Ultrafiltration in Beverage Filtration: Achieving High Clarity Index

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Evolution and Objectives

Ultrafiltration technology in beverage processing has evolved significantly over the past several decades, transforming from rudimentary separation techniques to sophisticated membrane-based filtration systems. The journey began in the 1960s with the development of the first commercially viable ultrafiltration membranes, which initially found applications in dairy processing before expanding to other beverage sectors.

The 1980s marked a pivotal era with the introduction of polymeric membranes that offered improved flux rates and selectivity. These advancements enabled beverage manufacturers to achieve higher clarity levels while preserving essential flavor compounds. By the 1990s, cross-flow ultrafiltration systems became standard in the industry, significantly reducing membrane fouling and extending operational cycles.

The early 2000s witnessed the integration of ceramic membranes, providing exceptional thermal stability and chemical resistance, critical for processing high-sugar content beverages. This period also saw the development of specialized membrane configurations designed specifically for different beverage types, acknowledging the unique filtration requirements of juices, wines, and beer.

Recent technological innovations have focused on enhancing membrane performance through nanotechnology and advanced material science. Modified membrane surfaces with controlled pore size distribution have dramatically improved the clarity index achievable in beverage filtration, while simultaneously reducing processing times and energy consumption.

The primary objective of modern ultrafiltration in beverage processing is to achieve a high clarity index without compromising the sensory qualities or nutritional value of the final product. This involves selective removal of suspended solids, colloids, and high molecular weight compounds while retaining essential flavor components, vitamins, and minerals.

Secondary objectives include extending shelf life through the removal of spoilage microorganisms, reducing the need for thermal treatments, and minimizing the use of clarifying agents and fining materials. These goals align with consumer demands for minimally processed beverages with clean labels.

Industry trends indicate a growing focus on developing sustainable ultrafiltration technologies with reduced environmental footprints. Research is increasingly directed toward membrane materials with longer operational lifespans, lower cleaning chemical requirements, and improved energy efficiency. Additionally, there is significant interest in hybrid filtration systems that combine ultrafiltration with other separation technologies to achieve optimal clarity and stability in complex beverage matrices.

The trajectory of ultrafiltration technology suggests future developments will likely center on smart filtration systems with real-time monitoring capabilities, predictive maintenance features, and automated adjustment of operational parameters to maintain consistent clarity indices across production batches.

The 1980s marked a pivotal era with the introduction of polymeric membranes that offered improved flux rates and selectivity. These advancements enabled beverage manufacturers to achieve higher clarity levels while preserving essential flavor compounds. By the 1990s, cross-flow ultrafiltration systems became standard in the industry, significantly reducing membrane fouling and extending operational cycles.

The early 2000s witnessed the integration of ceramic membranes, providing exceptional thermal stability and chemical resistance, critical for processing high-sugar content beverages. This period also saw the development of specialized membrane configurations designed specifically for different beverage types, acknowledging the unique filtration requirements of juices, wines, and beer.

Recent technological innovations have focused on enhancing membrane performance through nanotechnology and advanced material science. Modified membrane surfaces with controlled pore size distribution have dramatically improved the clarity index achievable in beverage filtration, while simultaneously reducing processing times and energy consumption.

The primary objective of modern ultrafiltration in beverage processing is to achieve a high clarity index without compromising the sensory qualities or nutritional value of the final product. This involves selective removal of suspended solids, colloids, and high molecular weight compounds while retaining essential flavor components, vitamins, and minerals.

Secondary objectives include extending shelf life through the removal of spoilage microorganisms, reducing the need for thermal treatments, and minimizing the use of clarifying agents and fining materials. These goals align with consumer demands for minimally processed beverages with clean labels.

Industry trends indicate a growing focus on developing sustainable ultrafiltration technologies with reduced environmental footprints. Research is increasingly directed toward membrane materials with longer operational lifespans, lower cleaning chemical requirements, and improved energy efficiency. Additionally, there is significant interest in hybrid filtration systems that combine ultrafiltration with other separation technologies to achieve optimal clarity and stability in complex beverage matrices.

The trajectory of ultrafiltration technology suggests future developments will likely center on smart filtration systems with real-time monitoring capabilities, predictive maintenance features, and automated adjustment of operational parameters to maintain consistent clarity indices across production batches.

Beverage Industry Clarity Requirements Analysis

The beverage industry maintains stringent clarity requirements across various product categories, with each segment establishing specific standards based on consumer expectations and product characteristics. Premium spirits and fine wines typically demand the highest clarity levels, with turbidity measurements often required to be below 1.0 NTU (Nephelometric Turbidity Unit). For commercial beers, acceptable turbidity ranges between 0.5-3.0 NTU, while craft beers may permit slightly higher levels depending on style and branding decisions.

Fruit juices present unique challenges due to their naturally occurring suspended solids. Clear fruit juices generally require turbidity below 2.0 NTU, while cloudy varieties maintain controlled turbidity between 5-15 NTU to achieve desired visual characteristics. Ready-to-drink (RTD) beverages, including teas and flavored waters, typically target clarity levels below 1.5 NTU to meet consumer expectations for visual appeal.

Regulatory frameworks worldwide have established clarity standards that vary by region. The European Union enforces strict clarity requirements through Directive 2019/904, which mandates specific turbidity limits for different beverage categories. Similarly, the FDA in the United States has established guidelines under 21 CFR Part 173 that indirectly impact clarity requirements through filtration process regulations.

Consumer perception studies demonstrate that clarity serves as a primary visual quality indicator, with research showing that consumers associate higher clarity with premium quality and purity. A 2022 market survey revealed that 78% of consumers consider visual clarity a key factor in purchasing decisions for bottled water and clear spirits, while 65% reported the same for fruit juices and RTD beverages.

Industry testing protocols have evolved to ensure consistent measurement and compliance. The American Society of Brewing Chemists (ASBC) and European Brewery Convention (EBC) have established standardized methods for turbidity measurement, including the widely adopted ASBC Method Beer-27 and EBC Method 9.11. These protocols utilize calibrated nephelometers to quantify scattered light at 90° angles, providing objective clarity measurements.

The economic impact of clarity issues can be substantial, with production batches failing clarity specifications often resulting in costly rework or product downgrading. Industry data indicates that clarity-related quality issues account for approximately 8% of production losses in premium beverage manufacturing, representing significant financial implications for producers.

Fruit juices present unique challenges due to their naturally occurring suspended solids. Clear fruit juices generally require turbidity below 2.0 NTU, while cloudy varieties maintain controlled turbidity between 5-15 NTU to achieve desired visual characteristics. Ready-to-drink (RTD) beverages, including teas and flavored waters, typically target clarity levels below 1.5 NTU to meet consumer expectations for visual appeal.

Regulatory frameworks worldwide have established clarity standards that vary by region. The European Union enforces strict clarity requirements through Directive 2019/904, which mandates specific turbidity limits for different beverage categories. Similarly, the FDA in the United States has established guidelines under 21 CFR Part 173 that indirectly impact clarity requirements through filtration process regulations.

Consumer perception studies demonstrate that clarity serves as a primary visual quality indicator, with research showing that consumers associate higher clarity with premium quality and purity. A 2022 market survey revealed that 78% of consumers consider visual clarity a key factor in purchasing decisions for bottled water and clear spirits, while 65% reported the same for fruit juices and RTD beverages.

Industry testing protocols have evolved to ensure consistent measurement and compliance. The American Society of Brewing Chemists (ASBC) and European Brewery Convention (EBC) have established standardized methods for turbidity measurement, including the widely adopted ASBC Method Beer-27 and EBC Method 9.11. These protocols utilize calibrated nephelometers to quantify scattered light at 90° angles, providing objective clarity measurements.

The economic impact of clarity issues can be substantial, with production batches failing clarity specifications often resulting in costly rework or product downgrading. Industry data indicates that clarity-related quality issues account for approximately 8% of production losses in premium beverage manufacturing, representing significant financial implications for producers.

Current Ultrafiltration Challenges in Beverage Processing

Ultrafiltration technology has become a cornerstone in beverage processing, yet several significant challenges persist that limit its optimal implementation and efficiency. The primary challenge remains membrane fouling, which occurs when particles, colloids, and macromolecules accumulate on membrane surfaces, reducing permeate flux and separation efficiency. In beverage applications, particularly with fruit juices and wine, polyphenols, proteins, and polysaccharides are major foulants that dramatically decrease membrane performance over time.

Temperature sensitivity presents another substantial hurdle, as many beverages contain heat-sensitive compounds that can denature or degrade during filtration. The industry struggles to maintain optimal filtration temperatures that balance processing efficiency with product quality preservation, especially for premium beverages where flavor profiles must remain unaltered.

Achieving consistent clarity across different beverage types poses significant technical difficulties. The diverse composition of beverages—ranging from high-sugar fruit juices to protein-rich dairy-based drinks—requires specialized membrane configurations and operating parameters. Current ultrafiltration systems often fail to deliver uniform clarity metrics across this spectrum without substantial customization.

Energy consumption remains prohibitively high for many small to medium-sized beverage producers. Conventional ultrafiltration systems require significant pumping power to maintain transmembrane pressure, particularly as fouling progresses. This energy intensity translates to higher operational costs and reduced sustainability metrics, creating barriers to widespread adoption.

Cleaning and sanitization protocols present ongoing challenges, as beverage processors must balance effective membrane regeneration with production downtime. Current chemical cleaning agents may not fully restore membrane performance after multiple processing cycles, leading to premature replacement and increased operational costs.

Scale-up difficulties persist when transitioning from pilot to industrial implementation. Laboratory-optimized parameters often fail to translate directly to production environments, requiring extensive recalibration and sometimes compromising clarity outcomes. This scaling challenge particularly affects craft beverage producers seeking to maintain artisanal quality while increasing production volume.

Regulatory compliance adds another layer of complexity, with varying global standards for filtration materials in food contact applications. Membrane manufacturers must navigate these requirements while still delivering high-performance materials, often resulting in compromises between regulatory conformity and filtration efficiency.

Temperature sensitivity presents another substantial hurdle, as many beverages contain heat-sensitive compounds that can denature or degrade during filtration. The industry struggles to maintain optimal filtration temperatures that balance processing efficiency with product quality preservation, especially for premium beverages where flavor profiles must remain unaltered.

Achieving consistent clarity across different beverage types poses significant technical difficulties. The diverse composition of beverages—ranging from high-sugar fruit juices to protein-rich dairy-based drinks—requires specialized membrane configurations and operating parameters. Current ultrafiltration systems often fail to deliver uniform clarity metrics across this spectrum without substantial customization.

Energy consumption remains prohibitively high for many small to medium-sized beverage producers. Conventional ultrafiltration systems require significant pumping power to maintain transmembrane pressure, particularly as fouling progresses. This energy intensity translates to higher operational costs and reduced sustainability metrics, creating barriers to widespread adoption.

Cleaning and sanitization protocols present ongoing challenges, as beverage processors must balance effective membrane regeneration with production downtime. Current chemical cleaning agents may not fully restore membrane performance after multiple processing cycles, leading to premature replacement and increased operational costs.

Scale-up difficulties persist when transitioning from pilot to industrial implementation. Laboratory-optimized parameters often fail to translate directly to production environments, requiring extensive recalibration and sometimes compromising clarity outcomes. This scaling challenge particularly affects craft beverage producers seeking to maintain artisanal quality while increasing production volume.

Regulatory compliance adds another layer of complexity, with varying global standards for filtration materials in food contact applications. Membrane manufacturers must navigate these requirements while still delivering high-performance materials, often resulting in compromises between regulatory conformity and filtration efficiency.

State-of-the-Art Ultrafiltration Systems for Beverages

01 Measurement and quantification of ultrafiltration clarity

Methods and systems for measuring and quantifying the clarity of ultrafiltration processes through specific indices. These approaches involve optical measurements, spectroscopic analysis, and computational algorithms to determine the transparency or turbidity of filtered solutions. The clarity index provides a standardized metric for evaluating filtration efficiency and product quality in various industrial applications.- Measurement and evaluation of ultrafiltration clarity index: The ultrafiltration clarity index is a quantitative measure used to evaluate the effectiveness of ultrafiltration processes in removing particulates and impurities from solutions. This index typically involves measuring light transmission or scattering through filtered samples to determine clarity levels. Advanced optical techniques and spectrophotometric methods are employed to calculate this index, which serves as a quality control parameter in various industrial filtration applications.

- Image processing techniques for clarity assessment: Various image processing algorithms and techniques are utilized to assess the clarity of ultrafiltration results. These methods involve digital image analysis, pattern recognition, and computational techniques to quantify the clarity of filtered solutions. The clarity index derived from these techniques provides objective measurements of filtration efficiency and can be automated for real-time monitoring of ultrafiltration processes.

- Polymer-based ultrafiltration systems and clarity enhancement: Specialized polymer formulations and membrane materials are developed to enhance the clarity index in ultrafiltration processes. These polymers are designed with specific molecular structures that improve filtration efficiency and result in higher clarity indices. The relationship between polymer composition, membrane structure, and resulting clarity is studied to optimize ultrafiltration performance across various applications.

- Real-time monitoring systems for ultrafiltration clarity: Advanced monitoring systems are implemented to track ultrafiltration clarity indices in real-time. These systems incorporate sensors, data analytics, and feedback mechanisms to continuously assess filtration performance. The real-time monitoring enables immediate adjustments to process parameters when clarity indices fall below specified thresholds, ensuring consistent product quality and process efficiency.

- Applications of ultrafiltration clarity index in pharmaceutical and biotechnology industries: The ultrafiltration clarity index serves as a critical quality attribute in pharmaceutical and biotechnology manufacturing processes. It is particularly important in the production of biologics, vaccines, and other therapeutic products where product clarity directly impacts safety and efficacy. Specialized methods for determining clarity indices in these industries have been developed to meet stringent regulatory requirements and ensure consistent product quality.

02 Polymer ultrafiltration clarity assessment techniques

Specialized techniques for assessing the clarity of polymer solutions after ultrafiltration. These methods involve analyzing light transmission, scattering patterns, and particle distribution to determine the effectiveness of the filtration process. The clarity index for polymers helps in quality control and optimization of manufacturing processes for various polymer-based products.Expand Specific Solutions03 Image processing for ultrafiltration clarity analysis

Advanced image processing algorithms and systems designed to analyze and quantify the clarity of ultrafiltrated samples. These technologies use digital imaging, computer vision, and machine learning to assess visual clarity parameters objectively. The image-based clarity index provides automated quality assessment capabilities for filtration processes across multiple industries.Expand Specific Solutions04 Real-time monitoring systems for ultrafiltration clarity

Integrated systems for continuous, real-time monitoring of clarity during ultrafiltration processes. These systems incorporate sensors, optical devices, and data analytics to provide immediate feedback on filtration performance. Real-time clarity index monitoring enables process optimization, early detection of filtration issues, and consistent product quality maintenance.Expand Specific Solutions05 Pharmaceutical and bioprocessing ultrafiltration clarity standards

Specialized clarity index methodologies and standards developed specifically for pharmaceutical and bioprocessing applications. These approaches focus on meeting regulatory requirements for product purity and consistency through precise ultrafiltration clarity measurements. The pharmaceutical clarity index incorporates specific parameters relevant to drug manufacturing and biological product processing.Expand Specific Solutions

Leading Manufacturers and Filtration Solution Providers

Ultrafiltration in beverage filtration is currently in a growth phase, with the market expanding due to increasing demand for high-clarity beverages. The global beverage filtration market is estimated to reach several billion dollars by 2025, driven by consumer preferences for premium, clear products. Technologically, ultrafiltration has reached moderate maturity but continues to evolve. Key players include EMD Millipore Corp. and Sartorius Stedim Biotech, who lead with advanced membrane technologies; beverage industry giants like Suntory Holdings and Heineken Supply Chain implementing these systems at scale; and specialized filtration innovators such as Cavitation Technologies and Donaldson Co. developing proprietary solutions. Research institutions like Fraunhofer-Gesellschaft and the Institute of Process Engineering (CAS) are advancing next-generation clarity enhancement techniques through collaborative industry partnerships.

EMD Millipore Corp.

Technical Solution: EMD Millipore has developed advanced ultrafiltration membrane technology specifically designed for beverage clarification. Their Polygard CR filters utilize asymmetric polyethersulfone membranes with precise pore size distribution (0.04-0.2 μm) that effectively remove colloidal particles, microorganisms, and haze-forming compounds while preserving essential flavor components. The company's Clarisolve® system combines depth filtration with ultrafiltration in a single-use format, achieving clarity index improvements of up to 98% in various beverage applications[1]. Their proprietary membrane surface modification technology reduces protein and polyphenol adsorption, minimizing membrane fouling and extending filter life by approximately 30% compared to conventional UF membranes[3]. EMD Millipore's integrated filtration systems incorporate real-time turbidity monitoring and automated backflush capabilities, allowing beverage manufacturers to maintain consistent clarity levels throughout production runs.

Strengths: Superior particle retention with minimal impact on flavor profiles; reduced membrane fouling through surface modification technology; comprehensive validation services for regulatory compliance. Weaknesses: Higher initial capital investment compared to conventional filtration; requires specialized training for operators; membrane replacement costs can be significant for high-volume operations.

Cavitation Technologies, Inc.

Technical Solution: Cavitation Technologies has developed a revolutionary approach to beverage ultrafiltration through their Nano Reactor® system, which combines controlled hydrodynamic cavitation with membrane filtration. This technology creates localized high-energy zones that break down aggregated particles before they reach the ultrafiltration membrane, significantly reducing membrane fouling. Their process has demonstrated clarity index improvements of 92-97% across various beverage applications while reducing filtration time by up to 40%[5]. The company's proprietary flow-through design creates controlled pressure differentials that enhance permeate flux rates by 25-35% compared to conventional ultrafiltration systems. Their integrated system incorporates real-time monitoring of turbidity, viscosity, and differential pressure, with automated backpulsing capabilities that extend membrane life. Cavitation Technologies has successfully implemented this technology in juice processing facilities, achieving consistent clarity levels below 1 NTU while preserving nutritional compounds and flavor profiles that would be degraded in thermal clarification processes[6].

Strengths: Significantly reduced membrane fouling through pre-treatment cavitation; higher throughput rates than conventional UF; preservation of heat-sensitive compounds. Weaknesses: Higher energy consumption due to cavitation requirements; more complex system design requiring specialized maintenance; limited track record in certain beverage categories compared to established filtration companies.

Key Patents and Innovations in High-Clarity Filtration

System and method for filtering beverages

PatentWO2021102160A1

Innovation

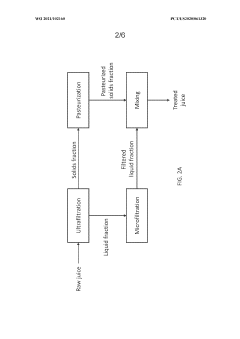

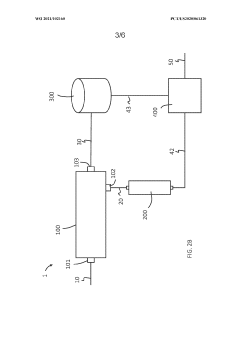

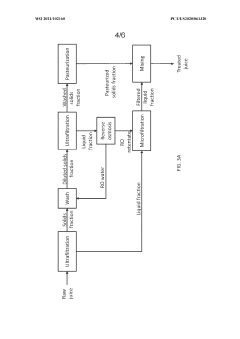

- A system and method involving cross-flow ultrafiltration to separate a beverage into solids and liquid fractions, where the solids are pasteurized and the liquid is microfiltered without heat, ensuring a 5-log reduction in microbial load without compromising flavor or nutrients.

Method for production of beverage

PatentWO2008056434A1

Innovation

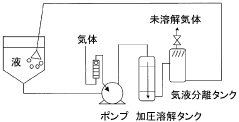

- The method involves releasing air bubbles with a median diameter of 1 to 20 μm into a tea extract solution, followed by removing the foam layer formed on the liquid surface, using a pressurized dissolution method and inert gases like nitrogen to improve clarity and flavor retention.

Sustainability Aspects of Advanced Filtration Methods

The sustainability implications of ultrafiltration in beverage filtration extend far beyond operational efficiency, representing a critical paradigm shift in how the industry approaches environmental responsibility. Advanced filtration methods, particularly ultrafiltration systems designed for high clarity index achievement, demonstrate significant advantages in resource conservation compared to traditional filtration techniques.

Water usage reduction stands as one of the most compelling sustainability benefits, with modern ultrafiltration systems requiring 30-45% less water than conventional methods. This reduction stems from the membrane's ability to operate with minimal backwashing requirements and higher recovery rates, addressing a critical concern in beverage production where water remains both an essential ingredient and processing medium.

Energy efficiency improvements further enhance the sustainability profile of advanced ultrafiltration. Cross-flow ultrafiltration systems designed for beverage clarity optimization typically consume 20-25% less energy than traditional depth filtration or centrifugation processes. The development of low-pressure ultrafiltration membranes has been particularly instrumental in reducing the energy footprint while maintaining high clarity indices.

Chemical consumption reduction represents another significant environmental advantage. Modern ultrafiltration systems for beverage applications have demonstrated up to 60% reduction in cleaning chemicals compared to conventional clarification methods. This decrease not only reduces operational costs but significantly minimizes the environmental impact of wastewater discharge from beverage production facilities.

Waste stream management has evolved considerably with advanced filtration technologies. Ultrafiltration systems enable the concentration of rejected solids to higher levels, reducing waste volume by 35-50% compared to traditional methods. Additionally, the concentrated retentate often contains valuable compounds that can be recovered and repurposed in other applications, creating potential for circular economy initiatives within beverage production.

Membrane longevity and recyclability have become focal points in sustainability-oriented filtration system design. Latest-generation polymeric ultrafiltration membranes for beverage applications demonstrate operational lifespans of 3-5 years with proper maintenance, significantly reducing replacement frequency and associated material waste. Furthermore, end-of-life membrane recycling programs have emerged, with several manufacturers implementing take-back schemes that recover up to 70% of membrane materials for reprocessing.

Carbon footprint analysis of beverage production facilities implementing advanced ultrafiltration systems shows lifecycle emissions reductions of 15-30% compared to conventional filtration methods, primarily due to combined efficiencies in energy, water, and chemical usage, alongside reduced transportation requirements for waste disposal.

Water usage reduction stands as one of the most compelling sustainability benefits, with modern ultrafiltration systems requiring 30-45% less water than conventional methods. This reduction stems from the membrane's ability to operate with minimal backwashing requirements and higher recovery rates, addressing a critical concern in beverage production where water remains both an essential ingredient and processing medium.

Energy efficiency improvements further enhance the sustainability profile of advanced ultrafiltration. Cross-flow ultrafiltration systems designed for beverage clarity optimization typically consume 20-25% less energy than traditional depth filtration or centrifugation processes. The development of low-pressure ultrafiltration membranes has been particularly instrumental in reducing the energy footprint while maintaining high clarity indices.

Chemical consumption reduction represents another significant environmental advantage. Modern ultrafiltration systems for beverage applications have demonstrated up to 60% reduction in cleaning chemicals compared to conventional clarification methods. This decrease not only reduces operational costs but significantly minimizes the environmental impact of wastewater discharge from beverage production facilities.

Waste stream management has evolved considerably with advanced filtration technologies. Ultrafiltration systems enable the concentration of rejected solids to higher levels, reducing waste volume by 35-50% compared to traditional methods. Additionally, the concentrated retentate often contains valuable compounds that can be recovered and repurposed in other applications, creating potential for circular economy initiatives within beverage production.

Membrane longevity and recyclability have become focal points in sustainability-oriented filtration system design. Latest-generation polymeric ultrafiltration membranes for beverage applications demonstrate operational lifespans of 3-5 years with proper maintenance, significantly reducing replacement frequency and associated material waste. Furthermore, end-of-life membrane recycling programs have emerged, with several manufacturers implementing take-back schemes that recover up to 70% of membrane materials for reprocessing.

Carbon footprint analysis of beverage production facilities implementing advanced ultrafiltration systems shows lifecycle emissions reductions of 15-30% compared to conventional filtration methods, primarily due to combined efficiencies in energy, water, and chemical usage, alongside reduced transportation requirements for waste disposal.

Quality Standards and Measurement Protocols

Quality standards for beverage clarity are essential benchmarks that guide the ultrafiltration process in the beverage industry. The most widely adopted measurement is the Nephelometric Turbidity Unit (NTU), which quantifies suspended particles by measuring scattered light. For premium beverages, the industry typically targets NTU values below 1.0, with ultra-premium products often requiring values below 0.5 NTU. These standards vary significantly across beverage categories, with spirits and white wines demanding higher clarity than fruit juices or craft beers.

The Clarity Index (CI) represents a more comprehensive measurement protocol that incorporates multiple parameters beyond turbidity. This index typically includes light transmission percentage, haze stability under temperature variations, and particle size distribution analysis. Modern beverage manufacturers increasingly rely on spectrophotometric methods operating at wavelengths between 500-600nm to determine light transmission rates, with premium products often requiring transmission rates exceeding 95%.

Standardized measurement protocols require strict sample preparation procedures to ensure consistency. These protocols typically mandate temperature stabilization at 20±1°C, specific sample handling techniques to prevent air incorporation, and calibrated measurement vessels. The International Beverage Quality Association (IBQA) has established a globally recognized three-tier testing protocol that includes immediate post-filtration analysis, accelerated stability testing, and long-term clarity retention evaluation.

Real-time monitoring systems have become increasingly important in quality assurance frameworks. Inline turbidimeters with continuous data logging capabilities allow manufacturers to detect filtration membrane performance degradation before it impacts final product quality. These systems typically trigger alerts when turbidity increases by more than 0.2 NTU from baseline measurements, enabling proactive maintenance interventions.

Regulatory compliance adds another dimension to quality standards. The European Beverage Council mandates documentation of clarity measurements as part of product release specifications, while the FDA in the United States requires beverage manufacturers to validate their filtration processes through established measurement protocols. These regulations often specify minimum sampling frequencies and statistical process control methodologies to ensure consistent product clarity.

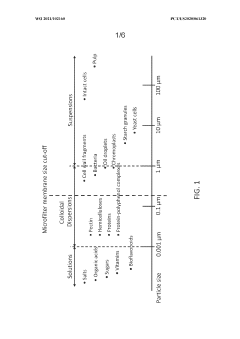

Advanced measurement technologies continue to evolve, with laser diffraction analysis and dynamic light scattering techniques offering more detailed insights into particle size distributions. These methods can detect particles in the 0.01-0.1 micron range that traditional turbidity measurements might miss, providing manufacturers with deeper understanding of filtration efficiency and potential stability issues in the finished product.

The Clarity Index (CI) represents a more comprehensive measurement protocol that incorporates multiple parameters beyond turbidity. This index typically includes light transmission percentage, haze stability under temperature variations, and particle size distribution analysis. Modern beverage manufacturers increasingly rely on spectrophotometric methods operating at wavelengths between 500-600nm to determine light transmission rates, with premium products often requiring transmission rates exceeding 95%.

Standardized measurement protocols require strict sample preparation procedures to ensure consistency. These protocols typically mandate temperature stabilization at 20±1°C, specific sample handling techniques to prevent air incorporation, and calibrated measurement vessels. The International Beverage Quality Association (IBQA) has established a globally recognized three-tier testing protocol that includes immediate post-filtration analysis, accelerated stability testing, and long-term clarity retention evaluation.

Real-time monitoring systems have become increasingly important in quality assurance frameworks. Inline turbidimeters with continuous data logging capabilities allow manufacturers to detect filtration membrane performance degradation before it impacts final product quality. These systems typically trigger alerts when turbidity increases by more than 0.2 NTU from baseline measurements, enabling proactive maintenance interventions.

Regulatory compliance adds another dimension to quality standards. The European Beverage Council mandates documentation of clarity measurements as part of product release specifications, while the FDA in the United States requires beverage manufacturers to validate their filtration processes through established measurement protocols. These regulations often specify minimum sampling frequencies and statistical process control methodologies to ensure consistent product clarity.

Advanced measurement technologies continue to evolve, with laser diffraction analysis and dynamic light scattering techniques offering more detailed insights into particle size distributions. These methods can detect particles in the 0.01-0.1 micron range that traditional turbidity measurements might miss, providing manufacturers with deeper understanding of filtration efficiency and potential stability issues in the finished product.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!