Structural Analysis of Reduced Graphene Oxide under Mechanical Stress

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO Mechanical Stress Analysis Background and Objectives

Reduced graphene oxide (rGO) has emerged as a revolutionary material in the field of nanomaterials since its initial discovery in the early 2000s. The evolution of graphene-based materials has progressed from graphite to graphene oxide (GO) and finally to reduced graphene oxide, with each transition marking significant advancements in material properties and applications. The structural analysis of rGO under mechanical stress represents a critical area of research that bridges fundamental materials science with practical engineering applications.

The historical trajectory of rGO research began with the Nobel Prize-winning isolation of graphene in 2004, which catalyzed extensive investigations into graphene derivatives. By 2010, researchers had developed various reduction methods for converting GO to rGO, opening new avenues for tailored material properties. The past decade has witnessed exponential growth in publications focused on rGO's mechanical behavior, indicating the scientific community's increasing interest in understanding how this material responds to external forces.

Current technological trends in rGO research are moving toward precise control of reduction processes to achieve specific mechanical properties, development of in-situ characterization techniques for real-time observation of structural changes under stress, and computational modeling approaches that can predict mechanical behavior at multiple scales. These trends collectively aim to address the gap between theoretical predictions and experimental observations of rGO's mechanical performance.

The primary objective of this technical research is to comprehensively analyze the structural transformations that occur in rGO when subjected to various forms of mechanical stress, including tensile, compressive, and shear forces. This analysis seeks to establish clear structure-property relationships that can inform the design and optimization of rGO-based materials for specific applications.

Secondary objectives include identifying the influence of reduction methods on the resulting mechanical properties, determining the role of residual functional groups in stress distribution and failure mechanisms, and developing predictive models that can accurately forecast the mechanical behavior of rGO under complex loading conditions. These objectives align with the broader goal of enabling rational design of rGO-based materials with tailored mechanical responses.

The expected outcomes of this research include a detailed mapping of structural defects and their evolution under stress, quantitative relationships between processing parameters and mechanical properties, and design guidelines for rGO-based composites with enhanced mechanical performance. These outcomes will directly contribute to advancing applications in flexible electronics, structural composites, and energy storage devices where mechanical reliability is paramount.

The historical trajectory of rGO research began with the Nobel Prize-winning isolation of graphene in 2004, which catalyzed extensive investigations into graphene derivatives. By 2010, researchers had developed various reduction methods for converting GO to rGO, opening new avenues for tailored material properties. The past decade has witnessed exponential growth in publications focused on rGO's mechanical behavior, indicating the scientific community's increasing interest in understanding how this material responds to external forces.

Current technological trends in rGO research are moving toward precise control of reduction processes to achieve specific mechanical properties, development of in-situ characterization techniques for real-time observation of structural changes under stress, and computational modeling approaches that can predict mechanical behavior at multiple scales. These trends collectively aim to address the gap between theoretical predictions and experimental observations of rGO's mechanical performance.

The primary objective of this technical research is to comprehensively analyze the structural transformations that occur in rGO when subjected to various forms of mechanical stress, including tensile, compressive, and shear forces. This analysis seeks to establish clear structure-property relationships that can inform the design and optimization of rGO-based materials for specific applications.

Secondary objectives include identifying the influence of reduction methods on the resulting mechanical properties, determining the role of residual functional groups in stress distribution and failure mechanisms, and developing predictive models that can accurately forecast the mechanical behavior of rGO under complex loading conditions. These objectives align with the broader goal of enabling rational design of rGO-based materials with tailored mechanical responses.

The expected outcomes of this research include a detailed mapping of structural defects and their evolution under stress, quantitative relationships between processing parameters and mechanical properties, and design guidelines for rGO-based composites with enhanced mechanical performance. These outcomes will directly contribute to advancing applications in flexible electronics, structural composites, and energy storage devices where mechanical reliability is paramount.

Market Applications for Stressed rGO Materials

The market for reduced graphene oxide (rGO) materials under mechanical stress presents significant commercial opportunities across multiple industries. Advanced materials incorporating stressed rGO are gaining traction in electronics, where their unique electrical conductivity properties enable development of flexible displays, wearable electronics, and next-generation sensors. When subjected to controlled mechanical stress, rGO exhibits enhanced electron mobility and conductivity characteristics that surpass conventional materials.

Energy storage represents another high-potential application domain. Batteries and supercapacitors incorporating stressed rGO demonstrate improved energy density and charging cycles. The structural changes induced by mechanical stress create more effective pathways for ion transport, addressing key limitations in current energy storage technologies. Market projections indicate particularly strong growth in electric vehicle applications where weight reduction and performance enhancement are critical factors.

Aerospace and automotive industries are increasingly exploring stressed rGO composites for structural components. These materials offer exceptional strength-to-weight ratios while maintaining electrical conductivity, enabling multifunctional parts that serve both structural and electronic purposes. The ability to tune mechanical properties through controlled stress application provides manufacturers with unprecedented design flexibility.

Biomedical applications represent an emerging frontier for stressed rGO materials. Research indicates that mechanically modified rGO structures can be optimized for biocompatibility while maintaining antimicrobial properties. This opens possibilities for advanced wound dressings, implantable sensors, and drug delivery systems. The market potential in this sector is driven by increasing demand for smart medical devices and personalized healthcare solutions.

Environmental remediation technologies are benefiting from stressed rGO materials in filtration and separation applications. The altered pore structure and surface chemistry resulting from mechanical stress enhance adsorption capacity for various contaminants. Water purification systems incorporating these materials demonstrate superior performance in removing heavy metals and organic pollutants compared to conventional filtration media.

Construction and infrastructure sectors are exploring stressed rGO additives for concrete and structural materials. Early research indicates potential for creating self-sensing structures capable of monitoring structural integrity through changes in electrical resistance. This application addresses growing market demand for smart infrastructure with integrated monitoring capabilities, particularly in regions with aging infrastructure or seismic activity concerns.

Energy storage represents another high-potential application domain. Batteries and supercapacitors incorporating stressed rGO demonstrate improved energy density and charging cycles. The structural changes induced by mechanical stress create more effective pathways for ion transport, addressing key limitations in current energy storage technologies. Market projections indicate particularly strong growth in electric vehicle applications where weight reduction and performance enhancement are critical factors.

Aerospace and automotive industries are increasingly exploring stressed rGO composites for structural components. These materials offer exceptional strength-to-weight ratios while maintaining electrical conductivity, enabling multifunctional parts that serve both structural and electronic purposes. The ability to tune mechanical properties through controlled stress application provides manufacturers with unprecedented design flexibility.

Biomedical applications represent an emerging frontier for stressed rGO materials. Research indicates that mechanically modified rGO structures can be optimized for biocompatibility while maintaining antimicrobial properties. This opens possibilities for advanced wound dressings, implantable sensors, and drug delivery systems. The market potential in this sector is driven by increasing demand for smart medical devices and personalized healthcare solutions.

Environmental remediation technologies are benefiting from stressed rGO materials in filtration and separation applications. The altered pore structure and surface chemistry resulting from mechanical stress enhance adsorption capacity for various contaminants. Water purification systems incorporating these materials demonstrate superior performance in removing heavy metals and organic pollutants compared to conventional filtration media.

Construction and infrastructure sectors are exploring stressed rGO additives for concrete and structural materials. Early research indicates potential for creating self-sensing structures capable of monitoring structural integrity through changes in electrical resistance. This application addresses growing market demand for smart infrastructure with integrated monitoring capabilities, particularly in regions with aging infrastructure or seismic activity concerns.

Current Challenges in rGO Structural Analysis

Despite significant advancements in reduced graphene oxide (rGO) research, structural analysis under mechanical stress presents several persistent challenges. The heterogeneous nature of rGO creates substantial difficulties in characterizing its structure precisely. Unlike pristine graphene, rGO contains various oxygen-containing functional groups and structural defects that are distributed non-uniformly across the material, making standardized analysis problematic.

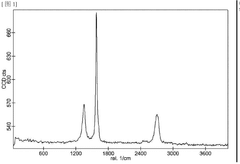

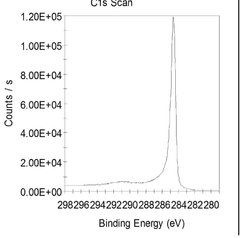

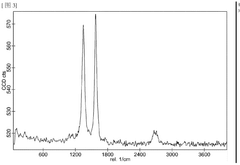

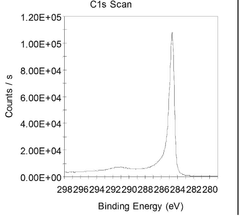

In-situ characterization techniques for observing structural changes during mechanical deformation remain limited. Current methods such as Raman spectroscopy, X-ray diffraction (XRD), and transmission electron microscopy (TEM) each have significant limitations when applied to rGO under stress conditions. Raman spectroscopy, while useful for identifying defects, lacks spatial resolution for nanoscale deformation analysis. XRD struggles with the partially amorphous nature of rGO, and TEM sample preparation can introduce artifacts that compromise data integrity.

The multi-scale nature of mechanical behavior in rGO compounds these challenges. Structural responses occur simultaneously at atomic, molecular, and macroscopic levels, requiring integrated analytical approaches that can correlate observations across these different scales. Current technologies typically excel at only one scale, creating significant gaps in comprehensive understanding.

Reproducibility issues further complicate structural analysis. The synthesis of rGO involves reduction processes that are difficult to control precisely, resulting in batch-to-batch variations that affect mechanical properties and structural characteristics. This inconsistency makes it challenging to establish reliable structure-property relationships and develop predictive models.

Computational modeling of rGO under mechanical stress faces its own set of obstacles. The complex, defect-rich structure of rGO requires sophisticated molecular dynamics simulations that are computationally intensive. Current models often make simplifying assumptions that fail to capture the full complexity of rGO's structural response to mechanical loading.

Environmental factors introduce additional variables that complicate analysis. Temperature, humidity, and chemical environment can significantly alter rGO's structural behavior under stress. Most current analytical techniques do not adequately account for these environmental influences, leading to discrepancies between laboratory findings and real-world performance.

Quantifying the relationship between defect density, oxygen content, and mechanical properties remains particularly challenging. While it is known that these factors significantly influence rGO's mechanical behavior, establishing precise correlations requires advanced characterization techniques that can simultaneously track structural changes and mechanical responses at high resolution.

In-situ characterization techniques for observing structural changes during mechanical deformation remain limited. Current methods such as Raman spectroscopy, X-ray diffraction (XRD), and transmission electron microscopy (TEM) each have significant limitations when applied to rGO under stress conditions. Raman spectroscopy, while useful for identifying defects, lacks spatial resolution for nanoscale deformation analysis. XRD struggles with the partially amorphous nature of rGO, and TEM sample preparation can introduce artifacts that compromise data integrity.

The multi-scale nature of mechanical behavior in rGO compounds these challenges. Structural responses occur simultaneously at atomic, molecular, and macroscopic levels, requiring integrated analytical approaches that can correlate observations across these different scales. Current technologies typically excel at only one scale, creating significant gaps in comprehensive understanding.

Reproducibility issues further complicate structural analysis. The synthesis of rGO involves reduction processes that are difficult to control precisely, resulting in batch-to-batch variations that affect mechanical properties and structural characteristics. This inconsistency makes it challenging to establish reliable structure-property relationships and develop predictive models.

Computational modeling of rGO under mechanical stress faces its own set of obstacles. The complex, defect-rich structure of rGO requires sophisticated molecular dynamics simulations that are computationally intensive. Current models often make simplifying assumptions that fail to capture the full complexity of rGO's structural response to mechanical loading.

Environmental factors introduce additional variables that complicate analysis. Temperature, humidity, and chemical environment can significantly alter rGO's structural behavior under stress. Most current analytical techniques do not adequately account for these environmental influences, leading to discrepancies between laboratory findings and real-world performance.

Quantifying the relationship between defect density, oxygen content, and mechanical properties remains particularly challenging. While it is known that these factors significantly influence rGO's mechanical behavior, establishing precise correlations requires advanced characterization techniques that can simultaneously track structural changes and mechanical responses at high resolution.

Existing Methodologies for rGO Mechanical Characterization

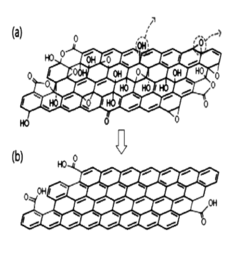

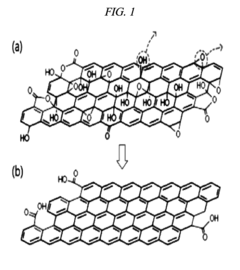

01 Structural characteristics and synthesis methods of reduced graphene oxide

Reduced graphene oxide (rGO) exhibits unique structural properties including high surface area, excellent electrical conductivity, and mechanical strength. Various synthesis methods can be employed to produce rGO with controlled structural properties, such as chemical reduction, thermal reduction, and electrochemical reduction. These methods affect the degree of reduction, defect density, and residual functional groups, which in turn influence the material's electrical, mechanical, and thermal properties.- Structural characteristics and preparation methods of reduced graphene oxide: Reduced graphene oxide (rGO) exhibits unique structural properties including high surface area, excellent electrical conductivity, and mechanical strength. The reduction process removes oxygen-containing functional groups from graphene oxide, restoring the sp2 carbon network. Various reduction methods including thermal, chemical, and electrochemical approaches affect the final structural properties. The degree of reduction influences the number of defects, layer stacking, and overall crystallinity of the material.

- Defect engineering and structural modification of reduced graphene oxide: Controlled introduction of defects and structural modifications in reduced graphene oxide can enhance specific properties for targeted applications. These modifications include doping with heteroatoms (N, B, S), creating vacancies, or introducing functional groups at specific sites. The type, density, and distribution of defects significantly impact the electronic, optical, and mechanical properties of rGO. Structural modifications can be achieved through post-reduction treatments or during the reduction process itself.

- Characterization techniques for reduced graphene oxide structural properties: Various analytical techniques are employed to characterize the structural properties of reduced graphene oxide, including Raman spectroscopy, X-ray diffraction (XRD), transmission electron microscopy (TEM), and X-ray photoelectron spectroscopy (XPS). These techniques provide information about the degree of reduction, layer stacking, defect density, and functional group content. Advanced microscopy methods reveal nanoscale features and morphological characteristics that influence material performance in applications.

- Relationship between reduction methods and resulting structural properties: Different reduction methods produce reduced graphene oxide with varying structural properties. Thermal reduction typically results in higher defect density but better electrical conductivity. Chemical reduction using agents like hydrazine, sodium borohydride, or ascorbic acid yields different degrees of reduction and defect patterns. The reduction temperature, time, and environment significantly impact the final structure. Hybrid reduction approaches combining multiple methods can be used to achieve tailored structural characteristics for specific applications.

- Structure-property relationships in reduced graphene oxide for applications: The structural properties of reduced graphene oxide directly influence its performance in various applications. The degree of reduction affects electrical conductivity for electronic applications. Defect density and surface functionality impact catalytic activity and sensing capabilities. Layer stacking and morphology influence mechanical properties for composite materials. Understanding these structure-property relationships enables the design of rGO with optimized characteristics for specific applications including energy storage, electronics, sensors, and environmental remediation.

02 Defect engineering and functionalization of reduced graphene oxide

The structural properties of reduced graphene oxide can be tailored through defect engineering and functionalization. Controlled introduction of defects and functional groups can modify the electronic structure, reactivity, and surface properties of rGO. These modifications enable tuning of properties such as band gap, electron mobility, and chemical reactivity, making the material suitable for various applications including electronics, energy storage, and sensing.Expand Specific Solutions03 Characterization techniques for reduced graphene oxide structural properties

Various analytical techniques are employed to characterize the structural properties of reduced graphene oxide, including Raman spectroscopy, X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), transmission electron microscopy (TEM), and atomic force microscopy (AFM). These techniques provide insights into the degree of reduction, layer structure, defect density, functional group content, and morphological features of rGO, which are crucial for understanding structure-property relationships.Expand Specific Solutions04 Thermal and mechanical properties of reduced graphene oxide

Reduced graphene oxide exhibits exceptional thermal and mechanical properties, including high thermal conductivity, thermal stability, and mechanical strength. These properties are influenced by the reduction degree, defect concentration, and residual functional groups. The thermal and mechanical behavior of rGO can be further enhanced through composite formation with polymers, metals, or ceramics, leading to materials with superior performance for thermal management and structural applications.Expand Specific Solutions05 Electrical and electronic properties of reduced graphene oxide

The electrical and electronic properties of reduced graphene oxide are highly dependent on its structural characteristics. The degree of reduction significantly affects the electrical conductivity, with higher reduction levels generally resulting in improved conductivity. The presence of defects and functional groups influences the electronic band structure, carrier mobility, and quantum transport properties. These properties can be tuned for applications in electronics, energy storage devices, and sensors by controlling the reduction process and post-treatment conditions.Expand Specific Solutions

Leading Research Groups and Companies in rGO Development

The structural analysis of reduced graphene oxide under mechanical stress is currently in an early growth phase, characterized by significant academic research but limited commercial applications. The market size is estimated to be modest but growing rapidly, driven by potential applications in advanced materials, electronics, and energy storage. Technologically, the field is still evolving, with varying levels of maturity among key players. Academic institutions like Beijing University of Chemical Technology, Fudan University, and The University of Manchester are leading fundamental research, while companies such as Cabot Corp., Sinopec, and Tata Steel are developing practical applications. Research collaborations between industry and academia, exemplified by partnerships involving Korea Atomic Energy Research Institute and Advanced Industrial Science & Technology, are accelerating technological development toward commercial viability.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary technologies for structural analysis of reduced graphene oxide under mechanical stress, particularly focused on applications in petroleum processing and composite materials for oil extraction equipment. Their approach integrates high-pressure testing chambers with in-situ X-ray diffraction to analyze rGO behavior under conditions similar to deep-well environments[1]. Sinopec has pioneered methods for evaluating the performance of rGO-reinforced polymers used in pipeline coatings, where mechanical stress analysis is conducted under simulated corrosive conditions to predict long-term material stability[2]. Their research has established correlations between reduction degree of graphene oxide and its mechanical resilience in high-temperature, high-pressure environments typical of petroleum processing. The company has developed specialized testing protocols that combine mechanical loading with chemical exposure tests to evaluate rGO-based materials for gaskets and seals in refineries[3]. Their analytical framework incorporates machine learning algorithms that process structural data from multiple characterization techniques to predict failure points and optimize rGO composition for specific mechanical requirements in petroleum industry applications.

Strengths: Their testing methodologies closely simulate real-world petroleum industry conditions, providing highly relevant data for practical applications. Their integrated approach combining mechanical testing with chemical exposure analysis offers comprehensive performance evaluation. Weaknesses: Their research is heavily focused on petroleum industry applications, potentially limiting broader applicability to other fields requiring different stress conditions or environments.

The University of Manchester

Technical Solution: The University of Manchester has developed advanced methodologies for structural analysis of reduced graphene oxide (rGO) under mechanical stress, leveraging their pioneering work in graphene research. Their approach combines in-situ Raman spectroscopy with atomic force microscopy to monitor real-time structural changes in rGO during mechanical deformation[1]. They've established correlations between defect density, oxygen functional groups, and mechanical properties, demonstrating that controlled reduction processes can enhance mechanical stability. Their research has revealed that rGO exhibits unique strain-dependent behavior where oxygen functionalities act as both reinforcement points and potential failure sites depending on loading conditions[2]. Manchester's work has also focused on the development of hierarchical composites where rGO interfaces with other materials, allowing for stress transfer mechanisms that can be tuned through chemical modification of the rGO surface[3]. Their analytical framework incorporates multi-scale modeling that bridges atomic-level deformations with macroscopic mechanical responses, providing comprehensive understanding of failure mechanisms in rGO-based materials under various stress conditions.

Strengths: World-leading expertise in graphene materials with access to state-of-the-art characterization facilities. Their multi-modal analytical approach provides comprehensive structural insights across multiple length scales. Weaknesses: Some of their advanced characterization techniques require specialized equipment not widely available, potentially limiting reproducibility of their methodologies by other research groups.

Key Scientific Breakthroughs in rGO Structural Mechanics

Graphene oxide reducing agent comprising a reducing agent containing a halogen element, method for manufacturing a reduced graphene oxide using same, and use of the reduced graphene oxide manufactured by the method

PatentActiveUS9090805B2

Innovation

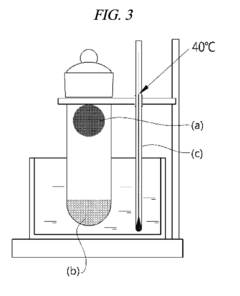

- A graphene oxide reducer containing a halogen element, preferably hydroiodic acid (HI), is used to react with graphene oxide at a temperature of 10°C or more, optionally with a weaker acid like acetic acid, to produce high-purity reduced graphene oxide with improved electrical conductivity.

Reduced graphene oxide and use thereof

PatentWO2025123466A1

Innovation

- Reduced graphene oxide is prepared by the steps of graphite oxidation, preparation of material cakes, puffing, and carbonization reduction. Controlling carbonization reduction is carried out under gas atmosphere or vacuum conditions, and appropriate gas is selected to avoid reaction with graphene or graphene oxide.

Computational Modeling Approaches for rGO Under Stress

Computational modeling has emerged as a critical tool for understanding the behavior of reduced graphene oxide (rGO) under mechanical stress. Various modeling approaches have been developed to simulate and predict the structural changes and mechanical properties of rGO materials when subjected to different stress conditions. These approaches span multiple scales, from quantum mechanical methods to continuum mechanics.

Density Functional Theory (DFT) calculations represent the most fundamental approach, providing atomic-level insights into the electronic structure and bonding characteristics of rGO under stress. These calculations can accurately predict bond breaking and formation processes, though they are computationally intensive and typically limited to systems containing hundreds of atoms. For larger systems, molecular dynamics (MD) simulations offer a viable alternative, enabling the modeling of thousands to millions of atoms using classical force fields.

Several specialized force fields have been developed specifically for graphene-based materials, including AIREBO (Adaptive Intermolecular Reactive Empirical Bond Order), ReaxFF (Reactive Force Field), and COMPASS (Condensed-phase Optimized Molecular Potentials for Atomistic Simulation Studies). These force fields can capture the complex interactions between carbon atoms and various functional groups present in rGO structures.

Coarse-grained modeling approaches further extend the accessible time and length scales by representing groups of atoms as single interaction sites. This simplification allows for the simulation of larger rGO sheets and their assemblies, though at the cost of atomic-level detail. For engineering applications, finite element analysis (FEA) provides a continuum-level description of rGO-based materials, enabling the prediction of macroscopic mechanical properties.

Multi-scale modeling frameworks that integrate these different approaches have shown particular promise. These frameworks typically combine quantum mechanical calculations for critical regions (such as defect sites or functional groups) with classical MD for the surrounding structure, and potentially coarse-grained or continuum methods for the bulk material. This hierarchical approach enables accurate modeling across multiple length scales.

Machine learning methods have recently revolutionized computational modeling of rGO materials. Neural network potentials trained on quantum mechanical data can achieve near-DFT accuracy at a fraction of the computational cost. These methods are particularly valuable for modeling the complex, heterogeneous nature of rGO structures with varying degrees of reduction and diverse functional groups.

The validation of these computational models remains challenging, requiring careful comparison with experimental data from techniques such as atomic force microscopy, Raman spectroscopy, and mechanical testing. As computational resources continue to advance, these modeling approaches will become increasingly powerful tools for designing and optimizing rGO-based materials for specific mechanical applications.

Density Functional Theory (DFT) calculations represent the most fundamental approach, providing atomic-level insights into the electronic structure and bonding characteristics of rGO under stress. These calculations can accurately predict bond breaking and formation processes, though they are computationally intensive and typically limited to systems containing hundreds of atoms. For larger systems, molecular dynamics (MD) simulations offer a viable alternative, enabling the modeling of thousands to millions of atoms using classical force fields.

Several specialized force fields have been developed specifically for graphene-based materials, including AIREBO (Adaptive Intermolecular Reactive Empirical Bond Order), ReaxFF (Reactive Force Field), and COMPASS (Condensed-phase Optimized Molecular Potentials for Atomistic Simulation Studies). These force fields can capture the complex interactions between carbon atoms and various functional groups present in rGO structures.

Coarse-grained modeling approaches further extend the accessible time and length scales by representing groups of atoms as single interaction sites. This simplification allows for the simulation of larger rGO sheets and their assemblies, though at the cost of atomic-level detail. For engineering applications, finite element analysis (FEA) provides a continuum-level description of rGO-based materials, enabling the prediction of macroscopic mechanical properties.

Multi-scale modeling frameworks that integrate these different approaches have shown particular promise. These frameworks typically combine quantum mechanical calculations for critical regions (such as defect sites or functional groups) with classical MD for the surrounding structure, and potentially coarse-grained or continuum methods for the bulk material. This hierarchical approach enables accurate modeling across multiple length scales.

Machine learning methods have recently revolutionized computational modeling of rGO materials. Neural network potentials trained on quantum mechanical data can achieve near-DFT accuracy at a fraction of the computational cost. These methods are particularly valuable for modeling the complex, heterogeneous nature of rGO structures with varying degrees of reduction and diverse functional groups.

The validation of these computational models remains challenging, requiring careful comparison with experimental data from techniques such as atomic force microscopy, Raman spectroscopy, and mechanical testing. As computational resources continue to advance, these modeling approaches will become increasingly powerful tools for designing and optimizing rGO-based materials for specific mechanical applications.

Environmental Impact of rGO Production and Applications

The production of reduced graphene oxide (rGO) involves several chemical processes that can have significant environmental implications. Traditional methods of rGO production often utilize hazardous chemicals such as hydrazine, sodium borohydride, and strong acids, which can lead to toxic waste generation and potential environmental contamination if not properly managed. The energy-intensive nature of thermal reduction processes also contributes to a considerable carbon footprint, raising concerns about the sustainability of large-scale rGO manufacturing.

Water consumption represents another critical environmental factor in rGO production. The synthesis process typically requires substantial amounts of water for washing and purification steps, potentially straining local water resources in manufacturing regions. Additionally, wastewater from these processes may contain graphene nanomaterials and chemical residues that could pose risks to aquatic ecosystems if released without adequate treatment.

The environmental fate of rGO in applications subjected to mechanical stress warrants particular attention. Under stress conditions, rGO-based materials may release nanoparticles through wear and degradation, potentially entering environmental systems. Recent studies indicate that these particles can persist in the environment and potentially bioaccumulate in organisms, though the long-term ecological consequences remain incompletely understood.

Life cycle assessment (LCA) studies of rGO applications reveal mixed environmental profiles. While rGO-enhanced materials often demonstrate improved durability and performance that can extend product lifespans, the environmental benefits must be weighed against production impacts. For instance, rGO-reinforced composites under mechanical stress show superior longevity compared to conventional materials, potentially reducing replacement frequency and associated resource consumption.

Emerging green synthesis approaches offer promising pathways to mitigate environmental impacts. Biomass-derived reducing agents, microwave-assisted reduction, and photocatalytic methods represent more environmentally benign alternatives to conventional chemical reduction techniques. These approaches typically operate at lower temperatures, use fewer hazardous substances, and generate less waste, though scale-up challenges remain.

Regulatory frameworks governing rGO production and disposal vary significantly across regions, creating inconsistent environmental protection standards. As mechanical stress testing becomes more standardized for rGO applications, there is growing recognition of the need to incorporate environmental impact assessments into material qualification protocols, particularly for applications where material degradation under stress could lead to environmental release.

Water consumption represents another critical environmental factor in rGO production. The synthesis process typically requires substantial amounts of water for washing and purification steps, potentially straining local water resources in manufacturing regions. Additionally, wastewater from these processes may contain graphene nanomaterials and chemical residues that could pose risks to aquatic ecosystems if released without adequate treatment.

The environmental fate of rGO in applications subjected to mechanical stress warrants particular attention. Under stress conditions, rGO-based materials may release nanoparticles through wear and degradation, potentially entering environmental systems. Recent studies indicate that these particles can persist in the environment and potentially bioaccumulate in organisms, though the long-term ecological consequences remain incompletely understood.

Life cycle assessment (LCA) studies of rGO applications reveal mixed environmental profiles. While rGO-enhanced materials often demonstrate improved durability and performance that can extend product lifespans, the environmental benefits must be weighed against production impacts. For instance, rGO-reinforced composites under mechanical stress show superior longevity compared to conventional materials, potentially reducing replacement frequency and associated resource consumption.

Emerging green synthesis approaches offer promising pathways to mitigate environmental impacts. Biomass-derived reducing agents, microwave-assisted reduction, and photocatalytic methods represent more environmentally benign alternatives to conventional chemical reduction techniques. These approaches typically operate at lower temperatures, use fewer hazardous substances, and generate less waste, though scale-up challenges remain.

Regulatory frameworks governing rGO production and disposal vary significantly across regions, creating inconsistent environmental protection standards. As mechanical stress testing becomes more standardized for rGO applications, there is growing recognition of the need to incorporate environmental impact assessments into material qualification protocols, particularly for applications where material degradation under stress could lead to environmental release.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!