Vacuum Forming Innovations in High-Performance Sportswear Design

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Sportswear: Evolution and Objectives

Vacuum forming has been a transformative technology in the sportswear industry, revolutionizing the design and production of high-performance athletic gear. The evolution of this technique can be traced back to the mid-20th century when it was primarily used in packaging and industrial applications. However, its potential in sportswear design was recognized in the late 1980s and early 1990s, as manufacturers sought innovative ways to enhance the performance and aesthetics of athletic apparel and equipment.

The initial adoption of vacuum forming in sportswear focused on creating protective gear such as shin guards and helmet components. As the technology advanced, its application expanded to include more intricate designs in footwear, particularly in the development of lightweight, form-fitting soles and uppers. This marked a significant shift in the industry, allowing for the creation of shoes that could be customized to an athlete's foot shape and movement patterns.

Throughout the 2000s, vacuum forming techniques were refined to accommodate a wider range of materials, including advanced polymers and composites. This broadened the scope of applications in sportswear, enabling the production of seamless, aerodynamic garments for sports like cycling, swimming, and track and field. The ability to create complex three-dimensional structures without traditional seams or stitching opened up new possibilities for improving athletic performance through reduced drag and enhanced comfort.

In recent years, the focus of vacuum forming innovations in sportswear has shifted towards sustainability and personalization. Manufacturers are exploring bio-based and recycled materials that can be effectively processed using vacuum forming techniques, addressing growing environmental concerns. Additionally, the integration of digital technologies with vacuum forming processes has paved the way for on-demand, customized sportswear production, aligning with the trend of mass customization in the consumer market.

The primary objectives of current vacuum forming innovations in high-performance sportswear design are multifaceted. Firstly, there is a push to further improve the performance characteristics of sportswear, such as weight reduction, enhanced breathability, and improved moisture management. Secondly, researchers and manufacturers are working on developing more sustainable production methods, aiming to reduce waste and energy consumption in the vacuum forming process. Thirdly, there is a growing emphasis on creating adaptive and responsive sportswear that can adjust to an athlete's body temperature, movement, or environmental conditions in real-time.

Looking ahead, the future of vacuum forming in sportswear design is likely to be shaped by advancements in material science and smart manufacturing technologies. The integration of sensors and actuators into vacuum-formed components could lead to the development of truly intelligent sportswear that can provide real-time feedback and adjust its properties to optimize athletic performance. As the technology continues to evolve, it promises to push the boundaries of what is possible in sportswear design, potentially redefining the relationship between athletes and their gear.

The initial adoption of vacuum forming in sportswear focused on creating protective gear such as shin guards and helmet components. As the technology advanced, its application expanded to include more intricate designs in footwear, particularly in the development of lightweight, form-fitting soles and uppers. This marked a significant shift in the industry, allowing for the creation of shoes that could be customized to an athlete's foot shape and movement patterns.

Throughout the 2000s, vacuum forming techniques were refined to accommodate a wider range of materials, including advanced polymers and composites. This broadened the scope of applications in sportswear, enabling the production of seamless, aerodynamic garments for sports like cycling, swimming, and track and field. The ability to create complex three-dimensional structures without traditional seams or stitching opened up new possibilities for improving athletic performance through reduced drag and enhanced comfort.

In recent years, the focus of vacuum forming innovations in sportswear has shifted towards sustainability and personalization. Manufacturers are exploring bio-based and recycled materials that can be effectively processed using vacuum forming techniques, addressing growing environmental concerns. Additionally, the integration of digital technologies with vacuum forming processes has paved the way for on-demand, customized sportswear production, aligning with the trend of mass customization in the consumer market.

The primary objectives of current vacuum forming innovations in high-performance sportswear design are multifaceted. Firstly, there is a push to further improve the performance characteristics of sportswear, such as weight reduction, enhanced breathability, and improved moisture management. Secondly, researchers and manufacturers are working on developing more sustainable production methods, aiming to reduce waste and energy consumption in the vacuum forming process. Thirdly, there is a growing emphasis on creating adaptive and responsive sportswear that can adjust to an athlete's body temperature, movement, or environmental conditions in real-time.

Looking ahead, the future of vacuum forming in sportswear design is likely to be shaped by advancements in material science and smart manufacturing technologies. The integration of sensors and actuators into vacuum-formed components could lead to the development of truly intelligent sportswear that can provide real-time feedback and adjust its properties to optimize athletic performance. As the technology continues to evolve, it promises to push the boundaries of what is possible in sportswear design, potentially redefining the relationship between athletes and their gear.

Market Analysis for High-Performance Sportswear

The high-performance sportswear market has experienced significant growth in recent years, driven by increasing health consciousness, rising participation in sports activities, and growing demand for functional and comfortable athletic apparel. This market segment is characterized by its focus on advanced materials, innovative designs, and cutting-edge technologies that enhance athletic performance and comfort.

The global high-performance sportswear market was valued at approximately $180 billion in 2020 and is projected to reach $250 billion by 2026, growing at a CAGR of around 6.5% during the forecast period. This growth is fueled by several factors, including the rising popularity of athleisure wear, increasing health awareness among consumers, and the growing influence of social media on fitness trends.

Key market segments within high-performance sportswear include running, cycling, swimming, team sports, and outdoor activities. Each segment has specific requirements for materials, design, and functionality. For instance, running apparel demands moisture-wicking fabrics and lightweight construction, while cycling gear requires aerodynamic properties and padding for comfort during long rides.

The market is highly competitive, with major players such as Nike, Adidas, Under Armour, and Lululemon dominating the landscape. These companies invest heavily in research and development to create innovative products that cater to the evolving needs of athletes and fitness enthusiasts. Smaller, specialized brands are also gaining traction by focusing on niche markets and offering unique, performance-driven products.

Consumer preferences in high-performance sportswear are shifting towards sustainability and eco-friendly materials. This trend is driving manufacturers to explore new production methods and materials that reduce environmental impact without compromising performance. Recycled plastics, organic cotton, and biodegradable fabrics are becoming increasingly popular in the industry.

Technological advancements play a crucial role in shaping the high-performance sportswear market. Innovations such as smart fabrics, 3D-printed components, and wearable technology are revolutionizing the industry. These technologies offer features like real-time performance tracking, temperature regulation, and personalized fit, enhancing the overall user experience and driving consumer demand.

The COVID-19 pandemic has had a mixed impact on the high-performance sportswear market. While retail sales initially declined due to store closures and reduced consumer spending, the market has shown resilience. The shift towards home workouts and outdoor activities has boosted demand for versatile, high-performance apparel suitable for various exercise routines.

The global high-performance sportswear market was valued at approximately $180 billion in 2020 and is projected to reach $250 billion by 2026, growing at a CAGR of around 6.5% during the forecast period. This growth is fueled by several factors, including the rising popularity of athleisure wear, increasing health awareness among consumers, and the growing influence of social media on fitness trends.

Key market segments within high-performance sportswear include running, cycling, swimming, team sports, and outdoor activities. Each segment has specific requirements for materials, design, and functionality. For instance, running apparel demands moisture-wicking fabrics and lightweight construction, while cycling gear requires aerodynamic properties and padding for comfort during long rides.

The market is highly competitive, with major players such as Nike, Adidas, Under Armour, and Lululemon dominating the landscape. These companies invest heavily in research and development to create innovative products that cater to the evolving needs of athletes and fitness enthusiasts. Smaller, specialized brands are also gaining traction by focusing on niche markets and offering unique, performance-driven products.

Consumer preferences in high-performance sportswear are shifting towards sustainability and eco-friendly materials. This trend is driving manufacturers to explore new production methods and materials that reduce environmental impact without compromising performance. Recycled plastics, organic cotton, and biodegradable fabrics are becoming increasingly popular in the industry.

Technological advancements play a crucial role in shaping the high-performance sportswear market. Innovations such as smart fabrics, 3D-printed components, and wearable technology are revolutionizing the industry. These technologies offer features like real-time performance tracking, temperature regulation, and personalized fit, enhancing the overall user experience and driving consumer demand.

The COVID-19 pandemic has had a mixed impact on the high-performance sportswear market. While retail sales initially declined due to store closures and reduced consumer spending, the market has shown resilience. The shift towards home workouts and outdoor activities has boosted demand for versatile, high-performance apparel suitable for various exercise routines.

Current Vacuum Forming Techniques and Challenges

Vacuum forming has been a cornerstone technique in the production of high-performance sportswear for decades. This process involves heating a plastic sheet until it becomes pliable, then using vacuum suction to form it over a mold. The current state of vacuum forming in sportswear design encompasses several advanced techniques, each with its own set of challenges.

One of the primary techniques in use today is thermoforming, which allows for the creation of complex, three-dimensional shapes in sportswear components. This method is particularly effective for producing lightweight, aerodynamic elements in cycling helmets and protective gear. However, the challenge lies in maintaining consistent material thickness across the formed part, especially in areas with deep draws or sharp corners.

Another prevalent technique is pressure forming, a variant of vacuum forming that uses both vacuum and positive air pressure. This method enables the production of more detailed and precise components, such as textured surfaces on running shoe soles for enhanced grip. The main challenge here is achieving uniform pressure distribution to ensure consistent product quality across large production runs.

Twin-sheet forming is gaining traction in sportswear manufacturing, allowing for the creation of hollow, double-walled structures. This technique is valuable for producing impact-resistant gear like shin guards or shoulder pads. However, the complexity of the process and the need for precise temperature control present significant challenges in maintaining production efficiency.

The integration of advanced materials poses another set of challenges. High-performance polymers and composites used in modern sportswear often require specific forming temperatures and cooling rates. Achieving optimal material properties while maintaining the desired shape and thickness uniformity is a delicate balance that manufacturers continually strive to perfect.

Automation and process control represent both a current technique and a challenge in vacuum forming for sportswear. While automated systems have improved consistency and productivity, they also demand sophisticated monitoring and adjustment capabilities to account for variations in material properties and environmental conditions.

A persistent challenge across all vacuum forming techniques is the reduction of material waste. The trim scrap generated during the forming process can be substantial, and finding ways to minimize this waste or effectively recycle it remains a focus of ongoing research and development efforts in the industry.

As the demand for increasingly specialized and high-performance sportswear grows, manufacturers are also grappling with the challenge of scalability. Adapting vacuum forming techniques to accommodate both mass production and customized, small-batch runs requires flexible and adaptable manufacturing systems, which are still in development.

One of the primary techniques in use today is thermoforming, which allows for the creation of complex, three-dimensional shapes in sportswear components. This method is particularly effective for producing lightweight, aerodynamic elements in cycling helmets and protective gear. However, the challenge lies in maintaining consistent material thickness across the formed part, especially in areas with deep draws or sharp corners.

Another prevalent technique is pressure forming, a variant of vacuum forming that uses both vacuum and positive air pressure. This method enables the production of more detailed and precise components, such as textured surfaces on running shoe soles for enhanced grip. The main challenge here is achieving uniform pressure distribution to ensure consistent product quality across large production runs.

Twin-sheet forming is gaining traction in sportswear manufacturing, allowing for the creation of hollow, double-walled structures. This technique is valuable for producing impact-resistant gear like shin guards or shoulder pads. However, the complexity of the process and the need for precise temperature control present significant challenges in maintaining production efficiency.

The integration of advanced materials poses another set of challenges. High-performance polymers and composites used in modern sportswear often require specific forming temperatures and cooling rates. Achieving optimal material properties while maintaining the desired shape and thickness uniformity is a delicate balance that manufacturers continually strive to perfect.

Automation and process control represent both a current technique and a challenge in vacuum forming for sportswear. While automated systems have improved consistency and productivity, they also demand sophisticated monitoring and adjustment capabilities to account for variations in material properties and environmental conditions.

A persistent challenge across all vacuum forming techniques is the reduction of material waste. The trim scrap generated during the forming process can be substantial, and finding ways to minimize this waste or effectively recycle it remains a focus of ongoing research and development efforts in the industry.

As the demand for increasingly specialized and high-performance sportswear grows, manufacturers are also grappling with the challenge of scalability. Adapting vacuum forming techniques to accommodate both mass production and customized, small-batch runs requires flexible and adaptable manufacturing systems, which are still in development.

Existing Vacuum Forming Solutions for Sportswear

01 Vacuum forming process optimization

Techniques for optimizing vacuum forming processes, including adjusting parameters such as temperature, pressure, and material properties to enhance performance and efficiency. This may involve using sensors and control systems to monitor and adjust the process in real-time, resulting in improved product quality and reduced waste.- Vacuum forming process optimization: Techniques for optimizing vacuum forming processes, including adjusting parameters such as temperature, pressure, and material properties to enhance performance and efficiency. This may involve using sensors and control systems to monitor and adjust the process in real-time.

- Material selection and preparation for vacuum forming: Methods for selecting and preparing materials suitable for vacuum forming, focusing on properties such as formability, strength, and thermal characteristics. This includes techniques for pre-treating materials and developing new composite materials optimized for vacuum forming applications.

- Mold design and fabrication for vacuum forming: Innovative approaches to designing and fabricating molds for vacuum forming, including the use of advanced materials, 3D printing technologies, and modular designs. These improvements aim to enhance mold durability, reduce cycle times, and improve the quality of formed parts.

- Quality control and defect detection in vacuum forming: Development of advanced quality control methods and defect detection systems for vacuum formed products. This includes the use of machine vision, non-destructive testing techniques, and AI-powered inspection systems to ensure consistent product quality and identify potential issues early in the production process.

- Energy efficiency and sustainability in vacuum forming: Strategies for improving energy efficiency and sustainability in vacuum forming processes. This includes the development of energy-efficient heating systems, recycling of process materials, and the use of biodegradable or recyclable forming materials to reduce environmental impact.

02 Material selection and preparation for vacuum forming

Methods for selecting and preparing materials suitable for vacuum forming, focusing on properties such as formability, strength, and thermal characteristics. This includes techniques for pre-treating materials, such as heating or conditioning, to improve their performance during the vacuum forming process.Expand Specific Solutions03 Mold design and fabrication for vacuum forming

Innovations in mold design and fabrication specifically for vacuum forming applications. This encompasses the use of advanced materials, precision manufacturing techniques, and design optimizations to create molds that enhance the quality and consistency of vacuum-formed products.Expand Specific Solutions04 Vacuum system enhancements

Advancements in vacuum systems used in the forming process, including improved pump designs, sealing mechanisms, and vacuum distribution methods. These enhancements aim to achieve more uniform and efficient vacuum application, resulting in better product quality and reduced cycle times.Expand Specific Solutions05 Quality control and performance monitoring

Implementation of quality control measures and performance monitoring systems in vacuum forming processes. This includes the use of sensors, imaging systems, and data analysis techniques to detect defects, optimize process parameters, and ensure consistent product quality across production runs.Expand Specific Solutions

Key Players in Sportswear Vacuum Forming Industry

The vacuum forming innovations in high-performance sportswear design market is in a growth phase, with increasing demand for advanced athletic apparel. The global sportswear market size is projected to reach $248.1 billion by 2026, driven by technological advancements and consumer preferences for performance-enhancing gear. Major players like NIKE, Adidas, and PUMA are investing heavily in R&D to develop cutting-edge vacuum forming techniques. These companies, along with emerging players such as X-Technology Swiss GmbH and Toray Industries, are pushing the boundaries of material science and manufacturing processes to create lightweight, breathable, and form-fitting sportswear. The technology's maturity is advancing rapidly, with continuous improvements in precision, efficiency, and sustainability of vacuum forming processes for sportswear applications.

NIKE, Inc.

Technical Solution: Nike has developed innovative vacuum forming techniques for high-performance sportswear, focusing on their Flyknit technology. This process involves creating a seamless upper for shoes using precision-engineered yarns and fabric variations. The vacuum forming allows for strategic areas of support, flexibility, and breathability[1]. Nike has also applied this technology to create form-fitting, lightweight apparel that reduces material waste by up to 60% compared to traditional cut-and-sew methods[2]. Their latest innovation combines vacuum forming with 3D printing to create custom-fit performance gear, allowing for rapid prototyping and personalization[3].

Strengths: Reduced material waste, improved fit and performance, customization capabilities. Weaknesses: High initial investment in technology, potential limitations in scalability for mass production.

PUMA SE

Technical Solution: Puma has introduced vacuum forming innovations in their NETFIT technology, which features a customizable lacing system. The process involves vacuum forming a net-like structure onto the upper of the shoe, allowing for multiple lacing options to suit individual foot shapes and preferences[7]. Puma has also developed a vacuum-assisted thermoforming technique for creating seamless, body-mapped compression wear that enhances muscle support and recovery[8]. Their latest innovation combines vacuum forming with bio-based materials to create sustainable, high-performance sportswear with reduced environmental impact[9].

Strengths: Customization options, enhanced fit and comfort, sustainability focus. Weaknesses: Complexity in manufacturing process, potential durability concerns with net structure.

Innovative Vacuum Forming Patents in Sportswear

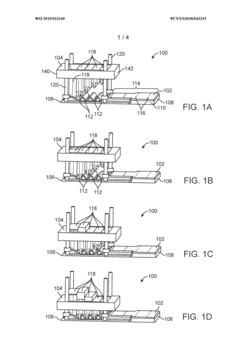

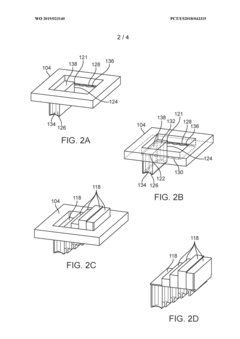

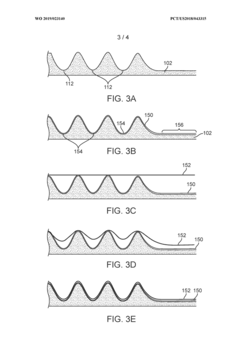

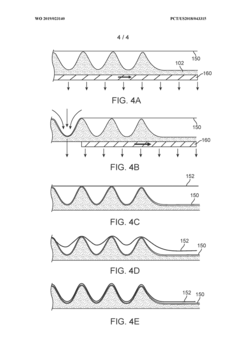

Sequential press and co-mold system

PatentWO2019023140A1

Innovation

- A sequential press and co-mold system is used, featuring a mold with depressions and through-holes for vacuum application, where a first sheet is press-fitted into the mold to prevent tearing and a second sheet is heated and vacuum-pulled to bond with the first sheet, allowing for co-molding without adhesives.

Clothing item

PatentInactiveEP2418975A1

Innovation

- Incorporating highly elastic three-dimensional fabric areas with temperature-regulating properties, featuring channels and rib structures for enhanced ventilation and flexibility, allowing for improved air circulation and movement while maintaining wind and water resistance.

Sustainability in Vacuum Formed Sportswear Production

Sustainability has become a critical focus in the vacuum forming process for high-performance sportswear production. As environmental concerns grow, manufacturers are increasingly seeking ways to reduce their ecological footprint while maintaining product quality and performance. One of the primary areas of innovation is in material selection, with a shift towards using recycled and biodegradable polymers in vacuum forming processes.

Recycled polyethylene terephthalate (rPET) has gained significant traction in the industry. This material, derived from post-consumer plastic bottles, offers a sustainable alternative to virgin plastics while maintaining the necessary properties for high-performance sportswear. Manufacturers are developing techniques to ensure that rPET can be effectively vacuum formed without compromising the material's integrity or the final product's performance characteristics.

Another promising development is the use of bio-based polymers, such as polylactic acid (PLA), which is derived from renewable resources like corn starch or sugarcane. These materials offer the advantage of being biodegradable, potentially reducing the long-term environmental impact of sportswear products. However, challenges remain in optimizing the vacuum forming process for these materials to achieve the desired strength and durability required for high-performance applications.

Energy efficiency in the vacuum forming process itself is another area of focus for sustainability improvements. Manufacturers are investing in advanced heating systems that reduce energy consumption during the forming process. This includes the development of more precise temperature control mechanisms and the use of infrared heating technology, which can significantly reduce the energy required to heat the plastic sheets.

Water conservation is also a key consideration in sustainable vacuum forming practices. Innovative cooling systems are being implemented to minimize water usage in the cooling phase of the process. Closed-loop cooling systems and air-cooling techniques are being explored as alternatives to traditional water-intensive cooling methods.

Waste reduction is a critical aspect of sustainability in vacuum formed sportswear production. Advanced cutting technologies and optimized mold designs are being employed to minimize material waste during the forming and trimming processes. Additionally, manufacturers are developing systems to recycle and reuse scrap material generated during production, further reducing the overall environmental impact.

The industry is also exploring the potential of additive manufacturing techniques in conjunction with vacuum forming to create more sustainable production processes. This hybrid approach allows for the creation of complex mold designs with minimal material waste, potentially reducing the overall resource consumption in sportswear production.

As the demand for sustainable sportswear continues to grow, these innovations in vacuum forming processes are likely to play a crucial role in shaping the future of high-performance sportswear design and production. The ongoing research and development in this area promise to deliver sportswear that not only meets the performance needs of athletes but also aligns with the growing consumer demand for environmentally responsible products.

Recycled polyethylene terephthalate (rPET) has gained significant traction in the industry. This material, derived from post-consumer plastic bottles, offers a sustainable alternative to virgin plastics while maintaining the necessary properties for high-performance sportswear. Manufacturers are developing techniques to ensure that rPET can be effectively vacuum formed without compromising the material's integrity or the final product's performance characteristics.

Another promising development is the use of bio-based polymers, such as polylactic acid (PLA), which is derived from renewable resources like corn starch or sugarcane. These materials offer the advantage of being biodegradable, potentially reducing the long-term environmental impact of sportswear products. However, challenges remain in optimizing the vacuum forming process for these materials to achieve the desired strength and durability required for high-performance applications.

Energy efficiency in the vacuum forming process itself is another area of focus for sustainability improvements. Manufacturers are investing in advanced heating systems that reduce energy consumption during the forming process. This includes the development of more precise temperature control mechanisms and the use of infrared heating technology, which can significantly reduce the energy required to heat the plastic sheets.

Water conservation is also a key consideration in sustainable vacuum forming practices. Innovative cooling systems are being implemented to minimize water usage in the cooling phase of the process. Closed-loop cooling systems and air-cooling techniques are being explored as alternatives to traditional water-intensive cooling methods.

Waste reduction is a critical aspect of sustainability in vacuum formed sportswear production. Advanced cutting technologies and optimized mold designs are being employed to minimize material waste during the forming and trimming processes. Additionally, manufacturers are developing systems to recycle and reuse scrap material generated during production, further reducing the overall environmental impact.

The industry is also exploring the potential of additive manufacturing techniques in conjunction with vacuum forming to create more sustainable production processes. This hybrid approach allows for the creation of complex mold designs with minimal material waste, potentially reducing the overall resource consumption in sportswear production.

As the demand for sustainable sportswear continues to grow, these innovations in vacuum forming processes are likely to play a crucial role in shaping the future of high-performance sportswear design and production. The ongoing research and development in this area promise to deliver sportswear that not only meets the performance needs of athletes but also aligns with the growing consumer demand for environmentally responsible products.

Material Advancements for Vacuum Forming in Sportswear

The advancements in materials for vacuum forming in sportswear have been pivotal in revolutionizing high-performance athletic apparel. Recent innovations have focused on developing lightweight, breathable, and highly durable materials that can withstand the rigors of vacuum forming while maintaining optimal performance characteristics.

One significant breakthrough has been the development of thermoplastic polyurethane (TPU) blends specifically engineered for vacuum forming applications in sportswear. These advanced TPU formulations offer enhanced elasticity, improved moisture-wicking properties, and superior resistance to abrasion and tearing. The ability to fine-tune the material's properties allows manufacturers to create sportswear that combines flexibility with targeted support in key areas.

Another notable advancement is the integration of nanofiber technology into vacuum-formable fabrics. These ultra-thin fibers, often less than 100 nanometers in diameter, can be incorporated into the base material to dramatically improve strength-to-weight ratios and enhance moisture management. When subjected to vacuum forming, these nanofiber-enhanced materials maintain their structural integrity while conforming precisely to complex body contours.

Researchers have also made strides in developing bio-based and sustainable materials suitable for vacuum forming in sportswear. These eco-friendly alternatives, derived from sources such as algae, bamboo, or recycled plastics, offer comparable performance to traditional synthetic materials while reducing the environmental impact of sportswear production. The challenge lies in optimizing these materials to withstand the heat and pressure involved in the vacuum forming process without compromising their sustainable attributes.

The incorporation of phase-change materials (PCMs) into vacuum-formable fabrics represents another frontier in sportswear innovation. These materials can absorb, store, and release heat in response to temperature fluctuations, providing athletes with dynamic thermoregulation. When vacuum-formed, PCM-infused sportswear can be tailored to specific body zones, offering targeted temperature control during intense physical activities.

Advancements in multi-layer composite materials have also expanded the possibilities for vacuum forming in sportswear design. By combining different materials with complementary properties, manufacturers can create apparel that offers a perfect balance of compression, support, and breathability. The vacuum forming process allows these multi-layer composites to be molded into complex shapes that conform precisely to the athlete's body, enhancing both comfort and performance.

One significant breakthrough has been the development of thermoplastic polyurethane (TPU) blends specifically engineered for vacuum forming applications in sportswear. These advanced TPU formulations offer enhanced elasticity, improved moisture-wicking properties, and superior resistance to abrasion and tearing. The ability to fine-tune the material's properties allows manufacturers to create sportswear that combines flexibility with targeted support in key areas.

Another notable advancement is the integration of nanofiber technology into vacuum-formable fabrics. These ultra-thin fibers, often less than 100 nanometers in diameter, can be incorporated into the base material to dramatically improve strength-to-weight ratios and enhance moisture management. When subjected to vacuum forming, these nanofiber-enhanced materials maintain their structural integrity while conforming precisely to complex body contours.

Researchers have also made strides in developing bio-based and sustainable materials suitable for vacuum forming in sportswear. These eco-friendly alternatives, derived from sources such as algae, bamboo, or recycled plastics, offer comparable performance to traditional synthetic materials while reducing the environmental impact of sportswear production. The challenge lies in optimizing these materials to withstand the heat and pressure involved in the vacuum forming process without compromising their sustainable attributes.

The incorporation of phase-change materials (PCMs) into vacuum-formable fabrics represents another frontier in sportswear innovation. These materials can absorb, store, and release heat in response to temperature fluctuations, providing athletes with dynamic thermoregulation. When vacuum-formed, PCM-infused sportswear can be tailored to specific body zones, offering targeted temperature control during intense physical activities.

Advancements in multi-layer composite materials have also expanded the possibilities for vacuum forming in sportswear design. By combining different materials with complementary properties, manufacturers can create apparel that offers a perfect balance of compression, support, and breathability. The vacuum forming process allows these multi-layer composites to be molded into complex shapes that conform precisely to the athlete's body, enhancing both comfort and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!