Reduced Graphene Oxide in the Aerospace Industry: A Technical Assessment

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace rGO Background and Objectives

Reduced Graphene Oxide (rGO) has emerged as a revolutionary material in the aerospace industry over the past decade, offering exceptional mechanical, thermal, and electrical properties that address critical challenges in aircraft and spacecraft design. The evolution of rGO technology can be traced back to the groundbreaking isolation of graphene in 2004, which subsequently led to the development of various graphene derivatives, including rGO. This material represents a more economically viable and scalable alternative to pristine graphene while retaining many of its desirable characteristics.

The aerospace industry has historically been at the forefront of adopting advanced materials, from aluminum alloys in early aircraft to carbon fiber composites in modern designs. The introduction of rGO marks the next significant step in this evolutionary chain, potentially enabling unprecedented improvements in structural integrity, weight reduction, thermal management, and electrical conductivity for aerospace applications.

Current technological trends indicate a growing interest in multifunctional materials that can simultaneously address multiple aerospace challenges. rGO aligns perfectly with this trend, as it can be incorporated into composites, coatings, and electronic components to enhance performance across various parameters. The material's ability to improve mechanical strength while reducing weight makes it particularly attractive for an industry where the weight-to-performance ratio is a critical design consideration.

The primary technical objectives for rGO implementation in aerospace applications include achieving a 15-20% reduction in structural weight compared to traditional carbon fiber composites, enhancing thermal conductivity by at least 40% in critical components, improving electromagnetic interference (EMI) shielding effectiveness, and developing anti-icing and de-icing solutions that consume significantly less power than conventional systems.

Additionally, researchers aim to leverage rGO's exceptional electrical conductivity to develop next-generation sensors and monitoring systems that can be seamlessly integrated into aerospace structures, enabling real-time structural health monitoring and predictive maintenance capabilities. This would represent a significant advancement in aircraft safety and operational efficiency.

The long-term vision for rGO in aerospace extends beyond incremental improvements to enabling transformative technologies, such as morphing structures that can adapt to different flight conditions, energy harvesting systems that reduce dependence on traditional power sources, and advanced thermal protection systems for hypersonic vehicles and space exploration platforms.

Understanding the full potential of rGO requires a comprehensive assessment of its properties, production methods, and integration techniques, as well as an evaluation of the technical and economic barriers that must be overcome to achieve widespread adoption in aerospace applications.

The aerospace industry has historically been at the forefront of adopting advanced materials, from aluminum alloys in early aircraft to carbon fiber composites in modern designs. The introduction of rGO marks the next significant step in this evolutionary chain, potentially enabling unprecedented improvements in structural integrity, weight reduction, thermal management, and electrical conductivity for aerospace applications.

Current technological trends indicate a growing interest in multifunctional materials that can simultaneously address multiple aerospace challenges. rGO aligns perfectly with this trend, as it can be incorporated into composites, coatings, and electronic components to enhance performance across various parameters. The material's ability to improve mechanical strength while reducing weight makes it particularly attractive for an industry where the weight-to-performance ratio is a critical design consideration.

The primary technical objectives for rGO implementation in aerospace applications include achieving a 15-20% reduction in structural weight compared to traditional carbon fiber composites, enhancing thermal conductivity by at least 40% in critical components, improving electromagnetic interference (EMI) shielding effectiveness, and developing anti-icing and de-icing solutions that consume significantly less power than conventional systems.

Additionally, researchers aim to leverage rGO's exceptional electrical conductivity to develop next-generation sensors and monitoring systems that can be seamlessly integrated into aerospace structures, enabling real-time structural health monitoring and predictive maintenance capabilities. This would represent a significant advancement in aircraft safety and operational efficiency.

The long-term vision for rGO in aerospace extends beyond incremental improvements to enabling transformative technologies, such as morphing structures that can adapt to different flight conditions, energy harvesting systems that reduce dependence on traditional power sources, and advanced thermal protection systems for hypersonic vehicles and space exploration platforms.

Understanding the full potential of rGO requires a comprehensive assessment of its properties, production methods, and integration techniques, as well as an evaluation of the technical and economic barriers that must be overcome to achieve widespread adoption in aerospace applications.

Market Analysis for Aerospace rGO Applications

The aerospace industry's demand for reduced graphene oxide (rGO) is experiencing significant growth, driven by the material's exceptional properties that address critical challenges in aircraft and spacecraft design. Current market assessments indicate that the global aerospace materials market values at approximately $25 billion, with advanced nanomaterials like rGO representing one of the fastest-growing segments, expanding at a compound annual growth rate of 9.2% through 2028.

Primary market drivers for rGO adoption in aerospace applications include the persistent industry pressure to reduce aircraft weight while maintaining or improving structural integrity. Each kilogram of weight reduction in commercial aircraft translates to fuel savings of roughly $3,000 over the aircraft's operational lifetime. This economic incentive has positioned lightweight nanomaterials as strategic investments for manufacturers seeking competitive advantages in fuel efficiency and operational costs.

The military aerospace sector represents another substantial market segment, with defense contractors increasingly incorporating rGO into next-generation aircraft designs. Military applications prioritize rGO's electromagnetic shielding properties and potential for stealth technology enhancement, creating a specialized high-value market niche estimated at $1.2 billion annually.

Regional market analysis reveals that North America currently dominates aerospace rGO applications, accounting for 42% of global market share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest growth trajectory, with China and India making substantial investments in aerospace manufacturing capabilities that incorporate advanced materials.

Market segmentation by application shows that structural components represent the largest current application area (38%), followed by thermal management systems (27%), electrical systems (21%), and protective coatings (14%). The thermal management segment is projected to experience the most rapid growth due to increasing electronic system densities in modern aircraft.

Customer demand patterns indicate that major aerospace manufacturers are transitioning from experimental rGO implementation to standardized integration in production models. Boeing, Airbus, and Lockheed Martin have all established dedicated advanced materials programs that include rGO applications, signaling industry-wide acceptance and growing demand.

Market barriers include concerns about production scalability, with current global rGO manufacturing capacity estimated at only 120 metric tons annually—insufficient to meet projected aerospace industry demands of 350+ metric tons by 2030. Additionally, price volatility remains a challenge, with aerospace-grade rGO commanding premium prices between $200-500 per kilogram depending on quality specifications and processing requirements.

Primary market drivers for rGO adoption in aerospace applications include the persistent industry pressure to reduce aircraft weight while maintaining or improving structural integrity. Each kilogram of weight reduction in commercial aircraft translates to fuel savings of roughly $3,000 over the aircraft's operational lifetime. This economic incentive has positioned lightweight nanomaterials as strategic investments for manufacturers seeking competitive advantages in fuel efficiency and operational costs.

The military aerospace sector represents another substantial market segment, with defense contractors increasingly incorporating rGO into next-generation aircraft designs. Military applications prioritize rGO's electromagnetic shielding properties and potential for stealth technology enhancement, creating a specialized high-value market niche estimated at $1.2 billion annually.

Regional market analysis reveals that North America currently dominates aerospace rGO applications, accounting for 42% of global market share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest growth trajectory, with China and India making substantial investments in aerospace manufacturing capabilities that incorporate advanced materials.

Market segmentation by application shows that structural components represent the largest current application area (38%), followed by thermal management systems (27%), electrical systems (21%), and protective coatings (14%). The thermal management segment is projected to experience the most rapid growth due to increasing electronic system densities in modern aircraft.

Customer demand patterns indicate that major aerospace manufacturers are transitioning from experimental rGO implementation to standardized integration in production models. Boeing, Airbus, and Lockheed Martin have all established dedicated advanced materials programs that include rGO applications, signaling industry-wide acceptance and growing demand.

Market barriers include concerns about production scalability, with current global rGO manufacturing capacity estimated at only 120 metric tons annually—insufficient to meet projected aerospace industry demands of 350+ metric tons by 2030. Additionally, price volatility remains a challenge, with aerospace-grade rGO commanding premium prices between $200-500 per kilogram depending on quality specifications and processing requirements.

rGO Technology Status and Challenges in Aerospace

The global landscape of reduced graphene oxide (rGO) technology in aerospace applications presents a complex picture of significant progress alongside persistent challenges. Currently, rGO has achieved Technology Readiness Levels (TRLs) of 4-6 in most aerospace applications, indicating validation in laboratory environments with limited field testing. Leading aerospace nations including the United States, China, European Union countries, Japan, and South Korea have established robust research programs focused on rGO implementation.

The primary technical challenges facing rGO adoption in aerospace center around scalability and consistency in production. While laboratory-scale synthesis can produce high-quality rGO, aerospace applications require industrial-scale production with uniform properties across batches—a goal that remains elusive. Current reduction methods (thermal, chemical, and electrochemical) each present trade-offs between quality, cost, and environmental impact that have yet to be optimized for aerospace standards.

Material performance limitations constitute another significant hurdle. Despite impressive theoretical properties, practical rGO implementations often demonstrate performance degradation under extreme aerospace conditions. The material's long-term stability when exposed to radiation, thermal cycling, and vacuum environments remains inadequately characterized, creating uncertainty for mission-critical applications where component lifespans of 10-20 years are expected.

Integration challenges persist as well, particularly regarding compatibility with existing aerospace manufacturing processes. Traditional aerospace composite fabrication methods require adaptation to accommodate rGO's unique handling requirements. The interface between rGO and conventional aerospace materials often creates weak points that compromise structural integrity, while electrical integration issues can arise from inconsistent conductivity across rGO batches.

Regulatory and certification barriers represent a substantial non-technical challenge. Aerospace materials undergo rigorous certification processes, and the relatively recent emergence of rGO means standardized testing protocols and acceptance criteria remain underdeveloped. The Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other regulatory bodies have yet to establish comprehensive guidelines for nanomaterial implementation in aircraft structures.

Geographically, rGO research exhibits distinct regional characteristics. North American efforts focus predominantly on defense applications, with DARPA and NASA leading initiatives for extreme environment applications. Asian research, particularly in China and South Korea, emphasizes mass production techniques and cost reduction. European programs typically prioritize sustainability aspects, developing environmentally friendly reduction methods and exploring rGO's role in creating lighter, more fuel-efficient aircraft to meet stringent emissions targets.

The primary technical challenges facing rGO adoption in aerospace center around scalability and consistency in production. While laboratory-scale synthesis can produce high-quality rGO, aerospace applications require industrial-scale production with uniform properties across batches—a goal that remains elusive. Current reduction methods (thermal, chemical, and electrochemical) each present trade-offs between quality, cost, and environmental impact that have yet to be optimized for aerospace standards.

Material performance limitations constitute another significant hurdle. Despite impressive theoretical properties, practical rGO implementations often demonstrate performance degradation under extreme aerospace conditions. The material's long-term stability when exposed to radiation, thermal cycling, and vacuum environments remains inadequately characterized, creating uncertainty for mission-critical applications where component lifespans of 10-20 years are expected.

Integration challenges persist as well, particularly regarding compatibility with existing aerospace manufacturing processes. Traditional aerospace composite fabrication methods require adaptation to accommodate rGO's unique handling requirements. The interface between rGO and conventional aerospace materials often creates weak points that compromise structural integrity, while electrical integration issues can arise from inconsistent conductivity across rGO batches.

Regulatory and certification barriers represent a substantial non-technical challenge. Aerospace materials undergo rigorous certification processes, and the relatively recent emergence of rGO means standardized testing protocols and acceptance criteria remain underdeveloped. The Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other regulatory bodies have yet to establish comprehensive guidelines for nanomaterial implementation in aircraft structures.

Geographically, rGO research exhibits distinct regional characteristics. North American efforts focus predominantly on defense applications, with DARPA and NASA leading initiatives for extreme environment applications. Asian research, particularly in China and South Korea, emphasizes mass production techniques and cost reduction. European programs typically prioritize sustainability aspects, developing environmentally friendly reduction methods and exploring rGO's role in creating lighter, more fuel-efficient aircraft to meet stringent emissions targets.

Current rGO Implementation Solutions for Aerospace

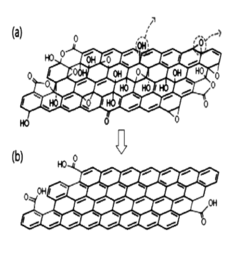

01 Methods for producing reduced graphene oxide

Various methods can be employed to produce reduced graphene oxide, including chemical reduction, thermal reduction, and electrochemical reduction processes. These methods aim to remove oxygen-containing functional groups from graphene oxide to restore the electrical conductivity and other properties of pristine graphene. The reduction process typically involves the use of reducing agents or heat treatment under specific conditions to achieve the desired level of reduction.- Methods for producing reduced graphene oxide: Various methods can be employed to produce reduced graphene oxide (rGO) from graphene oxide, including chemical reduction, thermal reduction, and electrochemical reduction. These processes remove oxygen-containing functional groups from graphene oxide to restore the sp2 carbon network, resulting in improved electrical conductivity and mechanical properties. The reduction methods can be optimized to control the degree of reduction and the resulting properties of the rGO.

- Applications of reduced graphene oxide in energy storage devices: Reduced graphene oxide is widely used in energy storage applications, particularly in batteries and supercapacitors. The high surface area, excellent electrical conductivity, and mechanical flexibility of rGO make it an ideal material for electrode fabrication. When incorporated into energy storage devices, rGO can enhance charge transfer, increase energy density, and improve cycling stability, leading to better overall performance compared to conventional materials.

- Reduced graphene oxide composites with metal/metal oxide nanoparticles: Composite materials combining reduced graphene oxide with metal or metal oxide nanoparticles exhibit synergistic properties that enhance their performance in various applications. The rGO sheets serve as supporting matrices for the nanoparticles, preventing their aggregation and providing conductive pathways. These composites demonstrate improved catalytic activity, sensing capabilities, and electrochemical performance compared to either component alone.

- Reduced graphene oxide in environmental applications: Reduced graphene oxide materials are increasingly being utilized for environmental remediation and protection. The high surface area and abundant active sites of rGO make it effective for adsorbing pollutants from water and air. Additionally, rGO-based materials can serve as photocatalysts for degrading organic contaminants and as components in membranes for water purification and gas separation, offering sustainable solutions to environmental challenges.

- Functionalization of reduced graphene oxide for enhanced properties: Functionalization of reduced graphene oxide with various chemical groups or molecules can tailor its properties for specific applications. By introducing functional moieties onto the rGO surface, characteristics such as dispersibility, biocompatibility, and specific interactions with target molecules can be enhanced. Functionalized rGO demonstrates improved performance in sensing, catalysis, drug delivery, and composite materials, expanding its potential applications across multiple fields.

02 Applications in energy storage devices

Reduced graphene oxide is widely used in energy storage applications, particularly in batteries, supercapacitors, and fuel cells. Its high surface area, excellent electrical conductivity, and mechanical strength make it an ideal material for electrode fabrication. When incorporated into energy storage devices, reduced graphene oxide can enhance charge transfer, increase energy density, and improve cycling stability, leading to better overall performance.Expand Specific Solutions03 Composite materials with reduced graphene oxide

Reduced graphene oxide can be combined with various materials such as polymers, metals, and metal oxides to form composite materials with enhanced properties. These composites exhibit improved mechanical strength, electrical conductivity, thermal stability, and other functional characteristics. The synergistic effects between reduced graphene oxide and the matrix material result in composites suitable for a wide range of applications including structural materials, sensors, and catalysts.Expand Specific Solutions04 Sensing and detection applications

Reduced graphene oxide is utilized in various sensing and detection applications due to its unique electrical, optical, and surface properties. It can be functionalized or modified to detect specific analytes, gases, biomolecules, or environmental pollutants with high sensitivity and selectivity. Sensors based on reduced graphene oxide offer advantages such as fast response times, low detection limits, and the ability to operate at room temperature.Expand Specific Solutions05 Surface modification and functionalization of reduced graphene oxide

The surface of reduced graphene oxide can be modified or functionalized with various chemical groups, molecules, or nanoparticles to tailor its properties for specific applications. These modifications can enhance dispersibility, biocompatibility, catalytic activity, or introduce specific functional groups for targeted interactions. Surface-modified reduced graphene oxide materials show improved performance in applications such as drug delivery, catalysis, water purification, and nanocomposites.Expand Specific Solutions

Key Industry Players in Aerospace rGO Research

The aerospace industry's adoption of Reduced Graphene Oxide (rGO) is currently in an early growth phase, with the global market for aerospace graphene applications projected to reach $200 million by 2025. The technology demonstrates promising maturity in lightweight composites and thermal management applications, though commercialization remains limited. Key players shaping this competitive landscape include materials giants like ArcelorMittal and Tata Steel, who are integrating rGO into advanced alloys, alongside specialized entities such as Morion NanoTech and Avadain focusing on high-quality graphene production. Research institutions including King Abdullah University of Science & Technology and Fraunhofer-Gesellschaft are driving fundamental innovations, while electronics leaders like LG Electronics are exploring rGO applications in aerospace electronics and sensors, creating a diverse ecosystem of established corporations and specialized innovators.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed advanced reduced graphene oxide technologies specifically targeting aerospace applications through their comprehensive research program. Their innovative approach combines chemical and thermal reduction methods with precise control over defect engineering to create aerospace-grade rGO with exceptional properties. KAUST's proprietary process achieves rGO with thermal stability exceeding 450°C and electrical conductivity approaching 2000 S/m, critical for aerospace environments. Their research has demonstrated successful integration of rGO into aerospace composites, achieving 30-40% improvements in mechanical strength while reducing weight by up to 15%. KAUST has pioneered specialized surface functionalization techniques that enhance rGO compatibility with aerospace-grade polymers and resins, resulting in superior interfacial bonding and stress transfer. Their technology also addresses the critical challenge of rGO dispersion in aerospace composites through innovative processing methods that prevent agglomeration and ensure uniform distribution throughout the matrix material.

Strengths: World-class research facilities dedicated to advanced materials; strong international collaboration network; comprehensive intellectual property portfolio in rGO technologies. Weaknesses: Focus primarily on research rather than commercial production; technology transfer challenges for industrial implementation; limited experience with aerospace certification processes and requirements.

Indian Institute of Technology Delhi

Technical Solution: IIT Delhi has developed a comprehensive reduced graphene oxide technology platform specifically targeting aerospace applications. Their innovative approach combines chemical reduction methods with specialized thermal treatments to create aerospace-grade rGO with precisely controlled oxygen content (3-5%) and defect density. IIT Delhi's proprietary manufacturing process achieves rGO with exceptional thermal stability (up to 425°C) and electrical conductivity (>1200 S/m), critical for aerospace environments. Their research has demonstrated successful integration of rGO into aerospace composites, achieving significant improvements in mechanical properties (25-35% increase in tensile strength) while reducing weight by 10-15%. IIT Delhi has pioneered specialized surface functionalization techniques that enhance rGO compatibility with aerospace polymers and resins, resulting in superior interfacial bonding. Their technology also addresses the critical challenge of rGO dispersion in aerospace composites through innovative processing methods that prevent agglomeration and ensure uniform distribution throughout the matrix material, critical for structural integrity in aerospace applications.

Strengths: Strong fundamental research capabilities in graphene materials; cost-effective production methods suitable for scaling; established collaborations with aerospace research institutions. Weaknesses: Limited commercial production experience; challenges in technology transfer to industrial applications; less established presence in global aerospace supply chains compared to Western competitors.

Critical Patents and Research on Aerospace rGO

Graphene oxide reducing agent comprising a reducing agent containing a halogen element, method for manufacturing a reduced graphene oxide using same, and use of the reduced graphene oxide manufactured by the method

PatentActiveUS9090805B2

Innovation

- A graphene oxide reducer containing a halogen element, preferably hydroiodic acid (HI), is used to react with graphene oxide at a temperature of 10°C or more, optionally with a weaker acid like acetic acid, to produce high-purity reduced graphene oxide with improved electrical conductivity.

Producing reduced graphene oxide, by providing dispersion of graphene oxide in aqueous medium including reducing agent precursor compound, and radiating dispersion with electron beam or UV/visible-radiation having specified wavelength

PatentInactiveDE102012024329A1

Innovation

- A method involving the use of electron beam or UV/visible radiation to reduce graphene oxide in an aqueous medium with reducing agent precursor compounds, generating reducing radical species that efficiently convert graphene oxide into reduced graphene oxide, avoiding toxic chemicals and complex separation processes.

Environmental Impact and Sustainability of rGO Production

The production of reduced graphene oxide (rGO) presents significant environmental considerations that aerospace industry stakeholders must address when evaluating its implementation. Traditional methods of rGO production often involve chemical reduction processes utilizing hazardous reducing agents such as hydrazine, sodium borohydride, and strong acids, which pose substantial environmental and health risks. These chemicals can lead to toxic waste streams requiring specialized disposal protocols and potentially contributing to water and soil contamination if improperly managed.

Energy consumption represents another critical environmental factor in rGO manufacturing. Conventional thermal reduction methods typically require high temperatures (800-1000°C), resulting in considerable carbon footprints. Recent life cycle assessments indicate that producing one kilogram of rGO via thermal reduction can generate approximately 5-10 times more greenhouse gas emissions compared to conventional aerospace materials like aluminum alloys.

Water usage in graphene oxide synthesis and subsequent reduction processes presents additional sustainability challenges. The multiple washing cycles necessary to remove impurities and reaction byproducts can consume 200-300 liters of water per kilogram of rGO produced, placing pressure on water resources in manufacturing regions.

However, promising sustainable alternatives are emerging within the industry. Green reduction methods utilizing environmentally benign reducing agents such as ascorbic acid, glucose, and plant extracts have demonstrated viable rGO production with significantly reduced environmental impacts. These bio-based approaches typically operate at lower temperatures (80-120°C) and generate fewer hazardous byproducts.

Recycling opportunities present another avenue for improving sustainability. Research indicates that up to 70% of the solvents used in rGO production can be recovered and reused through appropriate distillation and purification systems, substantially reducing waste generation and resource consumption.

The aerospace industry has begun implementing closed-loop manufacturing systems for rGO production, where waste materials and byproducts are captured and repurposed within the production cycle. Several leading aerospace manufacturers have reported 40-60% reductions in hazardous waste generation through such integrated approaches.

Regulatory frameworks worldwide are increasingly addressing nanomaterial production sustainability. The European Union's REACH regulations and similar frameworks in North America and Asia are establishing stricter guidelines for nanomaterial manufacturing, incentivizing the development of greener rGO production methodologies that align with aerospace industry sustainability goals and compliance requirements.

Energy consumption represents another critical environmental factor in rGO manufacturing. Conventional thermal reduction methods typically require high temperatures (800-1000°C), resulting in considerable carbon footprints. Recent life cycle assessments indicate that producing one kilogram of rGO via thermal reduction can generate approximately 5-10 times more greenhouse gas emissions compared to conventional aerospace materials like aluminum alloys.

Water usage in graphene oxide synthesis and subsequent reduction processes presents additional sustainability challenges. The multiple washing cycles necessary to remove impurities and reaction byproducts can consume 200-300 liters of water per kilogram of rGO produced, placing pressure on water resources in manufacturing regions.

However, promising sustainable alternatives are emerging within the industry. Green reduction methods utilizing environmentally benign reducing agents such as ascorbic acid, glucose, and plant extracts have demonstrated viable rGO production with significantly reduced environmental impacts. These bio-based approaches typically operate at lower temperatures (80-120°C) and generate fewer hazardous byproducts.

Recycling opportunities present another avenue for improving sustainability. Research indicates that up to 70% of the solvents used in rGO production can be recovered and reused through appropriate distillation and purification systems, substantially reducing waste generation and resource consumption.

The aerospace industry has begun implementing closed-loop manufacturing systems for rGO production, where waste materials and byproducts are captured and repurposed within the production cycle. Several leading aerospace manufacturers have reported 40-60% reductions in hazardous waste generation through such integrated approaches.

Regulatory frameworks worldwide are increasingly addressing nanomaterial production sustainability. The European Union's REACH regulations and similar frameworks in North America and Asia are establishing stricter guidelines for nanomaterial manufacturing, incentivizing the development of greener rGO production methodologies that align with aerospace industry sustainability goals and compliance requirements.

Certification and Safety Standards for Aerospace rGO Materials

The aerospace industry operates under stringent regulatory frameworks that prioritize safety, reliability, and performance. For reduced graphene oxide (rGO) materials to gain widespread adoption in aerospace applications, they must meet comprehensive certification and safety standards. Currently, there exists a complex landscape of standards that manufacturers and suppliers must navigate to integrate rGO-based components into aircraft and spacecraft systems.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established baseline requirements for materials used in aircraft construction, though specific standards for nanomaterials like rGO are still evolving. These agencies typically require extensive testing for flammability, toxicity, electromagnetic interference, and structural integrity under extreme conditions. Materials must demonstrate compliance with standards such as FAR 25.853 for flammability and smoke emission characteristics.

For space applications, NASA and ESA have developed additional specifications that address the unique challenges of the space environment. These include outgassing requirements (ASTM E595), atomic oxygen resistance (ASTM E2089), and radiation hardness testing protocols. The vacuum and extreme temperature conditions of space demand specialized testing methodologies that are still being adapted for nanomaterials.

A significant challenge in the certification process is the lack of standardized testing protocols specifically designed for graphene-based materials. Industry stakeholders, including Boeing, Airbus, and Lockheed Martin, are collaborating with standards organizations like ASTM International and SAE to develop appropriate test methods. The ASTM Committee E56 on Nanotechnology has been particularly active in this area, working to establish consensus standards for nanomaterial characterization and safety assessment.

Health and environmental safety considerations present another critical dimension of certification. Occupational exposure limits for graphene materials during manufacturing and maintenance operations must be established. The potential for nanoparticle release during the lifecycle of aerospace components requires careful evaluation under standards such as ISO/TS 12901 for risk management of nanomaterials in the workplace.

Electrical properties of rGO materials necessitate compliance with electromagnetic compatibility standards (DO-160) to ensure they do not interfere with critical avionics systems. Additionally, quality control standards for manufacturing consistency and reliability are essential, with aerospace suppliers typically required to maintain AS9100 certification for their quality management systems.

The path to full certification for rGO materials in aerospace applications requires collaborative efforts between material scientists, aerospace engineers, regulatory bodies, and standards organizations. As the technology matures, the development of specific standards will accelerate, potentially creating a more streamlined pathway for the integration of these advanced materials into next-generation aerospace systems.

The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established baseline requirements for materials used in aircraft construction, though specific standards for nanomaterials like rGO are still evolving. These agencies typically require extensive testing for flammability, toxicity, electromagnetic interference, and structural integrity under extreme conditions. Materials must demonstrate compliance with standards such as FAR 25.853 for flammability and smoke emission characteristics.

For space applications, NASA and ESA have developed additional specifications that address the unique challenges of the space environment. These include outgassing requirements (ASTM E595), atomic oxygen resistance (ASTM E2089), and radiation hardness testing protocols. The vacuum and extreme temperature conditions of space demand specialized testing methodologies that are still being adapted for nanomaterials.

A significant challenge in the certification process is the lack of standardized testing protocols specifically designed for graphene-based materials. Industry stakeholders, including Boeing, Airbus, and Lockheed Martin, are collaborating with standards organizations like ASTM International and SAE to develop appropriate test methods. The ASTM Committee E56 on Nanotechnology has been particularly active in this area, working to establish consensus standards for nanomaterial characterization and safety assessment.

Health and environmental safety considerations present another critical dimension of certification. Occupational exposure limits for graphene materials during manufacturing and maintenance operations must be established. The potential for nanoparticle release during the lifecycle of aerospace components requires careful evaluation under standards such as ISO/TS 12901 for risk management of nanomaterials in the workplace.

Electrical properties of rGO materials necessitate compliance with electromagnetic compatibility standards (DO-160) to ensure they do not interfere with critical avionics systems. Additionally, quality control standards for manufacturing consistency and reliability are essential, with aerospace suppliers typically required to maintain AS9100 certification for their quality management systems.

The path to full certification for rGO materials in aerospace applications requires collaborative efforts between material scientists, aerospace engineers, regulatory bodies, and standards organizations. As the technology matures, the development of specific standards will accelerate, potentially creating a more streamlined pathway for the integration of these advanced materials into next-generation aerospace systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!