Analysis of Reduced Graphene Oxide's Thermal Conductivity

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO Thermal Conductivity Background and Objectives

Reduced graphene oxide (rGO) has emerged as a revolutionary material in the field of thermal management due to its exceptional thermal conductivity properties. The evolution of this technology can be traced back to the groundbreaking isolation of graphene in 2004 by Geim and Novoselevsky, which subsequently led to extensive research into graphene derivatives, including rGO. The thermal conductivity of pristine graphene has been reported to exceed 5000 W/mK at room temperature, positioning it as one of the most thermally conductive materials known to science.

However, the transition from graphene to reduced graphene oxide introduces significant complexities in thermal performance. The reduction process of graphene oxide (GO) to form rGO creates a material with varying degrees of oxygen-containing functional groups and structural defects, which substantially impacts its thermal conductivity. Historical data indicates that the thermal conductivity of rGO typically ranges from 30 to 1500 W/mK, depending on the reduction method, degree of reduction, and structural integrity.

The technological trajectory of rGO thermal conductivity research has been characterized by progressive improvements in reduction techniques, including chemical, thermal, and electrochemical approaches. Each method yields rGO with distinct thermal properties, reflecting the intricate relationship between processing parameters and material performance. Recent advancements have focused on developing hybrid reduction methods to optimize the removal of oxygen functionalities while minimizing structural damage.

The primary objective of analyzing rGO thermal conductivity is to establish a comprehensive understanding of the structure-property relationships that govern heat transfer mechanisms in this material. This includes investigating the influence of defect density, flake size, layer stacking, and residual functional groups on thermal transport pathways. Additionally, the research aims to develop standardized measurement protocols for accurately assessing thermal conductivity in rGO-based systems.

Another critical goal is to bridge the gap between theoretical predictions and experimental observations of rGO thermal behavior. Molecular dynamics simulations suggest that strategically engineered defects and interfaces could potentially enhance rather than diminish thermal conductivity under specific conditions, presenting an intriguing avenue for exploration.

From an application perspective, the analysis seeks to determine the feasibility of rGO as a cost-effective alternative to traditional thermal management materials in electronics, aerospace, and energy storage systems. The ultimate technological objective is to develop scalable production methods for rGO with tailored thermal conductivity profiles that can meet the demanding requirements of next-generation thermal management solutions.

However, the transition from graphene to reduced graphene oxide introduces significant complexities in thermal performance. The reduction process of graphene oxide (GO) to form rGO creates a material with varying degrees of oxygen-containing functional groups and structural defects, which substantially impacts its thermal conductivity. Historical data indicates that the thermal conductivity of rGO typically ranges from 30 to 1500 W/mK, depending on the reduction method, degree of reduction, and structural integrity.

The technological trajectory of rGO thermal conductivity research has been characterized by progressive improvements in reduction techniques, including chemical, thermal, and electrochemical approaches. Each method yields rGO with distinct thermal properties, reflecting the intricate relationship between processing parameters and material performance. Recent advancements have focused on developing hybrid reduction methods to optimize the removal of oxygen functionalities while minimizing structural damage.

The primary objective of analyzing rGO thermal conductivity is to establish a comprehensive understanding of the structure-property relationships that govern heat transfer mechanisms in this material. This includes investigating the influence of defect density, flake size, layer stacking, and residual functional groups on thermal transport pathways. Additionally, the research aims to develop standardized measurement protocols for accurately assessing thermal conductivity in rGO-based systems.

Another critical goal is to bridge the gap between theoretical predictions and experimental observations of rGO thermal behavior. Molecular dynamics simulations suggest that strategically engineered defects and interfaces could potentially enhance rather than diminish thermal conductivity under specific conditions, presenting an intriguing avenue for exploration.

From an application perspective, the analysis seeks to determine the feasibility of rGO as a cost-effective alternative to traditional thermal management materials in electronics, aerospace, and energy storage systems. The ultimate technological objective is to develop scalable production methods for rGO with tailored thermal conductivity profiles that can meet the demanding requirements of next-generation thermal management solutions.

Market Applications and Demand Analysis for rGO

The global market for reduced graphene oxide (rGO) is experiencing significant growth driven by its exceptional thermal conductivity properties. Current market analysis indicates that the thermal management sector represents one of the fastest-growing application segments for rGO materials, with particular demand in electronics cooling solutions. The thermal interface materials (TIMs) market, where rGO plays an increasingly important role, is projected to reach $4.3 billion by 2025, growing at a CAGR of approximately 11.2% from 2020.

Electronics manufacturers are actively seeking advanced thermal management solutions as device miniaturization continues while processing power increases. This paradoxical trend creates critical heat dissipation challenges that conventional materials cannot adequately address. rGO-based thermal interface materials offer superior performance with thermal conductivity values reaching up to 3000-5000 W/mK (theoretical maximum), significantly outperforming traditional options like thermal greases (3-8 W/mK) and phase change materials (0.7-3 W/mK).

The automotive industry represents another substantial market for rGO thermal applications, particularly with the rapid expansion of electric vehicles (EVs). Battery thermal management systems in EVs require materials that can efficiently dissipate heat to prevent thermal runaway and extend battery life. Market research indicates that the EV thermal management system market is expected to grow at 24.5% CAGR through 2028, creating substantial opportunities for rGO-based solutions.

Aerospace and defense sectors are also showing increased interest in rGO thermal management applications. These industries require materials that maintain structural integrity and thermal performance under extreme conditions. The lightweight nature of rGO combined with its thermal properties makes it particularly valuable for these high-performance applications where weight reduction directly impacts operational efficiency and costs.

Consumer electronics manufacturers represent the largest current adopters of rGO thermal management solutions. Smartphones, tablets, and laptops increasingly incorporate rGO-based thermal spreaders and interface materials. Market penetration in this sector is expected to accelerate as manufacturing processes for rGO become more standardized and cost-effective, with production volumes increasing approximately 35% annually.

Regional analysis shows Asia-Pacific dominating the market demand for rGO thermal applications, accounting for approximately 45% of global consumption. This regional concentration aligns with the geographic distribution of electronics manufacturing. North America and Europe follow with growing demand primarily in high-performance computing, aerospace, and premium consumer electronics applications.

Despite promising growth trajectories, market adoption faces challenges related to production scalability and cost considerations. Current rGO production methods yield materials with varying quality and thermal conductivity properties, creating inconsistencies that limit widespread industrial implementation. Industry stakeholders indicate that achieving price points below $200 per kilogram for high-quality rGO would significantly accelerate market penetration across multiple industries.

Electronics manufacturers are actively seeking advanced thermal management solutions as device miniaturization continues while processing power increases. This paradoxical trend creates critical heat dissipation challenges that conventional materials cannot adequately address. rGO-based thermal interface materials offer superior performance with thermal conductivity values reaching up to 3000-5000 W/mK (theoretical maximum), significantly outperforming traditional options like thermal greases (3-8 W/mK) and phase change materials (0.7-3 W/mK).

The automotive industry represents another substantial market for rGO thermal applications, particularly with the rapid expansion of electric vehicles (EVs). Battery thermal management systems in EVs require materials that can efficiently dissipate heat to prevent thermal runaway and extend battery life. Market research indicates that the EV thermal management system market is expected to grow at 24.5% CAGR through 2028, creating substantial opportunities for rGO-based solutions.

Aerospace and defense sectors are also showing increased interest in rGO thermal management applications. These industries require materials that maintain structural integrity and thermal performance under extreme conditions. The lightweight nature of rGO combined with its thermal properties makes it particularly valuable for these high-performance applications where weight reduction directly impacts operational efficiency and costs.

Consumer electronics manufacturers represent the largest current adopters of rGO thermal management solutions. Smartphones, tablets, and laptops increasingly incorporate rGO-based thermal spreaders and interface materials. Market penetration in this sector is expected to accelerate as manufacturing processes for rGO become more standardized and cost-effective, with production volumes increasing approximately 35% annually.

Regional analysis shows Asia-Pacific dominating the market demand for rGO thermal applications, accounting for approximately 45% of global consumption. This regional concentration aligns with the geographic distribution of electronics manufacturing. North America and Europe follow with growing demand primarily in high-performance computing, aerospace, and premium consumer electronics applications.

Despite promising growth trajectories, market adoption faces challenges related to production scalability and cost considerations. Current rGO production methods yield materials with varying quality and thermal conductivity properties, creating inconsistencies that limit widespread industrial implementation. Industry stakeholders indicate that achieving price points below $200 per kilogram for high-quality rGO would significantly accelerate market penetration across multiple industries.

Current Challenges in rGO Thermal Conductivity Research

Despite significant advancements in reduced graphene oxide (rGO) research, several critical challenges persist in accurately determining and optimizing its thermal conductivity properties. The primary obstacle remains the substantial variability in reported thermal conductivity values, ranging from 3 to 2000 W/mK, which creates significant uncertainty for practical applications. This inconsistency stems from multiple factors including synthesis methods, reduction degree, defect density, and measurement techniques.

The reduction process itself presents a fundamental challenge, as the removal of oxygen-containing functional groups significantly impacts thermal performance. Current reduction methods—chemical, thermal, and electrochemical—each produce rGO with different structural characteristics and defect distributions. Researchers struggle to establish standardized reduction protocols that consistently yield rGO with predictable thermal properties.

Structural defects represent another major hurdle in rGO thermal conductivity research. Vacancies, grain boundaries, and residual functional groups act as phonon scattering centers, dramatically reducing thermal transport efficiency. The quantitative relationship between defect density and thermal conductivity remains poorly understood, complicating efforts to engineer rGO with targeted thermal properties.

Measurement methodology presents additional complications. Techniques such as the 3ω method, time-domain thermoreflectance (TDTR), and laser flash analysis often yield divergent results when applied to the same rGO samples. This inconsistency arises from the anisotropic nature of rGO and the challenges in preparing uniform samples with well-defined geometries and interfaces.

Interface thermal resistance emerges as a critical but understudied factor. When integrating rGO into composite materials or devices, thermal boundary resistance at rGO-matrix interfaces can dominate the overall thermal performance. Current research lacks comprehensive models to predict and mitigate these interfacial effects.

Scale-up and manufacturing reproducibility constitute significant barriers to commercial adoption. Laboratory-scale synthesis methods that produce high-quality rGO with excellent thermal properties often prove difficult to scale while maintaining consistent quality. The trade-off between production volume, cost, and thermal performance remains unresolved.

Environmental stability represents an emerging concern, as rGO's thermal properties can degrade under operational conditions including temperature cycling, humidity exposure, and mechanical stress. Long-term reliability studies are scarce, limiting confidence in rGO-based thermal management solutions for demanding applications.

Addressing these interconnected challenges requires interdisciplinary approaches combining materials science, thermal physics, and advanced characterization techniques to develop standardized protocols for synthesis, measurement, and performance evaluation of rGO for thermal management applications.

The reduction process itself presents a fundamental challenge, as the removal of oxygen-containing functional groups significantly impacts thermal performance. Current reduction methods—chemical, thermal, and electrochemical—each produce rGO with different structural characteristics and defect distributions. Researchers struggle to establish standardized reduction protocols that consistently yield rGO with predictable thermal properties.

Structural defects represent another major hurdle in rGO thermal conductivity research. Vacancies, grain boundaries, and residual functional groups act as phonon scattering centers, dramatically reducing thermal transport efficiency. The quantitative relationship between defect density and thermal conductivity remains poorly understood, complicating efforts to engineer rGO with targeted thermal properties.

Measurement methodology presents additional complications. Techniques such as the 3ω method, time-domain thermoreflectance (TDTR), and laser flash analysis often yield divergent results when applied to the same rGO samples. This inconsistency arises from the anisotropic nature of rGO and the challenges in preparing uniform samples with well-defined geometries and interfaces.

Interface thermal resistance emerges as a critical but understudied factor. When integrating rGO into composite materials or devices, thermal boundary resistance at rGO-matrix interfaces can dominate the overall thermal performance. Current research lacks comprehensive models to predict and mitigate these interfacial effects.

Scale-up and manufacturing reproducibility constitute significant barriers to commercial adoption. Laboratory-scale synthesis methods that produce high-quality rGO with excellent thermal properties often prove difficult to scale while maintaining consistent quality. The trade-off between production volume, cost, and thermal performance remains unresolved.

Environmental stability represents an emerging concern, as rGO's thermal properties can degrade under operational conditions including temperature cycling, humidity exposure, and mechanical stress. Long-term reliability studies are scarce, limiting confidence in rGO-based thermal management solutions for demanding applications.

Addressing these interconnected challenges requires interdisciplinary approaches combining materials science, thermal physics, and advanced characterization techniques to develop standardized protocols for synthesis, measurement, and performance evaluation of rGO for thermal management applications.

Current Measurement and Enhancement Techniques

01 Thermal conductivity enhancement methods for reduced graphene oxide

Various methods can be employed to enhance the thermal conductivity of reduced graphene oxide (rGO). These include specific reduction processes, structural modifications, and optimization of reduction parameters. The thermal conductivity of rGO can be significantly improved through controlled reduction techniques that preserve the graphene structure while removing oxygen-containing groups. These methods result in materials with superior heat transfer capabilities suitable for thermal management applications.- Thermal conductivity enhancement methods for reduced graphene oxide: Various methods can be employed to enhance the thermal conductivity of reduced graphene oxide (rGO). These include specific reduction processes, structural modifications, and optimization of reduction parameters. The thermal conductivity of rGO can be significantly improved through controlled reduction techniques that preserve the graphene structure while removing oxygen-containing groups, resulting in better heat transfer properties.

- Composite materials with reduced graphene oxide for thermal management: Reduced graphene oxide can be incorporated into composite materials to enhance their thermal conductivity. These composites typically combine rGO with polymers, metals, or ceramics to create materials with superior heat dissipation properties. The dispersion method, interface engineering, and concentration of rGO in the matrix material significantly affect the resulting thermal conductivity of the composite, making these materials suitable for thermal management applications.

- Structural modifications of reduced graphene oxide for improved thermal properties: Structural modifications of reduced graphene oxide, such as creating three-dimensional architectures, controlling defect density, or introducing specific functional groups, can significantly impact its thermal conductivity. These modifications alter the phonon transport pathways and reduce thermal boundary resistance, resulting in enhanced heat transfer capabilities. Techniques like controlled annealing, chemical functionalization, and physical structuring can be employed to optimize the thermal properties of rGO.

- Reduced graphene oxide films and coatings for thermal applications: Thin films and coatings based on reduced graphene oxide demonstrate promising thermal conductivity properties for various applications. These films can be prepared through methods such as vacuum filtration, spray coating, or layer-by-layer assembly. The thickness, density, and alignment of rGO sheets within these films significantly influence their thermal conductivity. Such films can be applied to surfaces requiring efficient heat dissipation or used as interfacial thermal materials.

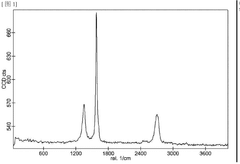

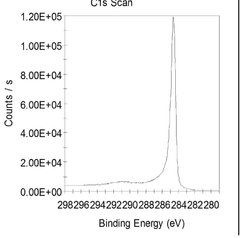

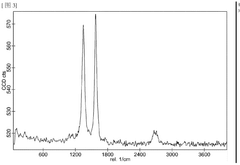

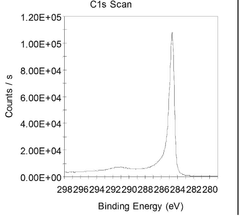

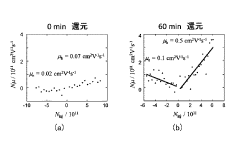

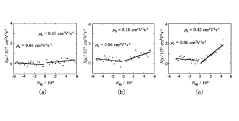

- Measurement and characterization techniques for rGO thermal conductivity: Various techniques are employed to accurately measure and characterize the thermal conductivity of reduced graphene oxide materials. These include laser flash analysis, thermal bridge methods, 3-omega technique, and transient plane source methods. The measurement approaches must account for the anisotropic nature of rGO thermal conductivity, with in-plane conductivity typically being much higher than through-plane conductivity. Standardized characterization methods are essential for comparing different rGO materials and evaluating their performance in thermal management applications.

02 Composite materials with reduced graphene oxide for improved thermal conductivity

Reduced graphene oxide can be incorporated into various composite materials to enhance their thermal conductivity. These composites typically combine rGO with polymers, metals, or ceramics to create materials with superior heat dissipation properties. The addition of rGO, even in small quantities, can significantly improve the thermal conductivity of the base material due to the formation of efficient heat conduction pathways. These composites find applications in electronics cooling, thermal interface materials, and heat exchangers.Expand Specific Solutions03 Structural modifications of reduced graphene oxide for thermal applications

The thermal conductivity of reduced graphene oxide can be enhanced through various structural modifications. These include creating 3D architectures, controlling the degree of reduction, manipulating defect density, and optimizing the flake size and orientation. By engineering the structure at the nano and microscale, the phonon transport pathways can be optimized, leading to improved thermal conductivity. These structurally modified rGO materials are particularly valuable in thermal management systems where efficient heat dissipation is critical.Expand Specific Solutions04 Functionalization of reduced graphene oxide for thermal conductivity control

Functionalization of reduced graphene oxide with various chemical groups or nanoparticles can be used to tailor its thermal conductivity properties. By attaching specific functional groups or incorporating nanoparticles onto the rGO surface, the thermal transport behavior can be modified. This approach allows for precise control over the thermal conductivity, making it possible to design materials with targeted thermal properties for specific applications such as thermal interface materials, heat spreaders, or thermal energy storage systems.Expand Specific Solutions05 Measurement and characterization techniques for reduced graphene oxide thermal conductivity

Various techniques have been developed to accurately measure and characterize the thermal conductivity of reduced graphene oxide materials. These include laser flash analysis, steady-state methods, transient plane source techniques, and optical methods. Accurate measurement is crucial for understanding the relationship between the structure, processing conditions, and resulting thermal properties of rGO. These characterization methods help in optimizing the material for specific thermal management applications and validating theoretical models of heat transport in graphene-based materials.Expand Specific Solutions

Leading Research Groups and Companies in rGO Development

The thermal conductivity analysis of reduced graphene oxide (rGO) is currently in a growth phase, with increasing market interest driven by applications in thermal management and electronics. The global market for rGO thermal materials is expanding rapidly, though still smaller than established thermal interface materials. Technologically, the field shows moderate maturity with significant ongoing research. Leading players include Global Graphene Group and LG Electronics focusing on commercial applications, while academic institutions like The University of Manchester and Fudan University drive fundamental research. Industrial players such as Tata Steel and NTT are exploring integration into existing products, while specialized materials companies like Jiangsu Sidike and Nippon Shokubai work on enhancing rGO's thermal properties for specific applications.

GLOBAL GRAPHENE GROUP INC

Technical Solution: Global Graphene Group has developed proprietary technologies for producing reduced graphene oxide (rGO) with enhanced thermal conductivity properties. Their approach involves precise control of reduction processes to optimize the removal of oxygen-containing functional groups while preserving the graphene lattice structure. The company employs a combination of chemical and thermal reduction methods that can be tailored to achieve specific thermal conductivity values ranging from 300-1500 W/mK depending on the application requirements. Their manufacturing process includes post-reduction treatments that minimize defects and restore sp2 carbon networks, which are critical for high thermal conductivity. Global Graphene Group has also developed composite materials incorporating their rGO to enhance thermal management in electronics, batteries, and automotive applications.

Strengths: Scalable production capabilities for high-quality rGO with consistent thermal properties; extensive IP portfolio covering reduction processes. Weaknesses: Higher production costs compared to conventional thermal materials; challenges in achieving uniform thermal conductivity across large-area films.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed proprietary technologies for utilizing reduced graphene oxide with optimized thermal conductivity in electronic devices. Their approach focuses on practical applications of rGO in thermal management systems for consumer electronics. LG has created specialized reduction processes that balance the degree of reduction with processability, achieving thermal conductivity values of 300-600 W/mK in their rGO materials while maintaining compatibility with their manufacturing processes. The company has integrated these materials into thermal interface materials, heat spreaders, and cooling systems for smartphones, displays, and home appliances. LG's technology includes methods for creating rGO-polymer composites with enhanced thermal conductivity that can be applied as coatings or formed into complex shapes required for modern electronic devices.

Strengths: Strong integration capabilities with existing product lines; practical focus on manufacturability and cost-effectiveness; extensive testing infrastructure for thermal performance validation. Weaknesses: Less emphasis on pushing the theoretical limits of thermal conductivity; proprietary nature limits broader scientific contribution to the field.

Key Scientific Breakthroughs in rGO Thermal Properties

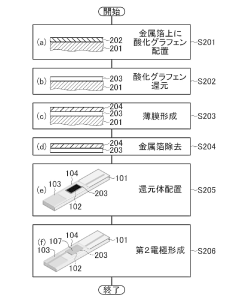

Reduced graphene oxide and use thereof

PatentWO2025123466A1

Innovation

- Reduced graphene oxide is prepared by the steps of graphite oxidation, preparation of material cakes, puffing, and carbonization reduction. Controlling carbonization reduction is carried out under gas atmosphere or vacuum conditions, and appropriate gas is selected to avoid reaction with graphene or graphene oxide.

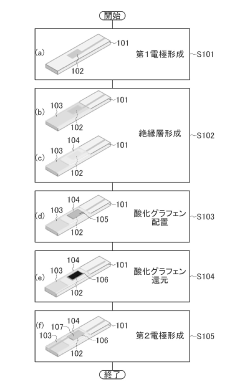

Method for evaluating conductivity of graphene oxide reductant

PatentActiveJP2017044475A

Innovation

- A method involving the formation of a first electrode on a substrate, followed by an insulating layer resistant to reducing atmospheres, placement of graphene oxide, reduction to a reductant form using hydrazine, and subsequent evaluation using time-resolved microwave conductivity measurement, with the insulating layer made of materials like amorphous fluororesin or polyvinylidene chloride, allowing for accurate conductivity assessment.

Manufacturing Scalability and Cost Analysis

The scalability of reduced graphene oxide (rGO) manufacturing processes represents a critical factor in its commercial viability for thermal management applications. Current production methods vary significantly in their scalability potential, with chemical reduction of graphene oxide emerging as the most industrially adaptable approach. This method allows for batch processing that can be scaled to multi-ton annual production capacities, though maintaining consistent thermal conductivity properties across large production volumes remains challenging. Thermal reduction methods, while effective at laboratory scale, face significant engineering challenges when scaled to industrial levels, particularly in achieving uniform heat distribution across larger material volumes.

Cost analysis reveals that raw material expenses constitute approximately 40-45% of total production costs for rGO with optimized thermal conductivity properties. High-purity graphite precursors, essential for achieving superior thermal performance, command premium prices ranging from $5,000 to $8,000 per ton. Chemical reducing agents add another significant cost component, particularly when environmentally friendly alternatives to hydrazine are employed. These green reducing agents can increase this cost segment by 15-30% but are increasingly necessary to meet regulatory requirements in major markets.

Processing costs represent another 35-40% of the total manufacturing expense, with energy consumption during thermal treatments being particularly significant. The energy requirements for producing thermally conductive rGO (approximately 12-18 kWh per kilogram) contribute substantially to the final product cost. Advanced quality control measures, necessary to ensure consistent thermal conductivity properties, add approximately 8-12% to overall production expenses but are essential for applications requiring reliable thermal performance.

Current market pricing for high thermal conductivity rGO ranges from $200 to $500 per kilogram, depending on quality specifications and thermal performance metrics. This price point remains prohibitive for mass-market applications but is becoming increasingly competitive for specialized thermal management solutions in electronics and aerospace sectors. Industry projections suggest that economies of scale could reduce production costs by 30-40% over the next five years, potentially bringing prices below $150 per kilogram for industrial-grade thermally conductive rGO.

The economic viability threshold for widespread adoption in consumer electronics cooling solutions is estimated at $80-100 per kilogram. Achieving this price point will require significant innovations in precursor material sourcing and processing efficiency. Several manufacturers are exploring vertical integration strategies, securing graphite mining operations to stabilize raw material costs and investing in continuous flow production systems that could reduce energy consumption by up to 25% compared to batch processing methods.

Cost analysis reveals that raw material expenses constitute approximately 40-45% of total production costs for rGO with optimized thermal conductivity properties. High-purity graphite precursors, essential for achieving superior thermal performance, command premium prices ranging from $5,000 to $8,000 per ton. Chemical reducing agents add another significant cost component, particularly when environmentally friendly alternatives to hydrazine are employed. These green reducing agents can increase this cost segment by 15-30% but are increasingly necessary to meet regulatory requirements in major markets.

Processing costs represent another 35-40% of the total manufacturing expense, with energy consumption during thermal treatments being particularly significant. The energy requirements for producing thermally conductive rGO (approximately 12-18 kWh per kilogram) contribute substantially to the final product cost. Advanced quality control measures, necessary to ensure consistent thermal conductivity properties, add approximately 8-12% to overall production expenses but are essential for applications requiring reliable thermal performance.

Current market pricing for high thermal conductivity rGO ranges from $200 to $500 per kilogram, depending on quality specifications and thermal performance metrics. This price point remains prohibitive for mass-market applications but is becoming increasingly competitive for specialized thermal management solutions in electronics and aerospace sectors. Industry projections suggest that economies of scale could reduce production costs by 30-40% over the next five years, potentially bringing prices below $150 per kilogram for industrial-grade thermally conductive rGO.

The economic viability threshold for widespread adoption in consumer electronics cooling solutions is estimated at $80-100 per kilogram. Achieving this price point will require significant innovations in precursor material sourcing and processing efficiency. Several manufacturers are exploring vertical integration strategies, securing graphite mining operations to stabilize raw material costs and investing in continuous flow production systems that could reduce energy consumption by up to 25% compared to batch processing methods.

Environmental Impact and Sustainability Considerations

The production and processing of reduced graphene oxide (rGO) for thermal conductivity applications presents significant environmental considerations that must be addressed for sustainable implementation. The chemical reduction methods commonly used to convert graphene oxide to rGO often involve hazardous reducing agents such as hydrazine, sodium borohydride, and strong acids, which can generate toxic byproducts and waste streams. These processes require careful management to prevent environmental contamination and potential health risks to workers and surrounding communities.

Water usage represents another critical environmental factor in rGO production. The synthesis of graphene oxide, the precursor to rGO, typically employs the modified Hummers method which demands substantial quantities of water for washing and purification steps. In regions facing water scarcity, this intensive consumption pattern raises sustainability concerns that necessitate the development of water-efficient or water-recycling production techniques.

Energy consumption during thermal reduction processes for converting GO to rGO contributes significantly to the carbon footprint of these materials. High-temperature annealing methods commonly employed can require temperatures exceeding 1000°C, resulting in considerable energy expenditure. This energy demand underscores the importance of developing lower-temperature reduction methods or utilizing renewable energy sources to minimize environmental impact.

The life cycle assessment (LCA) of rGO-based thermal management solutions reveals potential environmental benefits despite production challenges. When properly implemented in electronic devices and thermal interface materials, rGO's superior thermal conductivity can enhance energy efficiency and extend product lifespans, potentially offsetting initial production impacts through reduced electronic waste generation and lower operational energy requirements over time.

Recycling and end-of-life considerations for rGO-containing products remain underdeveloped areas requiring further research. The nanoscale nature of rGO presents unique challenges for material recovery and separation from composite materials. Developing effective recycling methodologies for rGO-enhanced products would significantly improve their overall environmental sustainability profile and contribute to circular economy principles.

Emerging green synthesis approaches offer promising pathways to mitigate environmental concerns. Bio-based reducing agents derived from plant extracts, environmentally benign chemicals, and microwave-assisted reduction techniques are being explored as alternatives to conventional methods. These approaches aim to reduce toxic waste generation while maintaining the desirable thermal conductivity properties that make rGO valuable for thermal management applications.

Water usage represents another critical environmental factor in rGO production. The synthesis of graphene oxide, the precursor to rGO, typically employs the modified Hummers method which demands substantial quantities of water for washing and purification steps. In regions facing water scarcity, this intensive consumption pattern raises sustainability concerns that necessitate the development of water-efficient or water-recycling production techniques.

Energy consumption during thermal reduction processes for converting GO to rGO contributes significantly to the carbon footprint of these materials. High-temperature annealing methods commonly employed can require temperatures exceeding 1000°C, resulting in considerable energy expenditure. This energy demand underscores the importance of developing lower-temperature reduction methods or utilizing renewable energy sources to minimize environmental impact.

The life cycle assessment (LCA) of rGO-based thermal management solutions reveals potential environmental benefits despite production challenges. When properly implemented in electronic devices and thermal interface materials, rGO's superior thermal conductivity can enhance energy efficiency and extend product lifespans, potentially offsetting initial production impacts through reduced electronic waste generation and lower operational energy requirements over time.

Recycling and end-of-life considerations for rGO-containing products remain underdeveloped areas requiring further research. The nanoscale nature of rGO presents unique challenges for material recovery and separation from composite materials. Developing effective recycling methodologies for rGO-enhanced products would significantly improve their overall environmental sustainability profile and contribute to circular economy principles.

Emerging green synthesis approaches offer promising pathways to mitigate environmental concerns. Bio-based reducing agents derived from plant extracts, environmentally benign chemicals, and microwave-assisted reduction techniques are being explored as alternatives to conventional methods. These approaches aim to reduce toxic waste generation while maintaining the desirable thermal conductivity properties that make rGO valuable for thermal management applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!