Digital projection surface 3D printing system, method, adjusting method and device

A technology of 3D printing and adjustment methods, which is applied in the directions of manufacturing auxiliary devices, 3D object support structures, processing data acquisition/processing, etc., can solve the problems of restricting 3D printing and the unsatisfactory digital projection surface light source, and achieve the effect of printing format

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

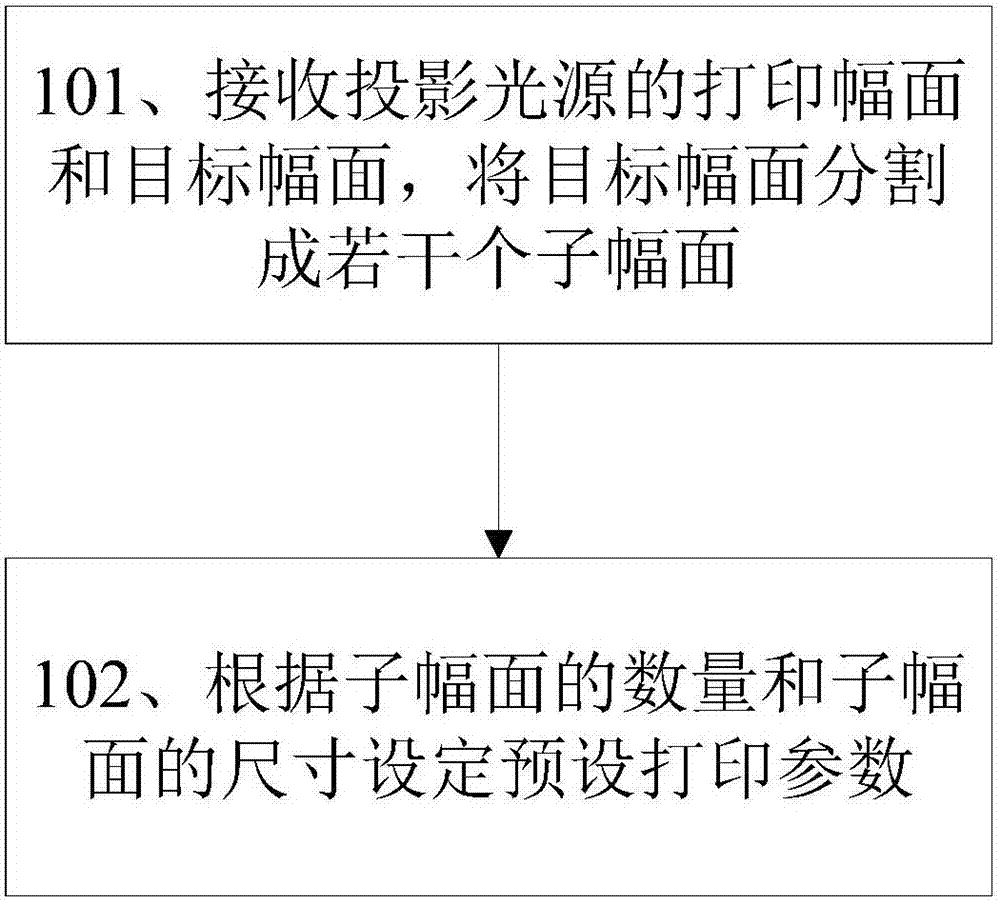

[0038] A digital projection surface adjustment method, such as figure 1 shown, including the following steps:

[0039] Step 101, receiving the printing format and the target format, dividing the target format into several sub-formats, the size of the sub-formats is not larger than the printing format of the projection light source;

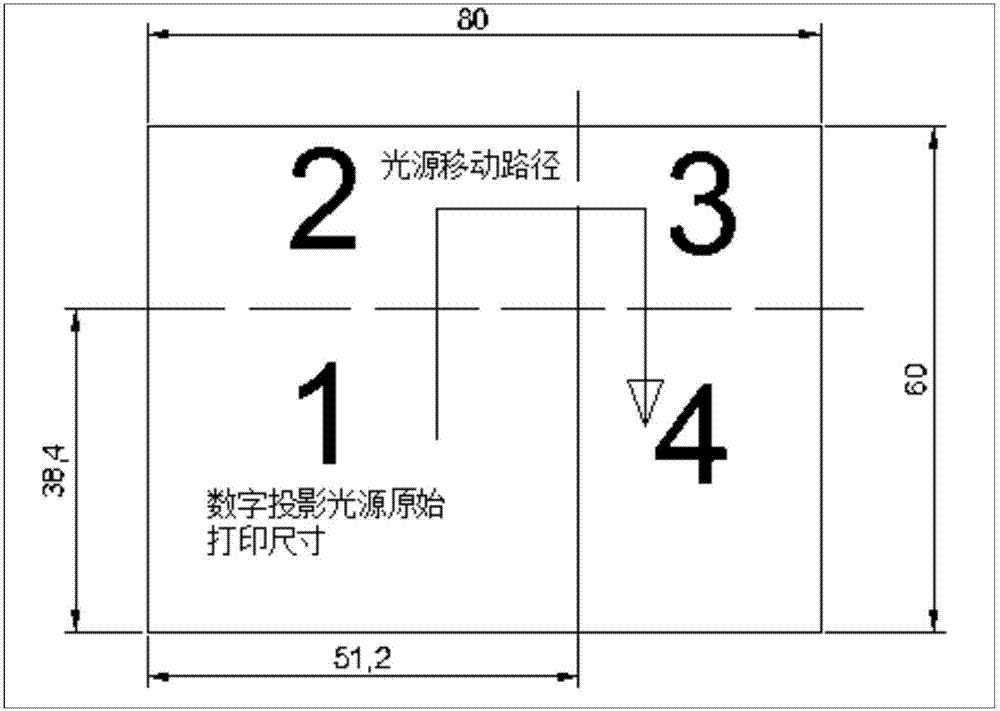

[0040] For example, if figure 2 As shown, the printing format of the projection light source is 51.2*38.4mm, and the target printing format of the user is 80*60mm; the target printing format is divided into four sub-formats: sub-format 1, sub-format 2, sub-format 3 and sub-format 4, The size of each sub-frame is not larger than the printing frame of the projection light source.

[0041] Step 102, generating printing parameters according to the number of sub-frames and the size of the sub-frames, where the printing param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com