How Heat Treatment Alters Reduced Graphene Oxide Properties

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Oxide Heat Treatment Background and Objectives

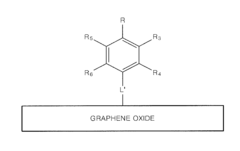

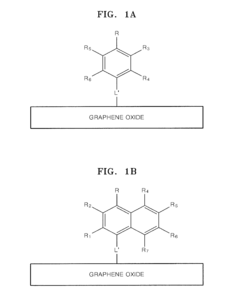

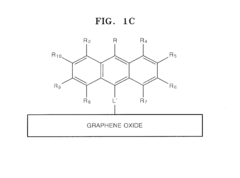

Graphene oxide (GO) has emerged as a revolutionary material in the field of nanotechnology since its discovery in the early 2000s. This two-dimensional carbon-based material, derived from graphite through oxidation processes, possesses unique physical and chemical properties that make it valuable across multiple industries. Heat treatment of GO represents a critical processing technique that fundamentally transforms its structure and properties, resulting in reduced graphene oxide (rGO) with characteristics that more closely resemble pristine graphene.

The evolution of GO heat treatment techniques has progressed significantly over the past decade. Initially, thermal reduction methods focused primarily on high-temperature annealing in inert atmospheres, typically at temperatures exceeding 1000°C. Recent advancements have expanded to include more energy-efficient approaches such as microwave-assisted reduction, flash reduction, and laser scribing, which offer more precise control over the reduction process while requiring less energy input.

Current technological trends indicate a growing interest in developing scalable and environmentally friendly reduction methods that maintain or enhance the desirable properties of rGO. The industry is moving toward techniques that allow for selective functionalization during the reduction process, enabling tailored material properties for specific applications.

The primary objective of this technical research is to comprehensively analyze how various heat treatment parameters—including temperature profiles, heating rates, atmosphere composition, and treatment duration—affect the structural, electrical, mechanical, and chemical properties of reduced graphene oxide. Understanding these relationships is crucial for optimizing rGO production for targeted applications.

Additionally, this research aims to identify the correlation between heat treatment conditions and the removal of oxygen-containing functional groups, which directly impacts the restoration of sp² carbon networks and consequently the electrical conductivity of the material. The degree of reduction achieved through heat treatment significantly influences rGO's performance in applications ranging from energy storage devices to sensors and composite materials.

Another key objective is to evaluate the scalability and industrial viability of different heat treatment methodologies, considering factors such as energy consumption, processing time, equipment requirements, and environmental impact. This assessment is essential for determining the most promising approaches for commercial-scale production of rGO with consistent quality and properties.

By establishing clear relationships between processing parameters and material properties, this research seeks to provide a foundation for the development of standardized protocols for GO heat treatment, addressing the current challenge of reproducibility in rGO production across different research groups and manufacturing facilities.

The evolution of GO heat treatment techniques has progressed significantly over the past decade. Initially, thermal reduction methods focused primarily on high-temperature annealing in inert atmospheres, typically at temperatures exceeding 1000°C. Recent advancements have expanded to include more energy-efficient approaches such as microwave-assisted reduction, flash reduction, and laser scribing, which offer more precise control over the reduction process while requiring less energy input.

Current technological trends indicate a growing interest in developing scalable and environmentally friendly reduction methods that maintain or enhance the desirable properties of rGO. The industry is moving toward techniques that allow for selective functionalization during the reduction process, enabling tailored material properties for specific applications.

The primary objective of this technical research is to comprehensively analyze how various heat treatment parameters—including temperature profiles, heating rates, atmosphere composition, and treatment duration—affect the structural, electrical, mechanical, and chemical properties of reduced graphene oxide. Understanding these relationships is crucial for optimizing rGO production for targeted applications.

Additionally, this research aims to identify the correlation between heat treatment conditions and the removal of oxygen-containing functional groups, which directly impacts the restoration of sp² carbon networks and consequently the electrical conductivity of the material. The degree of reduction achieved through heat treatment significantly influences rGO's performance in applications ranging from energy storage devices to sensors and composite materials.

Another key objective is to evaluate the scalability and industrial viability of different heat treatment methodologies, considering factors such as energy consumption, processing time, equipment requirements, and environmental impact. This assessment is essential for determining the most promising approaches for commercial-scale production of rGO with consistent quality and properties.

By establishing clear relationships between processing parameters and material properties, this research seeks to provide a foundation for the development of standardized protocols for GO heat treatment, addressing the current challenge of reproducibility in rGO production across different research groups and manufacturing facilities.

Market Applications and Demand Analysis for rGO Materials

The global market for reduced graphene oxide (rGO) materials has been experiencing significant growth, driven by the material's exceptional properties that can be tailored through heat treatment processes. Current market analysis indicates that the global graphene market, including rGO, is projected to reach approximately 1.5 billion USD by 2025, with a compound annual growth rate exceeding 38% between 2020-2025. The heat-treated rGO segment represents a substantial portion of this market due to its enhanced functionality and application versatility.

The electronics industry constitutes the largest demand sector for heat-treated rGO materials, particularly in energy storage applications. The superior electrical conductivity achieved through precise thermal reduction processes has positioned rGO as a critical component in next-generation batteries and supercapacitors. Market research shows that energy storage applications alone account for roughly 35% of the total rGO market value, with demand increasing as electric vehicle adoption accelerates globally.

Biomedical applications represent another rapidly expanding market segment for thermally modified rGO. The biocompatibility and surface functionality of rGO can be precisely controlled through heat treatment parameters, creating opportunities in drug delivery systems, biosensors, and tissue engineering. This sector is growing at approximately 42% annually, outpacing the overall market growth rate.

Advanced composite materials incorporating heat-treated rGO have gained significant traction in aerospace, automotive, and construction industries. The mechanical strength, thermal stability, and lightweight properties of rGO-enhanced composites offer substantial performance improvements over traditional materials. Market penetration in these sectors has increased by nearly 30% annually since 2018, with particular growth in high-performance applications requiring precise material properties.

Environmental applications, including water purification and environmental sensing, represent an emerging market for specially heat-treated rGO materials. The adsorption capabilities and surface chemistry modifications achieved through controlled thermal processing have enabled new filtration and remediation technologies. This segment is projected to grow at over 45% annually through 2025, driven by increasing global water scarcity and environmental regulations.

Regional analysis reveals that Asia-Pacific dominates the rGO materials market, accounting for approximately 45% of global demand, followed by North America (28%) and Europe (22%). China, Japan, and South Korea lead in production capacity and consumption, while significant research activities in North America and Europe continue to expand application possibilities through advanced heat treatment techniques that unlock new material properties.

The electronics industry constitutes the largest demand sector for heat-treated rGO materials, particularly in energy storage applications. The superior electrical conductivity achieved through precise thermal reduction processes has positioned rGO as a critical component in next-generation batteries and supercapacitors. Market research shows that energy storage applications alone account for roughly 35% of the total rGO market value, with demand increasing as electric vehicle adoption accelerates globally.

Biomedical applications represent another rapidly expanding market segment for thermally modified rGO. The biocompatibility and surface functionality of rGO can be precisely controlled through heat treatment parameters, creating opportunities in drug delivery systems, biosensors, and tissue engineering. This sector is growing at approximately 42% annually, outpacing the overall market growth rate.

Advanced composite materials incorporating heat-treated rGO have gained significant traction in aerospace, automotive, and construction industries. The mechanical strength, thermal stability, and lightweight properties of rGO-enhanced composites offer substantial performance improvements over traditional materials. Market penetration in these sectors has increased by nearly 30% annually since 2018, with particular growth in high-performance applications requiring precise material properties.

Environmental applications, including water purification and environmental sensing, represent an emerging market for specially heat-treated rGO materials. The adsorption capabilities and surface chemistry modifications achieved through controlled thermal processing have enabled new filtration and remediation technologies. This segment is projected to grow at over 45% annually through 2025, driven by increasing global water scarcity and environmental regulations.

Regional analysis reveals that Asia-Pacific dominates the rGO materials market, accounting for approximately 45% of global demand, followed by North America (28%) and Europe (22%). China, Japan, and South Korea lead in production capacity and consumption, while significant research activities in North America and Europe continue to expand application possibilities through advanced heat treatment techniques that unlock new material properties.

Current Challenges in Thermal Reduction of Graphene Oxide

Despite significant advancements in thermal reduction techniques for graphene oxide (GO), several critical challenges persist that impede the widespread industrial application and commercialization of reduced graphene oxide (rGO). The primary challenge lies in achieving complete deoxygenation without compromising the structural integrity of the graphene lattice. Current thermal reduction processes typically operate at temperatures ranging from 700°C to 1200°C, which often leads to carbon lattice damage and the creation of structural defects that significantly diminish the electrical conductivity and mechanical properties of the resulting rGO.

Another substantial challenge is the lack of precise control over the reduction process. The removal of oxygen-containing functional groups during thermal treatment occurs in a somewhat unpredictable manner, with different groups (hydroxyl, epoxy, carboxyl) requiring varying energy thresholds for removal. This variability results in inconsistent product quality and properties between batches, making standardization difficult for industrial applications.

The energy consumption associated with high-temperature thermal reduction processes presents both economic and environmental challenges. The substantial energy requirements not only increase production costs but also contribute to a larger carbon footprint, contradicting the sustainable applications for which graphene materials are often intended.

Scalability remains a significant hurdle in thermal reduction processes. Laboratory-scale methods that produce high-quality rGO often face complications when scaled to industrial production levels. Issues such as uneven heating, temperature gradients across larger sample volumes, and difficulties in maintaining optimal gas environments at scale all contribute to reduced quality and performance consistency in mass-produced rGO.

The release of toxic gases during thermal reduction, particularly carbon monoxide, carbon dioxide, and various sulfur compounds, necessitates sophisticated gas handling systems and safety protocols, further complicating the production process and increasing costs.

Residual defects and impurities in thermally reduced GO significantly impact its performance in applications requiring high electrical conductivity or mechanical strength. Even after high-temperature treatment, rGO typically retains approximately 5-10% oxygen content, which continues to affect its properties and limits its performance compared to pristine graphene.

Finally, there exists a fundamental trade-off between reduction efficiency and structural preservation. More aggressive thermal treatments achieve better deoxygenation but cause greater structural damage, while milder conditions preserve structure but leave higher oxygen content. Finding the optimal balance for specific applications remains a significant challenge in the field of graphene oxide thermal reduction.

Another substantial challenge is the lack of precise control over the reduction process. The removal of oxygen-containing functional groups during thermal treatment occurs in a somewhat unpredictable manner, with different groups (hydroxyl, epoxy, carboxyl) requiring varying energy thresholds for removal. This variability results in inconsistent product quality and properties between batches, making standardization difficult for industrial applications.

The energy consumption associated with high-temperature thermal reduction processes presents both economic and environmental challenges. The substantial energy requirements not only increase production costs but also contribute to a larger carbon footprint, contradicting the sustainable applications for which graphene materials are often intended.

Scalability remains a significant hurdle in thermal reduction processes. Laboratory-scale methods that produce high-quality rGO often face complications when scaled to industrial production levels. Issues such as uneven heating, temperature gradients across larger sample volumes, and difficulties in maintaining optimal gas environments at scale all contribute to reduced quality and performance consistency in mass-produced rGO.

The release of toxic gases during thermal reduction, particularly carbon monoxide, carbon dioxide, and various sulfur compounds, necessitates sophisticated gas handling systems and safety protocols, further complicating the production process and increasing costs.

Residual defects and impurities in thermally reduced GO significantly impact its performance in applications requiring high electrical conductivity or mechanical strength. Even after high-temperature treatment, rGO typically retains approximately 5-10% oxygen content, which continues to affect its properties and limits its performance compared to pristine graphene.

Finally, there exists a fundamental trade-off between reduction efficiency and structural preservation. More aggressive thermal treatments achieve better deoxygenation but cause greater structural damage, while milder conditions preserve structure but leave higher oxygen content. Finding the optimal balance for specific applications remains a significant challenge in the field of graphene oxide thermal reduction.

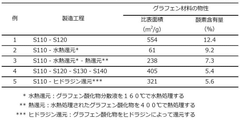

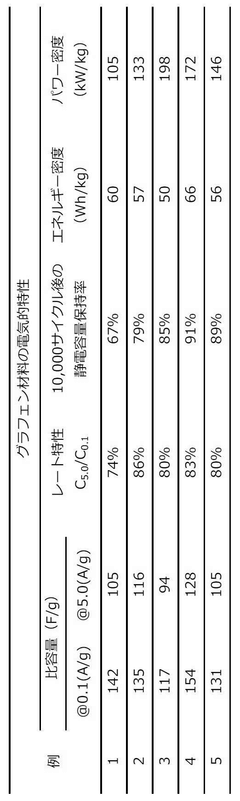

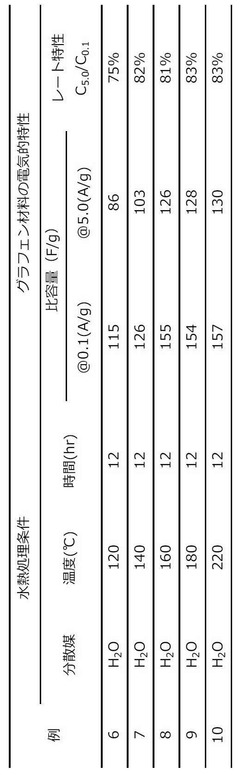

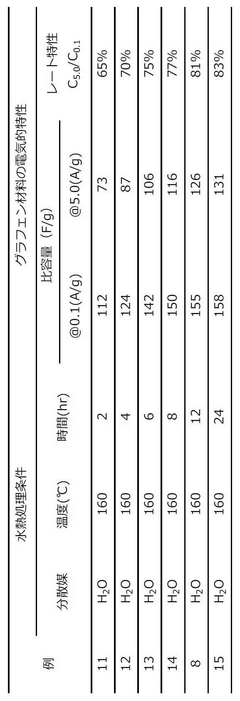

Established Heat Treatment Protocols and Their Effects

01 Electrical properties of reduced graphene oxide

Reduced graphene oxide (rGO) exhibits excellent electrical conductivity properties that make it suitable for various electronic applications. The reduction process removes oxygen-containing functional groups, restoring the sp² carbon network and enhancing electron mobility. The electrical conductivity can be tuned by controlling the degree of reduction, with higher reduction levels generally resulting in better conductivity. These properties make rGO valuable for applications in flexible electronics, sensors, and energy storage devices.- Electrical properties of reduced graphene oxide: Reduced graphene oxide (rGO) exhibits excellent electrical conductivity properties that make it suitable for various electronic applications. The reduction process removes oxygen-containing functional groups from graphene oxide, restoring the sp² carbon network and enhancing electron mobility. The electrical conductivity can be tuned by controlling the degree of reduction, with higher reduction levels generally resulting in better conductivity. These properties make rGO valuable for applications in electronic devices, sensors, and energy storage systems.

- Mechanical and structural properties of reduced graphene oxide: Reduced graphene oxide possesses remarkable mechanical strength and structural stability. The reduction process affects the mechanical properties by altering the sheet morphology and interlayer spacing. rGO typically exhibits high tensile strength, flexibility, and durability, making it suitable for composite materials and structural applications. The mechanical properties can be further enhanced through various processing techniques and by controlling the reduction conditions. These characteristics enable rGO to be used in applications requiring robust materials with lightweight properties.

- Thermal and optical properties of reduced graphene oxide: Reduced graphene oxide demonstrates excellent thermal conductivity and unique optical properties. The thermal conductivity of rGO is significantly higher than that of graphene oxide due to the restoration of the sp² carbon network during reduction. rGO also exhibits tunable optical properties, including light absorption across a wide spectrum and photoluminescence characteristics. These properties can be modified by controlling the reduction degree and processing conditions, making rGO suitable for thermal management applications, optoelectronic devices, and photocatalytic systems.

- Chemical and surface properties of reduced graphene oxide: Reduced graphene oxide features unique chemical and surface properties that can be tailored for specific applications. The reduction process leaves residual oxygen-containing functional groups that provide reactive sites for further functionalization. rGO exhibits tunable hydrophobicity/hydrophilicity, surface area, and chemical reactivity depending on the reduction method and conditions. These properties make rGO valuable for applications in catalysis, adsorption, filtration, and chemical sensing. The surface chemistry can be further modified to enhance compatibility with various matrices or to introduce specific functionalities.

- Production methods affecting properties of reduced graphene oxide: Various production methods significantly influence the final properties of reduced graphene oxide. Chemical reduction using agents like hydrazine, thermal reduction at different temperatures, electrochemical reduction, and photocatalytic reduction each result in rGO with distinct characteristics. The reduction method affects the degree of reduction, defect density, sheet size, and functional group content, which in turn determine the electrical, mechanical, thermal, and chemical properties. By selecting appropriate reduction techniques and optimizing process parameters, rGO can be tailored with specific property profiles for targeted applications in energy storage, electronics, composites, and biomedical fields.

02 Mechanical and structural properties of reduced graphene oxide

Reduced graphene oxide possesses remarkable mechanical strength and flexibility while maintaining a lightweight structure. The reduction process affects the structural integrity and mechanical properties, with controlled reduction leading to improved tensile strength and elastic modulus. The 2D sheet structure of rGO provides high surface area and mechanical stability, making it suitable for composite reinforcement. These mechanical properties can be further enhanced through various processing techniques and combination with other materials.Expand Specific Solutions03 Thermal and optical properties of reduced graphene oxide

Reduced graphene oxide demonstrates excellent thermal conductivity and stability at high temperatures, making it valuable for thermal management applications. The reduction level affects its optical properties, with higher reduction typically resulting in increased opacity and absorption across the electromagnetic spectrum. rGO exhibits tunable optical properties including light absorption and transmission characteristics that can be modified through the reduction process. These properties make it suitable for applications in thermal interfaces, optoelectronic devices, and solar energy harvesting.Expand Specific Solutions04 Chemical and surface properties of reduced graphene oxide

Reduced graphene oxide features tunable surface chemistry with residual oxygen-containing functional groups that can be leveraged for further functionalization. The reduction process affects hydrophilicity/hydrophobicity, with more reduced forms typically becoming more hydrophobic. rGO maintains reactive sites that allow for chemical modification and attachment of various functional groups, enabling customization for specific applications. These surface properties make rGO valuable for applications in catalysis, filtration membranes, and chemical sensing.Expand Specific Solutions05 Applications of reduced graphene oxide based on its properties

The unique combination of properties in reduced graphene oxide enables its application across multiple fields. In energy storage, rGO serves as electrode material in supercapacitors and batteries due to its electrical conductivity and high surface area. For environmental applications, it functions as an adsorbent for pollutant removal and water purification. In biomedical fields, rGO is used for drug delivery, biosensing, and tissue engineering. Additionally, it enhances performance in composite materials, sensors, and electronic devices through property improvements.Expand Specific Solutions

Leading Research Groups and Commercial Producers in rGO Field

The heat treatment of reduced graphene oxide (rGO) is currently in a transitional phase from research to commercial applications, with the market expected to grow significantly as industries recognize its potential for enhancing material properties. The global market for modified graphene materials is projected to reach several billion dollars by 2030, driven by applications in electronics, energy storage, and composites. Technologically, companies are at varying maturity levels: Global Graphene Group and The Sixth Element have established commercial production capabilities for heat-treated rGO, while research institutions like Shanghai Institute of Ceramics and King Abdullah University are advancing fundamental understanding of thermal reduction processes. Major corporations including LG Electronics and Tata Steel are exploring industrial applications, indicating growing commercial interest in this technology as thermal treatment methods continue to evolve toward scalable, cost-effective processes.

GLOBAL GRAPHENE GROUP INC

Technical Solution: Global Graphene Group has developed proprietary thermal reduction processes for graphene oxide that precisely control temperature gradients and atmospheric conditions during heat treatment. Their technology enables fine-tuning of oxygen functional groups at temperatures between 200-1200°C, creating reduced graphene oxide (rGO) with tailored electrical conductivity (up to 1000 S/cm) and surface area (300-2500 m²/g). Their patented flash reduction method uses rapid thermal shock to create highly conductive rGO while preserving structural integrity. The company has also developed specialized annealing protocols that can selectively remove specific oxygen groups while retaining others, allowing customization of hydrophilicity and reactivity for various applications including energy storage, composites, and coatings.

Strengths: Precise control over reduction parameters enables customized rGO properties for specific applications; scalable manufacturing processes suitable for industrial production. Weaknesses: Energy-intensive thermal processes may increase production costs; some reduction methods may introduce structural defects that limit performance in certain applications.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has pioneered multi-stage thermal reduction protocols for graphene oxide that precisely control the removal sequence of oxygen-containing functional groups. Their research demonstrates that staged heating (first at 200°C for 2 hours, then ramping to 800°C) preserves the structural integrity of graphene sheets while achieving high C/O ratios exceeding 20:1. Their studies have mapped the correlation between heat treatment temperature and resulting electrical properties, showing conductivity improvements from <10 S/m for GO to >5000 S/m for rGO treated at 1100°C. The institute has also developed specialized vacuum-assisted thermal reduction techniques that enhance the removal of intercalated water and oxygen groups while minimizing sheet restacking, resulting in rGO with surface areas approaching 1500 m²/g. Their research has established clear relationships between thermal treatment parameters and resulting material properties for applications in ceramics, electronics, and energy storage.

Strengths: Comprehensive fundamental understanding of reduction mechanisms; sophisticated characterization capabilities to analyze structural and chemical changes during heat treatment. Weaknesses: Some advanced reduction protocols may be difficult to scale economically; focus may be more on research advancement than commercial production.

Critical Patents and Research on Thermal Reduction Mechanisms

Graphene material, method for producing same, and use application of same

PatentWO2023013298A1

Innovation

- A two-step process involving heat-treating graphene oxide at 300°C to 700°C followed by hydrothermal treatment at 150°C to 250°C, without using a reducing agent, to produce thermally reduced graphene oxide with minimal oxygen content and reduced agglomeration, enhancing electrical properties.

Method of preparing reduced graphene oxide and reduced graphene oxide-polymer composites

PatentInactiveUS9318231B2

Innovation

- A method involving the mixing of graphene oxide with halogen-substituted aromatic compounds, followed by stirring and heat treatment at temperatures between 100 to 450°C, to achieve high electrical conductivity in reduced graphene oxide and its polymer composites.

Environmental Impact and Sustainability of rGO Production Methods

The production of reduced graphene oxide (rGO) through heat treatment processes presents significant environmental considerations that must be addressed as this material gains prominence in industrial applications. Traditional thermal reduction methods often involve high energy consumption, with temperatures ranging from 200°C to over 1000°C depending on the desired properties, resulting in substantial carbon footprints. These energy-intensive processes contribute to greenhouse gas emissions, particularly when powered by non-renewable energy sources.

Chemical reduction alternatives to heat treatment frequently employ hazardous reducing agents such as hydrazine, sodium borohydride, or hydroiodic acid, which pose serious environmental and health risks. The disposal of these toxic chemicals and their byproducts creates additional environmental challenges, including potential water and soil contamination if not properly managed.

Recent sustainability assessments of rGO production have highlighted the importance of life cycle analysis (LCA) in evaluating environmental impacts. Studies indicate that heat treatment methods, despite their energy requirements, may present lower overall environmental impacts compared to chemical reduction when considering the entire production chain, especially when renewable energy sources are utilized for the thermal processes.

Emerging eco-friendly approaches to rGO production include microwave-assisted reduction, which can significantly reduce energy consumption by up to 80% compared to conventional thermal methods. Additionally, green reducing agents derived from plant extracts, ascorbic acid, or even microbial reduction processes are being explored as sustainable alternatives that minimize environmental hazards.

Water usage represents another critical environmental concern in rGO production. Heat treatment methods typically require less water compared to chemical reduction processes, potentially reducing the water footprint of production. However, the high temperatures involved in thermal reduction can generate airborne particulates and gaseous emissions that require proper filtration and treatment systems.

The recyclability of process materials and waste recovery systems are increasingly becoming focal points in sustainable rGO production. Closed-loop systems that capture and reuse solvents, recover unreacted materials, and utilize waste heat from thermal processes can substantially improve the environmental profile of rGO manufacturing operations.

As regulatory frameworks around nanomaterial production tighten globally, manufacturers are increasingly incentivized to develop and implement cleaner production technologies. This regulatory pressure, combined with growing market demand for sustainably produced materials, is driving innovation toward more environmentally responsible heat treatment processes for rGO production that balance technical performance requirements with ecological considerations.

Chemical reduction alternatives to heat treatment frequently employ hazardous reducing agents such as hydrazine, sodium borohydride, or hydroiodic acid, which pose serious environmental and health risks. The disposal of these toxic chemicals and their byproducts creates additional environmental challenges, including potential water and soil contamination if not properly managed.

Recent sustainability assessments of rGO production have highlighted the importance of life cycle analysis (LCA) in evaluating environmental impacts. Studies indicate that heat treatment methods, despite their energy requirements, may present lower overall environmental impacts compared to chemical reduction when considering the entire production chain, especially when renewable energy sources are utilized for the thermal processes.

Emerging eco-friendly approaches to rGO production include microwave-assisted reduction, which can significantly reduce energy consumption by up to 80% compared to conventional thermal methods. Additionally, green reducing agents derived from plant extracts, ascorbic acid, or even microbial reduction processes are being explored as sustainable alternatives that minimize environmental hazards.

Water usage represents another critical environmental concern in rGO production. Heat treatment methods typically require less water compared to chemical reduction processes, potentially reducing the water footprint of production. However, the high temperatures involved in thermal reduction can generate airborne particulates and gaseous emissions that require proper filtration and treatment systems.

The recyclability of process materials and waste recovery systems are increasingly becoming focal points in sustainable rGO production. Closed-loop systems that capture and reuse solvents, recover unreacted materials, and utilize waste heat from thermal processes can substantially improve the environmental profile of rGO manufacturing operations.

As regulatory frameworks around nanomaterial production tighten globally, manufacturers are increasingly incentivized to develop and implement cleaner production technologies. This regulatory pressure, combined with growing market demand for sustainably produced materials, is driving innovation toward more environmentally responsible heat treatment processes for rGO production that balance technical performance requirements with ecological considerations.

Quality Control and Characterization Techniques for Heat-Treated rGO

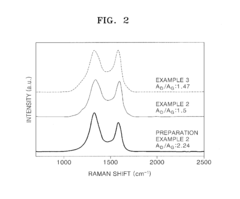

Quality control and characterization of heat-treated reduced graphene oxide (rGO) requires sophisticated analytical techniques to ensure consistent material properties. Raman spectroscopy serves as a primary characterization method, providing critical information about defect density and degree of reduction through analysis of D and G bands. The ID/IG ratio typically decreases with effective heat treatment, indicating restoration of the graphene lattice structure.

X-ray photoelectron spectroscopy (XPS) offers precise quantification of oxygen-containing functional groups, allowing researchers to track the reduction efficiency during thermal treatment. The C/O ratio increases significantly with higher treatment temperatures, with optimal reduction often observed between 800-1000°C, though this varies based on specific processing conditions.

Electrical conductivity measurements provide direct performance indicators for heat-treated rGO. Four-point probe testing reveals that conductivity generally increases exponentially with treatment temperature until reaching a plateau, typically between 900-1200°C. This plateau represents the practical limit of thermal reduction effectiveness.

Thermogravimetric analysis (TGA) enables process optimization by revealing mass loss patterns during heating, with major losses occurring at specific temperature ranges corresponding to different functional group removals. This data helps establish optimal heating rates and dwell times for desired material properties.

Surface area and porosity characterization via BET analysis demonstrates that heat treatment significantly impacts the specific surface area of rGO. Moderate temperatures (400-700°C) often maximize surface area by creating micropores, while higher temperatures can cause sheet restacking and surface area reduction.

Transmission electron microscopy (TEM) and atomic force microscopy (AFM) provide visual confirmation of structural changes, revealing layer numbers, sheet dimensions, and wrinkle formation patterns that correlate with treatment conditions. These techniques help establish structure-property relationships essential for application-specific optimization.

Statistical process control methods must be implemented to ensure batch-to-batch consistency, with key parameters including oxygen content (±2%), electrical conductivity (±5%), and sheet size distribution (±10%). Establishing these control limits requires comprehensive baseline data collection across multiple production batches.

Emerging characterization techniques include terahertz spectroscopy for non-destructive evaluation and in-line monitoring systems utilizing optical methods for real-time quality assessment during production, representing the future direction of rGO quality control methodologies.

X-ray photoelectron spectroscopy (XPS) offers precise quantification of oxygen-containing functional groups, allowing researchers to track the reduction efficiency during thermal treatment. The C/O ratio increases significantly with higher treatment temperatures, with optimal reduction often observed between 800-1000°C, though this varies based on specific processing conditions.

Electrical conductivity measurements provide direct performance indicators for heat-treated rGO. Four-point probe testing reveals that conductivity generally increases exponentially with treatment temperature until reaching a plateau, typically between 900-1200°C. This plateau represents the practical limit of thermal reduction effectiveness.

Thermogravimetric analysis (TGA) enables process optimization by revealing mass loss patterns during heating, with major losses occurring at specific temperature ranges corresponding to different functional group removals. This data helps establish optimal heating rates and dwell times for desired material properties.

Surface area and porosity characterization via BET analysis demonstrates that heat treatment significantly impacts the specific surface area of rGO. Moderate temperatures (400-700°C) often maximize surface area by creating micropores, while higher temperatures can cause sheet restacking and surface area reduction.

Transmission electron microscopy (TEM) and atomic force microscopy (AFM) provide visual confirmation of structural changes, revealing layer numbers, sheet dimensions, and wrinkle formation patterns that correlate with treatment conditions. These techniques help establish structure-property relationships essential for application-specific optimization.

Statistical process control methods must be implemented to ensure batch-to-batch consistency, with key parameters including oxygen content (±2%), electrical conductivity (±5%), and sheet size distribution (±10%). Establishing these control limits requires comprehensive baseline data collection across multiple production batches.

Emerging characterization techniques include terahertz spectroscopy for non-destructive evaluation and in-line monitoring systems utilizing optical methods for real-time quality assessment during production, representing the future direction of rGO quality control methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!