Validation of predictive maintenance models for gate valves

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Predictive Maintenance Model Background and Objectives

Predictive maintenance has emerged as a critical strategy in industrial operations, particularly for critical components such as gate valves. The evolution of this technology has been driven by the increasing need for operational efficiency, cost reduction, and minimization of unplanned downtime. Gate valves, being integral to fluid control systems across various industries, have become a focal point for predictive maintenance efforts.

The development of predictive maintenance models for gate valves has its roots in traditional preventive maintenance practices. However, the advent of advanced sensors, data analytics, and machine learning algorithms has revolutionized this field. The progression from reactive maintenance to condition-based maintenance, and finally to predictive maintenance, represents a significant technological leap in industrial asset management.

The primary objective of predictive maintenance models for gate valves is to accurately forecast potential failures before they occur. This involves continuous monitoring of valve performance parameters, analysis of historical data, and application of sophisticated algorithms to predict future behavior. The ultimate goal is to optimize maintenance schedules, extend equipment lifespan, and enhance overall system reliability.

Key technological trends in this domain include the integration of Internet of Things (IoT) devices for real-time data collection, the application of artificial intelligence and machine learning for pattern recognition and anomaly detection, and the development of digital twin technologies for virtual simulation and testing. These advancements have significantly improved the accuracy and reliability of predictive models.

The validation of these models is a critical step in ensuring their effectiveness and reliability in real-world applications. This process involves rigorous testing, comparison with historical data, and continuous refinement based on actual performance outcomes. The validation phase aims to confirm the model's ability to accurately predict valve failures, identify maintenance needs, and provide actionable insights for operational decision-making.

As the technology continues to evolve, there is a growing emphasis on developing more robust and adaptable models capable of handling diverse operational conditions and valve types. This includes efforts to incorporate a wider range of data sources, improve model interpretability, and enhance the integration of predictive maintenance systems with existing industrial control and management platforms.

The future trajectory of predictive maintenance models for gate valves is expected to focus on increasing precision, expanding applicability across different industries, and seamless integration with broader asset management strategies. The ultimate vision is to create a proactive maintenance ecosystem that not only predicts failures but also autonomously initiates and manages maintenance activities, leading to unprecedented levels of operational efficiency and reliability in industrial systems.

The development of predictive maintenance models for gate valves has its roots in traditional preventive maintenance practices. However, the advent of advanced sensors, data analytics, and machine learning algorithms has revolutionized this field. The progression from reactive maintenance to condition-based maintenance, and finally to predictive maintenance, represents a significant technological leap in industrial asset management.

The primary objective of predictive maintenance models for gate valves is to accurately forecast potential failures before they occur. This involves continuous monitoring of valve performance parameters, analysis of historical data, and application of sophisticated algorithms to predict future behavior. The ultimate goal is to optimize maintenance schedules, extend equipment lifespan, and enhance overall system reliability.

Key technological trends in this domain include the integration of Internet of Things (IoT) devices for real-time data collection, the application of artificial intelligence and machine learning for pattern recognition and anomaly detection, and the development of digital twin technologies for virtual simulation and testing. These advancements have significantly improved the accuracy and reliability of predictive models.

The validation of these models is a critical step in ensuring their effectiveness and reliability in real-world applications. This process involves rigorous testing, comparison with historical data, and continuous refinement based on actual performance outcomes. The validation phase aims to confirm the model's ability to accurately predict valve failures, identify maintenance needs, and provide actionable insights for operational decision-making.

As the technology continues to evolve, there is a growing emphasis on developing more robust and adaptable models capable of handling diverse operational conditions and valve types. This includes efforts to incorporate a wider range of data sources, improve model interpretability, and enhance the integration of predictive maintenance systems with existing industrial control and management platforms.

The future trajectory of predictive maintenance models for gate valves is expected to focus on increasing precision, expanding applicability across different industries, and seamless integration with broader asset management strategies. The ultimate vision is to create a proactive maintenance ecosystem that not only predicts failures but also autonomously initiates and manages maintenance activities, leading to unprecedented levels of operational efficiency and reliability in industrial systems.

Market Demand for Gate Valve Predictive Maintenance

The market demand for predictive maintenance solutions in gate valves has been steadily increasing due to the critical role these components play in various industries. Gate valves are essential in controlling fluid flow in pipelines, and their failure can lead to significant operational disruptions, safety hazards, and financial losses. As industries strive for greater efficiency and reliability, the need for advanced maintenance strategies has become paramount.

The oil and gas sector represents a substantial portion of the market demand for gate valve predictive maintenance. With extensive pipeline networks and high-pressure operations, this industry requires robust solutions to prevent unexpected valve failures. The petrochemical and chemical processing industries also contribute significantly to the market, as gate valves are crucial in managing the flow of various substances throughout production processes.

Water and wastewater treatment facilities have emerged as another key market segment. These plants rely heavily on gate valves for controlling water flow and distribution, making predictive maintenance essential for ensuring uninterrupted service to communities. The power generation sector, including nuclear, thermal, and hydroelectric plants, also demonstrates a growing demand for predictive maintenance solutions to enhance operational reliability and safety.

The market is driven by several factors, including the increasing focus on minimizing downtime and reducing maintenance costs. Traditional reactive maintenance approaches are being phased out in favor of predictive strategies that can identify potential issues before they escalate into critical failures. This shift is supported by advancements in sensor technologies, data analytics, and machine learning algorithms, which enable more accurate predictions of valve performance and remaining useful life.

Another significant driver is the growing emphasis on safety and regulatory compliance across industries. Predictive maintenance helps organizations meet stringent safety standards and environmental regulations by ensuring the proper functioning of gate valves and preventing leaks or emissions.

The adoption of Industrial Internet of Things (IIoT) technologies has further fueled the demand for predictive maintenance solutions. The integration of smart sensors and connectivity solutions allows for real-time monitoring of valve conditions, enabling more informed decision-making and optimized maintenance schedules.

Market analysts project a compound annual growth rate (CAGR) for the gate valve predictive maintenance market in the range of 25-30% over the next five years. This growth is attributed to the increasing awareness of the benefits of predictive maintenance, the rising costs associated with unexpected equipment failures, and the continuous technological advancements in predictive analytics capabilities.

As industries continue to prioritize operational excellence and asset optimization, the demand for gate valve predictive maintenance solutions is expected to expand further. This trend is likely to drive innovation in sensor technologies, data analysis techniques, and machine learning models specifically tailored for valve performance prediction and maintenance optimization.

The oil and gas sector represents a substantial portion of the market demand for gate valve predictive maintenance. With extensive pipeline networks and high-pressure operations, this industry requires robust solutions to prevent unexpected valve failures. The petrochemical and chemical processing industries also contribute significantly to the market, as gate valves are crucial in managing the flow of various substances throughout production processes.

Water and wastewater treatment facilities have emerged as another key market segment. These plants rely heavily on gate valves for controlling water flow and distribution, making predictive maintenance essential for ensuring uninterrupted service to communities. The power generation sector, including nuclear, thermal, and hydroelectric plants, also demonstrates a growing demand for predictive maintenance solutions to enhance operational reliability and safety.

The market is driven by several factors, including the increasing focus on minimizing downtime and reducing maintenance costs. Traditional reactive maintenance approaches are being phased out in favor of predictive strategies that can identify potential issues before they escalate into critical failures. This shift is supported by advancements in sensor technologies, data analytics, and machine learning algorithms, which enable more accurate predictions of valve performance and remaining useful life.

Another significant driver is the growing emphasis on safety and regulatory compliance across industries. Predictive maintenance helps organizations meet stringent safety standards and environmental regulations by ensuring the proper functioning of gate valves and preventing leaks or emissions.

The adoption of Industrial Internet of Things (IIoT) technologies has further fueled the demand for predictive maintenance solutions. The integration of smart sensors and connectivity solutions allows for real-time monitoring of valve conditions, enabling more informed decision-making and optimized maintenance schedules.

Market analysts project a compound annual growth rate (CAGR) for the gate valve predictive maintenance market in the range of 25-30% over the next five years. This growth is attributed to the increasing awareness of the benefits of predictive maintenance, the rising costs associated with unexpected equipment failures, and the continuous technological advancements in predictive analytics capabilities.

As industries continue to prioritize operational excellence and asset optimization, the demand for gate valve predictive maintenance solutions is expected to expand further. This trend is likely to drive innovation in sensor technologies, data analysis techniques, and machine learning models specifically tailored for valve performance prediction and maintenance optimization.

Current Challenges in Valve Maintenance Prediction

Predictive maintenance models for gate valves face several significant challenges in their validation process. One of the primary obstacles is the lack of comprehensive historical data on valve failures and maintenance activities. Many industrial facilities have not systematically collected or stored detailed information about valve performance, making it difficult to establish reliable baselines for predictive models.

The complexity of gate valve systems presents another challenge. These valves operate in diverse environments and are subject to various factors that can affect their performance, such as temperature, pressure, fluid composition, and operational cycles. Developing models that accurately account for all these variables and their interactions is a formidable task, often requiring sophisticated machine learning algorithms and extensive data preprocessing.

Data quality and consistency issues further complicate the validation process. Sensor data collected from valves may be noisy, incomplete, or inconsistent due to equipment malfunctions, communication errors, or human factors. Ensuring the integrity and reliability of input data is crucial for model validation but remains a persistent challenge in many industrial settings.

The dynamic nature of industrial processes adds another layer of complexity. Operating conditions and maintenance practices may change over time, potentially rendering historical data less relevant for future predictions. This necessitates continuous model updating and revalidation, which can be resource-intensive and technically challenging.

Balancing model complexity with interpretability is an ongoing struggle in valve maintenance prediction. While more complex models may offer higher accuracy, they often lack transparency, making it difficult for maintenance personnel to understand and trust the predictions. Simpler, more interpretable models may be preferred in practice but may sacrifice predictive power.

The scarcity of failure events poses a significant challenge for model validation. Gate valves are designed for reliability, and actual failures are relatively rare. This imbalance in the dataset makes it difficult to train and validate models effectively, particularly for predicting rare but critical failure modes.

Lastly, the validation of predictive maintenance models for gate valves is hindered by the lack of standardized performance metrics and validation methodologies specific to valve maintenance. Different industries and organizations may have varying criteria for what constitutes successful prediction, making it challenging to compare and benchmark different models across the field.

The complexity of gate valve systems presents another challenge. These valves operate in diverse environments and are subject to various factors that can affect their performance, such as temperature, pressure, fluid composition, and operational cycles. Developing models that accurately account for all these variables and their interactions is a formidable task, often requiring sophisticated machine learning algorithms and extensive data preprocessing.

Data quality and consistency issues further complicate the validation process. Sensor data collected from valves may be noisy, incomplete, or inconsistent due to equipment malfunctions, communication errors, or human factors. Ensuring the integrity and reliability of input data is crucial for model validation but remains a persistent challenge in many industrial settings.

The dynamic nature of industrial processes adds another layer of complexity. Operating conditions and maintenance practices may change over time, potentially rendering historical data less relevant for future predictions. This necessitates continuous model updating and revalidation, which can be resource-intensive and technically challenging.

Balancing model complexity with interpretability is an ongoing struggle in valve maintenance prediction. While more complex models may offer higher accuracy, they often lack transparency, making it difficult for maintenance personnel to understand and trust the predictions. Simpler, more interpretable models may be preferred in practice but may sacrifice predictive power.

The scarcity of failure events poses a significant challenge for model validation. Gate valves are designed for reliability, and actual failures are relatively rare. This imbalance in the dataset makes it difficult to train and validate models effectively, particularly for predicting rare but critical failure modes.

Lastly, the validation of predictive maintenance models for gate valves is hindered by the lack of standardized performance metrics and validation methodologies specific to valve maintenance. Different industries and organizations may have varying criteria for what constitutes successful prediction, making it challenging to compare and benchmark different models across the field.

Existing Predictive Maintenance Model Validation Methods

01 Data-driven predictive maintenance models

Utilizing machine learning and data analytics to develop predictive maintenance models for gate valves. These models analyze historical data, sensor readings, and operational parameters to forecast potential failures and optimize maintenance schedules.- Data-driven predictive maintenance models: Utilizing machine learning and data analytics to develop predictive maintenance models for gate valves. These models analyze historical data, sensor readings, and operational parameters to forecast potential failures and optimize maintenance schedules.

- Real-time monitoring and fault detection: Implementing real-time monitoring systems that continuously collect and analyze data from gate valves. These systems use advanced algorithms to detect anomalies, predict failures, and trigger maintenance alerts before critical issues occur.

- Validation techniques for predictive models: Developing and applying validation methodologies to ensure the accuracy and reliability of predictive maintenance models for gate valves. This includes cross-validation, performance metrics assessment, and comparison with actual maintenance outcomes.

- Integration of IoT and sensor technologies: Incorporating Internet of Things (IoT) devices and advanced sensors into gate valve systems to collect comprehensive data for predictive maintenance models. This enables more accurate predictions and facilitates remote monitoring capabilities.

- Adaptive maintenance scheduling: Implementing adaptive maintenance scheduling systems that dynamically adjust maintenance plans based on the predictions of validated models. This approach optimizes resource allocation and minimizes unnecessary maintenance activities while ensuring valve reliability.

02 Sensor-based monitoring systems

Implementing advanced sensor networks to continuously monitor gate valve performance. These systems collect real-time data on valve position, pressure, temperature, and other critical parameters to detect anomalies and predict maintenance needs.Expand Specific Solutions03 Validation techniques for predictive models

Developing and applying rigorous validation methodologies to ensure the accuracy and reliability of predictive maintenance models for gate valves. This includes cross-validation, historical data comparison, and real-world testing to verify model performance.Expand Specific Solutions04 Integration with control systems

Incorporating predictive maintenance models into existing control systems for gate valves. This integration allows for automated adjustments, alerts, and maintenance scheduling based on model predictions, improving overall system efficiency and reliability.Expand Specific Solutions05 Failure mode analysis and prediction

Conducting comprehensive failure mode analysis to identify potential causes of gate valve malfunctions. This information is used to enhance predictive models, enabling more accurate forecasting of specific failure types and targeted maintenance interventions.Expand Specific Solutions

Key Players in Valve Predictive Maintenance Industry

The validation of predictive maintenance models for gate valves is currently in an emerging stage, with the market showing significant growth potential. The global predictive maintenance market is expanding rapidly, driven by Industry 4.0 initiatives and the increasing adoption of IoT technologies. Companies like Azbil Corp., Cummins, Inc., and Hitachi Ltd. are at the forefront of developing advanced predictive maintenance solutions, leveraging their expertise in industrial automation and data analytics. The technology is maturing, with machine learning algorithms and sensor technologies improving model accuracy. However, challenges remain in data integration and model validation across diverse valve types and operating conditions, indicating that the field is still evolving towards full maturity.

Azbil Corp.

Technical Solution: Azbil Corporation has developed a valve predictive maintenance system that combines their expertise in control valve technology with advanced analytics. Their approach utilizes a combination of acoustic emissions analysis and machine learning algorithms to detect and predict valve failures. Azbil's system employs specialized sensors to capture high-frequency sound waves emitted by valves during operation. These acoustic signatures are then analyzed using proprietary algorithms to identify patterns indicative of wear, leakage, or impending failure. The system also incorporates process data and historical maintenance records to enhance prediction accuracy. Azbil's solution provides real-time monitoring and alerts, allowing for timely intervention and maintenance planning[2][4].

Strengths: Non-invasive monitoring technique, high sensitivity to early-stage defects. Weaknesses: May be affected by ambient noise in industrial environments, potentially requiring additional noise reduction measures.

Dresser LLC

Technical Solution: Dresser LLC has developed a comprehensive predictive maintenance solution for gate valves, leveraging their extensive experience in valve manufacturing. Their system utilizes a multi-sensor approach, combining pressure, temperature, and position sensors with advanced flow modeling techniques. Dresser's predictive maintenance model incorporates machine learning algorithms that analyze both real-time and historical data to identify patterns and anomalies indicative of valve degradation. The system also takes into account environmental factors and operational conditions to improve prediction accuracy. Dresser's solution includes a user-friendly interface that provides maintenance personnel with actionable insights and recommended maintenance schedules[5][6].

Strengths: Comprehensive sensor integration, industry-specific expertise in valve design and operation. Weaknesses: May require regular model updates to account for new valve designs or operational scenarios.

Core Innovations in Gate Valve Failure Prediction

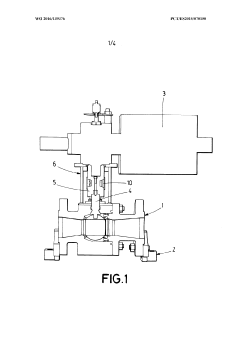

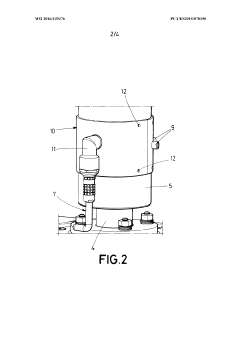

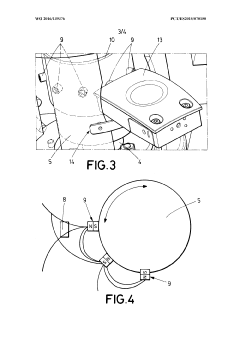

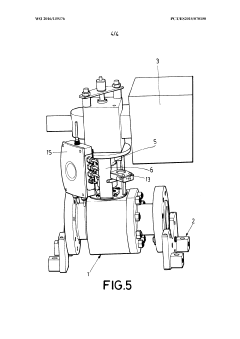

System for the predictive maintenance of valves and method for carrying out said maintenance

PatentWO2016139376A1

Innovation

- A predictive maintenance system utilizing torque and position sensors to record and analyze valve operation data, generating torque-position curves to anticipate potential failures, reduce maintenance costs, and provide real-time reporting and alarms, which can be adapted for various valve types and installations, including remote locations without internet access.

Valve diagnosis method and valve diagnosis device

PatentWO2017169849A1

Innovation

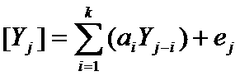

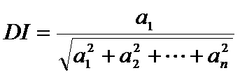

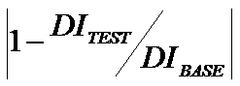

- A valve diagnostic method using an autoregressive model to calculate damage indices and rate of change values from vibration data, allowing for non-destructive prediction of valve state changes and constant monitoring without the need for structural analysis models or permanent sensors.

Regulatory Framework for Industrial Maintenance Models

The regulatory framework for industrial maintenance models, particularly in the context of predictive maintenance for gate valves, is a complex and evolving landscape. Regulatory bodies across different regions have recognized the importance of ensuring the reliability and safety of industrial equipment through proper maintenance practices.

In the United States, the Occupational Safety and Health Administration (OSHA) has established guidelines for process safety management that indirectly impact predictive maintenance models. These regulations require facilities to implement and maintain written procedures for the ongoing integrity of process equipment, including valves. The Environmental Protection Agency (EPA) also enforces regulations that necessitate proper maintenance of equipment to prevent environmental hazards.

The European Union has implemented the Machinery Directive (2006/42/EC), which sets out essential health and safety requirements for machinery. This directive indirectly influences the development and implementation of predictive maintenance models by emphasizing the importance of safe and reliable equipment operation throughout its lifecycle.

In the specific context of gate valves, industry standards such as those set by the American Petroleum Institute (API) and the International Organization for Standardization (ISO) play a crucial role. These standards often serve as the basis for regulatory compliance and provide guidelines for maintenance practices, including the use of predictive models.

The validation of predictive maintenance models for gate valves must adhere to these regulatory frameworks and industry standards. This typically involves demonstrating that the models can accurately predict equipment failures, optimize maintenance schedules, and contribute to overall system reliability and safety.

Regulatory bodies are increasingly recognizing the potential of advanced analytics and machine learning in industrial maintenance. However, the use of these technologies also raises questions about data privacy, cybersecurity, and the interpretability of model outputs. As a result, regulations are evolving to address these concerns, with some jurisdictions requiring transparency in algorithmic decision-making processes.

The integration of predictive maintenance models into safety-critical systems, such as those in nuclear power plants or offshore oil platforms, is subject to particularly stringent regulations. In these cases, model validation processes must meet rigorous standards and may require certification by regulatory authorities before implementation.

As the field of predictive maintenance continues to advance, it is likely that regulatory frameworks will adapt to keep pace with technological developments. This may include the establishment of specific guidelines for the validation and certification of AI-driven maintenance models, ensuring that they meet the necessary standards for reliability, accuracy, and safety in industrial applications.

In the United States, the Occupational Safety and Health Administration (OSHA) has established guidelines for process safety management that indirectly impact predictive maintenance models. These regulations require facilities to implement and maintain written procedures for the ongoing integrity of process equipment, including valves. The Environmental Protection Agency (EPA) also enforces regulations that necessitate proper maintenance of equipment to prevent environmental hazards.

The European Union has implemented the Machinery Directive (2006/42/EC), which sets out essential health and safety requirements for machinery. This directive indirectly influences the development and implementation of predictive maintenance models by emphasizing the importance of safe and reliable equipment operation throughout its lifecycle.

In the specific context of gate valves, industry standards such as those set by the American Petroleum Institute (API) and the International Organization for Standardization (ISO) play a crucial role. These standards often serve as the basis for regulatory compliance and provide guidelines for maintenance practices, including the use of predictive models.

The validation of predictive maintenance models for gate valves must adhere to these regulatory frameworks and industry standards. This typically involves demonstrating that the models can accurately predict equipment failures, optimize maintenance schedules, and contribute to overall system reliability and safety.

Regulatory bodies are increasingly recognizing the potential of advanced analytics and machine learning in industrial maintenance. However, the use of these technologies also raises questions about data privacy, cybersecurity, and the interpretability of model outputs. As a result, regulations are evolving to address these concerns, with some jurisdictions requiring transparency in algorithmic decision-making processes.

The integration of predictive maintenance models into safety-critical systems, such as those in nuclear power plants or offshore oil platforms, is subject to particularly stringent regulations. In these cases, model validation processes must meet rigorous standards and may require certification by regulatory authorities before implementation.

As the field of predictive maintenance continues to advance, it is likely that regulatory frameworks will adapt to keep pace with technological developments. This may include the establishment of specific guidelines for the validation and certification of AI-driven maintenance models, ensuring that they meet the necessary standards for reliability, accuracy, and safety in industrial applications.

Economic Impact of Predictive Maintenance Implementation

The implementation of predictive maintenance models for gate valves can have significant economic impacts across various industries. By accurately predicting potential failures and optimizing maintenance schedules, organizations can realize substantial cost savings and operational improvements.

One of the primary economic benefits is the reduction in unplanned downtime. Gate valves are critical components in many industrial processes, and their unexpected failure can lead to costly production interruptions. Predictive maintenance models enable companies to schedule maintenance activities during planned shutdowns, minimizing disruptions to operations and preserving revenue streams.

Furthermore, these models contribute to extending the lifespan of gate valves. By addressing potential issues before they escalate, organizations can avoid premature equipment replacement, thereby reducing capital expenditures. This approach also optimizes inventory management, as maintenance teams can better anticipate spare part requirements, reducing excess inventory costs while ensuring critical components are available when needed.

The implementation of predictive maintenance models also leads to more efficient resource allocation. Maintenance personnel can be deployed more strategically, focusing on high-priority tasks identified by the models. This optimization of human resources can result in reduced labor costs and improved productivity across maintenance operations.

Energy efficiency is another area where economic benefits can be realized. Well-maintained gate valves operate more efficiently, reducing energy consumption in fluid handling systems. Over time, these energy savings can translate into significant cost reductions, particularly in energy-intensive industries.

Additionally, predictive maintenance models can enhance safety performance, potentially reducing incidents and associated costs such as worker compensation, regulatory fines, and reputational damage. By proactively addressing potential failure modes, organizations can mitigate risks and create safer working environments.

The economic impact extends beyond direct cost savings. Improved reliability and performance of gate valves can lead to enhanced product quality and customer satisfaction. This, in turn, can strengthen market position, potentially leading to increased sales and market share.

However, it is important to consider the initial investment required for implementing predictive maintenance models. This includes costs associated with sensor installation, data collection infrastructure, and analytics platforms. Organizations must carefully evaluate the return on investment, considering both short-term implementation costs and long-term operational benefits.

In conclusion, while the economic impact of predictive maintenance model implementation for gate valves can be substantial, it requires a comprehensive assessment of an organization's specific operational context and strategic objectives to fully realize its potential benefits.

One of the primary economic benefits is the reduction in unplanned downtime. Gate valves are critical components in many industrial processes, and their unexpected failure can lead to costly production interruptions. Predictive maintenance models enable companies to schedule maintenance activities during planned shutdowns, minimizing disruptions to operations and preserving revenue streams.

Furthermore, these models contribute to extending the lifespan of gate valves. By addressing potential issues before they escalate, organizations can avoid premature equipment replacement, thereby reducing capital expenditures. This approach also optimizes inventory management, as maintenance teams can better anticipate spare part requirements, reducing excess inventory costs while ensuring critical components are available when needed.

The implementation of predictive maintenance models also leads to more efficient resource allocation. Maintenance personnel can be deployed more strategically, focusing on high-priority tasks identified by the models. This optimization of human resources can result in reduced labor costs and improved productivity across maintenance operations.

Energy efficiency is another area where economic benefits can be realized. Well-maintained gate valves operate more efficiently, reducing energy consumption in fluid handling systems. Over time, these energy savings can translate into significant cost reductions, particularly in energy-intensive industries.

Additionally, predictive maintenance models can enhance safety performance, potentially reducing incidents and associated costs such as worker compensation, regulatory fines, and reputational damage. By proactively addressing potential failure modes, organizations can mitigate risks and create safer working environments.

The economic impact extends beyond direct cost savings. Improved reliability and performance of gate valves can lead to enhanced product quality and customer satisfaction. This, in turn, can strengthen market position, potentially leading to increased sales and market share.

However, it is important to consider the initial investment required for implementing predictive maintenance models. This includes costs associated with sensor installation, data collection infrastructure, and analytics platforms. Organizations must carefully evaluate the return on investment, considering both short-term implementation costs and long-term operational benefits.

In conclusion, while the economic impact of predictive maintenance model implementation for gate valves can be substantial, it requires a comprehensive assessment of an organization's specific operational context and strategic objectives to fully realize its potential benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!