Ultrafiltration Implementation Challenges in Remote Areas: Solutions

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly over the past five decades, transforming from an experimental separation technique to a cornerstone of modern water treatment systems. Initially developed in the 1960s for laboratory applications, ultrafiltration has progressively expanded into industrial, municipal, and now remote area applications. The technology operates on the principle of semi-permeable membrane filtration, where pressure drives water through membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers, effectively removing suspended solids, bacteria, viruses, and macromolecules.

The evolution of ultrafiltration has been marked by several key advancements, including the development of more durable membrane materials, improved module designs, and enhanced energy efficiency. Polymeric membranes, particularly polysulfone, polyethersulfone, and PVDF (polyvinylidene fluoride), have become industry standards due to their balance of performance, durability, and cost-effectiveness. Recent innovations have focused on creating membranes with higher flux rates, better fouling resistance, and longer operational lifespans.

In remote areas, ultrafiltration presents a promising solution to address critical water scarcity and quality challenges. These regions often lack conventional infrastructure, technical expertise, and reliable energy sources, creating unique implementation hurdles. The technology's ability to produce safe drinking water without complex chemical treatments makes it particularly valuable in these contexts, where sophisticated water treatment facilities are impractical.

The primary technical objectives for ultrafiltration implementation in remote areas include developing systems that are: energy-efficient or capable of operating with renewable energy sources; robust enough to withstand harsh environmental conditions; simple to operate and maintain with minimal technical expertise; and cost-effective throughout their lifecycle. Additionally, these systems must be adaptable to varying water quality conditions, as remote areas often face seasonal fluctuations in water sources and contaminant profiles.

Current research trends are focusing on creating ultrafiltration systems specifically designed for remote applications, incorporating innovations such as gravity-driven filtration, solar-powered operations, and simplified maintenance protocols. Material science advancements are yielding membranes with enhanced resistance to biological fouling and chemical degradation, critical factors for longevity in areas with limited maintenance capabilities.

The trajectory of ultrafiltration technology suggests continued miniaturization, increased automation, and further reductions in energy requirements. These developments align with the ultimate goal of providing sustainable, reliable water treatment solutions for the estimated 2.2 billion people worldwide who lack access to safely managed drinking water, many of whom reside in remote or underserved regions.

The evolution of ultrafiltration has been marked by several key advancements, including the development of more durable membrane materials, improved module designs, and enhanced energy efficiency. Polymeric membranes, particularly polysulfone, polyethersulfone, and PVDF (polyvinylidene fluoride), have become industry standards due to their balance of performance, durability, and cost-effectiveness. Recent innovations have focused on creating membranes with higher flux rates, better fouling resistance, and longer operational lifespans.

In remote areas, ultrafiltration presents a promising solution to address critical water scarcity and quality challenges. These regions often lack conventional infrastructure, technical expertise, and reliable energy sources, creating unique implementation hurdles. The technology's ability to produce safe drinking water without complex chemical treatments makes it particularly valuable in these contexts, where sophisticated water treatment facilities are impractical.

The primary technical objectives for ultrafiltration implementation in remote areas include developing systems that are: energy-efficient or capable of operating with renewable energy sources; robust enough to withstand harsh environmental conditions; simple to operate and maintain with minimal technical expertise; and cost-effective throughout their lifecycle. Additionally, these systems must be adaptable to varying water quality conditions, as remote areas often face seasonal fluctuations in water sources and contaminant profiles.

Current research trends are focusing on creating ultrafiltration systems specifically designed for remote applications, incorporating innovations such as gravity-driven filtration, solar-powered operations, and simplified maintenance protocols. Material science advancements are yielding membranes with enhanced resistance to biological fouling and chemical degradation, critical factors for longevity in areas with limited maintenance capabilities.

The trajectory of ultrafiltration technology suggests continued miniaturization, increased automation, and further reductions in energy requirements. These developments align with the ultimate goal of providing sustainable, reliable water treatment solutions for the estimated 2.2 billion people worldwide who lack access to safely managed drinking water, many of whom reside in remote or underserved regions.

Market Demand Analysis for Remote Area Water Treatment

The global market for remote area water treatment solutions has witnessed significant growth in recent years, driven by increasing water scarcity, population growth in rural and remote regions, and rising awareness about waterborne diseases. The ultrafiltration technology segment specifically has emerged as a promising solution for these challenges, with an estimated market value reaching $3.5 billion in 2022 and projected to grow at a CAGR of 7.2% through 2030.

Remote communities across developing nations represent the largest demand segment, with approximately 2.2 billion people worldwide lacking access to safely managed drinking water services. This creates substantial market potential for decentralized water treatment systems that can operate effectively in areas with limited infrastructure. Humanitarian organizations and government initiatives focused on achieving Sustainable Development Goal 6 (clean water and sanitation for all) have become significant procurement channels for ultrafiltration systems designed for remote applications.

The mining and resource extraction industries form another crucial market segment, requiring reliable water treatment solutions for remote operational sites. These commercial applications value systems with minimal maintenance requirements and robust performance under harsh environmental conditions. Market research indicates that companies in these sectors are willing to invest 15-20% premium for systems demonstrating superior reliability in remote settings.

Tourism developments in remote locations constitute an emerging market segment with growing demand for sustainable water treatment solutions. Eco-resorts, remote hospitality ventures, and adventure tourism facilities increasingly incorporate ultrafiltration systems as part of their sustainability initiatives, creating a specialized market niche estimated at $420 million annually.

Regional analysis reveals that Sub-Saharan Africa, South Asia, and remote parts of Latin America represent the highest growth potential markets, with annual demand increases exceeding 10%. These regions face acute challenges in water access and quality, creating urgent needs for appropriate treatment technologies. Government policies supporting rural development in these regions are expected to further stimulate market growth through subsidies and implementation programs.

Consumer preferences within these markets demonstrate clear priorities: energy efficiency ranks as the primary consideration due to limited or unreliable power infrastructure, followed by operational simplicity, maintenance requirements, and initial cost. Systems incorporating renewable energy sources show 30% higher adoption rates compared to conventional power-dependent alternatives, indicating strong market preference for integrated sustainable solutions.

The competitive landscape remains fragmented, with numerous regional players addressing specific geographical needs alongside global water technology companies expanding their remote application portfolios. This market structure creates opportunities for innovative solutions that can effectively address the unique challenges of ultrafiltration implementation in remote settings.

Remote communities across developing nations represent the largest demand segment, with approximately 2.2 billion people worldwide lacking access to safely managed drinking water services. This creates substantial market potential for decentralized water treatment systems that can operate effectively in areas with limited infrastructure. Humanitarian organizations and government initiatives focused on achieving Sustainable Development Goal 6 (clean water and sanitation for all) have become significant procurement channels for ultrafiltration systems designed for remote applications.

The mining and resource extraction industries form another crucial market segment, requiring reliable water treatment solutions for remote operational sites. These commercial applications value systems with minimal maintenance requirements and robust performance under harsh environmental conditions. Market research indicates that companies in these sectors are willing to invest 15-20% premium for systems demonstrating superior reliability in remote settings.

Tourism developments in remote locations constitute an emerging market segment with growing demand for sustainable water treatment solutions. Eco-resorts, remote hospitality ventures, and adventure tourism facilities increasingly incorporate ultrafiltration systems as part of their sustainability initiatives, creating a specialized market niche estimated at $420 million annually.

Regional analysis reveals that Sub-Saharan Africa, South Asia, and remote parts of Latin America represent the highest growth potential markets, with annual demand increases exceeding 10%. These regions face acute challenges in water access and quality, creating urgent needs for appropriate treatment technologies. Government policies supporting rural development in these regions are expected to further stimulate market growth through subsidies and implementation programs.

Consumer preferences within these markets demonstrate clear priorities: energy efficiency ranks as the primary consideration due to limited or unreliable power infrastructure, followed by operational simplicity, maintenance requirements, and initial cost. Systems incorporating renewable energy sources show 30% higher adoption rates compared to conventional power-dependent alternatives, indicating strong market preference for integrated sustainable solutions.

The competitive landscape remains fragmented, with numerous regional players addressing specific geographical needs alongside global water technology companies expanding their remote application portfolios. This market structure creates opportunities for innovative solutions that can effectively address the unique challenges of ultrafiltration implementation in remote settings.

Current Challenges in Remote Ultrafiltration Implementation

Implementing ultrafiltration systems in remote areas presents significant challenges that require innovative solutions. The geographical isolation of these regions creates logistical hurdles for equipment transportation, installation, and maintenance. Many remote locations lack adequate infrastructure, including reliable electricity supply, which is essential for operating ultrafiltration systems. Power outages or inconsistent voltage can damage sensitive filtration equipment and disrupt water treatment processes.

Water source variability compounds these challenges, as remote areas often rely on seasonal water bodies or sources with fluctuating quality parameters. Ultrafiltration systems must be designed to handle these variations while maintaining consistent output quality. High turbidity levels during rainy seasons can lead to rapid membrane fouling, necessitating more frequent maintenance than typically required in controlled environments.

Limited technical expertise in remote communities presents another significant barrier. Ultrafiltration systems require skilled personnel for operation, monitoring, and troubleshooting. When technical issues arise, the absence of qualified technicians can lead to prolonged system downtime. Training local operators becomes essential but is complicated by educational barriers and high turnover rates in isolated communities.

Financial sustainability remains a critical concern for remote ultrafiltration implementations. The higher per-capita costs of serving dispersed populations, combined with limited ability to pay, creates challenges for cost recovery. Traditional funding models often fail in these contexts, requiring innovative financing approaches that balance affordability with operational sustainability.

Membrane fouling occurs more rapidly in remote settings due to suboptimal pre-treatment capabilities and challenging source water conditions. Without proper maintenance protocols, membrane performance deteriorates quickly, reducing system efficiency and lifespan. The cost and logistics of replacement membranes further exacerbate this issue, as shipping specialized components to remote locations involves significant expense and time delays.

Cultural acceptance and community engagement represent less technical but equally important challenges. Ultrafiltration systems may face resistance if they conflict with traditional water practices or beliefs. Successful implementation requires culturally sensitive approaches that incorporate local knowledge and preferences into system design and operation protocols.

Regulatory oversight is often minimal in remote areas, creating uncertainty regarding water quality standards and monitoring requirements. This regulatory vacuum can lead to inconsistent implementation practices and difficulty in establishing appropriate performance metrics. Without clear guidelines, system operators may struggle to determine when interventions are necessary or how to prioritize maintenance activities.

Water source variability compounds these challenges, as remote areas often rely on seasonal water bodies or sources with fluctuating quality parameters. Ultrafiltration systems must be designed to handle these variations while maintaining consistent output quality. High turbidity levels during rainy seasons can lead to rapid membrane fouling, necessitating more frequent maintenance than typically required in controlled environments.

Limited technical expertise in remote communities presents another significant barrier. Ultrafiltration systems require skilled personnel for operation, monitoring, and troubleshooting. When technical issues arise, the absence of qualified technicians can lead to prolonged system downtime. Training local operators becomes essential but is complicated by educational barriers and high turnover rates in isolated communities.

Financial sustainability remains a critical concern for remote ultrafiltration implementations. The higher per-capita costs of serving dispersed populations, combined with limited ability to pay, creates challenges for cost recovery. Traditional funding models often fail in these contexts, requiring innovative financing approaches that balance affordability with operational sustainability.

Membrane fouling occurs more rapidly in remote settings due to suboptimal pre-treatment capabilities and challenging source water conditions. Without proper maintenance protocols, membrane performance deteriorates quickly, reducing system efficiency and lifespan. The cost and logistics of replacement membranes further exacerbate this issue, as shipping specialized components to remote locations involves significant expense and time delays.

Cultural acceptance and community engagement represent less technical but equally important challenges. Ultrafiltration systems may face resistance if they conflict with traditional water practices or beliefs. Successful implementation requires culturally sensitive approaches that incorporate local knowledge and preferences into system design and operation protocols.

Regulatory oversight is often minimal in remote areas, creating uncertainty regarding water quality standards and monitoring requirements. This regulatory vacuum can lead to inconsistent implementation practices and difficulty in establishing appropriate performance metrics. Without clear guidelines, system operators may struggle to determine when interventions are necessary or how to prioritize maintenance activities.

Current Technical Solutions for Remote Ultrafiltration

01 Membrane fouling and scaling challenges

Membrane fouling and scaling are significant challenges in ultrafiltration implementation. These issues occur when particles, colloids, or dissolved substances accumulate on the membrane surface or within its pores, reducing filtration efficiency and increasing operational costs. Solutions include optimized pretreatment processes, chemical cleaning protocols, and advanced membrane materials that resist fouling. Proper monitoring and maintenance schedules are essential to maintain system performance and extend membrane life.- Membrane fouling and cleaning challenges: Membrane fouling is a significant challenge in ultrafiltration implementation, causing reduced flux and increased operational costs. Fouling occurs when particles, colloids, or biological materials accumulate on membrane surfaces, requiring regular cleaning procedures. Effective cleaning protocols must be developed to maintain membrane performance without damaging the membrane structure. Chemical cleaning agents must be carefully selected based on membrane material compatibility and fouling type.

- Energy consumption optimization: Ultrafiltration systems face challenges related to high energy consumption, particularly in maintaining transmembrane pressure. Optimizing energy usage requires careful system design, including pump selection, pressure control mechanisms, and operational parameters. Advanced control systems can help balance filtration efficiency with energy consumption by adjusting operating conditions based on feed water quality and filtration requirements. Energy recovery devices may be implemented to capture and reuse energy from reject streams.

- System integration and automation: Integrating ultrafiltration systems with existing water treatment infrastructure presents significant implementation challenges. Automation systems must be designed to monitor and control multiple parameters simultaneously, including pressure, flow rate, and water quality. Data management systems need to process information from various sensors to optimize performance and detect potential issues. Compatibility with existing SCADA systems and communication protocols must be ensured for seamless operation.

- Pretreatment requirements and feed water variability: Ultrafiltration performance is highly dependent on feed water quality, which can vary significantly based on source and environmental conditions. Implementing appropriate pretreatment systems is essential to remove larger particles and reduce membrane fouling. Seasonal variations in water quality require flexible operational strategies to maintain consistent performance. Monitoring systems must be capable of detecting changes in feed water characteristics to allow for timely adjustments to operational parameters.

- Security and data protection in automated systems: As ultrafiltration systems become more automated and connected, cybersecurity emerges as a critical implementation challenge. Protecting operational data and control systems from unauthorized access is essential for maintaining system integrity and preventing potential sabotage. Authentication protocols must be implemented to ensure only authorized personnel can make system adjustments. Encryption of data transmission between system components helps prevent interception of sensitive operational information. Regular security audits and updates are necessary to address emerging vulnerabilities.

02 Process control and automation systems

Implementing effective process control and automation systems presents challenges in ultrafiltration operations. These systems must accurately monitor and adjust critical parameters such as pressure, flow rate, and backwash cycles to maintain optimal performance. Integration with existing plant infrastructure and ensuring reliable data collection for quality control are common hurdles. Advanced control algorithms and user-friendly interfaces are needed to manage complex filtration processes while minimizing operator intervention and human error.Expand Specific Solutions03 Energy consumption optimization

High energy consumption is a significant challenge in ultrafiltration implementation. The process requires substantial energy for pumping, maintaining transmembrane pressure, and performing backwash operations. Optimizing energy usage while maintaining filtration performance involves implementing energy recovery devices, designing efficient hydraulic systems, and developing smart operational strategies that adjust power consumption based on feed water quality and production demands. Energy-efficient designs must balance initial capital costs against long-term operational savings.Expand Specific Solutions04 System integration and scalability

Integrating ultrafiltration systems into existing water treatment infrastructure presents significant implementation challenges. These include ensuring compatibility with upstream and downstream processes, managing space constraints, and designing systems that can be scaled up to meet increasing demand. Modular approaches to system design allow for phased implementation and expansion, but require careful planning of hydraulic profiles, control systems, and maintenance access. Successful integration depends on comprehensive site assessment and customized engineering solutions that address specific operational requirements.Expand Specific Solutions05 Regulatory compliance and validation

Meeting regulatory requirements and validating ultrafiltration system performance present significant implementation challenges. These include demonstrating consistent removal of contaminants, establishing appropriate testing protocols, and maintaining comprehensive documentation of system performance. Regulatory frameworks vary by region and application, requiring tailored compliance strategies. Validation procedures must verify membrane integrity, filtrate quality, and system reliability under various operating conditions. Ongoing monitoring and reporting systems are essential to maintain compliance and ensure public health protection in water treatment applications.Expand Specific Solutions

Key Industry Players in Remote Water Treatment Solutions

Ultrafiltration implementation in remote areas faces significant challenges within a competitive landscape currently in the growth phase. The global market for remote water treatment solutions is expanding rapidly, with an estimated value of $2-3 billion and projected annual growth of 8-10%. Technology maturity varies significantly among key players. Industry leaders like Evoqua Water Technologies, Toyobo Co., and Kurita Water Industries have developed robust commercial solutions, while research institutions such as Tianjin University, CNRS, and Xinjiang Institute of Ecology are advancing innovative approaches for challenging environments. Companies like Siemens Water Technologies and Degremont offer integrated systems specifically designed for remote applications, focusing on energy efficiency and operational simplicity. The sector is witnessing increased collaboration between academic institutions and industrial partners to overcome implementation barriers related to energy requirements, maintenance challenges, and environmental adaptability.

Siemens Water Technologies Corp.

Technical Solution: Siemens Water Technologies has pioneered ultrafiltration solutions for remote areas through their Memcor® XP ultrafiltration technology. This system utilizes pressurized hollow fiber membranes with an innovative backwash mechanism that significantly extends membrane life in challenging water conditions. For remote implementations, Siemens has developed containerized UF units that arrive pre-assembled and require minimal site preparation, reducing deployment time by up to 60%[2]. Their systems incorporate intelligent automation with the Simatic PCS 7 control system, allowing for operation with minimal human intervention—critical for remote locations with limited access to skilled operators. The technology includes a proprietary low-energy operation mode that automatically adjusts filtration parameters based on feed water quality, reducing energy consumption by up to 25% during periods of good water quality[4]. Siemens has also developed specialized pre-treatment solutions for high-turbidity source waters commonly encountered in remote areas, including advanced screening and sedimentation techniques that protect membrane integrity and extend operational cycles between cleanings.

Strengths: Highly automated operation reduces dependence on skilled operators. Containerized, modular design enables rapid deployment and future capacity expansion. Robust pre-treatment options handle challenging source waters. Weaknesses: Higher capital costs compared to conventional treatment methods. Requires reliable power supply despite efficiency improvements, which can be challenging in very remote locations.

Degremont

Technical Solution: Degremont (now part of SUEZ) has developed specialized ultrafiltration solutions for remote areas through their Ultrazur™ technology platform. Their approach integrates decentralized UF systems with innovative pre-treatment processes specifically designed to handle highly variable water quality common in remote regions. Degremont's remote implementation strategy includes containerized units with membrane modules that can withstand intermittent operation—a critical feature for areas with unreliable power supply. Their systems incorporate a proprietary low-pressure operation mode that reduces energy requirements by approximately 20% compared to conventional UF systems[5]. For extremely remote locations, Degremont has pioneered gravity-fed UF configurations that can operate with minimal electrical input, utilizing elevation differences to provide the necessary filtration pressure. The company has implemented a unique chemical cleaning protocol that extends the interval between intensive cleanings by up to 40%, reducing chemical consumption and maintenance requirements[6]. Their remote monitoring platform enables satellite-based system oversight, allowing technical experts to diagnose issues and guide local operators through necessary interventions without physical presence at the site.

Strengths: Gravity-fed options provide resilience against power outages. Robust design handles intermittent operation without membrane damage. Extended cleaning intervals reduce chemical requirements and maintenance frequency. Weaknesses: Performance efficiency decreases in gravity-fed mode compared to pressurized operation. Initial training requirements for local operators remain significant despite simplified interfaces.

Core Innovations in Off-Grid Ultrafiltration Systems

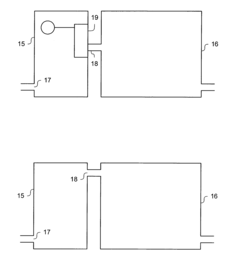

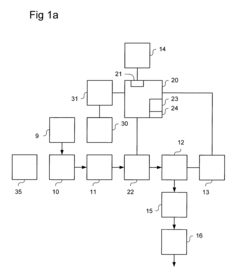

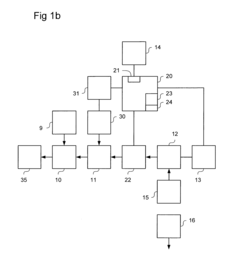

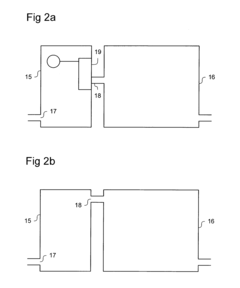

Filtration system forcing water in either direction

PatentInactiveUS20110100926A1

Innovation

- A solar-powered water filtration system with a reversible pump, pressure sensor, and controller that forces water through a filter in both forward and reverse directions, using a positive displacement pump and air blower for efficient purification and maintenance, and includes storage tanks for continuous water availability.

High FLUX and low fouling filtration media

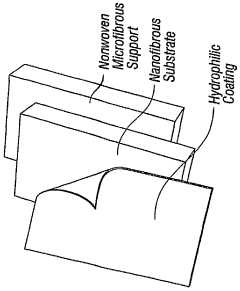

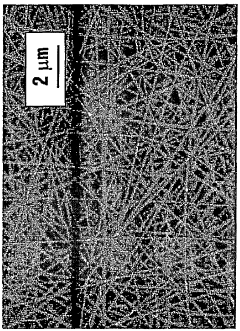

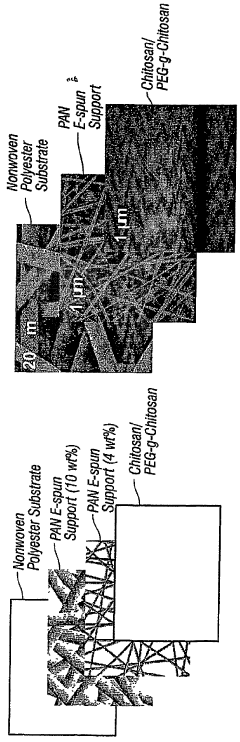

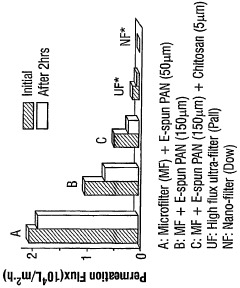

PatentWO2007001405A9

Innovation

- Development of high-flux, low-fouling filtration media using electro-spun/electro-blown nano-fibrous scaffolds with a coating of polymers and functionalized nanofillers, creating a three-tier composite membrane structure for enhanced mechanical, chemical, and thermal stability.

Energy Requirements and Sustainable Power Solutions

Implementing ultrafiltration systems in remote areas presents significant energy challenges that require innovative solutions. Conventional ultrafiltration systems typically demand consistent electrical power ranging from 1-3 kWh per cubic meter of treated water, making energy availability a critical barrier in regions lacking reliable grid infrastructure. Remote communities often face intermittent or non-existent power supplies, necessitating alternative approaches to ensure sustainable operation of water treatment facilities.

Solar photovoltaic systems have emerged as a primary solution, with decreasing panel costs (approximately 70% reduction over the past decade) making them increasingly viable for remote applications. Modern solar-powered ultrafiltration units can process 500-2000 liters per day with 250-500W panel arrays, sufficient for small community needs. These systems typically incorporate energy storage through battery banks, allowing for 24-48 hours of operation during low sunlight conditions.

Wind energy presents another promising option in suitable geographic locations, with small-scale turbines (1-5kW) capable of powering ultrafiltration systems in areas with average wind speeds exceeding 4-5 m/s. Hybrid wind-solar solutions offer enhanced reliability by compensating for seasonal variations in resource availability, though they require more complex control systems.

Micro-hydro power systems have demonstrated exceptional efficiency in mountainous regions with flowing water sources, converting kinetic energy to electricity with minimal environmental impact. These systems can achieve 70-90% energy conversion efficiency, significantly higher than solar alternatives, while providing consistent power output regardless of weather conditions.

Recent innovations in energy-efficient ultrafiltration designs have reduced power requirements by 30-40% compared to conventional systems. Low-pressure membranes operating at 0.5-1 bar (versus traditional 2-5 bar systems) significantly decrease pumping energy needs. Gravity-fed configurations eliminate electrical pumping requirements entirely in locations with sufficient elevation differences, though they operate at reduced flow rates.

Energy recovery devices represent another advancement, capturing and reusing pressure energy that would otherwise be lost during the filtration process. These systems can reclaim 30-60% of energy inputs, substantially improving overall efficiency. Additionally, smart control systems that optimize operation based on water demand patterns can reduce energy consumption by 15-25% through strategic scheduling of filtration cycles.

For extremely remote locations, human-powered ultrafiltration systems utilizing hand or pedal-operated mechanisms provide a last-resort solution, capable of producing 100-300 liters of clean water per hour of operation without any external power source, though requiring significant human labor input.

Solar photovoltaic systems have emerged as a primary solution, with decreasing panel costs (approximately 70% reduction over the past decade) making them increasingly viable for remote applications. Modern solar-powered ultrafiltration units can process 500-2000 liters per day with 250-500W panel arrays, sufficient for small community needs. These systems typically incorporate energy storage through battery banks, allowing for 24-48 hours of operation during low sunlight conditions.

Wind energy presents another promising option in suitable geographic locations, with small-scale turbines (1-5kW) capable of powering ultrafiltration systems in areas with average wind speeds exceeding 4-5 m/s. Hybrid wind-solar solutions offer enhanced reliability by compensating for seasonal variations in resource availability, though they require more complex control systems.

Micro-hydro power systems have demonstrated exceptional efficiency in mountainous regions with flowing water sources, converting kinetic energy to electricity with minimal environmental impact. These systems can achieve 70-90% energy conversion efficiency, significantly higher than solar alternatives, while providing consistent power output regardless of weather conditions.

Recent innovations in energy-efficient ultrafiltration designs have reduced power requirements by 30-40% compared to conventional systems. Low-pressure membranes operating at 0.5-1 bar (versus traditional 2-5 bar systems) significantly decrease pumping energy needs. Gravity-fed configurations eliminate electrical pumping requirements entirely in locations with sufficient elevation differences, though they operate at reduced flow rates.

Energy recovery devices represent another advancement, capturing and reusing pressure energy that would otherwise be lost during the filtration process. These systems can reclaim 30-60% of energy inputs, substantially improving overall efficiency. Additionally, smart control systems that optimize operation based on water demand patterns can reduce energy consumption by 15-25% through strategic scheduling of filtration cycles.

For extremely remote locations, human-powered ultrafiltration systems utilizing hand or pedal-operated mechanisms provide a last-resort solution, capable of producing 100-300 liters of clean water per hour of operation without any external power source, though requiring significant human labor input.

Maintenance Strategies for Limited-Resource Environments

Maintenance strategies in remote areas with limited resources require innovative approaches to ensure ultrafiltration systems remain operational despite challenging conditions. The primary maintenance challenge stems from the combination of geographical isolation, limited technical expertise, and restricted access to replacement parts and specialized tools.

Implementing preventive maintenance protocols specifically designed for resource-constrained environments represents a critical first step. These protocols should emphasize visual inspections, simple mechanical tests, and basic water quality monitoring that can be performed by local operators with minimal training. Documentation must be simplified, utilizing visual guides and pictorial instructions to overcome potential literacy or language barriers.

Remote monitoring systems adapted for low-connectivity environments offer significant advantages. These systems can operate with intermittent power and limited internet access, storing data locally and transmitting when connections become available. Simple sensor packages that monitor pressure differentials, flow rates, and basic water quality parameters can provide early warning of system deterioration without requiring sophisticated equipment.

Training programs for local maintenance personnel must be practical and hands-on, focusing on common failure modes and simple troubleshooting techniques. The development of a tiered maintenance approach allows basic maintenance to be performed locally while establishing clear protocols for when external expertise must be engaged. This approach should include creating a network of regional technical hubs that can provide more advanced support when necessary.

Component standardization and modular design principles significantly enhance maintainability in remote locations. By utilizing interchangeable parts across multiple systems and designing components that can be serviced with basic tools, the complexity of maintenance operations is substantially reduced. The strategic stockpiling of essential spare parts based on failure rate analysis further ensures continuity of operation.

Developing maintenance partnerships with nearby communities can create resource-sharing opportunities, allowing for the pooling of technical expertise and spare parts. These collaborative networks can establish rotating maintenance schedules where technicians visit multiple sites during planned maintenance trips, maximizing efficiency and reducing costs.

Incorporating indigenous knowledge and adapting maintenance practices to local conditions often yields innovative solutions. Local communities frequently develop creative approaches to problem-solving that can be formalized and integrated into standard maintenance procedures, enhancing system resilience while building community ownership and engagement.

Implementing preventive maintenance protocols specifically designed for resource-constrained environments represents a critical first step. These protocols should emphasize visual inspections, simple mechanical tests, and basic water quality monitoring that can be performed by local operators with minimal training. Documentation must be simplified, utilizing visual guides and pictorial instructions to overcome potential literacy or language barriers.

Remote monitoring systems adapted for low-connectivity environments offer significant advantages. These systems can operate with intermittent power and limited internet access, storing data locally and transmitting when connections become available. Simple sensor packages that monitor pressure differentials, flow rates, and basic water quality parameters can provide early warning of system deterioration without requiring sophisticated equipment.

Training programs for local maintenance personnel must be practical and hands-on, focusing on common failure modes and simple troubleshooting techniques. The development of a tiered maintenance approach allows basic maintenance to be performed locally while establishing clear protocols for when external expertise must be engaged. This approach should include creating a network of regional technical hubs that can provide more advanced support when necessary.

Component standardization and modular design principles significantly enhance maintainability in remote locations. By utilizing interchangeable parts across multiple systems and designing components that can be serviced with basic tools, the complexity of maintenance operations is substantially reduced. The strategic stockpiling of essential spare parts based on failure rate analysis further ensures continuity of operation.

Developing maintenance partnerships with nearby communities can create resource-sharing opportunities, allowing for the pooling of technical expertise and spare parts. These collaborative networks can establish rotating maintenance schedules where technicians visit multiple sites during planned maintenance trips, maximizing efficiency and reducing costs.

Incorporating indigenous knowledge and adapting maintenance practices to local conditions often yields innovative solutions. Local communities frequently develop creative approaches to problem-solving that can be formalized and integrated into standard maintenance procedures, enhancing system resilience while building community ownership and engagement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!