Ultrafiltration vs Nanofiltration: Achieving Desired Purity Levels

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane Filtration Technology Evolution and Objectives

Membrane filtration technology has evolved significantly over the past century, transforming from rudimentary separation methods to sophisticated purification systems. The journey began in the 1920s with the development of microfiltration membranes, primarily used for laboratory applications. By the 1960s, ultrafiltration technology emerged as a viable industrial solution, marking a pivotal advancement in separation science. The subsequent decades witnessed the introduction of nanofiltration in the 1980s, bridging the gap between ultrafiltration and reverse osmosis capabilities.

The evolution of membrane materials has been equally transformative. Early cellulose acetate membranes have given way to advanced polymeric materials, ceramic composites, and more recently, graphene-based structures. These material innovations have dramatically enhanced membrane performance metrics including selectivity, flux rates, fouling resistance, and operational lifespan. Concurrently, module designs have progressed from simple flat sheets to sophisticated spiral-wound, hollow fiber, and tubular configurations, each optimized for specific applications.

In the context of ultrafiltration versus nanofiltration, the technological trajectory has been driven by increasing demands for precision in separation processes. Ultrafiltration, with pore sizes typically ranging from 0.01 to 0.1 micrometers, established itself as the standard for removing macromolecules, colloids, and microorganisms. Nanofiltration later emerged with pore sizes between 0.001 and 0.01 micrometers, enabling the separation of multivalent ions and smaller organic compounds that ultrafiltration cannot effectively target.

The primary objective of current membrane filtration technology development is achieving optimal purity levels while maximizing operational efficiency. This involves balancing several competing factors: selectivity (the ability to discriminate between desired and undesired components), permeability (throughput capacity), energy consumption, and economic viability. For industries ranging from pharmaceuticals to food processing and water treatment, the ability to precisely control separation at the molecular level represents a critical competitive advantage.

Looking forward, the technological roadmap focuses on several key objectives: developing membranes with enhanced selectivity for specific contaminants, improving energy efficiency through reduced pressure requirements, extending membrane lifespan through advanced anti-fouling properties, and creating more environmentally sustainable manufacturing processes. The ultimate goal is to establish filtration systems capable of delivering customized purity profiles tailored to specific application requirements, while minimizing resource consumption and environmental impact.

The evolution of membrane materials has been equally transformative. Early cellulose acetate membranes have given way to advanced polymeric materials, ceramic composites, and more recently, graphene-based structures. These material innovations have dramatically enhanced membrane performance metrics including selectivity, flux rates, fouling resistance, and operational lifespan. Concurrently, module designs have progressed from simple flat sheets to sophisticated spiral-wound, hollow fiber, and tubular configurations, each optimized for specific applications.

In the context of ultrafiltration versus nanofiltration, the technological trajectory has been driven by increasing demands for precision in separation processes. Ultrafiltration, with pore sizes typically ranging from 0.01 to 0.1 micrometers, established itself as the standard for removing macromolecules, colloids, and microorganisms. Nanofiltration later emerged with pore sizes between 0.001 and 0.01 micrometers, enabling the separation of multivalent ions and smaller organic compounds that ultrafiltration cannot effectively target.

The primary objective of current membrane filtration technology development is achieving optimal purity levels while maximizing operational efficiency. This involves balancing several competing factors: selectivity (the ability to discriminate between desired and undesired components), permeability (throughput capacity), energy consumption, and economic viability. For industries ranging from pharmaceuticals to food processing and water treatment, the ability to precisely control separation at the molecular level represents a critical competitive advantage.

Looking forward, the technological roadmap focuses on several key objectives: developing membranes with enhanced selectivity for specific contaminants, improving energy efficiency through reduced pressure requirements, extending membrane lifespan through advanced anti-fouling properties, and creating more environmentally sustainable manufacturing processes. The ultimate goal is to establish filtration systems capable of delivering customized purity profiles tailored to specific application requirements, while minimizing resource consumption and environmental impact.

Market Applications and Demand Analysis for UF/NF Systems

The global market for membrane filtration technologies has witnessed substantial growth, with ultrafiltration (UF) and nanofiltration (NF) systems experiencing particularly strong demand across multiple sectors. The combined UF/NF market reached approximately $3.5 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2028, driven by increasing water scarcity concerns and stringent regulatory frameworks for water quality.

Water treatment represents the largest application segment for UF/NF technologies, accounting for nearly 45% of the total market share. Municipal water treatment facilities are increasingly adopting these technologies to meet drinking water standards and remove contaminants including bacteria, viruses, and organic compounds. The pharmaceutical sector constitutes the second-largest market, valued at approximately $800 million, where these filtration technologies are essential for producing high-purity water for manufacturing processes and product formulations.

Food and beverage applications represent another significant market segment, growing at 9.2% annually. UF/NF systems are widely employed for clarification, concentration, and purification processes in dairy processing, fruit juice production, and wine making. The dairy industry alone accounts for 38% of food sector applications, utilizing these technologies for protein concentration and whey processing.

Regional analysis reveals Asia-Pacific as the fastest-growing market for UF/NF systems, expanding at 10.5% annually, primarily driven by rapid industrialization in China and India. North America and Europe remain mature markets with stable growth rates of 5-6%, focusing on replacement and technological upgrades of existing systems.

End-user demand patterns indicate a growing preference for integrated systems that combine UF and NF technologies to achieve optimal purification results across different applications. This trend is particularly evident in pharmaceutical and biotechnology sectors where achieving precise purity levels is critical for product quality and regulatory compliance.

Market research indicates that customers increasingly prioritize energy efficiency and operational cost reduction, with 67% of surveyed industrial users citing operational expenditure as a primary consideration in system selection. This has driven innovation toward low-pressure operation systems and energy recovery technologies in newer UF/NF installations.

The industrial segment shows strong demand for customized solutions that address specific separation challenges, particularly in chemical processing and textile industries where selective removal of compounds while retaining valuable components is essential. This specialized application segment is expected to grow at 8.7% annually through 2028.

Water treatment represents the largest application segment for UF/NF technologies, accounting for nearly 45% of the total market share. Municipal water treatment facilities are increasingly adopting these technologies to meet drinking water standards and remove contaminants including bacteria, viruses, and organic compounds. The pharmaceutical sector constitutes the second-largest market, valued at approximately $800 million, where these filtration technologies are essential for producing high-purity water for manufacturing processes and product formulations.

Food and beverage applications represent another significant market segment, growing at 9.2% annually. UF/NF systems are widely employed for clarification, concentration, and purification processes in dairy processing, fruit juice production, and wine making. The dairy industry alone accounts for 38% of food sector applications, utilizing these technologies for protein concentration and whey processing.

Regional analysis reveals Asia-Pacific as the fastest-growing market for UF/NF systems, expanding at 10.5% annually, primarily driven by rapid industrialization in China and India. North America and Europe remain mature markets with stable growth rates of 5-6%, focusing on replacement and technological upgrades of existing systems.

End-user demand patterns indicate a growing preference for integrated systems that combine UF and NF technologies to achieve optimal purification results across different applications. This trend is particularly evident in pharmaceutical and biotechnology sectors where achieving precise purity levels is critical for product quality and regulatory compliance.

Market research indicates that customers increasingly prioritize energy efficiency and operational cost reduction, with 67% of surveyed industrial users citing operational expenditure as a primary consideration in system selection. This has driven innovation toward low-pressure operation systems and energy recovery technologies in newer UF/NF installations.

The industrial segment shows strong demand for customized solutions that address specific separation challenges, particularly in chemical processing and textile industries where selective removal of compounds while retaining valuable components is essential. This specialized application segment is expected to grow at 8.7% annually through 2028.

Technical Comparison and Challenges Between UF and NF

Ultrafiltration (UF) and nanofiltration (NF) represent two distinct membrane filtration technologies that operate on different principles and achieve varying levels of separation. UF membranes typically have pore sizes ranging from 0.01 to 0.1 micrometers, making them effective for removing bacteria, viruses, colloids, and macromolecules while allowing smaller molecules and dissolved solids to pass through. In contrast, NF membranes feature significantly smaller pores (0.001 to 0.01 micrometers), enabling them to reject multivalent ions, larger monovalent ions, and organic compounds with molecular weights above 200-400 Daltons.

The fundamental technical difference between these technologies lies in their separation mechanisms. UF primarily relies on size exclusion and operates at relatively low pressures (1-10 bar), while NF combines size exclusion with charge effects (Donnan exclusion) and requires higher operating pressures (5-35 bar). This distinction results in UF being more energy-efficient but less selective compared to NF, which offers higher selectivity at the cost of increased energy consumption.

Performance metrics reveal significant differences in filtration capabilities. UF systems typically achieve 90-98% removal of suspended solids, colloids, and high-molecular-weight compounds but allow most dissolved salts to pass through. NF systems demonstrate 60-80% rejection of monovalent ions and over 95% rejection of divalent ions and organic compounds above their molecular weight cut-off, positioning them between UF and reverse osmosis in the filtration spectrum.

Both technologies face distinct technical challenges. UF systems struggle with membrane fouling from organic matter and biological growth, requiring frequent cleaning and potentially shortened membrane life. The relatively large pore size limits UF's ability to remove dissolved contaminants, necessitating additional treatment steps for high-purity applications. NF systems contend with concentration polarization at the membrane surface, which reduces flux and separation efficiency over time.

Material limitations present ongoing challenges for both technologies. UF membranes, typically made from polysulfone, polyethersulfone, or polyvinylidene fluoride, offer good mechanical strength but limited chemical resistance. NF membranes, commonly composed of thin-film composites with polyamide active layers, provide excellent separation but are vulnerable to oxidative damage and have narrower pH tolerance ranges.

The selection between UF and NF ultimately depends on the specific purity requirements of the application. UF excels in applications requiring removal of particulates and macromolecules while maintaining high flow rates, such as pretreatment for reverse osmosis or clarification processes. NF is preferred when partial desalination and removal of smaller organic compounds are needed, as in water softening, pharmaceutical processing, or certain food industry applications.

The fundamental technical difference between these technologies lies in their separation mechanisms. UF primarily relies on size exclusion and operates at relatively low pressures (1-10 bar), while NF combines size exclusion with charge effects (Donnan exclusion) and requires higher operating pressures (5-35 bar). This distinction results in UF being more energy-efficient but less selective compared to NF, which offers higher selectivity at the cost of increased energy consumption.

Performance metrics reveal significant differences in filtration capabilities. UF systems typically achieve 90-98% removal of suspended solids, colloids, and high-molecular-weight compounds but allow most dissolved salts to pass through. NF systems demonstrate 60-80% rejection of monovalent ions and over 95% rejection of divalent ions and organic compounds above their molecular weight cut-off, positioning them between UF and reverse osmosis in the filtration spectrum.

Both technologies face distinct technical challenges. UF systems struggle with membrane fouling from organic matter and biological growth, requiring frequent cleaning and potentially shortened membrane life. The relatively large pore size limits UF's ability to remove dissolved contaminants, necessitating additional treatment steps for high-purity applications. NF systems contend with concentration polarization at the membrane surface, which reduces flux and separation efficiency over time.

Material limitations present ongoing challenges for both technologies. UF membranes, typically made from polysulfone, polyethersulfone, or polyvinylidene fluoride, offer good mechanical strength but limited chemical resistance. NF membranes, commonly composed of thin-film composites with polyamide active layers, provide excellent separation but are vulnerable to oxidative damage and have narrower pH tolerance ranges.

The selection between UF and NF ultimately depends on the specific purity requirements of the application. UF excels in applications requiring removal of particulates and macromolecules while maintaining high flow rates, such as pretreatment for reverse osmosis or clarification processes. NF is preferred when partial desalination and removal of smaller organic compounds are needed, as in water softening, pharmaceutical processing, or certain food industry applications.

Current UF/NF Implementation Strategies for Purity Control

01 Pore size and filtration efficiency

Ultrafiltration and nanofiltration membranes are characterized by their pore sizes, which directly determine their filtration efficiency and purity levels. Ultrafiltration typically has pore sizes ranging from 0.01 to 0.1 micrometers, while nanofiltration has smaller pores in the range of 0.001 to 0.01 micrometers. These differences in pore size allow for selective separation of particles, molecules, and contaminants, resulting in different levels of purity in the filtered product. The smaller pore size of nanofiltration membranes enables them to achieve higher purity levels by removing smaller particles and even some dissolved substances.- Purity levels achieved in ultrafiltration and nanofiltration systems: Ultrafiltration and nanofiltration technologies can achieve different purity levels depending on membrane characteristics and operating conditions. Nanofiltration typically achieves higher purity levels with removal of particles in the 0.001-0.01 μm range, while ultrafiltration removes particles in the 0.01-0.1 μm range. These filtration methods can achieve removal rates of 95-99.9% for various contaminants, making them suitable for applications requiring high purity standards.

- Membrane materials and structures for enhanced filtration efficiency: Advanced membrane materials and structures significantly impact the purity levels achievable in ultrafiltration and nanofiltration processes. Composite membranes with multiple layers, ceramic membranes, and polymer-based membranes with controlled pore sizes can enhance separation efficiency. Modifications such as surface functionalization and incorporation of nanomaterials can improve selectivity and reduce fouling, thereby maintaining consistent purity levels during operation.

- Process optimization techniques for maximizing purity: Various process optimization techniques can be employed to maximize purity levels in ultrafiltration and nanofiltration systems. These include cross-flow operation, pressure and temperature control, pH adjustment, and feed pretreatment. Multi-stage filtration configurations, with sequential ultrafiltration and nanofiltration steps, can achieve progressively higher purity levels. Optimization of operational parameters such as transmembrane pressure, flow rate, and recovery ratio significantly impacts the final purity of the filtered product.

- Monitoring and quality control systems for purity verification: Advanced monitoring and quality control systems are essential for verifying and maintaining purity levels in ultrafiltration and nanofiltration processes. Real-time monitoring of parameters such as turbidity, conductivity, and particle counts helps ensure consistent purity levels. Automated control systems can adjust operational parameters based on feedback from sensors to maintain desired purity specifications. Regular integrity testing and performance validation protocols are implemented to verify membrane integrity and filtration efficiency.

- Industry-specific purity requirements and applications: Different industries have specific purity requirements that dictate the design and operation of ultrafiltration and nanofiltration systems. In pharmaceutical manufacturing, these technologies must meet stringent purity standards for water and process fluids. Food and beverage applications require removal of specific contaminants while preserving essential nutrients. Water treatment applications focus on removal of pathogens, organic matter, and specific pollutants. Electronics manufacturing requires ultrapure water with extremely low levels of particles and dissolved solids.

02 Membrane materials and construction

The materials used in manufacturing ultrafiltration and nanofiltration membranes significantly impact the achievable purity levels. Advanced composite materials, polymer blends, and ceramic membranes offer different separation capabilities and resistance to fouling. The physical construction of the membrane, including its thickness, surface charge, and hydrophilicity/hydrophobicity, affects how efficiently it can remove contaminants while maintaining flow rates. Innovations in membrane materials have led to improvements in both selectivity and permeability, allowing for higher purity levels while minimizing energy consumption during the filtration process.Expand Specific Solutions03 Multi-stage filtration systems

Combining ultrafiltration and nanofiltration in multi-stage systems can achieve higher purity levels than either technology alone. These integrated systems typically use ultrafiltration as a pre-treatment step to remove larger particles and protect the nanofiltration membranes from fouling. The sequential arrangement of different filtration technologies allows for progressive removal of contaminants, with each stage targeting specific size ranges of particles or molecules. This approach optimizes the overall filtration efficiency and extends the operational life of the more sensitive nanofiltration membranes, while achieving superior final purity levels in applications requiring high-quality filtrate.Expand Specific Solutions04 Process parameters and operating conditions

The purity levels achieved by ultrafiltration and nanofiltration systems are heavily influenced by operating parameters such as pressure, temperature, pH, and cross-flow velocity. Higher transmembrane pressures can increase flux rates but may lead to compaction or fouling that reduces separation efficiency. Temperature affects both the viscosity of the feed solution and the membrane properties, impacting the filtration performance. Optimizing these parameters for specific applications is crucial for achieving desired purity levels while maintaining energy efficiency and membrane longevity. Advanced control systems that dynamically adjust operating conditions can help maintain consistent purity levels despite variations in feed composition.Expand Specific Solutions05 Industry-specific purity requirements

Different industries have established specific purity standards that dictate the required performance of ultrafiltration and nanofiltration systems. In pharmaceutical manufacturing, filtration systems must meet stringent requirements for removing bacteria, viruses, and endotoxins. The food and beverage industry requires removal of specific contaminants while preserving essential nutrients and flavor compounds. Water treatment applications focus on removing pathogens, organic matter, and specific chemical contaminants to meet drinking water standards. These industry-specific requirements drive the development of specialized filtration solutions with tailored membrane properties and system designs to achieve the necessary purity levels for each application.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Filtration

The ultrafiltration and nanofiltration market is currently in a growth phase, with an estimated global market size exceeding $3 billion and projected to expand at a CAGR of 6-8% through 2028. The competitive landscape features established players like Kurita Water Industries and EMD Millipore (MilliporeSigma) dominating with comprehensive filtration portfolios, while specialized firms such as FilmTec (DuPont) and Sartorius Stedim Biotech focus on technological innovation. The technology has reached commercial maturity in water treatment applications but remains in development for specialized industrial processes. Recent advancements from companies like Dow Global Technologies and LANXESS Deutschland are driving improvements in membrane selectivity and fouling resistance, while academic partnerships with institutions like National University of Singapore and Rice University are accelerating next-generation membrane development.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has developed proprietary ultrafiltration and nanofiltration technologies as part of their integrated water treatment solutions. Their MEMCLEAR™ ultrafiltration systems utilize hollow fiber membranes with pore sizes ranging from 0.01-0.1 μm, while their nanofiltration systems employ spiral-wound thin-film composite membranes targeting 200-1000 Da rejection ranges. Kurita's approach integrates chemical pretreatment with membrane filtration, using their proprietary antiscalants and flocculants to extend membrane life by up to 40% compared to standard operations. Their UF systems typically operate at transmembrane pressures of 0.5-2 bar, while NF systems operate at 5-15 bar, optimized for energy efficiency. Kurita has developed automated membrane integrity testing protocols that continuously monitor performance and predict maintenance needs, reducing unplanned downtime by approximately 30%. Their hybrid UF-NF systems allow for tailored water quality outputs meeting specific industrial requirements while minimizing waste streams.

Strengths: Comprehensive integration of chemical and physical treatment approaches; extensive experience across multiple industrial sectors; strong presence in Asian markets with specialized solutions for regional water challenges. Weaknesses: Less established presence in pharmaceutical/biotechnology applications compared to specialized competitors; more limited membrane manufacturing capabilities requiring partnerships with membrane suppliers.

EMD Millipore Corp.

Technical Solution: EMD Millipore has developed a comprehensive portfolio of ultrafiltration and nanofiltration solutions under their Millipore® and Ultracel® brands. Their UF technology utilizes regenerated cellulose, polyethersulfone (PES), and polyvinylidene fluoride (PVDF) membranes with precisely controlled pore sizes ranging from 1 kDa to 1000 kDa MWCO. For nanofiltration, they've engineered composite membranes with thin-film layers capable of rejecting molecules in the 200-1000 Da range. Their proprietary Biomax® membranes incorporate modified PES chemistry that reduces protein binding by up to 90% compared to standard membranes. EMD Millipore's Cogent® μScale system integrates both UF and NF capabilities in a single platform, allowing for sequential filtration processes without intermediate handling. Their membranes feature asymmetric pore structures that maximize flux rates while maintaining selectivity, achieving up to 30% higher throughput than conventional symmetric membranes under equivalent operating conditions.

Strengths: Exceptional biocompatibility for pharmaceutical and biotechnology applications; comprehensive validation documentation supporting regulatory compliance; modular systems allowing for easy scale-up from laboratory to production. Weaknesses: Higher cost structure compared to industrial-focused competitors; more limited options for extremely large-scale applications.

Key Patents and Innovations in Selective Membrane Design

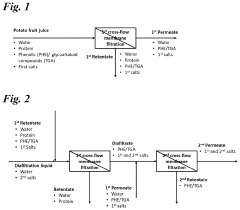

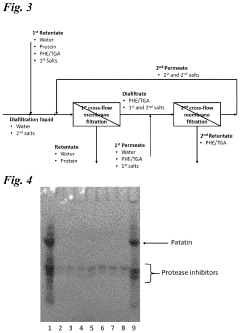

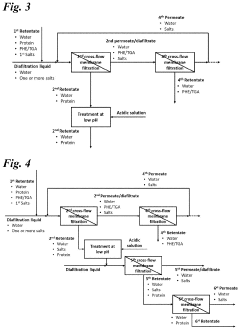

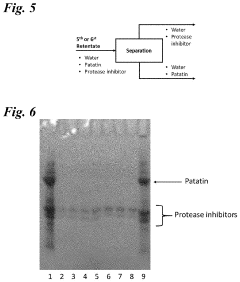

Method for separation of potato proteins from phenolic and/or gl y co alkaloid compounds

PatentPendingUS20230225355A1

Innovation

- A membrane filtration process using diafiltration solvents with increased ionic strength is employed, enhancing the permeability of phenolic and glycoalkaloid compounds and improving average permeate flux, allowing for the separation of potato proteins and phenolic/glycoalkaloid compounds in potato fruit juice.

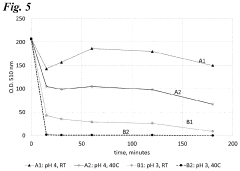

Method for separation of potato proteins with reduced enzymatic activity from potato fruit juice

PatentPendingUS20230225356A1

Innovation

- A membrane filtration process using diafiltration with increased ionic strength and pH control between 4.5 to 8.5, followed by a temporary pH drop to reduce enzymatic activity, effectively separates potato proteins and phenolic compounds while maintaining their functionality.

Energy Efficiency Considerations in Filtration Processes

Energy efficiency has become a critical factor in the selection and operation of filtration systems, particularly when comparing ultrafiltration (UF) and nanofiltration (NF) technologies. The energy consumption profile of these filtration processes directly impacts operational costs, environmental footprint, and overall system sustainability.

Ultrafiltration systems typically operate at lower pressures (1-10 bar) compared to nanofiltration (5-40 bar), resulting in significantly different energy requirements. This pressure differential translates to approximately 0.5-2 kWh/m³ for UF versus 1-5 kWh/m³ for NF, depending on specific applications and system configurations. The higher energy demand of NF is directly correlated with its ability to remove smaller particles and achieve higher purity levels.

Recent advancements in membrane materials and module designs have substantially improved the energy efficiency of both technologies. High-flux membranes with optimized pore structures have reduced the pressure requirements while maintaining separation performance. For instance, the latest generation of UF membranes demonstrates up to 30% energy savings compared to conventional designs when achieving similar purity levels.

Process optimization strategies play a crucial role in enhancing energy efficiency. Cross-flow velocity management, backwashing protocols, and feed water pre-treatment significantly impact energy consumption. Studies indicate that optimized backwashing sequences can reduce energy usage by 15-25% in UF systems while extending membrane life. Similarly, implementing pressure recovery devices in NF systems can recapture up to 40% of energy that would otherwise be lost.

Temperature management represents another important consideration, as filtration efficiency typically improves at higher temperatures due to decreased viscosity. However, this must be balanced against potential membrane degradation and microbial growth concerns. Operating at the optimal temperature range (typically 20-35°C) can reduce energy requirements by 10-20% compared to sub-optimal conditions.

Hybrid filtration systems that strategically combine UF and NF technologies have emerged as an energy-efficient approach for achieving desired purity levels. These integrated systems leverage the strengths of each technology while minimizing overall energy consumption. For applications requiring moderate purity levels, UF followed by partial-stream NF can reduce energy consumption by up to 40% compared to treating the entire stream with NF.

The energy efficiency gap between UF and NF continues to narrow as technological innovations progress. Energy recovery systems, smart control algorithms, and renewable energy integration are transforming the operational economics of high-purity filtration processes. Forward-looking facilities are increasingly implementing real-time monitoring and adaptive control systems that optimize energy usage based on feed water quality fluctuations and output requirements.

Ultrafiltration systems typically operate at lower pressures (1-10 bar) compared to nanofiltration (5-40 bar), resulting in significantly different energy requirements. This pressure differential translates to approximately 0.5-2 kWh/m³ for UF versus 1-5 kWh/m³ for NF, depending on specific applications and system configurations. The higher energy demand of NF is directly correlated with its ability to remove smaller particles and achieve higher purity levels.

Recent advancements in membrane materials and module designs have substantially improved the energy efficiency of both technologies. High-flux membranes with optimized pore structures have reduced the pressure requirements while maintaining separation performance. For instance, the latest generation of UF membranes demonstrates up to 30% energy savings compared to conventional designs when achieving similar purity levels.

Process optimization strategies play a crucial role in enhancing energy efficiency. Cross-flow velocity management, backwashing protocols, and feed water pre-treatment significantly impact energy consumption. Studies indicate that optimized backwashing sequences can reduce energy usage by 15-25% in UF systems while extending membrane life. Similarly, implementing pressure recovery devices in NF systems can recapture up to 40% of energy that would otherwise be lost.

Temperature management represents another important consideration, as filtration efficiency typically improves at higher temperatures due to decreased viscosity. However, this must be balanced against potential membrane degradation and microbial growth concerns. Operating at the optimal temperature range (typically 20-35°C) can reduce energy requirements by 10-20% compared to sub-optimal conditions.

Hybrid filtration systems that strategically combine UF and NF technologies have emerged as an energy-efficient approach for achieving desired purity levels. These integrated systems leverage the strengths of each technology while minimizing overall energy consumption. For applications requiring moderate purity levels, UF followed by partial-stream NF can reduce energy consumption by up to 40% compared to treating the entire stream with NF.

The energy efficiency gap between UF and NF continues to narrow as technological innovations progress. Energy recovery systems, smart control algorithms, and renewable energy integration are transforming the operational economics of high-purity filtration processes. Forward-looking facilities are increasingly implementing real-time monitoring and adaptive control systems that optimize energy usage based on feed water quality fluctuations and output requirements.

Environmental Impact and Sustainability of Filtration Methods

The environmental impact of filtration technologies has become increasingly significant as industries strive for sustainable operations. Ultrafiltration (UF) and nanofiltration (NF) systems demonstrate varying ecological footprints throughout their lifecycle, from manufacturing to disposal.

Energy consumption represents a critical sustainability factor when comparing these filtration methods. Nanofiltration typically requires higher operating pressures (5-20 bar) than ultrafiltration (1-5 bar), resulting in greater energy demands. However, this energy differential must be balanced against purification efficiency; NF may achieve desired purity levels in fewer passes, potentially offsetting its higher energy requirements in specific applications.

Water recovery rates significantly influence the environmental profile of filtration systems. UF systems generally achieve recovery rates of 90-95%, while NF systems operate at 85-90% recovery. This difference translates to varying volumes of concentrate discharge, with important implications for wastewater management and potential environmental contamination.

Chemical usage presents another environmental consideration. Membrane cleaning protocols differ substantially between technologies, with nanofiltration often requiring more aggressive chemical cleaning regimens due to its tighter pore structure and greater fouling susceptibility. These chemicals eventually enter wastewater streams, necessitating additional treatment before environmental discharge.

Membrane lifespan and disposal issues further differentiate these technologies' sustainability profiles. NF membranes typically last 2-5 years while UF membranes may function effectively for 5-7 years under optimal conditions. Longer operational lifespans reduce replacement frequency and associated manufacturing impacts, though end-of-life management remains challenging for both technologies due to limited recycling options.

Carbon footprint assessments reveal that filtration technology selection can significantly impact greenhouse gas emissions. Life cycle analyses indicate that electricity consumption during operation constitutes 60-80% of total carbon emissions for both technologies, with NF generally producing higher emissions due to its energy intensity.

Recent innovations are addressing these environmental concerns through development of anti-fouling membranes that reduce cleaning requirements, energy-recovery devices that capture pressure energy, and biodegradable membrane materials. These advancements are gradually narrowing the sustainability gap between UF and NF systems.

When selecting between ultrafiltration and nanofiltration, organizations must conduct comprehensive environmental impact assessments specific to their application, considering local energy sources, water scarcity conditions, and waste management infrastructure to determine the most sustainable approach for achieving desired purity levels.

Energy consumption represents a critical sustainability factor when comparing these filtration methods. Nanofiltration typically requires higher operating pressures (5-20 bar) than ultrafiltration (1-5 bar), resulting in greater energy demands. However, this energy differential must be balanced against purification efficiency; NF may achieve desired purity levels in fewer passes, potentially offsetting its higher energy requirements in specific applications.

Water recovery rates significantly influence the environmental profile of filtration systems. UF systems generally achieve recovery rates of 90-95%, while NF systems operate at 85-90% recovery. This difference translates to varying volumes of concentrate discharge, with important implications for wastewater management and potential environmental contamination.

Chemical usage presents another environmental consideration. Membrane cleaning protocols differ substantially between technologies, with nanofiltration often requiring more aggressive chemical cleaning regimens due to its tighter pore structure and greater fouling susceptibility. These chemicals eventually enter wastewater streams, necessitating additional treatment before environmental discharge.

Membrane lifespan and disposal issues further differentiate these technologies' sustainability profiles. NF membranes typically last 2-5 years while UF membranes may function effectively for 5-7 years under optimal conditions. Longer operational lifespans reduce replacement frequency and associated manufacturing impacts, though end-of-life management remains challenging for both technologies due to limited recycling options.

Carbon footprint assessments reveal that filtration technology selection can significantly impact greenhouse gas emissions. Life cycle analyses indicate that electricity consumption during operation constitutes 60-80% of total carbon emissions for both technologies, with NF generally producing higher emissions due to its energy intensity.

Recent innovations are addressing these environmental concerns through development of anti-fouling membranes that reduce cleaning requirements, energy-recovery devices that capture pressure energy, and biodegradable membrane materials. These advancements are gradually narrowing the sustainability gap between UF and NF systems.

When selecting between ultrafiltration and nanofiltration, organizations must conduct comprehensive environmental impact assessments specific to their application, considering local energy sources, water scarcity conditions, and waste management infrastructure to determine the most sustainable approach for achieving desired purity levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!