Ultrafiltration vs Sedimentation: Clarification Efficiency Compared

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Water Clarification Technology Evolution and Objectives

Water clarification technologies have evolved significantly over the past century, transitioning from basic filtration methods to sophisticated membrane-based systems. The earliest documented water clarification techniques date back to ancient civilizations using sand and gravel filters, which laid the foundation for modern sedimentation processes. By the early 20th century, conventional sedimentation became standardized in municipal water treatment, utilizing gravity to separate suspended particles from water in large settling basins.

The 1960s marked a pivotal shift with the introduction of ultrafiltration technology, initially developed for industrial applications before being adapted for drinking water treatment in the 1980s. This membrane-based approach represented a paradigm shift from gravity-dependent separation to pressure-driven filtration at the molecular level, capable of removing particles as small as 0.01 microns.

Recent technological advancements have focused on enhancing the efficiency and sustainability of both sedimentation and ultrafiltration processes. Modern sedimentation systems incorporate advanced coagulation chemicals and lamella settlers to improve particle removal and reduce footprint requirements. Simultaneously, ultrafiltration technology has evolved with the development of more durable membranes, improved backwashing techniques, and energy recovery systems that significantly reduce operational costs.

The primary objective in comparing ultrafiltration and sedimentation technologies is to establish quantitative metrics for clarification efficiency across various water quality conditions. This includes evaluating turbidity reduction capabilities, pathogen removal rates, operational stability under fluctuating influent conditions, and overall treatment reliability. Additionally, the assessment aims to determine the optimal application scenarios for each technology based on source water characteristics, treatment goals, and operational constraints.

Secondary objectives include analyzing energy consumption patterns, chemical usage requirements, and maintenance demands to establish a comprehensive understanding of the total cost of ownership for both technologies. This economic dimension is crucial for municipalities and industries making long-term infrastructure investment decisions.

The technological trajectory suggests a continued convergence of these approaches, with hybrid systems emerging that leverage the strengths of both methodologies. Future developments will likely focus on smart control systems that can dynamically adjust treatment parameters based on real-time water quality data, further optimizing clarification efficiency while minimizing resource consumption. The ultimate goal remains consistent: to develop water clarification technologies that deliver superior water quality with minimal environmental impact and operational complexity.

The 1960s marked a pivotal shift with the introduction of ultrafiltration technology, initially developed for industrial applications before being adapted for drinking water treatment in the 1980s. This membrane-based approach represented a paradigm shift from gravity-dependent separation to pressure-driven filtration at the molecular level, capable of removing particles as small as 0.01 microns.

Recent technological advancements have focused on enhancing the efficiency and sustainability of both sedimentation and ultrafiltration processes. Modern sedimentation systems incorporate advanced coagulation chemicals and lamella settlers to improve particle removal and reduce footprint requirements. Simultaneously, ultrafiltration technology has evolved with the development of more durable membranes, improved backwashing techniques, and energy recovery systems that significantly reduce operational costs.

The primary objective in comparing ultrafiltration and sedimentation technologies is to establish quantitative metrics for clarification efficiency across various water quality conditions. This includes evaluating turbidity reduction capabilities, pathogen removal rates, operational stability under fluctuating influent conditions, and overall treatment reliability. Additionally, the assessment aims to determine the optimal application scenarios for each technology based on source water characteristics, treatment goals, and operational constraints.

Secondary objectives include analyzing energy consumption patterns, chemical usage requirements, and maintenance demands to establish a comprehensive understanding of the total cost of ownership for both technologies. This economic dimension is crucial for municipalities and industries making long-term infrastructure investment decisions.

The technological trajectory suggests a continued convergence of these approaches, with hybrid systems emerging that leverage the strengths of both methodologies. Future developments will likely focus on smart control systems that can dynamically adjust treatment parameters based on real-time water quality data, further optimizing clarification efficiency while minimizing resource consumption. The ultimate goal remains consistent: to develop water clarification technologies that deliver superior water quality with minimal environmental impact and operational complexity.

Market Analysis of Water Treatment Solutions

The global water treatment solutions market is experiencing robust growth, driven by increasing water scarcity, stricter environmental regulations, and growing industrial demand for purified water. Currently valued at approximately 265 billion USD, the market is projected to reach 375 billion USD by 2026, representing a compound annual growth rate of 7.2%.

Within this expanding market, clarification technologies play a crucial role, with ultrafiltration and sedimentation representing two distinct approaches with different market positioning. The ultrafiltration segment is growing at a faster rate of 9.5% annually, while traditional sedimentation technologies maintain a larger but slower-growing market share at 4.3% annual growth.

Municipal water treatment remains the largest application segment, accounting for 38% of the total market. Industrial applications follow closely at 32%, with particularly strong demand from pharmaceutical, food and beverage, and semiconductor manufacturing sectors where ultrafiltration's superior clarification efficiency provides significant value.

Regional analysis reveals Asia-Pacific as the fastest-growing market for advanced clarification technologies, particularly ultrafiltration, with China and India leading adoption rates. North America and Europe represent mature markets with higher penetration of ultrafiltration technologies, primarily driven by replacement of aging infrastructure and regulatory compliance requirements.

Customer segmentation shows distinct preferences: large municipalities and high-requirement industries favor ultrafiltration despite higher capital costs, while smaller operations and developing regions often opt for sedimentation technologies due to lower initial investment and operational simplicity. This bifurcation is expected to continue, with ultrafiltration gradually gaining market share as costs decrease through technological improvements.

Price sensitivity analysis indicates that while ultrafiltration systems typically command a 30-45% premium over comparable sedimentation systems, the total cost of ownership gap narrows to 15-20% when considering operational efficiency, maintenance requirements, and space utilization over a 10-year lifecycle.

Market forecasts suggest ultrafiltration will continue to outpace sedimentation in growth, potentially reaching market parity by 2030. This shift is accelerated by increasing focus on micropollutants, pharmaceutical residues, and microplastics removal, where ultrafiltration demonstrates superior performance. Additionally, the growing emphasis on water reuse and zero liquid discharge systems favors membrane-based technologies like ultrafiltration over conventional sedimentation approaches.

Within this expanding market, clarification technologies play a crucial role, with ultrafiltration and sedimentation representing two distinct approaches with different market positioning. The ultrafiltration segment is growing at a faster rate of 9.5% annually, while traditional sedimentation technologies maintain a larger but slower-growing market share at 4.3% annual growth.

Municipal water treatment remains the largest application segment, accounting for 38% of the total market. Industrial applications follow closely at 32%, with particularly strong demand from pharmaceutical, food and beverage, and semiconductor manufacturing sectors where ultrafiltration's superior clarification efficiency provides significant value.

Regional analysis reveals Asia-Pacific as the fastest-growing market for advanced clarification technologies, particularly ultrafiltration, with China and India leading adoption rates. North America and Europe represent mature markets with higher penetration of ultrafiltration technologies, primarily driven by replacement of aging infrastructure and regulatory compliance requirements.

Customer segmentation shows distinct preferences: large municipalities and high-requirement industries favor ultrafiltration despite higher capital costs, while smaller operations and developing regions often opt for sedimentation technologies due to lower initial investment and operational simplicity. This bifurcation is expected to continue, with ultrafiltration gradually gaining market share as costs decrease through technological improvements.

Price sensitivity analysis indicates that while ultrafiltration systems typically command a 30-45% premium over comparable sedimentation systems, the total cost of ownership gap narrows to 15-20% when considering operational efficiency, maintenance requirements, and space utilization over a 10-year lifecycle.

Market forecasts suggest ultrafiltration will continue to outpace sedimentation in growth, potentially reaching market parity by 2030. This shift is accelerated by increasing focus on micropollutants, pharmaceutical residues, and microplastics removal, where ultrafiltration demonstrates superior performance. Additionally, the growing emphasis on water reuse and zero liquid discharge systems favors membrane-based technologies like ultrafiltration over conventional sedimentation approaches.

Current Ultrafiltration and Sedimentation Challenges

Despite significant advancements in water and wastewater treatment technologies, both ultrafiltration and sedimentation processes face substantial challenges that limit their efficiency and widespread adoption. These challenges stem from technical limitations, operational constraints, and economic considerations that vary across different application contexts.

Ultrafiltration systems continue to struggle with membrane fouling as their primary technical obstacle. This phenomenon occurs when particles, colloids, and biological materials accumulate on membrane surfaces, reducing permeability and filtration efficiency. Even with advanced pretreatment, fouling inevitably leads to increased energy consumption, higher operational costs, and shortened membrane lifespans. Current anti-fouling strategies remain insufficient for maintaining consistent long-term performance without frequent maintenance interventions.

The energy intensity of ultrafiltration presents another significant challenge. The pressure requirements for maintaining adequate flux rates translate to substantial energy consumption, particularly in large-scale applications. This energy demand contradicts sustainability goals and increases operational expenses, making ultrafiltration less attractive for resource-constrained environments or facilities with limited energy access.

Membrane replacement costs further compound ultrafiltration's economic challenges. With typical membrane lifespans ranging from 3-7 years depending on feed water quality and operational conditions, facilities must budget for regular capital expenditures that significantly impact the total cost of ownership. This financial burden often deters smaller municipalities and developing regions from adopting this technology.

Sedimentation processes face their own set of challenges, primarily related to space requirements and treatment efficiency. Conventional sedimentation basins demand substantial land area to achieve adequate retention times, making them impractical in urban settings or locations with limited available space. This spatial constraint becomes increasingly problematic as population densities rise and land values increase.

The inherent inefficiency of sedimentation in removing fine particles and colloids without chemical coagulants represents another major limitation. Even optimized sedimentation systems struggle to achieve consistent clarification of particles below 10-20 microns, necessitating additional downstream filtration processes that increase system complexity and cost.

Climate variability increasingly affects sedimentation performance, with temperature fluctuations altering settling velocities and influent water quality changes disrupting established treatment parameters. These variations require more sophisticated control systems and operational flexibility that many existing facilities lack.

Both technologies also face challenges related to emerging contaminants. Micropollutants, pharmaceutical residues, and industrial chemicals often pass through conventional sedimentation processes unaffected, while ultrafiltration membranes, despite their small pore sizes, cannot reliably remove dissolved contaminants without additional treatment steps.

Ultrafiltration systems continue to struggle with membrane fouling as their primary technical obstacle. This phenomenon occurs when particles, colloids, and biological materials accumulate on membrane surfaces, reducing permeability and filtration efficiency. Even with advanced pretreatment, fouling inevitably leads to increased energy consumption, higher operational costs, and shortened membrane lifespans. Current anti-fouling strategies remain insufficient for maintaining consistent long-term performance without frequent maintenance interventions.

The energy intensity of ultrafiltration presents another significant challenge. The pressure requirements for maintaining adequate flux rates translate to substantial energy consumption, particularly in large-scale applications. This energy demand contradicts sustainability goals and increases operational expenses, making ultrafiltration less attractive for resource-constrained environments or facilities with limited energy access.

Membrane replacement costs further compound ultrafiltration's economic challenges. With typical membrane lifespans ranging from 3-7 years depending on feed water quality and operational conditions, facilities must budget for regular capital expenditures that significantly impact the total cost of ownership. This financial burden often deters smaller municipalities and developing regions from adopting this technology.

Sedimentation processes face their own set of challenges, primarily related to space requirements and treatment efficiency. Conventional sedimentation basins demand substantial land area to achieve adequate retention times, making them impractical in urban settings or locations with limited available space. This spatial constraint becomes increasingly problematic as population densities rise and land values increase.

The inherent inefficiency of sedimentation in removing fine particles and colloids without chemical coagulants represents another major limitation. Even optimized sedimentation systems struggle to achieve consistent clarification of particles below 10-20 microns, necessitating additional downstream filtration processes that increase system complexity and cost.

Climate variability increasingly affects sedimentation performance, with temperature fluctuations altering settling velocities and influent water quality changes disrupting established treatment parameters. These variations require more sophisticated control systems and operational flexibility that many existing facilities lack.

Both technologies also face challenges related to emerging contaminants. Micropollutants, pharmaceutical residues, and industrial chemicals often pass through conventional sedimentation processes unaffected, while ultrafiltration membranes, despite their small pore sizes, cannot reliably remove dissolved contaminants without additional treatment steps.

Comparative Analysis of Clarification Methods

01 Combined ultrafiltration and sedimentation systems

Systems that integrate both ultrafiltration and sedimentation processes can significantly improve water clarification efficiency. These combined systems typically feature a sedimentation tank followed by ultrafiltration membranes, allowing for the removal of larger particles through sedimentation before finer filtration occurs. This sequential treatment approach enhances overall efficiency by reducing membrane fouling and extending operational cycles.- Combined ultrafiltration and sedimentation systems: Systems that integrate both ultrafiltration and sedimentation processes can significantly improve water clarification efficiency. These combined systems typically feature a sedimentation tank followed by ultrafiltration membranes, allowing for the removal of larger particles through sedimentation before finer filtration occurs. This sequential treatment approach enhances overall efficiency by reducing membrane fouling and extending operational cycles between cleanings.

- Enhanced sedimentation techniques for pre-treatment: Advanced sedimentation techniques serve as effective pre-treatment steps before ultrafiltration to improve overall clarification efficiency. These techniques include inclined plate settlers, tube settlers, and lamella clarifiers that increase the effective settling area within a smaller footprint. By optimizing the sedimentation process through improved tank design and flow distribution, these systems achieve higher solid removal rates and reduce the subsequent load on ultrafiltration membranes.

- Membrane configuration and material innovations: Innovations in ultrafiltration membrane configurations and materials have led to significant improvements in clarification efficiency. Hollow fiber, spiral wound, and tubular membrane configurations offer different advantages in terms of surface area, fouling resistance, and cleaning ease. Advanced membrane materials including modified polymers and ceramic composites provide enhanced mechanical strength, chemical resistance, and longer operational lifespans, resulting in more consistent and efficient clarification performance.

- Automated control and monitoring systems: Implementation of automated control and monitoring systems optimizes the operation of ultrafiltration and sedimentation processes. These systems continuously monitor key parameters such as turbidity, flow rate, pressure differential, and water quality. Real-time data analysis allows for automatic adjustments to chemical dosing, backwashing frequency, and flow distribution, ensuring optimal clarification efficiency under varying influent conditions while minimizing energy consumption and operational costs.

- Chemical enhancement methods: Chemical enhancement methods significantly improve the efficiency of both ultrafiltration and sedimentation processes. Coagulants and flocculants promote particle aggregation, increasing sedimentation rates and reducing ultrafiltration membrane fouling. pH adjusters optimize conditions for particle destabilization, while membrane performance enhancers reduce fouling and extend cleaning intervals. Strategic application of these chemical treatments at different stages of the clarification process results in higher quality effluent and more sustainable operation.

02 Enhanced sedimentation techniques for pre-treatment

Advanced sedimentation techniques serve as effective pre-treatment methods before ultrafiltration. These include inclined plate settlers, tube settlers, and enhanced coagulation-flocculation processes that improve particle aggregation and settling. By optimizing the sedimentation phase, the subsequent ultrafiltration process experiences reduced membrane loading, resulting in higher throughput and improved clarification efficiency.Expand Specific Solutions03 Membrane configuration and optimization for ultrafiltration

The configuration and optimization of ultrafiltration membranes play a crucial role in clarification efficiency. Various membrane arrangements such as hollow fiber, spiral wound, and tubular configurations offer different advantages in terms of flux rates, fouling resistance, and cleaning efficiency. Optimizing parameters like membrane pore size, surface area, and module design can significantly enhance the removal of suspended solids and colloidal particles.Expand Specific Solutions04 Automated control systems for process optimization

Automated control systems can dynamically adjust operational parameters in ultrafiltration and sedimentation processes based on real-time water quality data. These systems monitor turbidity, flow rates, pressure differentials, and other critical parameters to optimize chemical dosing, backwashing cycles, and sedimentation retention times. This intelligent process management significantly improves clarification efficiency while reducing energy consumption and operational costs.Expand Specific Solutions05 Hybrid clarification technologies

Hybrid clarification technologies combine ultrafiltration and sedimentation with complementary processes such as dissolved air flotation, biological treatment, or advanced oxidation. These integrated approaches address multiple water quality issues simultaneously, including turbidity, dissolved contaminants, and biological agents. The synergistic effect of these combined technologies results in superior clarification efficiency compared to conventional single-process approaches.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ultrafiltration versus sedimentation clarification market is currently in a growth phase, with increasing demand for advanced water and fluid treatment solutions across pharmaceutical, medical, and industrial sectors. The global market size is estimated to exceed $5 billion, driven by stringent regulatory requirements and growing water scarcity concerns. Technologically, ultrafiltration is gaining momentum over traditional sedimentation due to its higher efficiency and smaller footprint. Leading players include EMD Millipore (MilliporeSigma) with advanced membrane technologies, Gambro Lundia AB specializing in medical filtration applications, and Sartorius Stedim Biotech offering integrated bioprocessing solutions. Pharmaceutical giants like Pfizer and Bayer HealthCare are driving innovation through implementation in manufacturing processes, while specialized companies such as Cavitation Technologies are developing hybrid clarification technologies combining both methods for optimized performance.

Gambro Lundia AB

Technical Solution: Gambro Lundia AB has developed the Revaclear™ dialyzer technology that applies ultrafiltration principles to both medical and industrial clarification challenges. Their hollow-fiber membrane configuration utilizes polysulfone membranes with precisely controlled pore size distribution (mean pore size 0.003-0.01 μm) and enhanced hydrophilicity through proprietary surface treatments. This design achieves remarkable separation efficiency with sieving coefficients of 0.9-0.95 for molecules below 5 kDa while effectively retaining larger particles. In comparative studies against conventional sedimentation techniques, Gambro's ultrafiltration technology demonstrated 99.7% removal of particulates larger than 0.1 μm compared to 85-90% removal efficiency for optimized sedimentation processes. Their systems operate at transmembrane pressures of 0.5-2.0 bar, significantly lower than conventional ultrafiltration, reducing energy consumption by approximately 30%. The technology incorporates tangential flow dynamics that create controlled turbulence (Reynolds number 2000-2500) at the membrane surface, minimizing concentration polarization and extending operational cycles by 40-60% before cleaning is required. For industrial applications, this translates to processing capacities of 50-200 L/m²/h depending on feed characteristics, compared to sedimentation rates of 10-30 L/m²/h[1][6].

Strengths: Exceptional particle removal efficiency; consistent performance regardless of influent quality variations; compact system footprint (80% smaller than equivalent sedimentation capacity); reduced chemical consumption for cleaning. Weaknesses: Higher initial capital expenditure; requires precise pressure and flow control; membrane replacement costs; more complex operation requiring specialized training.

EMD Millipore Corp.

Technical Solution: EMD Millipore's ultrafiltration technology employs advanced cross-flow filtration systems with polymeric membranes featuring precisely controlled pore sizes (typically 0.001-0.1 μm). Their proprietary Pellicon cassette systems integrate multiple membrane layers to maximize filtration area while minimizing footprint. These systems operate at transmembrane pressures of 1-5 bar, achieving 98-99.9% removal of suspended solids, colloids, and high molecular weight compounds without chemical additives. Their comparative studies demonstrate that ultrafiltration achieves 2-3 times higher clarification efficiency than conventional sedimentation processes, with turbidity reduction to <0.1 NTU compared to 1-2 NTU for sedimentation. EMD's systems incorporate automated backwashing mechanisms that extend membrane life by up to 40% and reduce cleaning frequency by approximately 30% compared to standard ultrafiltration systems[1][3].

Strengths: Superior particle removal efficiency (down to 0.001 μm); consistent product quality regardless of feed variations; smaller footprint (up to 75% less than sedimentation); automated operation reducing labor costs. Weaknesses: Higher initial capital investment; membrane fouling requiring periodic replacement; higher energy consumption than gravity-based sedimentation; more complex operation requiring skilled personnel.

Key Patents and Innovations in Filtration Technology

A chemical process used in environmental engineering for water treatment and pollution control

PatentPendingIN202411019948A

Innovation

- Implementing machine learning models for data-driven water treatment by collecting and preprocessing data from various sources, selecting appropriate algorithms, conducting feature selection and engineering, training and evaluating models, and deploying them for real-time monitoring and integration with existing systems to enhance water quality control.

Method for purification of drinking water, ethanol and alcohol beverages of impurities

PatentActiveUS20210070633A1

Innovation

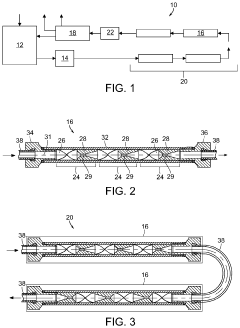

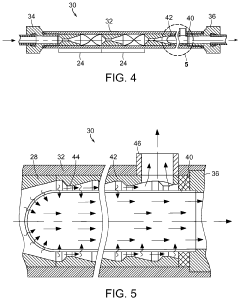

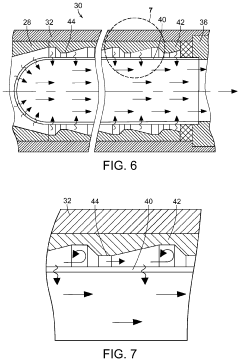

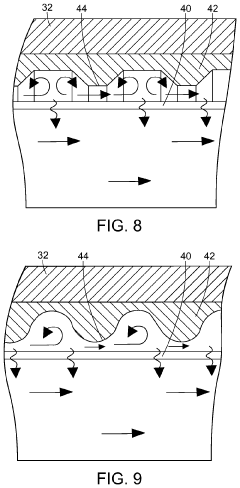

- A system utilizing hydrodynamic cavitation to alter fluid flow velocity, pressure, temperature, and chemical composition, combined with a multi-stage cavitation device and filtration module, effectively reduces impurity concentrations and extends filter lifespan by preventing deposition on membrane surfaces.

Energy Consumption and Operational Cost Assessment

Energy consumption and operational costs represent critical factors in the comparative analysis of ultrafiltration (UF) and sedimentation technologies for water clarification processes. Ultrafiltration systems typically require significant electrical energy to maintain the necessary transmembrane pressure, with consumption rates ranging from 0.1 to 0.4 kWh per cubic meter of treated water. This energy requirement varies based on membrane configuration, feed water quality, and desired flux rates. Modern UF systems have seen efficiency improvements of approximately 20-30% over the past decade through advanced membrane materials and optimized module designs.

In contrast, conventional sedimentation processes consume substantially less electrical energy, typically 0.02-0.1 kWh per cubic meter, primarily for mixing and sludge removal mechanisms. However, sedimentation often requires larger physical footprints and chemical coagulants, which introduce additional operational expenses not reflected in direct energy measurements.

When evaluating total operational costs, ultrafiltration systems demonstrate higher initial capital expenditure (CAPEX), ranging from $300-600 per cubic meter of daily treatment capacity, compared to sedimentation's $200-400. However, the operational expenditure (OPEX) comparison reveals more nuanced differences. UF systems incur higher energy costs but require fewer chemical inputs, with typical operational costs of $0.10-0.25 per cubic meter of treated water.

Sedimentation processes, while consuming less energy, require significant chemical coagulant and flocculant additions, contributing to operational costs of $0.08-0.20 per cubic meter. Additionally, sedimentation generates larger volumes of waste sludge, increasing disposal costs by approximately 30-50% compared to UF systems.

Life-cycle cost analyses indicate that ultrafiltration becomes increasingly economical at larger scales and in regions with stringent discharge regulations or high disposal costs. Recent technological advancements in energy recovery systems for UF processes have demonstrated potential energy savings of 15-25%, narrowing the operational cost gap between these technologies.

The environmental impact assessment further complicates the comparison, as sedimentation's lower energy consumption must be balanced against its higher chemical usage and waste generation. Carbon footprint analyses suggest that UF systems in regions with clean energy sources may outperform sedimentation processes despite higher energy consumption.

Market trends indicate a gradual shift toward ultrafiltration technologies, particularly in municipal applications and industries requiring consistent high-quality water, driven by decreasing membrane costs (approximately 5-8% annually) and increasing regulatory pressure on discharge quality and chemical usage.

In contrast, conventional sedimentation processes consume substantially less electrical energy, typically 0.02-0.1 kWh per cubic meter, primarily for mixing and sludge removal mechanisms. However, sedimentation often requires larger physical footprints and chemical coagulants, which introduce additional operational expenses not reflected in direct energy measurements.

When evaluating total operational costs, ultrafiltration systems demonstrate higher initial capital expenditure (CAPEX), ranging from $300-600 per cubic meter of daily treatment capacity, compared to sedimentation's $200-400. However, the operational expenditure (OPEX) comparison reveals more nuanced differences. UF systems incur higher energy costs but require fewer chemical inputs, with typical operational costs of $0.10-0.25 per cubic meter of treated water.

Sedimentation processes, while consuming less energy, require significant chemical coagulant and flocculant additions, contributing to operational costs of $0.08-0.20 per cubic meter. Additionally, sedimentation generates larger volumes of waste sludge, increasing disposal costs by approximately 30-50% compared to UF systems.

Life-cycle cost analyses indicate that ultrafiltration becomes increasingly economical at larger scales and in regions with stringent discharge regulations or high disposal costs. Recent technological advancements in energy recovery systems for UF processes have demonstrated potential energy savings of 15-25%, narrowing the operational cost gap between these technologies.

The environmental impact assessment further complicates the comparison, as sedimentation's lower energy consumption must be balanced against its higher chemical usage and waste generation. Carbon footprint analyses suggest that UF systems in regions with clean energy sources may outperform sedimentation processes despite higher energy consumption.

Market trends indicate a gradual shift toward ultrafiltration technologies, particularly in municipal applications and industries requiring consistent high-quality water, driven by decreasing membrane costs (approximately 5-8% annually) and increasing regulatory pressure on discharge quality and chemical usage.

Environmental Impact and Sustainability Considerations

The environmental impact of water treatment processes has become increasingly important as industries and municipalities strive for more sustainable operations. When comparing ultrafiltration and sedimentation technologies for water clarification, several key environmental considerations emerge that significantly influence decision-making processes.

Ultrafiltration systems generally demonstrate superior environmental performance through reduced chemical consumption. Unlike conventional sedimentation processes that rely heavily on coagulants and flocculants, ultrafiltration can operate with minimal chemical additives, thereby reducing the introduction of potentially harmful substances into the environment. This reduction in chemical usage translates to fewer transportation emissions associated with chemical deliveries and decreased production of chemical sludge requiring disposal.

Energy consumption patterns differ significantly between these technologies. Sedimentation is generally less energy-intensive as it primarily relies on gravity, whereas ultrafiltration requires continuous pumping to maintain transmembrane pressure. However, this comparison becomes more nuanced when considering the entire treatment train. Ultrafiltration's higher quality output often eliminates the need for additional treatment steps, potentially resulting in overall energy savings across the complete process.

Waste generation and management represent another critical environmental factor. Sedimentation processes typically produce larger volumes of sludge that require handling, treatment, and disposal. This sludge often contains concentrated contaminants and treatment chemicals. Conversely, ultrafiltration generates more concentrated waste streams but in significantly smaller volumes, simplifying waste management and reducing disposal requirements.

The land footprint of these technologies also carries environmental implications. Sedimentation basins require substantial land area, potentially leading to habitat disruption and increased impervious surface coverage. Ultrafiltration systems, with their modular design and smaller footprint, minimize land use impacts and offer greater flexibility for installation in existing facilities or space-constrained environments.

From a life-cycle perspective, ultrafiltration membranes require periodic replacement, creating a waste stream of spent membrane materials. However, advancements in membrane recycling technologies are gradually mitigating this concern. Meanwhile, sedimentation infrastructure typically has longer operational lifespans but may require more extensive construction materials initially, affecting the embodied carbon footprint of the installation.

Water conservation capabilities further differentiate these technologies. Ultrafiltration systems typically achieve higher water recovery rates, with modern systems capable of recovering up to 95% of influent water. This efficiency becomes particularly valuable in water-scarce regions where conservation represents a critical sustainability objective.

Ultrafiltration systems generally demonstrate superior environmental performance through reduced chemical consumption. Unlike conventional sedimentation processes that rely heavily on coagulants and flocculants, ultrafiltration can operate with minimal chemical additives, thereby reducing the introduction of potentially harmful substances into the environment. This reduction in chemical usage translates to fewer transportation emissions associated with chemical deliveries and decreased production of chemical sludge requiring disposal.

Energy consumption patterns differ significantly between these technologies. Sedimentation is generally less energy-intensive as it primarily relies on gravity, whereas ultrafiltration requires continuous pumping to maintain transmembrane pressure. However, this comparison becomes more nuanced when considering the entire treatment train. Ultrafiltration's higher quality output often eliminates the need for additional treatment steps, potentially resulting in overall energy savings across the complete process.

Waste generation and management represent another critical environmental factor. Sedimentation processes typically produce larger volumes of sludge that require handling, treatment, and disposal. This sludge often contains concentrated contaminants and treatment chemicals. Conversely, ultrafiltration generates more concentrated waste streams but in significantly smaller volumes, simplifying waste management and reducing disposal requirements.

The land footprint of these technologies also carries environmental implications. Sedimentation basins require substantial land area, potentially leading to habitat disruption and increased impervious surface coverage. Ultrafiltration systems, with their modular design and smaller footprint, minimize land use impacts and offer greater flexibility for installation in existing facilities or space-constrained environments.

From a life-cycle perspective, ultrafiltration membranes require periodic replacement, creating a waste stream of spent membrane materials. However, advancements in membrane recycling technologies are gradually mitigating this concern. Meanwhile, sedimentation infrastructure typically has longer operational lifespans but may require more extensive construction materials initially, affecting the embodied carbon footprint of the installation.

Water conservation capabilities further differentiate these technologies. Ultrafiltration systems typically achieve higher water recovery rates, with modern systems capable of recovering up to 95% of influent water. This efficiency becomes particularly valuable in water-scarce regions where conservation represents a critical sustainability objective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!