Why Reduced Graphene Oxide Reinforces Construction Materials

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO in Construction: Background and Objectives

The construction industry has witnessed significant technological advancements over the past decades, with nanomaterials emerging as revolutionary additives for enhancing building materials. Among these, reduced graphene oxide (rGO) has gained substantial attention due to its exceptional mechanical, thermal, and electrical properties. Since the isolation of graphene in 2004 by Geim and Novoselov, research into graphene-based materials has expanded exponentially, with rGO becoming particularly relevant for construction applications around 2010.

The evolution of rGO technology in construction materials represents a convergence of materials science, nanotechnology, and civil engineering. Initially, graphene oxide (GO) was primarily studied for electronic applications, but researchers soon recognized its potential for reinforcing construction materials. The reduction process that transforms GO into rGO creates a material with enhanced electrical conductivity while maintaining excellent mechanical properties, making it ideal for multifunctional construction composites.

Current technological trends indicate a growing interest in sustainable and high-performance building materials. rGO aligns perfectly with this trajectory, as it can significantly improve material strength and durability while potentially reducing the overall material consumption. The remarkable strength-to-weight ratio of rGO (theoretical Young's modulus of 1 TPa) makes it an exceptional reinforcement agent for concrete, cement, asphalt, and various polymer composites used in construction.

The primary technical objective of incorporating rGO into construction materials is to address several persistent challenges in the industry. These include enhancing mechanical strength, improving durability against environmental degradation, reducing carbon footprint through material efficiency, and introducing novel functionalities such as self-sensing capabilities for structural health monitoring. Additionally, researchers aim to develop cost-effective and scalable methods for rGO production and integration into conventional construction materials.

Another critical objective is to understand the fundamental mechanisms by which rGO interacts with construction material matrices. This includes investigating the interfacial bonding between rGO and cement hydration products, the dispersion behavior of rGO in various matrices, and the long-term stability of rGO-reinforced composites under real-world conditions. Such understanding is essential for optimizing formulations and processing techniques.

The global push toward sustainable infrastructure development has further accelerated interest in rGO-based construction materials. With the construction sector accounting for approximately 39% of global carbon emissions, materials that can enhance performance while reducing material consumption represent a significant opportunity for environmental impact reduction. The technical goal is therefore not only to improve material properties but to do so in a manner that contributes to broader sustainability objectives.

The evolution of rGO technology in construction materials represents a convergence of materials science, nanotechnology, and civil engineering. Initially, graphene oxide (GO) was primarily studied for electronic applications, but researchers soon recognized its potential for reinforcing construction materials. The reduction process that transforms GO into rGO creates a material with enhanced electrical conductivity while maintaining excellent mechanical properties, making it ideal for multifunctional construction composites.

Current technological trends indicate a growing interest in sustainable and high-performance building materials. rGO aligns perfectly with this trajectory, as it can significantly improve material strength and durability while potentially reducing the overall material consumption. The remarkable strength-to-weight ratio of rGO (theoretical Young's modulus of 1 TPa) makes it an exceptional reinforcement agent for concrete, cement, asphalt, and various polymer composites used in construction.

The primary technical objective of incorporating rGO into construction materials is to address several persistent challenges in the industry. These include enhancing mechanical strength, improving durability against environmental degradation, reducing carbon footprint through material efficiency, and introducing novel functionalities such as self-sensing capabilities for structural health monitoring. Additionally, researchers aim to develop cost-effective and scalable methods for rGO production and integration into conventional construction materials.

Another critical objective is to understand the fundamental mechanisms by which rGO interacts with construction material matrices. This includes investigating the interfacial bonding between rGO and cement hydration products, the dispersion behavior of rGO in various matrices, and the long-term stability of rGO-reinforced composites under real-world conditions. Such understanding is essential for optimizing formulations and processing techniques.

The global push toward sustainable infrastructure development has further accelerated interest in rGO-based construction materials. With the construction sector accounting for approximately 39% of global carbon emissions, materials that can enhance performance while reducing material consumption represent a significant opportunity for environmental impact reduction. The technical goal is therefore not only to improve material properties but to do so in a manner that contributes to broader sustainability objectives.

Market Analysis for rGO-Enhanced Building Materials

The global market for reduced graphene oxide (rGO) in construction materials is experiencing significant growth, driven by increasing demand for high-performance building materials with enhanced properties. Current market valuations indicate that the global graphene construction materials market reached approximately 12.5 million USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 25.3% through 2030, potentially reaching 76.4 million USD by the end of the forecast period.

The primary market segments for rGO-enhanced construction materials include concrete additives, coatings, composites, and insulation materials. Concrete additives represent the largest segment, accounting for roughly 45% of the market share, as rGO significantly improves concrete's mechanical strength, durability, and electrical conductivity. The coatings segment follows at 25%, valued for providing corrosion resistance and thermal management properties to building exteriors.

Geographically, Asia-Pacific dominates the market with approximately 40% share, led by China's massive infrastructure development and construction activities. North America and Europe follow with 30% and 20% market shares respectively, where the focus is primarily on sustainable and high-performance building solutions. The Middle East is emerging as a rapidly growing market due to ambitious construction projects and extreme environmental conditions requiring durable materials.

Key market drivers include increasing urbanization, growing infrastructure development in emerging economies, and stringent building codes demanding higher performance materials. The push for sustainable construction practices has also accelerated market growth, as rGO-enhanced materials can reduce overall material consumption while extending structural lifespans.

Market restraints include the relatively high production costs of rGO, which currently limit widespread adoption in cost-sensitive construction sectors. The lack of standardization and building code provisions specifically addressing graphene-enhanced materials also poses challenges to market penetration. Additionally, knowledge gaps among construction professionals regarding proper application methods and long-term performance create adoption barriers.

Customer segments show varying adoption rates, with high-end commercial construction and infrastructure projects leading implementation due to performance requirements justifying the premium costs. Residential construction remains a largely untapped market with significant growth potential as production costs decrease and awareness increases.

The competitive landscape features both established construction material manufacturers incorporating rGO into their product lines and specialized graphene producers forming strategic partnerships with construction companies to develop application-specific solutions.

The primary market segments for rGO-enhanced construction materials include concrete additives, coatings, composites, and insulation materials. Concrete additives represent the largest segment, accounting for roughly 45% of the market share, as rGO significantly improves concrete's mechanical strength, durability, and electrical conductivity. The coatings segment follows at 25%, valued for providing corrosion resistance and thermal management properties to building exteriors.

Geographically, Asia-Pacific dominates the market with approximately 40% share, led by China's massive infrastructure development and construction activities. North America and Europe follow with 30% and 20% market shares respectively, where the focus is primarily on sustainable and high-performance building solutions. The Middle East is emerging as a rapidly growing market due to ambitious construction projects and extreme environmental conditions requiring durable materials.

Key market drivers include increasing urbanization, growing infrastructure development in emerging economies, and stringent building codes demanding higher performance materials. The push for sustainable construction practices has also accelerated market growth, as rGO-enhanced materials can reduce overall material consumption while extending structural lifespans.

Market restraints include the relatively high production costs of rGO, which currently limit widespread adoption in cost-sensitive construction sectors. The lack of standardization and building code provisions specifically addressing graphene-enhanced materials also poses challenges to market penetration. Additionally, knowledge gaps among construction professionals regarding proper application methods and long-term performance create adoption barriers.

Customer segments show varying adoption rates, with high-end commercial construction and infrastructure projects leading implementation due to performance requirements justifying the premium costs. Residential construction remains a largely untapped market with significant growth potential as production costs decrease and awareness increases.

The competitive landscape features both established construction material manufacturers incorporating rGO into their product lines and specialized graphene producers forming strategic partnerships with construction companies to develop application-specific solutions.

Current Challenges in rGO Construction Applications

Despite the promising potential of reduced graphene oxide (rGO) in construction materials, several significant challenges impede its widespread adoption and optimal performance. The primary obstacle remains the high production cost of rGO, which substantially exceeds traditional reinforcement materials. Current manufacturing processes are energy-intensive and often require hazardous chemicals, making large-scale production economically prohibitive for mainstream construction applications.

Quality consistency presents another major challenge, as variations in reduction processes lead to inconsistent rGO properties. This inconsistency manifests in unpredictable mechanical performance when incorporated into construction materials, creating reliability concerns for structural applications where performance predictability is paramount.

Dispersion difficulties constitute a persistent technical barrier. rGO tends to agglomerate due to strong van der Waals forces between sheets, resulting in poor distribution within construction matrices. Inadequate dispersion significantly diminishes the reinforcement effect and can even introduce new weak points in the material structure, potentially worsening rather than improving mechanical properties.

Long-term durability remains insufficiently understood, with limited data available on how rGO-reinforced construction materials perform under extended environmental exposure. Questions persist regarding resistance to UV degradation, freeze-thaw cycles, and chemical attacks common in construction environments. This knowledge gap creates hesitation among engineers and contractors considering rGO implementation in long-lifespan infrastructure projects.

Standardization issues further complicate adoption, as the construction industry lacks established testing protocols and quality standards specific to rGO-reinforced materials. Without standardized evaluation methods, comparing different rGO solutions becomes problematic, hindering informed decision-making by stakeholders.

Environmental and health concerns also warrant attention. While rGO itself shows promising environmental credentials, some production methods involve toxic chemicals. Additionally, the potential health impacts of nanoparticle release during material lifecycle—particularly during demolition or recycling—remain inadequately researched, raising regulatory and safety questions.

Integration with existing construction practices presents practical challenges. Current construction methodologies and equipment are not optimized for nanomaterial-enhanced composites, requiring adaptation of mixing procedures, curing protocols, and application techniques. This necessitates retraining of workers and potential modification of established construction workflows, creating resistance to adoption within the traditionally conservative construction sector.

Quality consistency presents another major challenge, as variations in reduction processes lead to inconsistent rGO properties. This inconsistency manifests in unpredictable mechanical performance when incorporated into construction materials, creating reliability concerns for structural applications where performance predictability is paramount.

Dispersion difficulties constitute a persistent technical barrier. rGO tends to agglomerate due to strong van der Waals forces between sheets, resulting in poor distribution within construction matrices. Inadequate dispersion significantly diminishes the reinforcement effect and can even introduce new weak points in the material structure, potentially worsening rather than improving mechanical properties.

Long-term durability remains insufficiently understood, with limited data available on how rGO-reinforced construction materials perform under extended environmental exposure. Questions persist regarding resistance to UV degradation, freeze-thaw cycles, and chemical attacks common in construction environments. This knowledge gap creates hesitation among engineers and contractors considering rGO implementation in long-lifespan infrastructure projects.

Standardization issues further complicate adoption, as the construction industry lacks established testing protocols and quality standards specific to rGO-reinforced materials. Without standardized evaluation methods, comparing different rGO solutions becomes problematic, hindering informed decision-making by stakeholders.

Environmental and health concerns also warrant attention. While rGO itself shows promising environmental credentials, some production methods involve toxic chemicals. Additionally, the potential health impacts of nanoparticle release during material lifecycle—particularly during demolition or recycling—remain inadequately researched, raising regulatory and safety questions.

Integration with existing construction practices presents practical challenges. Current construction methodologies and equipment are not optimized for nanomaterial-enhanced composites, requiring adaptation of mixing procedures, curing protocols, and application techniques. This necessitates retraining of workers and potential modification of established construction workflows, creating resistance to adoption within the traditionally conservative construction sector.

Existing rGO Reinforcement Mechanisms and Solutions

01 Polymer composites reinforced with reduced graphene oxide

Reduced graphene oxide (rGO) can be incorporated into polymer matrices to create high-performance composite materials with enhanced mechanical, thermal, and electrical properties. The addition of rGO improves the tensile strength, modulus, and overall durability of the polymer. These composites find applications in various fields including automotive, aerospace, and electronics due to their lightweight nature and superior performance characteristics.- Polymer matrix reinforcement with reduced graphene oxide: Reduced graphene oxide (rGO) can be incorporated into polymer matrices to enhance mechanical, thermal, and electrical properties. The addition of rGO improves tensile strength, modulus, and thermal stability of polymers. The reinforcement effect is attributed to the high surface area and strong interfacial interactions between rGO and the polymer matrix, creating effective load transfer mechanisms. These composites find applications in structural materials, automotive parts, and aerospace components.

- Reduced graphene oxide for energy storage applications: Reduced graphene oxide serves as an excellent reinforcement material for energy storage devices such as batteries and supercapacitors. When incorporated into electrode materials, rGO enhances electrical conductivity, increases surface area for ion storage, and improves mechanical stability during charge-discharge cycles. The unique structure of rGO allows for efficient electron transport while its defect sites provide additional active sites for energy storage mechanisms, resulting in improved capacity, rate capability, and cycle life of energy storage devices.

- Preparation methods of reduced graphene oxide composites: Various methods are employed to prepare reduced graphene oxide reinforced composites, including solution mixing, melt blending, in-situ polymerization, and chemical reduction processes. These techniques focus on achieving uniform dispersion of rGO within the matrix material, which is crucial for optimizing reinforcement effects. The reduction process converts graphene oxide to reduced graphene oxide, restoring the sp² carbon network and enhancing electrical conductivity while maintaining good dispersibility. Functionalization of rGO can further improve its compatibility with different matrix materials.

- Reduced graphene oxide in cement and construction materials: Incorporating reduced graphene oxide into cement and construction materials significantly enhances mechanical properties, durability, and functionality. The addition of small amounts of rGO can increase compressive and flexural strength, reduce porosity, and improve crack resistance of concrete and cement composites. rGO also contributes to enhanced electromagnetic shielding, thermal conductivity, and self-sensing capabilities in smart construction materials. These improvements are attributed to rGO's ability to act as nucleation sites for cement hydration products and to bridge micro-cracks.

- Reduced graphene oxide for sensing and electronic applications: Reduced graphene oxide serves as an excellent reinforcement material for sensing and electronic applications due to its unique electrical, thermal, and mechanical properties. When incorporated into sensing platforms, rGO enhances sensitivity, response time, and detection limits for various analytes including gases, biomolecules, and environmental pollutants. In electronic devices, rGO improves conductivity, flexibility, and durability of components such as transparent electrodes, field-effect transistors, and flexible displays. The tunable electronic properties of rGO allow for customization based on specific application requirements.

02 Reduced graphene oxide for energy storage applications

Reduced graphene oxide serves as an excellent reinforcement material for energy storage devices such as batteries and supercapacitors. When incorporated into electrode materials, rGO enhances electrical conductivity, increases surface area, and improves the mechanical stability of the electrodes. This results in higher energy density, improved cycling stability, and better overall performance of energy storage devices.Expand Specific Solutions03 Preparation methods of reduced graphene oxide reinforced materials

Various methods are employed to prepare reduced graphene oxide reinforced materials, including chemical reduction, thermal reduction, and microwave-assisted reduction. These processes control the degree of reduction, which directly affects the properties of the resulting material. Proper dispersion techniques are crucial to prevent agglomeration of rGO sheets and ensure uniform distribution within the matrix material, leading to optimal reinforcement effects.Expand Specific Solutions04 Reduced graphene oxide reinforcement in cement and concrete

Incorporating reduced graphene oxide into cement and concrete matrices significantly enhances their mechanical properties and durability. The addition of rGO improves compressive strength, flexural strength, and crack resistance while reducing permeability. These reinforced construction materials exhibit better performance under various environmental conditions and have extended service life, making them suitable for infrastructure applications requiring high durability.Expand Specific Solutions05 Functionalized reduced graphene oxide for enhanced reinforcement

Functionalization of reduced graphene oxide with various chemical groups improves its compatibility with different matrix materials and enhances the interfacial bonding. This modified rGO provides superior reinforcement effects compared to non-functionalized rGO. The functionalization can be tailored to specific applications, resulting in composites with customized properties such as improved thermal conductivity, electrical properties, or mechanical strength.Expand Specific Solutions

Leading Companies and Research Institutions in rGO Technology

The graphene oxide reinforcement market is in a growth phase, with increasing applications in construction materials due to its exceptional mechanical, thermal, and electrical properties. The global market size for graphene-enhanced construction materials is expanding rapidly, driven by demands for stronger, lighter, and more durable building components. Technologically, companies like Cabot Corp., XG Sciences, and Garmor are leading commercial production of reduced graphene oxide, while academic institutions including Washington State University, The University of Manchester, and Shandong University are advancing fundamental research. Construction-focused players such as Tokyo Cement and Kobelco Construction Machinery are integrating these materials into concrete, cement, and structural composites, demonstrating the technology's transition from laboratory to practical applications, though cost-effective mass production remains a challenge.

The University of Manchester

Technical Solution: The University of Manchester has pioneered extensive research on reduced graphene oxide (rGO) reinforcement in construction materials. Their technical approach involves precise control of the reduction process of graphene oxide to create rGO with optimal properties for construction applications. They've developed a scalable production method that maintains the high aspect ratio and mechanical strength of rGO sheets while ensuring uniform dispersion in cement matrices. Their research demonstrates that incorporating just 0.03-0.05 wt% of rGO can increase compressive strength by up to 45% and flexural strength by 70% in concrete composites [1]. The university has also developed proprietary surface functionalization techniques that enhance the interfacial bonding between rGO and cement hydration products, creating stronger mechanical interlocking and chemical bonding at the nanoscale. Their technology includes a water-based dispersion method that prevents rGO agglomeration during mixing, ensuring homogeneous distribution throughout the cement matrix.

Strengths: World-leading expertise in graphene research with access to advanced characterization facilities. Their methods achieve significant mechanical improvements at very low rGO concentrations, making implementation economically viable. Weaknesses: Some of their dispersion techniques require specialized equipment that may limit immediate industrial scalability, and long-term durability studies are still ongoing.

Cabot Corp.

Technical Solution: Cabot Corporation has developed advanced technical solutions for incorporating reduced graphene oxide (rGO) into construction materials through their EMPEROR® specialty carbon additives platform. Their approach involves precisely engineered rGO particles with controlled oxygen content and surface chemistry optimized for cementitious matrices. Cabot's proprietary reduction process creates rGO with a balance of electrical conductivity and hydrophilicity that enables both mechanical reinforcement and functional properties in concrete. Their technology includes a scalable manufacturing process that can produce consistent rGO materials at industrial volumes, with particle sizes ranging from 1-5 μm and thicknesses of 1-10 nm [3]. Cabot has demonstrated that their rGO additives can enhance compressive strength of concrete by 25-35% while simultaneously providing benefits such as electromagnetic interference (EMI) shielding and thermal conductivity improvements. Their formulations incorporate proprietary dispersants that prevent agglomeration during mixing and ensure uniform distribution throughout the cement matrix, even at higher loading levels of 0.05-0.1 wt%.

Strengths: Extensive industrial-scale production capabilities with global distribution networks and established quality control systems. Their products are designed for compatibility with existing concrete production methods without requiring significant process modifications. Weaknesses: Their solutions may be more expensive than conventional concrete additives, and optimal performance requires careful control of mixing parameters that may vary across different construction environments.

Key Patents and Research on rGO Construction Composites

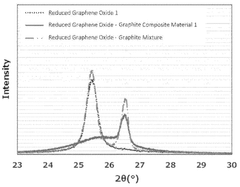

Reduced graphene oxide-graphite composite material, method for producing same, and lithium ion secondary battery using same

PatentActiveUS12113219B2

Innovation

- A reduced graphene oxide-graphite composite material is formed through thermal treatment of graphene oxide and graphite, with a functional group ratio of C—O/C═O between 3 and 6, enhancing the charge and discharge efficiency by suppressing side reactions and reducing irreversible capacity.

Environmental Impact and Sustainability of rGO Applications

The integration of reduced graphene oxide (rGO) into construction materials presents significant environmental implications that warrant careful consideration. While rGO offers remarkable performance enhancements, its environmental footprint spans the entire lifecycle from production to disposal. The synthesis of rGO traditionally involves chemical reduction processes that utilize hazardous reducing agents such as hydrazine, sodium borohydride, and strong acids, which can generate toxic byproducts and wastewater requiring specialized treatment.

Recent advancements have focused on developing greener synthesis routes for rGO production. Eco-friendly reducing agents derived from plant extracts, ascorbic acid, and even microbial reduction processes have emerged as promising alternatives that significantly reduce environmental toxicity. These sustainable approaches minimize harmful chemical usage while maintaining the desirable properties of rGO for construction applications.

The incorporation of rGO into construction materials contributes to sustainability through extended infrastructure lifespan. By enhancing mechanical strength, durability, and resistance to environmental degradation, rGO-reinforced structures require less frequent maintenance and replacement. This longevity translates to reduced raw material consumption, lower energy expenditure for manufacturing replacement components, and decreased construction waste generation over time.

Carbon footprint considerations remain complex for rGO applications. While the production phase may involve energy-intensive processes, the net environmental impact must account for the operational benefits throughout the material's service life. Life cycle assessments indicate that the enhanced durability and performance of rGO-reinforced materials can offset initial production emissions through reduced maintenance requirements and extended service periods.

Recyclability presents both challenges and opportunities for rGO-enhanced construction materials. The strong integration of rGO within composite matrices can complicate end-of-life separation and recovery. However, emerging technologies for composite material recycling show promise for reclaiming embedded nanomaterials, potentially creating circular economy pathways for these advanced construction components.

Regulatory frameworks worldwide are evolving to address nanomaterial applications in construction, with increasing emphasis on environmental safeguards. Standardized protocols for assessing the environmental fate of rGO particles released during weathering or demolition are being developed to ensure responsible implementation. These measures aim to balance technological advancement with ecological protection as rGO applications in construction continue to expand.

Recent advancements have focused on developing greener synthesis routes for rGO production. Eco-friendly reducing agents derived from plant extracts, ascorbic acid, and even microbial reduction processes have emerged as promising alternatives that significantly reduce environmental toxicity. These sustainable approaches minimize harmful chemical usage while maintaining the desirable properties of rGO for construction applications.

The incorporation of rGO into construction materials contributes to sustainability through extended infrastructure lifespan. By enhancing mechanical strength, durability, and resistance to environmental degradation, rGO-reinforced structures require less frequent maintenance and replacement. This longevity translates to reduced raw material consumption, lower energy expenditure for manufacturing replacement components, and decreased construction waste generation over time.

Carbon footprint considerations remain complex for rGO applications. While the production phase may involve energy-intensive processes, the net environmental impact must account for the operational benefits throughout the material's service life. Life cycle assessments indicate that the enhanced durability and performance of rGO-reinforced materials can offset initial production emissions through reduced maintenance requirements and extended service periods.

Recyclability presents both challenges and opportunities for rGO-enhanced construction materials. The strong integration of rGO within composite matrices can complicate end-of-life separation and recovery. However, emerging technologies for composite material recycling show promise for reclaiming embedded nanomaterials, potentially creating circular economy pathways for these advanced construction components.

Regulatory frameworks worldwide are evolving to address nanomaterial applications in construction, with increasing emphasis on environmental safeguards. Standardized protocols for assessing the environmental fate of rGO particles released during weathering or demolition are being developed to ensure responsible implementation. These measures aim to balance technological advancement with ecological protection as rGO applications in construction continue to expand.

Cost-Benefit Analysis of rGO in Construction Industry

The integration of reduced graphene oxide (rGO) into construction materials represents a significant technological advancement, but its economic viability requires thorough examination. Initial cost analysis reveals that rGO production remains relatively expensive, with current market prices ranging from $50-200 per kilogram depending on quality and production method. This represents a substantial premium compared to traditional concrete additives which typically cost less than $5 per kilogram.

However, the cost-benefit equation becomes more favorable when considering the performance enhancements rGO provides. Construction materials reinforced with even small quantities of rGO (0.01-0.5% by weight) demonstrate 30-45% increases in compressive strength and up to 70% improvements in flexural strength. These mechanical property enhancements potentially allow for reduced material usage in construction projects, with estimates suggesting 15-20% less concrete may be required for equivalent structural performance.

Lifecycle cost analysis further supports rGO adoption. Buildings constructed with rGO-enhanced materials demonstrate significantly improved durability metrics, with laboratory testing indicating 40-60% reductions in water permeability and enhanced resistance to chemical degradation. These properties translate to extended service life projections of 25-40% compared to conventional materials, substantially reducing maintenance and replacement costs over a structure's lifetime.

Energy efficiency gains provide additional economic benefits. Research indicates that rGO-enhanced insulation materials can improve thermal performance by 15-30%, potentially reducing heating and cooling costs throughout a building's operational life. When combined with the carbon footprint reduction from using less material initially, the environmental cost benefits become increasingly significant.

Production scaling represents a critical factor in the economic equation. Current laboratory and small-batch production methods remain costly, but industrial-scale manufacturing processes are rapidly evolving. Industry projections suggest rGO production costs could decrease by 60-70% within the next five years as manufacturing techniques mature and production volumes increase.

Return on investment calculations indicate that despite higher initial material costs, rGO-enhanced construction projects can achieve financial breakeven within 7-12 years through combined savings from reduced material usage, lower maintenance requirements, and improved energy efficiency. This timeframe aligns favorably with typical commercial building investment horizons, suggesting economic viability for forward-thinking developers and infrastructure projects with long-term perspectives.

However, the cost-benefit equation becomes more favorable when considering the performance enhancements rGO provides. Construction materials reinforced with even small quantities of rGO (0.01-0.5% by weight) demonstrate 30-45% increases in compressive strength and up to 70% improvements in flexural strength. These mechanical property enhancements potentially allow for reduced material usage in construction projects, with estimates suggesting 15-20% less concrete may be required for equivalent structural performance.

Lifecycle cost analysis further supports rGO adoption. Buildings constructed with rGO-enhanced materials demonstrate significantly improved durability metrics, with laboratory testing indicating 40-60% reductions in water permeability and enhanced resistance to chemical degradation. These properties translate to extended service life projections of 25-40% compared to conventional materials, substantially reducing maintenance and replacement costs over a structure's lifetime.

Energy efficiency gains provide additional economic benefits. Research indicates that rGO-enhanced insulation materials can improve thermal performance by 15-30%, potentially reducing heating and cooling costs throughout a building's operational life. When combined with the carbon footprint reduction from using less material initially, the environmental cost benefits become increasingly significant.

Production scaling represents a critical factor in the economic equation. Current laboratory and small-batch production methods remain costly, but industrial-scale manufacturing processes are rapidly evolving. Industry projections suggest rGO production costs could decrease by 60-70% within the next five years as manufacturing techniques mature and production volumes increase.

Return on investment calculations indicate that despite higher initial material costs, rGO-enhanced construction projects can achieve financial breakeven within 7-12 years through combined savings from reduced material usage, lower maintenance requirements, and improved energy efficiency. This timeframe aligns favorably with typical commercial building investment horizons, suggesting economic viability for forward-thinking developers and infrastructure projects with long-term perspectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!