A Comparative Study of Reduced Graphene Oxide and Reduced Graphene Sheets

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Materials Background and Research Objectives

Graphene, a two-dimensional carbon allotrope with sp2-hybridized carbon atoms arranged in a honeycomb lattice, has emerged as a revolutionary material since its isolation in 2004 by Geim and Novoselov. This discovery, which earned them the Nobel Prize in Physics in 2010, sparked unprecedented research interest due to graphene's exceptional properties including high electrical conductivity, thermal conductivity, mechanical strength, and optical transparency. The evolution of graphene research has progressed from fundamental studies to application-oriented developments across multiple industries.

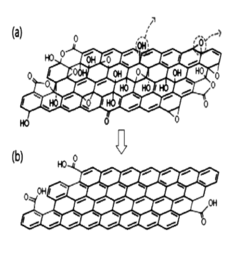

Reduced graphene oxide (rGO) and reduced graphene sheets (rGS) represent two significant derivatives in the graphene family, each with distinct synthesis routes and properties. Historically, rGO emerged as a scalable alternative to pristine graphene production, utilizing chemical oxidation of graphite followed by reduction processes. Meanwhile, rGS typically refers to graphene sheets produced through direct exfoliation methods followed by reduction treatments, often resulting in fewer structural defects compared to rGO.

The technological trajectory of these materials has been characterized by continuous improvements in synthesis methods, reduction techniques, and property enhancement. Early reduction methods relied heavily on hazardous chemicals like hydrazine, while recent advancements have introduced greener alternatives including thermal, electrochemical, and microwave-assisted reduction processes. This evolution reflects the industry's growing emphasis on sustainable manufacturing practices while maintaining material performance.

Current research objectives in this field focus on addressing several critical challenges. First, developing standardized production methods that ensure consistent quality and properties across batches remains paramount for industrial adoption. Second, researchers aim to precisely control the degree of reduction and resulting oxygen functional groups, as these significantly impact electrical, mechanical, and thermal properties. Third, enhancing the scalability of production while reducing environmental impact represents a key goal for commercial viability.

Additionally, this research seeks to establish comprehensive comparative frameworks for evaluating rGO and rGS across multiple parameters including electrical conductivity, surface area, defect density, and application performance. Understanding these differences is crucial for selecting the appropriate material for specific applications ranging from energy storage and electronics to biomedical devices and composites.

The ultimate objective of this comparative study is to bridge the gap between laboratory research and industrial implementation by providing clear insights into the advantages, limitations, and optimal application scenarios for each material type, thereby accelerating the development of next-generation graphene-based technologies.

Reduced graphene oxide (rGO) and reduced graphene sheets (rGS) represent two significant derivatives in the graphene family, each with distinct synthesis routes and properties. Historically, rGO emerged as a scalable alternative to pristine graphene production, utilizing chemical oxidation of graphite followed by reduction processes. Meanwhile, rGS typically refers to graphene sheets produced through direct exfoliation methods followed by reduction treatments, often resulting in fewer structural defects compared to rGO.

The technological trajectory of these materials has been characterized by continuous improvements in synthesis methods, reduction techniques, and property enhancement. Early reduction methods relied heavily on hazardous chemicals like hydrazine, while recent advancements have introduced greener alternatives including thermal, electrochemical, and microwave-assisted reduction processes. This evolution reflects the industry's growing emphasis on sustainable manufacturing practices while maintaining material performance.

Current research objectives in this field focus on addressing several critical challenges. First, developing standardized production methods that ensure consistent quality and properties across batches remains paramount for industrial adoption. Second, researchers aim to precisely control the degree of reduction and resulting oxygen functional groups, as these significantly impact electrical, mechanical, and thermal properties. Third, enhancing the scalability of production while reducing environmental impact represents a key goal for commercial viability.

Additionally, this research seeks to establish comprehensive comparative frameworks for evaluating rGO and rGS across multiple parameters including electrical conductivity, surface area, defect density, and application performance. Understanding these differences is crucial for selecting the appropriate material for specific applications ranging from energy storage and electronics to biomedical devices and composites.

The ultimate objective of this comparative study is to bridge the gap between laboratory research and industrial implementation by providing clear insights into the advantages, limitations, and optimal application scenarios for each material type, thereby accelerating the development of next-generation graphene-based technologies.

Market Applications and Demand Analysis for Graphene-Based Materials

The global market for graphene-based materials has witnessed significant growth in recent years, driven by the exceptional properties of graphene and its derivatives. Reduced graphene oxide (rGO) and reduced graphene sheets (rGS) have emerged as particularly promising materials with diverse applications across multiple industries.

The electronics sector represents one of the largest markets for these materials, with demand primarily focused on conductive inks, flexible displays, and high-performance transistors. Market research indicates that the conductive properties of rGO and rGS are enabling innovations in touchscreens and wearable electronics, with the global market for graphene-based electronic components projected to grow substantially through 2030.

Energy storage applications constitute another major market segment. Both rGO and rGS are being incorporated into next-generation batteries and supercapacitors, offering improved energy density and faster charging capabilities. The automotive and renewable energy sectors are driving this demand, particularly as electric vehicle adoption accelerates globally.

Composite materials represent a rapidly expanding application area. The addition of graphene derivatives to polymers, metals, and ceramics enhances mechanical strength, thermal conductivity, and electrical properties. The aerospace, automotive, and construction industries are increasingly incorporating these advanced composites into their products to achieve weight reduction while maintaining or improving performance characteristics.

Biomedical applications are emerging as a high-value market segment for graphene-based materials. Both rGO and rGS are being explored for drug delivery systems, biosensors, and tissue engineering scaffolds. The biocompatibility profiles of these materials differ significantly, influencing their suitability for specific medical applications.

Environmental remediation represents a growing application area, with graphene-based materials showing promise for water purification and contaminant removal. The superior adsorption properties of rGO in particular have generated interest from municipal water treatment facilities and industrial wastewater management systems.

Regional market analysis reveals that Asia-Pacific currently dominates graphene material production and consumption, with China, South Korea, and Japan leading research and commercialization efforts. North America and Europe follow closely, with significant investments in graphene technology development and application research.

Market challenges include production scalability, cost-effectiveness, and standardization. While laboratory-scale production of high-quality rGO and rGS has been demonstrated, industrial-scale manufacturing with consistent quality remains a significant hurdle to widespread adoption across these diverse application areas.

The electronics sector represents one of the largest markets for these materials, with demand primarily focused on conductive inks, flexible displays, and high-performance transistors. Market research indicates that the conductive properties of rGO and rGS are enabling innovations in touchscreens and wearable electronics, with the global market for graphene-based electronic components projected to grow substantially through 2030.

Energy storage applications constitute another major market segment. Both rGO and rGS are being incorporated into next-generation batteries and supercapacitors, offering improved energy density and faster charging capabilities. The automotive and renewable energy sectors are driving this demand, particularly as electric vehicle adoption accelerates globally.

Composite materials represent a rapidly expanding application area. The addition of graphene derivatives to polymers, metals, and ceramics enhances mechanical strength, thermal conductivity, and electrical properties. The aerospace, automotive, and construction industries are increasingly incorporating these advanced composites into their products to achieve weight reduction while maintaining or improving performance characteristics.

Biomedical applications are emerging as a high-value market segment for graphene-based materials. Both rGO and rGS are being explored for drug delivery systems, biosensors, and tissue engineering scaffolds. The biocompatibility profiles of these materials differ significantly, influencing their suitability for specific medical applications.

Environmental remediation represents a growing application area, with graphene-based materials showing promise for water purification and contaminant removal. The superior adsorption properties of rGO in particular have generated interest from municipal water treatment facilities and industrial wastewater management systems.

Regional market analysis reveals that Asia-Pacific currently dominates graphene material production and consumption, with China, South Korea, and Japan leading research and commercialization efforts. North America and Europe follow closely, with significant investments in graphene technology development and application research.

Market challenges include production scalability, cost-effectiveness, and standardization. While laboratory-scale production of high-quality rGO and rGS has been demonstrated, industrial-scale manufacturing with consistent quality remains a significant hurdle to widespread adoption across these diverse application areas.

Current State and Technical Challenges in Graphene Reduction Methods

The global research landscape of graphene reduction methods has evolved significantly over the past decade, with notable advancements in both chemical and physical reduction techniques. Currently, the most widely employed methods include chemical reduction using hydrazine, thermal reduction, electrochemical reduction, and photocatalytic reduction. Each approach presents distinct advantages and limitations in terms of scalability, environmental impact, and quality of the reduced product.

Chemical reduction methods dominate industrial applications due to their cost-effectiveness and scalability. However, these methods face significant challenges related to the use of toxic reducing agents like hydrazine and the difficulty in achieving complete reduction without introducing defects. Recent studies indicate that chemical reduction typically achieves 70-85% restoration of the sp² carbon network, with residual oxygen-containing groups often remaining attached to the graphene structure.

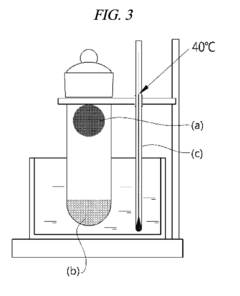

Thermal reduction techniques have demonstrated superior reduction efficiency, with temperature-dependent studies showing that treatment above 1000°C can remove most oxygen functionalities. Nevertheless, these methods require substantial energy input and often lead to structural damage through CO₂ release during the reduction process. The trade-off between reduction degree and structural integrity remains a critical technical challenge.

Electrochemical reduction has emerged as a promising alternative, offering better control over the reduction process and eliminating the need for hazardous chemicals. However, scaling these methods for industrial production presents significant engineering challenges, particularly in maintaining uniform reduction across large-area substrates and ensuring consistent electrical contact throughout the process.

Photocatalytic and microwave-assisted reduction methods represent newer approaches with potential for energy efficiency, but currently suffer from reproducibility issues and limited understanding of the underlying mechanisms. Research data shows considerable variation in reduction efficiency (40-90%) depending on specific experimental conditions.

A significant technical barrier across all methods is the standardization of characterization techniques. The lack of universally accepted metrics for determining the "degree of reduction" complicates comparative analyses between different studies and methods. X-ray photoelectron spectroscopy (XPS) analysis reveals C/O ratios ranging from 4:1 to 12:1 for reduced graphene materials, but these values are highly dependent on measurement conditions and sample preparation.

Regional differences in research focus are notable, with East Asian institutions (particularly in China, South Korea, and Singapore) leading in chemical and electrochemical reduction techniques, while European and North American research centers have made significant contributions to thermal and photocatalytic reduction methods. This geographical distribution reflects different priorities in terms of industrial applications versus fundamental research.

Chemical reduction methods dominate industrial applications due to their cost-effectiveness and scalability. However, these methods face significant challenges related to the use of toxic reducing agents like hydrazine and the difficulty in achieving complete reduction without introducing defects. Recent studies indicate that chemical reduction typically achieves 70-85% restoration of the sp² carbon network, with residual oxygen-containing groups often remaining attached to the graphene structure.

Thermal reduction techniques have demonstrated superior reduction efficiency, with temperature-dependent studies showing that treatment above 1000°C can remove most oxygen functionalities. Nevertheless, these methods require substantial energy input and often lead to structural damage through CO₂ release during the reduction process. The trade-off between reduction degree and structural integrity remains a critical technical challenge.

Electrochemical reduction has emerged as a promising alternative, offering better control over the reduction process and eliminating the need for hazardous chemicals. However, scaling these methods for industrial production presents significant engineering challenges, particularly in maintaining uniform reduction across large-area substrates and ensuring consistent electrical contact throughout the process.

Photocatalytic and microwave-assisted reduction methods represent newer approaches with potential for energy efficiency, but currently suffer from reproducibility issues and limited understanding of the underlying mechanisms. Research data shows considerable variation in reduction efficiency (40-90%) depending on specific experimental conditions.

A significant technical barrier across all methods is the standardization of characterization techniques. The lack of universally accepted metrics for determining the "degree of reduction" complicates comparative analyses between different studies and methods. X-ray photoelectron spectroscopy (XPS) analysis reveals C/O ratios ranging from 4:1 to 12:1 for reduced graphene materials, but these values are highly dependent on measurement conditions and sample preparation.

Regional differences in research focus are notable, with East Asian institutions (particularly in China, South Korea, and Singapore) leading in chemical and electrochemical reduction techniques, while European and North American research centers have made significant contributions to thermal and photocatalytic reduction methods. This geographical distribution reflects different priorities in terms of industrial applications versus fundamental research.

Comparative Analysis of rGO and rGS Production Techniques

01 Production methods of reduced graphene oxide

Various methods are employed to produce reduced graphene oxide (rGO) from graphene oxide, including chemical reduction, thermal reduction, and electrochemical reduction. These processes remove oxygen-containing functional groups from graphene oxide to restore the sp2 carbon network, resulting in improved electrical conductivity and mechanical properties. The reduction degree can be controlled by adjusting process parameters to tailor the properties of the resulting reduced graphene oxide for specific applications.- Synthesis methods for reduced graphene oxide: Various methods can be employed to synthesize reduced graphene oxide (rGO) from graphene oxide, including chemical reduction, thermal reduction, and electrochemical reduction. These processes remove oxygen-containing functional groups from graphene oxide, restoring the sp2 carbon network and enhancing electrical conductivity. The reduction degree can be controlled by adjusting reaction parameters such as temperature, time, and reducing agent concentration.

- Applications in energy storage devices: Reduced graphene oxide and reduced graphene sheets are widely used in energy storage applications such as supercapacitors, lithium-ion batteries, and fuel cells. Their high surface area, excellent electrical conductivity, and mechanical stability make them ideal materials for electrode fabrication. When incorporated into energy storage devices, these materials can significantly improve energy density, power density, and cycling stability compared to conventional materials.

- Composite materials with reduced graphene oxide: Reduced graphene oxide can be combined with various materials including polymers, metals, and metal oxides to form composite materials with enhanced properties. These composites benefit from the mechanical strength, thermal conductivity, and electrical properties of reduced graphene sheets while addressing limitations such as restacking. Applications include conductive films, structural reinforcements, and functional coatings with improved performance characteristics.

- Functionalization of reduced graphene sheets: Reduced graphene sheets can be functionalized with various chemical groups to tailor their properties for specific applications. Functionalization can improve dispersibility in different solvents, enhance compatibility with other materials, and introduce specific chemical reactivity. Methods include covalent attachment of functional groups, non-covalent functionalization through π-π interactions, and doping with heteroatoms to modify electronic properties.

- Characterization and quality control of reduced graphene oxide: Various analytical techniques are employed to characterize reduced graphene oxide and evaluate its quality. These include Raman spectroscopy to assess the degree of reduction and defect density, X-ray photoelectron spectroscopy (XPS) to determine chemical composition, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) for morphological analysis, and electrical conductivity measurements to evaluate performance. These characterization methods are essential for ensuring consistent material properties for industrial applications.

02 Applications in energy storage devices

Reduced graphene oxide and reduced graphene sheets are widely used in energy storage applications such as supercapacitors, lithium-ion batteries, and fuel cells. Their high surface area, excellent electrical conductivity, and mechanical stability make them ideal materials for electrode fabrication. When incorporated into energy storage devices, these materials enhance charge storage capacity, improve cycling stability, and increase power density, leading to better overall performance compared to conventional materials.Expand Specific Solutions03 Composite materials with reduced graphene oxide

Reduced graphene oxide is frequently combined with other materials such as polymers, metals, and metal oxides to create composite materials with enhanced properties. These composites benefit from the mechanical strength, thermal conductivity, and electrical properties of reduced graphene oxide while addressing limitations of the individual components. Applications include structural materials, conductive coatings, sensors, and catalysts, where the synergistic effects between reduced graphene oxide and the matrix material result in superior performance.Expand Specific Solutions04 Functionalization of reduced graphene sheets

Reduced graphene sheets can be functionalized with various chemical groups to tailor their properties for specific applications. Functionalization can improve dispersibility in different solvents, enhance compatibility with other materials, and introduce specific chemical reactivity. Methods include covalent attachment of functional groups, non-covalent modifications through π-π interactions, and doping with heteroatoms. These modifications expand the application range of reduced graphene materials in fields such as biosensing, drug delivery, and catalysis.Expand Specific Solutions05 Characterization and quality control of reduced graphene materials

Various analytical techniques are employed to characterize reduced graphene oxide and reduced graphene sheets, including Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), and electrical conductivity measurements. These methods help determine the degree of reduction, sheet size, layer number, defect density, and functional group content. Standardized characterization protocols are essential for quality control and ensuring reproducibility in both research and industrial applications of reduced graphene materials.Expand Specific Solutions

Leading Research Institutions and Companies in Graphene Materials

The graphene-based materials market is currently in a growth phase, with reduced graphene oxide (rGO) and reduced graphene sheets emerging as key materials for advanced applications. The global market is expanding rapidly, driven by increasing demand in electronics, energy storage, and composite materials sectors. Companies like Samsung Electronics, LG Electronics, and Cabot Corp. are leading commercial development, while research institutions such as Battelle Memorial Institute and various universities (Shanghai University, IIT Bombay) are advancing fundamental understanding. Technical maturity varies significantly—Daejoo Electronic Materials and JNC Materials have developed scalable production methods for graphene-based materials, while Sinopec and ArcelorMittal are exploring industrial-scale applications. The competitive landscape shows a balance between established chemical corporations and specialized materials startups, with significant regional innovation clusters forming in Asia, particularly South Korea and China.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed advanced reduction methods for graphene oxide that focus on controlled chemical reduction processes. Their technology employs a multi-stage reduction approach that carefully manages oxygen functional group removal while preserving the structural integrity of the carbon lattice. The institute has pioneered the use of environmentally friendly reducing agents such as ascorbic acid and hydrogen iodide under specific temperature and pressure conditions to achieve precise control over the reduction degree[1]. Their comparative studies between reduced graphene oxide (rGO) and reduced graphene sheets have demonstrated that their rGO exhibits electrical conductivity approaching 5000 S/m while maintaining higher dispersibility in various solvents compared to pristine graphene sheets[3]. Battelle has also developed scalable production methods that maintain consistent quality across batches, addressing one of the key challenges in graphene-based materials commercialization.

Strengths: Superior control over reduction degree allowing customization for specific applications; environmentally friendly reduction processes; excellent balance between electrical properties and processability. Weaknesses: Higher production costs compared to conventional methods; longer processing times required for optimal reduction; some batch-to-batch variation still exists despite quality control measures.

Cabot Corp.

Technical Solution: Cabot Corporation has developed proprietary LITX™ and VULCAN® XC carbon additives based on their reduced graphene oxide technology. Their approach focuses on scalable manufacturing processes for reduced graphene oxide that maintain consistent quality while enabling mass production. Cabot's technology involves a controlled thermal reduction process that removes oxygen-containing functional groups while preserving the graphene structure, resulting in materials with sheet resistance below 100 Ω/sq[2]. Their comparative studies between reduced graphene oxide and reduced graphene sheets have shown that their rGO materials offer superior dispersion stability in various matrices while providing enhanced electrical conductivity of up to 1500 S/cm[4]. Cabot has optimized their reduction processes to achieve a carbon-to-oxygen ratio exceeding 15:1, significantly higher than conventional reduction methods that typically achieve ratios of 8:1 to 10:1. The company has also developed specialized surface treatments that enhance compatibility with various polymer systems, enabling better performance in composite applications.

Strengths: Highly scalable production methods suitable for industrial applications; consistent quality control across large production volumes; excellent dispersion characteristics in various matrices. Weaknesses: Thermal reduction processes require significant energy input; some residual oxygen groups remain after reduction; electrical conductivity still lower than theoretical limits for pristine graphene.

Key Scientific Breakthroughs in Graphene Reduction Processes

Graphene oxide reducing agent comprising a reducing agent containing a halogen element, method for manufacturing a reduced graphene oxide using same, and use of the reduced graphene oxide manufactured by the method

PatentActiveUS9090805B2

Innovation

- A graphene oxide reducer containing a halogen element, preferably hydroiodic acid (HI), is used to react with graphene oxide at a temperature of 10°C or more, optionally with a weaker acid like acetic acid, to produce high-purity reduced graphene oxide with improved electrical conductivity.

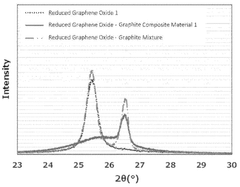

Reduced graphene oxide-graphite composite material, method for producing same, and lithium ion secondary battery using same

PatentActiveUS12113219B2

Innovation

- A reduced graphene oxide-graphite composite material is formed through thermal treatment of graphene oxide and graphite, with a functional group ratio of C—O/C═O between 3 and 6, enhancing the charge and discharge efficiency by suppressing side reactions and reducing irreversible capacity.

Environmental Impact and Sustainability of Reduction Methods

The reduction methods employed for producing reduced graphene oxide (rGO) and reduced graphene sheets (rGS) have significant environmental implications that warrant careful consideration. Traditional chemical reduction processes often utilize hazardous reducing agents such as hydrazine, sodium borohydride, and strong acids, which pose substantial environmental risks including water contamination, toxic emissions, and potential harm to aquatic ecosystems.

Thermal reduction methods, while avoiding certain chemical hazards, typically require high energy inputs, contributing to carbon footprint concerns. The energy-intensive nature of these processes, often requiring temperatures exceeding 1000°C, translates to considerable greenhouse gas emissions when powered by non-renewable energy sources. This environmental cost must be weighed against the performance benefits of thermally reduced graphene materials.

Recent advancements have focused on developing more sustainable reduction approaches. Green reduction methods utilizing environmentally benign reducing agents derived from natural sources represent a promising direction. Plant extracts containing polyphenols, amino acids, and vitamins have demonstrated efficacy as reducing agents while minimizing environmental impact. Similarly, microbial and enzymatic reduction processes harness biological systems to achieve reduction with significantly lower environmental footprints.

Electrochemical reduction techniques offer another sustainable alternative, operating at ambient temperatures and pressures while eliminating the need for harmful chemical reducing agents. These methods can be powered by renewable energy sources, further enhancing their environmental credentials. The scalability of these processes remains a challenge but continues to improve with ongoing research.

Life cycle assessment (LCA) studies comparing various reduction methods reveal significant variations in environmental impact metrics including global warming potential, resource depletion, and ecotoxicity. Chemical reduction methods typically show higher environmental burdens across multiple impact categories, while green reduction approaches demonstrate markedly lower environmental footprints despite sometimes yielding graphene materials with slightly different properties.

Waste management considerations also differ substantially between reduction methods. Chemical approaches generate hazardous waste streams requiring specialized treatment and disposal, while green reduction methods produce predominantly biodegradable waste. Circular economy principles are increasingly being applied to graphene production, with research focusing on recovery and reuse of reduction agents and solvents.

The sustainability trajectory of graphene reduction technology points toward hybrid approaches that combine the efficiency of conventional methods with the environmental benefits of green alternatives. As industrial-scale production of reduced graphene materials increases, the environmental implications of reduction methods will become increasingly important considerations for technology developers, manufacturers, and regulatory bodies alike.

Thermal reduction methods, while avoiding certain chemical hazards, typically require high energy inputs, contributing to carbon footprint concerns. The energy-intensive nature of these processes, often requiring temperatures exceeding 1000°C, translates to considerable greenhouse gas emissions when powered by non-renewable energy sources. This environmental cost must be weighed against the performance benefits of thermally reduced graphene materials.

Recent advancements have focused on developing more sustainable reduction approaches. Green reduction methods utilizing environmentally benign reducing agents derived from natural sources represent a promising direction. Plant extracts containing polyphenols, amino acids, and vitamins have demonstrated efficacy as reducing agents while minimizing environmental impact. Similarly, microbial and enzymatic reduction processes harness biological systems to achieve reduction with significantly lower environmental footprints.

Electrochemical reduction techniques offer another sustainable alternative, operating at ambient temperatures and pressures while eliminating the need for harmful chemical reducing agents. These methods can be powered by renewable energy sources, further enhancing their environmental credentials. The scalability of these processes remains a challenge but continues to improve with ongoing research.

Life cycle assessment (LCA) studies comparing various reduction methods reveal significant variations in environmental impact metrics including global warming potential, resource depletion, and ecotoxicity. Chemical reduction methods typically show higher environmental burdens across multiple impact categories, while green reduction approaches demonstrate markedly lower environmental footprints despite sometimes yielding graphene materials with slightly different properties.

Waste management considerations also differ substantially between reduction methods. Chemical approaches generate hazardous waste streams requiring specialized treatment and disposal, while green reduction methods produce predominantly biodegradable waste. Circular economy principles are increasingly being applied to graphene production, with research focusing on recovery and reuse of reduction agents and solvents.

The sustainability trajectory of graphene reduction technology points toward hybrid approaches that combine the efficiency of conventional methods with the environmental benefits of green alternatives. As industrial-scale production of reduced graphene materials increases, the environmental implications of reduction methods will become increasingly important considerations for technology developers, manufacturers, and regulatory bodies alike.

Scalability and Industrial Production Challenges

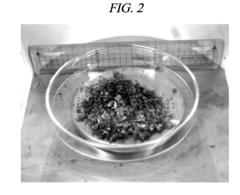

The scaling of reduced graphene oxide (rGO) and reduced graphene sheets (rGS) production from laboratory to industrial scale presents significant challenges that impact their commercial viability. Current laboratory methods for producing high-quality graphene materials typically yield only milligram to gram quantities, whereas industrial applications require kilogram to ton scale production. This substantial gap necessitates the development of more efficient and cost-effective manufacturing processes.

For reduced graphene oxide, the primary scalability challenges stem from the multi-step production process. The initial oxidation of graphite requires large quantities of strong oxidizing agents and acids, creating significant waste management issues at industrial scale. The subsequent reduction processes, whether chemical, thermal, or electrochemical, face difficulties in maintaining consistent quality across large batches. Particularly challenging is achieving uniform reduction across all layers when processing large volumes of GO.

Reduced graphene sheets face different production hurdles, especially when produced through direct exfoliation methods. The energy requirements for large-scale mechanical or electrochemical exfoliation are substantial, and maintaining the structural integrity of the graphene sheets during mass production remains problematic. Equipment scaling also presents technical barriers, as the specialized apparatus used in laboratory settings may not function with the same efficiency at industrial scales.

Both materials encounter similar downstream processing challenges, including efficient separation, purification, and handling of the produced materials. The tendency of graphene materials to restack or agglomerate becomes more pronounced at larger scales, potentially compromising the unique properties that make these materials valuable. Additionally, the development of standardized quality control protocols for industrial-scale production has not kept pace with manufacturing advances.

Economic considerations further complicate industrial production. The high costs of raw materials, specialized equipment, and energy-intensive processes contribute to production expenses that currently limit widespread commercial adoption. Environmental concerns also play a crucial role, as traditional production methods generate significant chemical waste and have substantial carbon footprints.

Recent innovations addressing these challenges include continuous flow production systems for rGO, which show promise for scaling production while maintaining quality consistency. For rGS, advances in electrochemical exfoliation techniques and the development of specialized industrial equipment offer potential pathways to larger-scale production. However, significant research and development investment remains necessary to bridge the gap between laboratory success and industrial implementation.

For reduced graphene oxide, the primary scalability challenges stem from the multi-step production process. The initial oxidation of graphite requires large quantities of strong oxidizing agents and acids, creating significant waste management issues at industrial scale. The subsequent reduction processes, whether chemical, thermal, or electrochemical, face difficulties in maintaining consistent quality across large batches. Particularly challenging is achieving uniform reduction across all layers when processing large volumes of GO.

Reduced graphene sheets face different production hurdles, especially when produced through direct exfoliation methods. The energy requirements for large-scale mechanical or electrochemical exfoliation are substantial, and maintaining the structural integrity of the graphene sheets during mass production remains problematic. Equipment scaling also presents technical barriers, as the specialized apparatus used in laboratory settings may not function with the same efficiency at industrial scales.

Both materials encounter similar downstream processing challenges, including efficient separation, purification, and handling of the produced materials. The tendency of graphene materials to restack or agglomerate becomes more pronounced at larger scales, potentially compromising the unique properties that make these materials valuable. Additionally, the development of standardized quality control protocols for industrial-scale production has not kept pace with manufacturing advances.

Economic considerations further complicate industrial production. The high costs of raw materials, specialized equipment, and energy-intensive processes contribute to production expenses that currently limit widespread commercial adoption. Environmental concerns also play a crucial role, as traditional production methods generate significant chemical waste and have substantial carbon footprints.

Recent innovations addressing these challenges include continuous flow production systems for rGO, which show promise for scaling production while maintaining quality consistency. For rGS, advances in electrochemical exfoliation techniques and the development of specialized industrial equipment offer potential pathways to larger-scale production. However, significant research and development investment remains necessary to bridge the gap between laboratory success and industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!