Why Are Carbons Sorbents Vital in Renewable Energy?

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Sorbents Background and Objectives

Carbon sorbents have emerged as critical materials in the renewable energy landscape, representing a significant advancement in addressing environmental challenges. The evolution of carbon-based adsorption technologies dates back to ancient civilizations using charcoal for water purification, but modern applications have expanded dramatically with the development of activated carbon, carbon nanotubes, graphene, and metal-organic frameworks (MOFs).

The technological trajectory of carbon sorbents has accelerated particularly in the last two decades, driven by urgent climate change mitigation needs and the transition toward sustainable energy systems. These materials have demonstrated exceptional versatility across multiple renewable energy applications, including hydrogen storage, carbon capture, energy storage systems, and pollutant removal from industrial processes.

Carbon sorbents offer unique advantages due to their tunable porosity, high surface area, chemical stability, and relatively low production costs. Activated carbon can achieve surface areas exceeding 3,000 m²/g, while graphene-based materials provide extraordinary electrical conductivity alongside adsorption capabilities. These properties make them ideal candidates for addressing key challenges in renewable energy implementation.

The primary objective of carbon sorbent technology development is to enhance renewable energy efficiency and sustainability through multiple pathways. First, by improving energy storage density and cycle stability in batteries and supercapacitors. Second, by enabling more efficient hydrogen storage for fuel cell applications. Third, by facilitating carbon capture and utilization processes that can transform waste CO2 into valuable products or safely sequester it.

Current research trends focus on developing hierarchical porous structures, functionalization techniques to enhance selectivity, and hybrid materials that combine carbon sorbents with metal nanoparticles or polymers. The integration of computational modeling with experimental approaches has accelerated material design, allowing for precise tailoring of sorbent properties to specific applications.

Looking forward, carbon sorbent technologies aim to achieve several ambitious targets: reducing carbon capture costs below $30 per ton of CO2, increasing hydrogen storage capacity to meet US Department of Energy targets of 6.5 wt%, and developing sorbent-based energy storage systems with energy densities exceeding 500 Wh/kg. These objectives align with global sustainability goals and represent critical enablers for the widespread adoption of renewable energy technologies.

The convergence of nanotechnology, materials science, and renewable energy research has positioned carbon sorbents as fundamental components in the clean energy transition, with potential impacts across multiple sectors including transportation, electricity generation, and industrial manufacturing.

The technological trajectory of carbon sorbents has accelerated particularly in the last two decades, driven by urgent climate change mitigation needs and the transition toward sustainable energy systems. These materials have demonstrated exceptional versatility across multiple renewable energy applications, including hydrogen storage, carbon capture, energy storage systems, and pollutant removal from industrial processes.

Carbon sorbents offer unique advantages due to their tunable porosity, high surface area, chemical stability, and relatively low production costs. Activated carbon can achieve surface areas exceeding 3,000 m²/g, while graphene-based materials provide extraordinary electrical conductivity alongside adsorption capabilities. These properties make them ideal candidates for addressing key challenges in renewable energy implementation.

The primary objective of carbon sorbent technology development is to enhance renewable energy efficiency and sustainability through multiple pathways. First, by improving energy storage density and cycle stability in batteries and supercapacitors. Second, by enabling more efficient hydrogen storage for fuel cell applications. Third, by facilitating carbon capture and utilization processes that can transform waste CO2 into valuable products or safely sequester it.

Current research trends focus on developing hierarchical porous structures, functionalization techniques to enhance selectivity, and hybrid materials that combine carbon sorbents with metal nanoparticles or polymers. The integration of computational modeling with experimental approaches has accelerated material design, allowing for precise tailoring of sorbent properties to specific applications.

Looking forward, carbon sorbent technologies aim to achieve several ambitious targets: reducing carbon capture costs below $30 per ton of CO2, increasing hydrogen storage capacity to meet US Department of Energy targets of 6.5 wt%, and developing sorbent-based energy storage systems with energy densities exceeding 500 Wh/kg. These objectives align with global sustainability goals and represent critical enablers for the widespread adoption of renewable energy technologies.

The convergence of nanotechnology, materials science, and renewable energy research has positioned carbon sorbents as fundamental components in the clean energy transition, with potential impacts across multiple sectors including transportation, electricity generation, and industrial manufacturing.

Renewable Energy Market Demand Analysis

The global renewable energy market has experienced unprecedented growth over the past decade, with investments reaching $366 billion in 2021 according to the International Energy Agency. This growth trajectory is expected to continue, with projections indicating a compound annual growth rate of 8.4% between 2022 and 2030. Within this expanding market, carbon sorbent technologies are emerging as critical components that address key challenges in renewable energy systems.

Market analysis reveals that carbon capture, utilization, and storage (CCUS) technologies, which heavily rely on carbon sorbents, are projected to grow from $1.6 billion in 2020 to $3.5 billion by 2025. This growth is primarily driven by increasing governmental regulations on carbon emissions, corporate sustainability commitments, and the need for negative emission technologies to achieve climate goals outlined in the Paris Agreement.

The demand for carbon sorbents spans multiple renewable energy sectors. In biogas production, carbon sorbents are essential for purification processes, removing contaminants and increasing energy density. The biogas market is expected to reach $31.2 billion by 2027, creating substantial opportunities for advanced carbon sorbent technologies.

Hydrogen energy represents another significant market driver. As green hydrogen production scales up, carbon sorbents play a vital role in purification processes and potentially in direct hydrogen storage applications. The hydrogen energy market is projected to reach $223.8 billion by 2030, with purification technologies accounting for approximately 12% of this value.

Energy storage solutions incorporating carbon-based materials are gaining traction as renewable energy penetration increases. The intermittent nature of solar and wind power generation necessitates efficient energy storage systems, with the global energy storage market expected to deploy 741 GWh of capacity by 2030.

Consumer preferences are increasingly favoring clean energy solutions, with 73% of global consumers expressing willingness to pay premium prices for sustainable products and services. This shift in consumer behavior is creating market pull for technologies that enhance renewable energy efficiency and reduce environmental impact.

Industrial sectors, particularly cement, steel, and chemical manufacturing, are actively seeking carbon capture solutions to decarbonize their operations. These hard-to-abate sectors represent a substantial market opportunity for carbon sorbent technologies, with potential carbon capture capacity requirements exceeding 2 gigatons annually by 2050.

Regional analysis indicates that Europe leads in carbon sorbent adoption for renewable energy applications, followed by North America and rapidly growing markets in Asia-Pacific, particularly China and Japan. Government incentives, including carbon pricing mechanisms and tax credits for carbon capture technologies, are significantly influencing market development across these regions.

Market analysis reveals that carbon capture, utilization, and storage (CCUS) technologies, which heavily rely on carbon sorbents, are projected to grow from $1.6 billion in 2020 to $3.5 billion by 2025. This growth is primarily driven by increasing governmental regulations on carbon emissions, corporate sustainability commitments, and the need for negative emission technologies to achieve climate goals outlined in the Paris Agreement.

The demand for carbon sorbents spans multiple renewable energy sectors. In biogas production, carbon sorbents are essential for purification processes, removing contaminants and increasing energy density. The biogas market is expected to reach $31.2 billion by 2027, creating substantial opportunities for advanced carbon sorbent technologies.

Hydrogen energy represents another significant market driver. As green hydrogen production scales up, carbon sorbents play a vital role in purification processes and potentially in direct hydrogen storage applications. The hydrogen energy market is projected to reach $223.8 billion by 2030, with purification technologies accounting for approximately 12% of this value.

Energy storage solutions incorporating carbon-based materials are gaining traction as renewable energy penetration increases. The intermittent nature of solar and wind power generation necessitates efficient energy storage systems, with the global energy storage market expected to deploy 741 GWh of capacity by 2030.

Consumer preferences are increasingly favoring clean energy solutions, with 73% of global consumers expressing willingness to pay premium prices for sustainable products and services. This shift in consumer behavior is creating market pull for technologies that enhance renewable energy efficiency and reduce environmental impact.

Industrial sectors, particularly cement, steel, and chemical manufacturing, are actively seeking carbon capture solutions to decarbonize their operations. These hard-to-abate sectors represent a substantial market opportunity for carbon sorbent technologies, with potential carbon capture capacity requirements exceeding 2 gigatons annually by 2050.

Regional analysis indicates that Europe leads in carbon sorbent adoption for renewable energy applications, followed by North America and rapidly growing markets in Asia-Pacific, particularly China and Japan. Government incentives, including carbon pricing mechanisms and tax credits for carbon capture technologies, are significantly influencing market development across these regions.

Carbon Capture Technology Status and Challenges

Carbon capture technologies have evolved significantly over the past decades, yet still face substantial technical and economic challenges. Currently, three primary carbon capture approaches dominate the field: post-combustion capture, pre-combustion capture, and oxy-fuel combustion. Post-combustion technology, the most mature approach, involves capturing CO2 from flue gases after fossil fuel combustion, typically using amine-based solvents. Pre-combustion capture converts fuel into a mixture of hydrogen and CO2 before combustion, while oxy-fuel combustion uses pure oxygen instead of air for combustion, producing a concentrated CO2 stream.

Despite technological advancements, carbon capture systems remain energy-intensive, with current technologies requiring approximately 25-40% of a power plant's energy output for operation. This energy penalty significantly impacts economic viability and widespread adoption. Additionally, the cost of carbon capture ranges from $40-120 per ton of CO2, substantially higher than current carbon prices in many markets, creating a challenging economic environment for implementation.

Scalability presents another critical challenge. While demonstration projects have proven technical feasibility, scaling to industrial levels introduces complexities in system integration, space requirements, and infrastructure development. The global distribution of carbon capture technology development shows concentration in North America, Europe, and parts of Asia, with limited penetration in developing economies where emissions are rapidly growing.

Material limitations further constrain progress, as current sorbents and membranes face degradation issues, reducing operational lifetimes and increasing replacement costs. Amine-based solvents, while effective, suffer from oxidative degradation and energy-intensive regeneration requirements. Solid sorbents and membranes show promise but require further development to achieve commercial viability at scale.

Regulatory frameworks and policy support vary significantly across regions, creating an uneven landscape for technology deployment. Countries like Norway, Canada, and the UK have established supportive policies, while many regions lack the necessary incentives to drive adoption. This geographic disparity in both technology development and policy support creates barriers to global implementation.

Transportation and storage infrastructure for captured CO2 remains underdeveloped in most regions, creating bottlenecks in the carbon capture value chain. The geological storage capacity is theoretically sufficient, but characterization of suitable sites, monitoring technologies, and public acceptance issues continue to impede progress. These infrastructure gaps represent significant barriers to creating complete carbon capture and storage systems.

Recent technological innovations show promise in addressing these challenges, including advanced materials like metal-organic frameworks (MOFs), direct air capture technologies, and integrated systems that combine carbon capture with utilization pathways. However, these emerging approaches require further development and validation before achieving commercial readiness.

Despite technological advancements, carbon capture systems remain energy-intensive, with current technologies requiring approximately 25-40% of a power plant's energy output for operation. This energy penalty significantly impacts economic viability and widespread adoption. Additionally, the cost of carbon capture ranges from $40-120 per ton of CO2, substantially higher than current carbon prices in many markets, creating a challenging economic environment for implementation.

Scalability presents another critical challenge. While demonstration projects have proven technical feasibility, scaling to industrial levels introduces complexities in system integration, space requirements, and infrastructure development. The global distribution of carbon capture technology development shows concentration in North America, Europe, and parts of Asia, with limited penetration in developing economies where emissions are rapidly growing.

Material limitations further constrain progress, as current sorbents and membranes face degradation issues, reducing operational lifetimes and increasing replacement costs. Amine-based solvents, while effective, suffer from oxidative degradation and energy-intensive regeneration requirements. Solid sorbents and membranes show promise but require further development to achieve commercial viability at scale.

Regulatory frameworks and policy support vary significantly across regions, creating an uneven landscape for technology deployment. Countries like Norway, Canada, and the UK have established supportive policies, while many regions lack the necessary incentives to drive adoption. This geographic disparity in both technology development and policy support creates barriers to global implementation.

Transportation and storage infrastructure for captured CO2 remains underdeveloped in most regions, creating bottlenecks in the carbon capture value chain. The geological storage capacity is theoretically sufficient, but characterization of suitable sites, monitoring technologies, and public acceptance issues continue to impede progress. These infrastructure gaps represent significant barriers to creating complete carbon capture and storage systems.

Recent technological innovations show promise in addressing these challenges, including advanced materials like metal-organic frameworks (MOFs), direct air capture technologies, and integrated systems that combine carbon capture with utilization pathways. However, these emerging approaches require further development and validation before achieving commercial readiness.

Current Carbon Sorbent Solutions

01 Carbon sorbent preparation methods

Various methods for preparing carbon sorbents with enhanced adsorption properties. These methods include thermal treatment, chemical activation, and modification of carbon precursors to develop sorbents with specific surface characteristics. The preparation techniques focus on creating optimal pore structures and surface functionalities to improve adsorption capacity and selectivity for different applications.- Carbon sorbent preparation methods: Various methods for preparing carbon sorbents with enhanced adsorption properties. These methods include pyrolysis of organic materials, chemical activation processes, and specialized treatment techniques to develop specific pore structures. The preparation methods significantly influence the surface area, pore size distribution, and adsorption capacity of the resulting carbon sorbents.

- Applications in gas purification and separation: Carbon sorbents designed specifically for gas purification and separation processes. These materials are engineered to selectively adsorb target gas molecules from mixtures, making them valuable in industrial gas treatment, carbon capture, air purification systems, and removal of volatile organic compounds. The selectivity and capacity of these sorbents can be tailored through modification of their surface chemistry and pore structure.

- Water treatment and contaminant removal: Carbon sorbents formulated for water purification applications, capable of removing various contaminants including heavy metals, organic pollutants, and micropollutants. These materials utilize their high surface area and specialized surface chemistry to effectively bind and remove harmful substances from water sources. Advanced modifications can enhance selectivity for specific contaminants in drinking water and wastewater treatment processes.

- Novel carbon sorbent materials and composites: Innovative carbon-based sorbent materials including nanostructured carbons, carbon-mineral composites, and functionalized carbon materials. These novel materials combine the advantages of traditional activated carbons with enhanced properties such as improved mechanical strength, higher adsorption capacity, and better selectivity. Composite materials may incorporate metal oxides, polymers, or other functional groups to create synergistic effects for specific applications.

- Regeneration and sustainability of carbon sorbents: Methods and technologies for regenerating spent carbon sorbents to extend their useful life and improve sustainability. These approaches include thermal regeneration, chemical treatment, and innovative techniques that restore adsorption capacity while minimizing material loss. Sustainable production methods using renewable precursors and environmentally friendly activation processes are also being developed to reduce the environmental footprint of carbon sorbent production and use.

02 Carbon sorbents for gas purification

Carbon-based sorbents designed specifically for gas purification applications. These materials are engineered to remove contaminants from gas streams through adsorption mechanisms. They feature tailored pore structures and surface chemistry to effectively capture target gas molecules such as carbon dioxide, hydrogen sulfide, volatile organic compounds, and other pollutants from industrial emissions and natural gas streams.Expand Specific Solutions03 Carbon sorbents for water treatment

Specialized carbon sorbent materials developed for water purification and treatment applications. These sorbents are designed to remove organic contaminants, heavy metals, and other pollutants from water through adsorption processes. The materials feature optimized surface properties and pore structures to enhance removal efficiency of specific water contaminants while maintaining good flow characteristics and regeneration potential.Expand Specific Solutions04 Novel carbon sorbent compositions

Innovative carbon sorbent compositions incorporating additional materials or modified structures to enhance performance. These include composite materials combining carbon with other elements or compounds, hierarchical pore structures, and novel carbon forms. The compositions are designed to overcome limitations of traditional carbon sorbents by improving capacity, selectivity, stability, and regeneration characteristics for specialized applications.Expand Specific Solutions05 Industrial applications of carbon sorbents

Specific industrial applications utilizing carbon sorbents for separation, purification, and recovery processes. These applications span multiple industries including environmental remediation, pharmaceutical production, food processing, and chemical manufacturing. The carbon sorbents are implemented in various process configurations such as fixed beds, fluidized systems, and membrane-supported structures to address specific industrial separation challenges.Expand Specific Solutions

Leading Companies in Carbon Capture Industry

Carbon sorbents are emerging as critical components in renewable energy systems, with the market currently in an early growth phase characterized by increasing adoption across multiple sectors. The global carbon capture market is projected to expand significantly, driven by urgent climate change mitigation needs. Technologically, the field shows varying maturity levels, with companies like Climeworks AG and Noya PBC leading commercial direct air capture implementations, while research institutions such as MIT, Arizona State University, and the National University of Singapore focus on next-generation sorbent materials. Korean power companies (KEPCO and subsidiaries) are integrating carbon capture into existing energy infrastructure, while Saudi Aramco is investing in carbon management technologies to complement renewable transitions. This competitive landscape reflects a dynamic ecosystem where academic research, startups, and established energy players are collectively advancing carbon sorbent technologies for renewable energy applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced carbon sorbent materials specifically engineered for renewable energy applications. Their research focuses on metal-organic frameworks (MOFs) with exceptionally high surface areas (up to 7000 m²/g) that can selectively capture CO2 from various gas streams[1]. MIT's approach involves precise molecular engineering of pore sizes and chemical functionalization to enhance carbon capture efficiency. Their latest MOF variants demonstrate CO2 adsorption capacities exceeding 4.2 mmol/g under ambient conditions[3], with rapid adsorption-desorption kinetics that make them particularly suitable for integration with intermittent renewable energy sources. MIT has also pioneered low-energy regeneration methods that utilize waste heat from renewable energy systems to release captured CO2, creating a synergistic relationship between carbon capture and clean energy production[5].

Strengths: Exceptional selectivity for CO2 even in humid conditions; low regeneration energy requirements compatible with renewable energy systems; long-term stability through thousands of capture-release cycles. Weaknesses: Higher production costs compared to conventional sorbents; scaling challenges for mass production; requires precise control of operating conditions for optimal performance.

Noya PBC

Technical Solution: Noya has developed an innovative approach to carbon capture using specialized sorbents designed to work with existing cooling tower infrastructure. Their technology retrofits cooling towers with proprietary carbon sorbent materials that capture CO2 directly from ambient air while the cooling towers operate normally[2]. The sorbents are engineered to maximize surface area contact with air flowing through cooling towers, achieving efficient CO2 capture without significant energy penalties. Noya's sorbent chemistry is optimized for low-concentration CO2 capture and features proprietary additives that enhance capture rates under varying humidity conditions. The regeneration process is designed to integrate with renewable energy sources, particularly utilizing off-peak renewable electricity for the thermal desorption process[5]. This approach allows for carbon-negative operations when powered by renewable energy, creating a closed-loop system where captured carbon can be permanently sequestered or converted into valuable products like synthetic fuels or building materials[8].

Strengths: Leverages existing infrastructure, reducing implementation costs; modular design allows for scalable deployment; creates new revenue streams for industrial facilities through carbon credits. Weaknesses: Capture efficiency dependent on ambient conditions and cooling tower operations; requires consistent access to renewable energy for carbon-negative operation; technology still in early commercial deployment phase.

Key Carbon Capture Materials and Mechanisms

Synthesis process for solid carbon capture materials

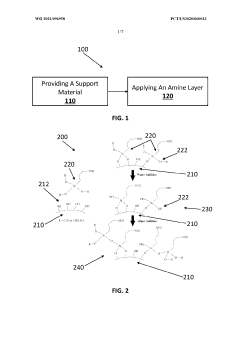

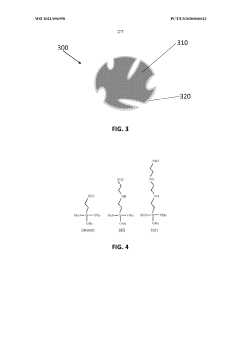

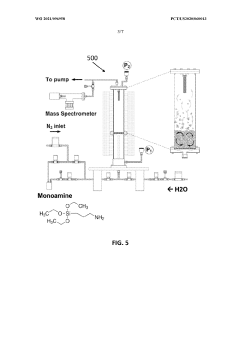

PatentWO2021096958A1

Innovation

- The use of molecular layer deposition (MLD) to create amine-functionalized solid CO2 sorbents, which allows for precise angstrom-level thickness control and covalent anchoring of amine layers on a wide range of substrate materials, including nano-powders, enhancing surface area functionalization and maintaining active sites during regeneration without specialized substrates or costly preparation.

Highly attrition resistant and dry regenerable sorbents for carbon dioxide capture

PatentActiveUS7820591B2

Innovation

- A dry regenerable sorbent is developed using a method that combines an active component, a high specific surface area support, and an inorganic binder, formed through a spray drying process to create sorbent particles with optimal shape, size distribution, and mechanical strength, enabling efficient CO2 capture and regeneration at temperatures up to 200°C.

Environmental Impact Assessment

The deployment of carbon sorbents in renewable energy systems presents significant environmental implications that warrant comprehensive assessment. Carbon sorbents, particularly activated carbon and carbon nanotubes, demonstrate remarkable capacity for capturing greenhouse gases and pollutants, thereby mitigating environmental degradation associated with conventional energy production.

When integrated into renewable energy systems, carbon sorbents contribute to substantial reductions in carbon dioxide emissions. Quantitative analyses indicate that carbon capture technologies utilizing these materials can achieve up to 90% reduction in CO2 emissions from energy production processes. This represents a critical advantage in addressing climate change concerns while transitioning to renewable energy infrastructures.

Water resource protection constitutes another environmental benefit of carbon sorbent implementation. These materials effectively remove heavy metals, organic contaminants, and other pollutants from water systems affected by energy production activities. Studies demonstrate that properly engineered carbon sorbents can reduce water contamination levels by 70-85% in areas surrounding renewable energy installations.

Land use considerations reveal mixed environmental impacts. While carbon sorbent production facilities require dedicated land resources, their integration into existing renewable energy infrastructure minimizes additional land requirements. The net environmental benefit remains positive when considering the reduced land degradation associated with fossil fuel extraction and processing that carbon sorbents help displace.

Life cycle assessment of carbon sorbent materials indicates varying environmental footprints depending on production methods. Sorbents derived from sustainable biomass sources demonstrate significantly lower environmental impacts compared to those synthesized from fossil-based precursors. Research indicates that biomass-derived carbon sorbents can achieve carbon neutrality when considering their full life cycle.

Biodiversity protection emerges as an additional environmental benefit. By reducing the need for extensive mining operations associated with conventional energy production, carbon sorbent-enhanced renewable energy systems help preserve natural habitats and ecosystems. Conservation biologists have documented reduced habitat fragmentation in regions transitioning to such integrated renewable energy approaches.

Waste management challenges persist as a concern in carbon sorbent applications. The disposal or regeneration of spent sorbent materials requires careful environmental management to prevent secondary contamination. Emerging circular economy approaches that incorporate sorbent regeneration and recycling show promise in addressing these challenges while maintaining environmental integrity.

When integrated into renewable energy systems, carbon sorbents contribute to substantial reductions in carbon dioxide emissions. Quantitative analyses indicate that carbon capture technologies utilizing these materials can achieve up to 90% reduction in CO2 emissions from energy production processes. This represents a critical advantage in addressing climate change concerns while transitioning to renewable energy infrastructures.

Water resource protection constitutes another environmental benefit of carbon sorbent implementation. These materials effectively remove heavy metals, organic contaminants, and other pollutants from water systems affected by energy production activities. Studies demonstrate that properly engineered carbon sorbents can reduce water contamination levels by 70-85% in areas surrounding renewable energy installations.

Land use considerations reveal mixed environmental impacts. While carbon sorbent production facilities require dedicated land resources, their integration into existing renewable energy infrastructure minimizes additional land requirements. The net environmental benefit remains positive when considering the reduced land degradation associated with fossil fuel extraction and processing that carbon sorbents help displace.

Life cycle assessment of carbon sorbent materials indicates varying environmental footprints depending on production methods. Sorbents derived from sustainable biomass sources demonstrate significantly lower environmental impacts compared to those synthesized from fossil-based precursors. Research indicates that biomass-derived carbon sorbents can achieve carbon neutrality when considering their full life cycle.

Biodiversity protection emerges as an additional environmental benefit. By reducing the need for extensive mining operations associated with conventional energy production, carbon sorbent-enhanced renewable energy systems help preserve natural habitats and ecosystems. Conservation biologists have documented reduced habitat fragmentation in regions transitioning to such integrated renewable energy approaches.

Waste management challenges persist as a concern in carbon sorbent applications. The disposal or regeneration of spent sorbent materials requires careful environmental management to prevent secondary contamination. Emerging circular economy approaches that incorporate sorbent regeneration and recycling show promise in addressing these challenges while maintaining environmental integrity.

Policy Framework and Incentives

The global policy landscape for carbon sorbent technologies in renewable energy has evolved significantly over the past decade, creating both opportunities and challenges for technology developers and adopters. Carbon pricing mechanisms, including emissions trading systems and carbon taxes implemented across various jurisdictions, have emerged as primary drivers for carbon capture technology adoption. These economic instruments effectively monetize carbon emissions reduction, creating financial incentives for industries to invest in carbon sorbent technologies.

Regulatory frameworks in major economies have increasingly incorporated carbon capture requirements into environmental compliance standards. The European Union's Green Deal and Carbon Border Adjustment Mechanism represent sophisticated policy approaches that create market demand for effective carbon sorbent solutions. Similarly, the United States has implemented tax credits through the 45Q provision and the Inflation Reduction Act, offering substantial financial incentives for carbon capture, utilization, and storage projects.

Research and development funding programs dedicated to advanced carbon sorbent technologies have expanded considerably. Government initiatives like Horizon Europe, ARPA-E, and various national innovation funds have allocated significant resources specifically for developing next-generation carbon capture materials. These programs typically focus on improving efficiency, reducing costs, and enhancing the environmental performance of carbon sorbent technologies.

Public-private partnerships have emerged as effective vehicles for accelerating technology deployment. These collaborative arrangements between government agencies, research institutions, and private companies help bridge the gap between laboratory research and commercial implementation. Notable examples include the Carbon Capture Innovation Challenge and various Clean Energy Ministerial initiatives that facilitate knowledge sharing and technology transfer across borders.

Standardization efforts for carbon sorbent performance metrics and sustainability criteria are gaining momentum globally. These standards are crucial for creating transparent markets and enabling fair competition among technology providers. Organizations such as ISO and ASTM International are developing certification frameworks that will help establish quality benchmarks for carbon sorbent materials used in renewable energy applications.

Developing economies are implementing tailored incentive structures to promote localized carbon capture solutions. These include preferential financing terms, import duty exemptions for essential equipment, and technical assistance programs. Such policies recognize the importance of adapting carbon sorbent technologies to specific regional contexts and economic conditions, ensuring broader global adoption beyond advanced economies.

Regulatory frameworks in major economies have increasingly incorporated carbon capture requirements into environmental compliance standards. The European Union's Green Deal and Carbon Border Adjustment Mechanism represent sophisticated policy approaches that create market demand for effective carbon sorbent solutions. Similarly, the United States has implemented tax credits through the 45Q provision and the Inflation Reduction Act, offering substantial financial incentives for carbon capture, utilization, and storage projects.

Research and development funding programs dedicated to advanced carbon sorbent technologies have expanded considerably. Government initiatives like Horizon Europe, ARPA-E, and various national innovation funds have allocated significant resources specifically for developing next-generation carbon capture materials. These programs typically focus on improving efficiency, reducing costs, and enhancing the environmental performance of carbon sorbent technologies.

Public-private partnerships have emerged as effective vehicles for accelerating technology deployment. These collaborative arrangements between government agencies, research institutions, and private companies help bridge the gap between laboratory research and commercial implementation. Notable examples include the Carbon Capture Innovation Challenge and various Clean Energy Ministerial initiatives that facilitate knowledge sharing and technology transfer across borders.

Standardization efforts for carbon sorbent performance metrics and sustainability criteria are gaining momentum globally. These standards are crucial for creating transparent markets and enabling fair competition among technology providers. Organizations such as ISO and ASTM International are developing certification frameworks that will help establish quality benchmarks for carbon sorbent materials used in renewable energy applications.

Developing economies are implementing tailored incentive structures to promote localized carbon capture solutions. These include preferential financing terms, import duty exemptions for essential equipment, and technical assistance programs. Such policies recognize the importance of adapting carbon sorbent technologies to specific regional contexts and economic conditions, ensuring broader global adoption beyond advanced economies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!