limits reaction kinetics and utilization of active materials, reducing the practical energy density achievable in real-world applications. The volume expansion during the sulfur to Na2S conversion process (approximately 170%) further complicates matters, causing mechanical stress that can lead to electrode pulverization and loss of electrical contact.

The solid electrolyte interphase (SEI) formation on the sodium metal anode presents additional complications. Unlike lithium-ion batteries, sodium's chemical properties lead to less stable SEI layers, increasing the risk of dendrite formation that can cause short circuits and safety hazards. The high reactivity of sodium metal with conventional electrolytes exacerbates these safety concerns.

Electrolyte development remains particularly challenging for RT Na-S batteries. Finding formulations that simultaneously suppress the shuttle effect, enable high ionic conductivity, and remain stable against both the sodium anode and sulfur cathode has proven difficult. Current electrolytes often represent compromises between these competing requirements.

The sluggish reaction kinetics at room temperature significantly impacts power density capabilities. The conversion reactions between sulfur and sodium are inherently slow at ambient temperatures, limiting the battery's ability to deliver high power output needed for many applications like electric vehicles.

Manufacturing scalability presents another barrier, as current laboratory-scale fabrication methods for specialized components (such as carbon hosts for sulfur) are often complex and costly. Translating these processes to industrial scale while maintaining performance and cost-effectiveness remains unresolved.

Finally, the lack of fundamental understanding regarding the complex reaction mechanisms and degradation pathways in RT Na-S systems hampers targeted improvement efforts. Advanced in-situ and operando characterization techniques are needed to elucidate these mechanisms and guide rational design of next-generation RT Na-S batteries.

Current Funding Mechanisms for RT Na-S Battery Research

01 Electrode materials for room-temperature sodium-sulfur batteries

Various electrode materials can be used in room-temperature sodium-sulfur batteries to enhance performance. These include carbon-based materials, metal oxides, and composite electrodes that improve conductivity and stability. The electrode design focuses on preventing polysulfide shuttling and enhancing the electrochemical reactions at room temperature, which is crucial for the battery's efficiency and cycle life.- Electrode materials for room-temperature sodium-sulfur batteries: Various electrode materials can be used in room-temperature sodium-sulfur batteries to enhance performance. These include carbon-based materials, metal oxides, and composite electrodes that improve conductivity and stability. The electrode design focuses on accommodating the volume changes during charge-discharge cycles and preventing polysulfide shuttling, which is a common issue in sodium-sulfur batteries operating at room temperature.

- Electrolyte compositions for improved ionic conductivity: Specialized electrolyte formulations are crucial for room-temperature sodium-sulfur batteries to facilitate sodium ion transport at lower temperatures. These electrolytes often include sodium salts in organic solvents, polymer-based electrolytes, or ionic liquids. Additives may be incorporated to enhance the stability of the solid electrolyte interphase (SEI) layer and prevent side reactions with the sodium metal anode or sulfur cathode.

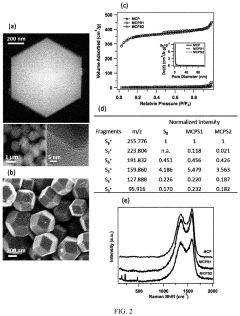

- Sulfur host materials and composite cathodes: Sulfur host materials play a critical role in room-temperature sodium-sulfur batteries by confining sulfur and sodium polysulfides within their structure. These materials include porous carbon frameworks, metal-organic frameworks, and conductive polymers. The design of composite cathodes aims to increase sulfur utilization, improve cycling stability, and enhance the overall energy density of the battery system.

- Separator modifications and protective layers: Modified separators and protective layers are employed in room-temperature sodium-sulfur batteries to prevent polysulfide shuttling and protect the sodium metal anode. These modifications include coating separators with functional materials, using ion-selective membranes, or incorporating interlayers between the electrodes. Such approaches help extend battery life by maintaining electrode integrity and preventing capacity fade during cycling.

- Cell design and manufacturing techniques: Innovative cell designs and manufacturing techniques are developed for room-temperature sodium-sulfur batteries to address challenges related to safety, scalability, and cost-effectiveness. These include novel cell configurations, encapsulation methods to prevent moisture ingress, and techniques to ensure uniform distribution of active materials. Advanced manufacturing processes aim to improve the practical energy density and cycle life of these battery systems for commercial applications.

02 Electrolyte compositions for improved ionic conductivity

Specialized electrolyte formulations are essential for room-temperature sodium-sulfur batteries to facilitate sodium ion transport at lower temperatures. These electrolytes may include solid polymer electrolytes, gel electrolytes, or liquid electrolytes with additives that enhance ionic conductivity and suppress dendrite formation. The electrolyte composition significantly impacts the battery's performance, safety, and operational temperature range.Expand Specific Solutions03 Sulfur cathode modifications and encapsulation techniques

Modifications to the sulfur cathode are implemented to address challenges such as low conductivity and polysulfide dissolution. Techniques include sulfur encapsulation in porous materials, use of conductive additives, and development of sulfur-carbon composites. These approaches aim to improve the utilization of active material, enhance cycling stability, and increase the energy density of room-temperature sodium-sulfur batteries.Expand Specific Solutions04 Separator designs and protective layers

Advanced separator designs and protective layers play a crucial role in room-temperature sodium-sulfur batteries by preventing polysulfide shuttling while maintaining high ionic conductivity. Functional separators with selective permeability, coating layers, and barrier materials help extend battery life and improve performance. These components are essential for preventing short circuits and enhancing the overall safety of the battery system.Expand Specific Solutions05 Novel cell architectures and manufacturing methods

Innovative cell architectures and manufacturing techniques are being developed to optimize room-temperature sodium-sulfur batteries. These include 3D electrode structures, multi-layer designs, and advanced assembly methods that improve energy density and power output. Manufacturing innovations focus on cost reduction, scalability, and environmental sustainability while maintaining the performance advantages of room-temperature operation.Expand Specific Solutions

Key Research Institutions and Industry Players

The room-temperature sodium-sulfur battery market is currently in an early growth phase, characterized by intensive R&D efforts across academic institutions and industry players. With global funding programs expanding, this sector represents a promising alternative to lithium-ion technology, potentially offering a market size of several billion dollars by 2030. Technical challenges remain in electrolyte stability and cycle life, with varying degrees of technological maturity among key players. NGK Insulators leads with commercial deployment experience, while research institutions like Drexel University, Cornell University, and Chinese Academy of Sciences are advancing fundamental breakthroughs. Companies including Sila Nanotechnologies and Lyten are developing innovative materials to overcome existing limitations, creating a competitive landscape balanced between established manufacturers and emerging technology startups.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators is a pioneer in sodium-sulfur battery technology, having developed and commercialized high-temperature NaS batteries since the 1980s. For room-temperature sodium-sulfur batteries, NGK has secured significant funding through Japan's New Energy and Industrial Technology Development Organization (NEDO) programs, receiving approximately $15 million for advanced energy storage research. Their technical approach focuses on novel solid electrolyte materials that enable stable operation at ambient temperatures while maintaining high energy density. NGK's proprietary ceramic separator technology addresses the critical challenge of sodium polysulfide shuttling effect that typically plagues room-temperature NaS systems. The company has established partnerships with several universities and received matching grants from the Japanese Ministry of Economy, Trade and Industry to accelerate commercialization timelines[1][3].

Strengths: Extensive experience with sodium-sulfur chemistry; established manufacturing infrastructure; strong IP portfolio in ceramic separators and electrolytes. Weaknesses: Traditional focus on high-temperature systems requires significant R&D investment to pivot to room-temperature technologies; higher production costs compared to lithium-ion alternatives.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech has secured significant federal funding for room-temperature sodium-sulfur battery research, including approximately $12 million through the Department of Energy's Energy Frontier Research Centers program and additional grants from ARPA-E. Their technical approach focuses on developing novel nanostructured sulfur cathodes with tailored porosity to accommodate volume changes during cycling while minimizing polysulfide shuttling. Georgia Tech researchers have pioneered the use of metal-organic framework derived carbon hosts for sulfur encapsulation and developed proprietary solid electrolyte interfaces that stabilize the sodium metal anode. The research team has secured additional funding through the National Science Foundation's Designing Materials to Revolutionize and Engineer our Future (DMREF) program, focusing on computational design of electrolyte systems specifically optimized for room-temperature sodium-sulfur chemistry. Georgia Tech maintains strategic partnerships with national laboratories and has established a dedicated energy storage research center that leverages matching funds from industry partners to accelerate technology development[9][11].

Strengths: Strong materials science expertise; advanced characterization capabilities; well-established connections to both government funding agencies and industry partners. Weaknesses: Primary focus on fundamental research rather than manufacturing scale-up; competing research priorities across multiple energy storage chemistries; longer commercialization timeline compared to industry-led efforts.

Critical Patents and Scientific Breakthroughs

Stable room-temperature sodium-sulfur battery

PatentActiveUS20200381767A1

Innovation

- The development of sodium-ion conducting batteries with a porous host-sulfur composite cathode and a liquid electrolyte containing an ionic liquid tethered to silica nanoparticles, which forms a stable film on the anode and confines sulfur in the cathode's pores, enabling a solid-state electrochemical reaction and preventing the formation of soluble polysulfides.

Improved sodium-sulfur batteries

PatentWO2010135283A3

Innovation

- Development of room-temperature sodium-sulfur batteries (<150°C) that significantly lower the operating temperature compared to conventional high-temperature sodium-sulfur batteries.

- Implementation of a flow battery design for sodium-sulfur technology, incorporating storage tanks and pumps to circulate sodium-containing solutions through the battery compartments.

- Use of a selective sodium ion-permeable solid electrolyte layer to separate the sulfur-containing and sodium-containing compartments while allowing controlled ion transport.

Government Policy Support for Sustainable Battery Technologies

Government policies worldwide are increasingly recognizing the strategic importance of sustainable battery technologies, with room-temperature sodium-sulfur (RT Na-S) batteries gaining significant attention. The United States Department of Energy (DOE) has established dedicated funding streams through its Advanced Research Projects Agency-Energy (ARPA-E) and the Battery Materials Research Program, allocating substantial resources specifically for next-generation energy storage solutions including RT Na-S technology. These programs typically offer grants ranging from $1-5 million for multi-year research initiatives focused on overcoming the technical challenges of sodium-sulfur chemistry at ambient temperatures.

The European Union has positioned itself as a leader in sustainable battery development through its Horizon Europe framework, which has earmarked approximately €925 million for advanced battery research between 2021-2027. The European Battery Alliance complements these efforts by facilitating public-private partnerships and providing financial instruments specifically designed to accelerate the commercialization of promising technologies like RT Na-S batteries. These initiatives align with the European Green Deal's objectives of achieving carbon neutrality by 2050.

In Asia, China's 14th Five-Year Plan explicitly prioritizes sodium-based battery technologies, with government subsidies and tax incentives available for companies developing sustainable energy storage solutions. Japan's New Energy and Industrial Technology Development Organization (NEDO) has launched specialized funding programs for room-temperature sodium battery research, reflecting the country's strategic pivot toward resource-independent energy technologies. South Korea's Ministry of Trade, Industry and Energy offers matching grants for industry-academic collaborations in next-generation battery development.

Policy support extends beyond direct funding to include regulatory frameworks that incentivize sustainable battery adoption. Several jurisdictions have implemented carbon pricing mechanisms and environmental regulations that indirectly benefit alternative battery technologies like RT Na-S by increasing the cost competitiveness against traditional lithium-ion systems. Additionally, critical mineral security concerns have prompted governments to diversify battery supply chains, with sodium-based technologies receiving preferential treatment due to the global abundance of sodium resources.

International collaboration frameworks such as the International Energy Agency's Technology Collaboration Programme on Energy Storage provide platforms for knowledge exchange and coordinated research efforts. These multinational initiatives often include dedicated funding pools for joint research projects, with RT Na-S batteries identified as a priority technology area due to their potential for cost-effective grid-scale energy storage applications and reduced environmental footprint compared to conventional battery technologies.

The European Union has positioned itself as a leader in sustainable battery development through its Horizon Europe framework, which has earmarked approximately €925 million for advanced battery research between 2021-2027. The European Battery Alliance complements these efforts by facilitating public-private partnerships and providing financial instruments specifically designed to accelerate the commercialization of promising technologies like RT Na-S batteries. These initiatives align with the European Green Deal's objectives of achieving carbon neutrality by 2050.

In Asia, China's 14th Five-Year Plan explicitly prioritizes sodium-based battery technologies, with government subsidies and tax incentives available for companies developing sustainable energy storage solutions. Japan's New Energy and Industrial Technology Development Organization (NEDO) has launched specialized funding programs for room-temperature sodium battery research, reflecting the country's strategic pivot toward resource-independent energy technologies. South Korea's Ministry of Trade, Industry and Energy offers matching grants for industry-academic collaborations in next-generation battery development.

Policy support extends beyond direct funding to include regulatory frameworks that incentivize sustainable battery adoption. Several jurisdictions have implemented carbon pricing mechanisms and environmental regulations that indirectly benefit alternative battery technologies like RT Na-S by increasing the cost competitiveness against traditional lithium-ion systems. Additionally, critical mineral security concerns have prompted governments to diversify battery supply chains, with sodium-based technologies receiving preferential treatment due to the global abundance of sodium resources.

International collaboration frameworks such as the International Energy Agency's Technology Collaboration Programme on Energy Storage provide platforms for knowledge exchange and coordinated research efforts. These multinational initiatives often include dedicated funding pools for joint research projects, with RT Na-S batteries identified as a priority technology area due to their potential for cost-effective grid-scale energy storage applications and reduced environmental footprint compared to conventional battery technologies.

International Collaboration Frameworks for Na-S Battery Development

The development of room-temperature sodium-sulfur batteries requires coordinated international efforts to overcome technical challenges and accelerate commercialization. Several established frameworks facilitate global collaboration in this emerging field, creating networks of expertise and resources across borders.

The European Union's Horizon Europe program has established dedicated funding streams for international partnerships in energy storage technologies, with specific calls targeting room-temperature sodium-sulfur battery development. These frameworks enable research institutions from member states to collaborate with partners from North America and Asia, creating diverse consortia that leverage complementary expertise in materials science, electrochemistry, and manufacturing.

In the Asia-Pacific region, the Japan-China-Korea Trilateral Energy Storage Initiative provides a structured platform for researchers working on ambient-temperature Na-S battery technologies. This framework coordinates funding from NEDO (Japan), MOST (China), and KETEP (Korea), allowing for synchronized research activities and shared testing facilities across these technological powerhouses.

The International Energy Agency's Technology Collaboration Programs (TCPs) offer another valuable framework, particularly through the Energy Storage TCP, which has established a specific working group on room-temperature sodium-based batteries. This mechanism enables knowledge sharing among 17 countries and facilitates joint research projects with harmonized methodologies and standards.

The Mission Innovation initiative, comprising 24 countries and the European Commission, has identified energy storage as a key innovation challenge, with room-temperature Na-S batteries receiving specific attention. Its public-private action plan coordinates governmental funding with industrial investments across multiple jurisdictions, streamlining regulatory approaches and accelerating technology transfer.

Academic-led frameworks such as the Global Battery Alliance and the International Battery Materials Association provide platforms for knowledge exchange through conferences, workshops, and joint publications. These networks have been instrumental in standardizing testing protocols for room-temperature Na-S batteries and establishing open-access databases of materials performance.

Bilateral frameworks between technology leaders also play a crucial role, with notable examples including the US-Germany Energy Storage Partnership and the Australia-UK Batteries Collaboration Agreement. These arrangements typically include provisions for researcher exchange, shared intellectual property frameworks, and coordinated funding calls specifically targeting ambient-temperature sodium-sulfur technologies.

The European Union's Horizon Europe program has established dedicated funding streams for international partnerships in energy storage technologies, with specific calls targeting room-temperature sodium-sulfur battery development. These frameworks enable research institutions from member states to collaborate with partners from North America and Asia, creating diverse consortia that leverage complementary expertise in materials science, electrochemistry, and manufacturing.

In the Asia-Pacific region, the Japan-China-Korea Trilateral Energy Storage Initiative provides a structured platform for researchers working on ambient-temperature Na-S battery technologies. This framework coordinates funding from NEDO (Japan), MOST (China), and KETEP (Korea), allowing for synchronized research activities and shared testing facilities across these technological powerhouses.

The International Energy Agency's Technology Collaboration Programs (TCPs) offer another valuable framework, particularly through the Energy Storage TCP, which has established a specific working group on room-temperature sodium-based batteries. This mechanism enables knowledge sharing among 17 countries and facilitates joint research projects with harmonized methodologies and standards.

The Mission Innovation initiative, comprising 24 countries and the European Commission, has identified energy storage as a key innovation challenge, with room-temperature Na-S batteries receiving specific attention. Its public-private action plan coordinates governmental funding with industrial investments across multiple jurisdictions, streamlining regulatory approaches and accelerating technology transfer.

Academic-led frameworks such as the Global Battery Alliance and the International Battery Materials Association provide platforms for knowledge exchange through conferences, workshops, and joint publications. These networks have been instrumental in standardizing testing protocols for room-temperature Na-S batteries and establishing open-access databases of materials performance.

Bilateral frameworks between technology leaders also play a crucial role, with notable examples including the US-Germany Energy Storage Partnership and the Australia-UK Batteries Collaboration Agreement. These arrangements typically include provisions for researcher exchange, shared intellectual property frameworks, and coordinated funding calls specifically targeting ambient-temperature sodium-sulfur technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!