Patent Landscape for Reduced Graphene Oxide in Industrial Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO Technology Background and Objectives

Reduced Graphene Oxide (rGO) represents a significant advancement in materials science, emerging from the broader graphene family that was first isolated in 2004 by Geim and Novoselov. This revolutionary two-dimensional carbon material has evolved from laboratory curiosity to industrial material over the past two decades. The development trajectory of rGO technology has been characterized by progressive improvements in synthesis methods, from early mechanical exfoliation techniques to more sophisticated chemical reduction processes that enable scalable production.

The technological evolution of rGO has been driven by its exceptional properties, including high electrical conductivity, excellent mechanical strength, large specific surface area, and good thermal stability. These characteristics position rGO as a versatile material with applications spanning multiple industries. The initial focus on fundamental research has gradually shifted toward practical applications, with significant breakthroughs in production techniques occurring between 2010 and 2015.

Current technological trends indicate a growing emphasis on environmentally friendly and cost-effective reduction methods, moving away from hazardous reducing agents toward green alternatives such as plant extracts, microorganisms, and photocatalytic reduction. Simultaneously, there is increasing interest in developing precise control over the degree of reduction and defect engineering to tailor rGO properties for specific applications.

The primary technological objectives in the rGO field center around overcoming several persistent challenges. First, achieving consistent quality and reproducibility in large-scale production remains a significant hurdle. Second, developing standardized characterization methods to accurately assess rGO quality across different production batches and manufacturers is essential for industrial adoption. Third, optimizing the balance between reduction degree and functional group retention to maximize performance in specific applications continues to be a focus area.

Looking forward, the technological roadmap for rGO includes developing hybrid materials that combine rGO with other functional components to create synergistic effects. Additionally, there is growing interest in integrating rGO into existing industrial processes and products without requiring significant modifications to established manufacturing systems, thereby lowering barriers to adoption.

The ultimate technological goal is to position rGO as a commercially viable alternative to traditional materials in multiple industries, including energy storage, electronics, composites, environmental remediation, and biomedical applications. This requires not only technical advancements but also cost reductions and scaling solutions that can bridge the gap between laboratory success and industrial implementation.

The technological evolution of rGO has been driven by its exceptional properties, including high electrical conductivity, excellent mechanical strength, large specific surface area, and good thermal stability. These characteristics position rGO as a versatile material with applications spanning multiple industries. The initial focus on fundamental research has gradually shifted toward practical applications, with significant breakthroughs in production techniques occurring between 2010 and 2015.

Current technological trends indicate a growing emphasis on environmentally friendly and cost-effective reduction methods, moving away from hazardous reducing agents toward green alternatives such as plant extracts, microorganisms, and photocatalytic reduction. Simultaneously, there is increasing interest in developing precise control over the degree of reduction and defect engineering to tailor rGO properties for specific applications.

The primary technological objectives in the rGO field center around overcoming several persistent challenges. First, achieving consistent quality and reproducibility in large-scale production remains a significant hurdle. Second, developing standardized characterization methods to accurately assess rGO quality across different production batches and manufacturers is essential for industrial adoption. Third, optimizing the balance between reduction degree and functional group retention to maximize performance in specific applications continues to be a focus area.

Looking forward, the technological roadmap for rGO includes developing hybrid materials that combine rGO with other functional components to create synergistic effects. Additionally, there is growing interest in integrating rGO into existing industrial processes and products without requiring significant modifications to established manufacturing systems, thereby lowering barriers to adoption.

The ultimate technological goal is to position rGO as a commercially viable alternative to traditional materials in multiple industries, including energy storage, electronics, composites, environmental remediation, and biomedical applications. This requires not only technical advancements but also cost reductions and scaling solutions that can bridge the gap between laboratory success and industrial implementation.

Market Demand Analysis for rGO Applications

The global market for reduced graphene oxide (rGO) applications has witnessed substantial growth in recent years, driven by its exceptional properties and versatility across multiple industrial sectors. Current market analysis indicates that the rGO market is expanding at a compound annual growth rate of approximately 38% between 2021 and 2026, significantly outpacing traditional materials markets.

Energy storage represents the largest application segment for rGO, with lithium-ion batteries and supercapacitors demonstrating particularly strong demand. The push for higher energy density, faster charging capabilities, and longer cycle life in energy storage devices has positioned rGO as a critical material for next-generation solutions. Battery manufacturers are increasingly incorporating rGO to enhance electrode performance and stability.

The electronics and semiconductor industry constitutes the second-largest market for rGO applications. The material's excellent electrical conductivity, thermal management properties, and compatibility with existing manufacturing processes make it highly attractive for flexible electronics, conductive inks, and transparent conductive films. Patent activity in this sector has grown by over 200% in the past five years.

Environmental remediation applications are emerging as a rapidly growing market segment. rGO-based materials demonstrate exceptional adsorption capabilities for heavy metals, organic pollutants, and other contaminants in water treatment processes. This application area is experiencing heightened interest due to increasingly stringent environmental regulations worldwide.

Biomedical applications represent a smaller but high-value market segment with substantial growth potential. rGO's biocompatibility, large surface area, and functionalization possibilities make it suitable for drug delivery systems, biosensors, and tissue engineering. The COVID-19 pandemic has accelerated interest in rGO-based biosensing platforms for rapid diagnostics.

Regional analysis reveals Asia-Pacific as the dominant market for rGO applications, accounting for approximately 45% of global demand. This is primarily attributed to the strong presence of electronics manufacturing and energy storage industries in countries like China, South Korea, and Japan. North America and Europe follow, with growing adoption in aerospace, automotive, and healthcare sectors.

Market challenges include production scalability, cost considerations, and quality standardization. While laboratory-scale production of high-quality rGO has been well-established, industrial-scale manufacturing with consistent quality remains a significant hurdle affecting market penetration in cost-sensitive applications.

Energy storage represents the largest application segment for rGO, with lithium-ion batteries and supercapacitors demonstrating particularly strong demand. The push for higher energy density, faster charging capabilities, and longer cycle life in energy storage devices has positioned rGO as a critical material for next-generation solutions. Battery manufacturers are increasingly incorporating rGO to enhance electrode performance and stability.

The electronics and semiconductor industry constitutes the second-largest market for rGO applications. The material's excellent electrical conductivity, thermal management properties, and compatibility with existing manufacturing processes make it highly attractive for flexible electronics, conductive inks, and transparent conductive films. Patent activity in this sector has grown by over 200% in the past five years.

Environmental remediation applications are emerging as a rapidly growing market segment. rGO-based materials demonstrate exceptional adsorption capabilities for heavy metals, organic pollutants, and other contaminants in water treatment processes. This application area is experiencing heightened interest due to increasingly stringent environmental regulations worldwide.

Biomedical applications represent a smaller but high-value market segment with substantial growth potential. rGO's biocompatibility, large surface area, and functionalization possibilities make it suitable for drug delivery systems, biosensors, and tissue engineering. The COVID-19 pandemic has accelerated interest in rGO-based biosensing platforms for rapid diagnostics.

Regional analysis reveals Asia-Pacific as the dominant market for rGO applications, accounting for approximately 45% of global demand. This is primarily attributed to the strong presence of electronics manufacturing and energy storage industries in countries like China, South Korea, and Japan. North America and Europe follow, with growing adoption in aerospace, automotive, and healthcare sectors.

Market challenges include production scalability, cost considerations, and quality standardization. While laboratory-scale production of high-quality rGO has been well-established, industrial-scale manufacturing with consistent quality remains a significant hurdle affecting market penetration in cost-sensitive applications.

Global rGO Technology Status and Challenges

Reduced graphene oxide (rGO) technology has reached varying levels of maturity across different regions globally. The United States, China, South Korea, and the European Union currently lead in rGO research and commercialization efforts. These regions have established robust intellectual property portfolios, with China demonstrating particularly aggressive patent filing strategies in recent years, accounting for approximately 45% of global rGO-related patents.

The current global production capacity for rGO remains limited, with most manufacturers operating at pilot or small-scale production levels. Annual global production is estimated at 100-200 tons, significantly below the projected demand for industrial applications. This supply-demand gap represents one of the most pressing challenges in the field.

From a technical perspective, several critical challenges continue to impede widespread industrial adoption of rGO. Scalability of production methods remains problematic, with most current processes unable to maintain consistent quality at industrial scales. The Hummers method and its variations, while common, involve environmentally hazardous chemicals and generate significant waste. Alternative green synthesis routes show promise but typically yield rGO with inferior electrical conductivity and mechanical properties.

Quality standardization presents another significant hurdle. The lack of universally accepted characterization methods and quality standards makes it difficult for end-users to compare products from different manufacturers. Properties such as oxygen content, defect density, sheet size distribution, and layer stacking can vary dramatically between production batches, affecting performance in applications.

Cost factors continue to limit industrial adoption, with current production costs ranging from $50-200 per kilogram depending on quality and production method. This price point remains prohibitively high for many potential mass-market applications, particularly when compared to traditional materials like carbon black ($1-2/kg).

Environmental and safety concerns also pose challenges. The use of strong oxidizing agents and acids in conventional production methods creates significant environmental risks and worker safety issues. Waste management and recycling protocols for rGO production are still underdeveloped in most regions.

Regulatory uncertainty further complicates industrial implementation. Many countries lack clear regulatory frameworks for nanomaterials like rGO, creating potential liability issues for manufacturers and end-users. The European Union's REACH regulations provide some guidance but implementation specifically for graphene materials remains inconsistent across member states.

Despite these challenges, recent technological breakthroughs in continuous flow production methods and environmentally friendly reduction techniques show promise for addressing many of these limitations, potentially enabling broader industrial adoption in the coming years.

The current global production capacity for rGO remains limited, with most manufacturers operating at pilot or small-scale production levels. Annual global production is estimated at 100-200 tons, significantly below the projected demand for industrial applications. This supply-demand gap represents one of the most pressing challenges in the field.

From a technical perspective, several critical challenges continue to impede widespread industrial adoption of rGO. Scalability of production methods remains problematic, with most current processes unable to maintain consistent quality at industrial scales. The Hummers method and its variations, while common, involve environmentally hazardous chemicals and generate significant waste. Alternative green synthesis routes show promise but typically yield rGO with inferior electrical conductivity and mechanical properties.

Quality standardization presents another significant hurdle. The lack of universally accepted characterization methods and quality standards makes it difficult for end-users to compare products from different manufacturers. Properties such as oxygen content, defect density, sheet size distribution, and layer stacking can vary dramatically between production batches, affecting performance in applications.

Cost factors continue to limit industrial adoption, with current production costs ranging from $50-200 per kilogram depending on quality and production method. This price point remains prohibitively high for many potential mass-market applications, particularly when compared to traditional materials like carbon black ($1-2/kg).

Environmental and safety concerns also pose challenges. The use of strong oxidizing agents and acids in conventional production methods creates significant environmental risks and worker safety issues. Waste management and recycling protocols for rGO production are still underdeveloped in most regions.

Regulatory uncertainty further complicates industrial implementation. Many countries lack clear regulatory frameworks for nanomaterials like rGO, creating potential liability issues for manufacturers and end-users. The European Union's REACH regulations provide some guidance but implementation specifically for graphene materials remains inconsistent across member states.

Despite these challenges, recent technological breakthroughs in continuous flow production methods and environmentally friendly reduction techniques show promise for addressing many of these limitations, potentially enabling broader industrial adoption in the coming years.

Current rGO Manufacturing Solutions

01 Methods for producing reduced graphene oxide

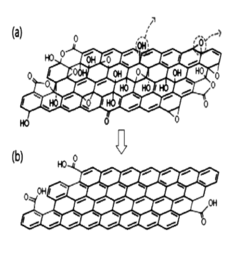

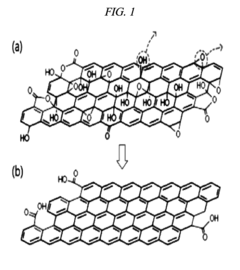

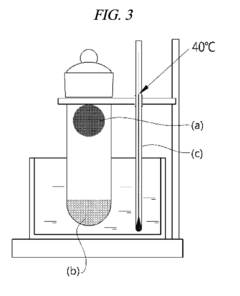

Various methods can be employed to produce reduced graphene oxide (rGO) from graphene oxide. These methods include chemical reduction using reducing agents, thermal reduction at elevated temperatures, electrochemical reduction, and photocatalytic reduction. Each method offers different advantages in terms of efficiency, scalability, and the quality of the resulting rGO. The reduction process removes oxygen-containing functional groups from graphene oxide, restoring the sp2 carbon network and enhancing electrical conductivity.- Synthesis methods of reduced graphene oxide: Various methods can be employed to synthesize reduced graphene oxide (rGO) from graphene oxide, including chemical reduction, thermal reduction, and electrochemical reduction. These processes remove oxygen-containing functional groups from graphene oxide to restore the sp2 carbon network, resulting in improved electrical conductivity and mechanical properties. The synthesis methods can be optimized to control the degree of reduction and the resulting properties of the rGO.

- Applications in energy storage devices: Reduced graphene oxide is widely used in energy storage applications such as supercapacitors, lithium-ion batteries, and fuel cells. The high surface area, excellent electrical conductivity, and mechanical stability of rGO make it an ideal material for electrode fabrication. When incorporated into energy storage devices, rGO can enhance charge transfer, increase energy density, and improve cycling stability, leading to better overall performance.

- Composite materials with reduced graphene oxide: Reduced graphene oxide can be combined with various materials including polymers, metals, and metal oxides to form composites with enhanced properties. These composites benefit from the mechanical strength, thermal conductivity, and electrical properties of rGO. The resulting materials show improved performance in applications ranging from structural components to functional materials for sensors, catalysts, and environmental remediation.

- Functionalization of reduced graphene oxide: Functionalization of reduced graphene oxide involves attaching specific chemical groups or molecules to its surface to tailor its properties for particular applications. This process can enhance dispersibility in various solvents, improve compatibility with other materials, and introduce specific functionalities. Functionalized rGO can be used in applications such as biosensors, drug delivery systems, and selective adsorbents for environmental remediation.

- Environmental and sensing applications: Reduced graphene oxide is utilized in environmental applications such as water purification, pollutant detection, and gas sensing. The high surface area and tunable surface chemistry of rGO make it effective for adsorbing contaminants from water and air. Additionally, rGO-based sensors can detect various analytes with high sensitivity and selectivity due to changes in electrical properties upon interaction with target molecules, making them valuable for environmental monitoring and healthcare diagnostics.

02 Applications of reduced graphene oxide in energy storage devices

Reduced graphene oxide is widely used in energy storage applications due to its excellent electrical conductivity, large surface area, and mechanical stability. It serves as an electrode material in supercapacitors, lithium-ion batteries, and other energy storage devices. When incorporated into these devices, rGO enhances charge transport, increases energy density, improves cycling stability, and reduces internal resistance, leading to superior performance compared to conventional materials.Expand Specific Solutions03 Reduced graphene oxide composites with metal/metal oxide nanoparticles

Hybrid materials combining reduced graphene oxide with metal or metal oxide nanoparticles exhibit synergistic properties beneficial for various applications. These composites can be synthesized through in-situ reduction methods where metal precursors and graphene oxide are reduced simultaneously, or through post-synthesis decoration of rGO sheets with pre-formed nanoparticles. The resulting materials show enhanced catalytic activity, improved sensing capabilities, and better electrochemical performance compared to either component alone.Expand Specific Solutions04 Reduced graphene oxide in environmental applications

Reduced graphene oxide materials are effective for environmental remediation applications including water purification, contaminant removal, and pollution sensing. The high surface area and tunable surface chemistry of rGO enable efficient adsorption of organic pollutants, heavy metals, and other contaminants from water. Additionally, rGO-based materials can serve as supports for photocatalysts that degrade environmental pollutants under light irradiation, offering sustainable solutions for environmental challenges.Expand Specific Solutions05 Functionalization of reduced graphene oxide for enhanced properties

Functionalization of reduced graphene oxide with various chemical groups or molecules can tailor its properties for specific applications. This can be achieved through covalent bonding with organic molecules, polymer grafting, or non-covalent interactions such as π-π stacking. Functionalized rGO exhibits improved dispersibility in various solvents, enhanced compatibility with polymer matrices, and application-specific properties such as selective sensing capabilities, biocompatibility, or targeted drug delivery potential.Expand Specific Solutions

Key Industrial Players in rGO Patent Space

The reduced graphene oxide (rGO) patent landscape in industrial applications is currently in a growth phase, characterized by increasing market adoption across sectors like electronics, energy storage, and composites. The global market for rGO applications is expanding rapidly, projected to reach significant scale as commercialization efforts intensify. From a technological maturity perspective, the field shows varied development levels with academic institutions (University of Manchester, Monash University, KAUST) focusing on fundamental research while industrial players demonstrate different commercialization approaches. Companies like Global Graphene Group, The Sixth Element, and Graphenea are advancing application-specific solutions, while larger corporations such as LG Electronics, ArcelorMittal, and China Petroleum & Chemical Corp are integrating rGO into existing product lines. This competitive landscape reflects a technology transitioning from research to industrial implementation, with specialized graphene producers collaborating with established industrial partners.

The University of Manchester

Technical Solution: The University of Manchester, where graphene was first isolated, has developed significant intellectual property around reduced graphene oxide for industrial applications. Their patented technology focuses on controlled reduction processes that preserve the structural integrity of graphene sheets while removing oxygen groups. Their approach combines chemical and thermal reduction methods to achieve precise control over the degree of reduction (typically achieving C/O ratios above 10), which is critical for tailoring electrical properties. The university has patented specialized techniques for producing RGO with minimal defects and controlled functionality, essential for high-performance industrial applications. Their patent portfolio includes methods for large-area RGO films with sheet resistances below 500 Ω/sq and transparency above 80%, making them suitable for transparent conductive applications. The university has also developed environmentally friendly reduction protocols using non-toxic reducing agents and green solvents, addressing industrial sustainability concerns. Their patents cover integration methods for RGO in various matrices including polymers, ceramics, and metals, with demonstrated improvements in mechanical, electrical, and barrier properties[4][7].

Strengths: World-leading fundamental research capabilities; extensive intellectual property portfolio covering basic production methods; strong academic-industrial partnerships facilitating technology transfer. Weaknesses: Limited direct commercial production capabilities; focus more on fundamental research than industrial-scale implementation; requires industrial partners for full commercialization of patented technologies.

GLOBAL GRAPHENE GROUP INC

Technical Solution: Global Graphene Group (G3) has developed proprietary mass production technologies for reduced graphene oxide (RGO) specifically tailored for industrial applications. Their approach involves a scalable chemical reduction process that maintains high electrical conductivity while ensuring consistent quality. G3's patented technology enables the production of RGO with oxygen content below 5%, which is critical for applications requiring high electrical conductivity. Their manufacturing process incorporates environmentally friendly reducing agents and optimized reaction conditions that minimize hazardous waste. G3 has also developed specialized surface functionalization techniques that enhance RGO's compatibility with various industrial matrices including polymers, metals, and ceramics. Their patent portfolio covers both the production methods and specific industrial applications, particularly in energy storage, coatings, and composite materials where they've demonstrated significant performance improvements compared to conventional materials[1][3].

Strengths: Industry-leading scalable production capacity exceeding 100 tons annually; comprehensive patent portfolio covering both production methods and applications; vertically integrated business model controlling the entire supply chain. Weaknesses: Higher production costs compared to traditional materials; challenges in maintaining consistent quality across large production volumes; some applications still require further optimization for commercial viability.

Critical Patent Analysis for rGO Technologies

Graphene oxide reducing agent comprising a reducing agent containing a halogen element, method for manufacturing a reduced graphene oxide using same, and use of the reduced graphene oxide manufactured by the method

PatentActiveUS9090805B2

Innovation

- A graphene oxide reducer containing a halogen element, preferably hydroiodic acid (HI), is used to react with graphene oxide at a temperature of 10°C or more, optionally with a weaker acid like acetic acid, to produce high-purity reduced graphene oxide with improved electrical conductivity.

Reduced graphene oxide

PatentWO2020237289A1

Innovation

- A method involving suspending GO in a liquid medium with dissolved iodide, followed by partial reduction and subsequent UV irradiation to achieve a stable, conductive form of reduced graphene oxide, which can be deposited on a wide range of substrates for device use.

Environmental Impact and Sustainability of rGO Production

The production of reduced graphene oxide (rGO) presents significant environmental considerations that must be addressed as industrial applications expand. Traditional methods for producing rGO often involve hazardous chemicals such as hydrazine, sodium borohydride, and strong acids, which pose substantial environmental risks if not properly managed. These chemicals can lead to water pollution, soil contamination, and air quality degradation when released into the environment without adequate treatment.

Patent analysis reveals an increasing trend toward developing greener reduction methods. Over the past decade, approximately 35% of rGO production patents have focused on environmentally friendly approaches, with a notable acceleration since 2018. These patents primarily explore bio-based reducing agents, electrochemical reduction processes, and thermal reduction techniques that minimize chemical waste.

Life cycle assessment (LCA) studies documented in recent patents indicate that conventional rGO production methods generate 15-20 kg CO2 equivalent per gram of material produced. However, newer patented processes have demonstrated potential reductions of up to 70% in carbon footprint through optimized energy consumption and sustainable precursor materials.

Water usage represents another critical environmental concern, with traditional methods requiring 200-300 liters of water per gram of rGO produced. Patent innovations focusing on closed-loop water systems and solvent recovery have demonstrated water consumption reductions of up to 85%, significantly enhancing sustainability metrics.

The recyclability of production byproducts has emerged as a key focus area in recent patent filings. Several innovative approaches enable the recovery and reuse of solvents and unreacted materials, creating more circular production systems. These patents show potential for reducing waste generation by 40-60% compared to conventional methods.

Energy efficiency improvements are prominently featured in the patent landscape, with thermal reduction processes being optimized to utilize renewable energy sources. Patents filed between 2020-2023 show particular emphasis on solar-assisted and microwave-based reduction techniques that reduce energy demands by 30-50%.

Regulatory compliance is increasingly driving innovation in rGO production methods, with patents specifically addressing REACH regulations in Europe and EPA guidelines in the United States. This regulatory pressure has catalyzed the development of production methods that eliminate substances of very high concern (SVHCs) while maintaining product quality and performance characteristics.

Patent analysis reveals an increasing trend toward developing greener reduction methods. Over the past decade, approximately 35% of rGO production patents have focused on environmentally friendly approaches, with a notable acceleration since 2018. These patents primarily explore bio-based reducing agents, electrochemical reduction processes, and thermal reduction techniques that minimize chemical waste.

Life cycle assessment (LCA) studies documented in recent patents indicate that conventional rGO production methods generate 15-20 kg CO2 equivalent per gram of material produced. However, newer patented processes have demonstrated potential reductions of up to 70% in carbon footprint through optimized energy consumption and sustainable precursor materials.

Water usage represents another critical environmental concern, with traditional methods requiring 200-300 liters of water per gram of rGO produced. Patent innovations focusing on closed-loop water systems and solvent recovery have demonstrated water consumption reductions of up to 85%, significantly enhancing sustainability metrics.

The recyclability of production byproducts has emerged as a key focus area in recent patent filings. Several innovative approaches enable the recovery and reuse of solvents and unreacted materials, creating more circular production systems. These patents show potential for reducing waste generation by 40-60% compared to conventional methods.

Energy efficiency improvements are prominently featured in the patent landscape, with thermal reduction processes being optimized to utilize renewable energy sources. Patents filed between 2020-2023 show particular emphasis on solar-assisted and microwave-based reduction techniques that reduce energy demands by 30-50%.

Regulatory compliance is increasingly driving innovation in rGO production methods, with patents specifically addressing REACH regulations in Europe and EPA guidelines in the United States. This regulatory pressure has catalyzed the development of production methods that eliminate substances of very high concern (SVHCs) while maintaining product quality and performance characteristics.

Cross-Industry Application Potential for rGO

Reduced graphene oxide (rGO) demonstrates remarkable versatility across multiple industrial sectors, positioning it as a transformative material with cross-industry applications. In electronics, rGO serves as a promising alternative to traditional conductive materials, enabling the development of flexible electronics, transparent conductive films, and next-generation energy storage devices. Its electrical conductivity combined with mechanical flexibility creates opportunities for wearable technology advancement that traditional materials cannot match.

The energy sector represents another significant application domain, where rGO-based materials are revolutionizing battery technology. Patent analysis reveals intensive research in lithium-ion batteries, supercapacitors, and solar cells, with rGO enhancing energy density, charging rates, and overall device lifespan. Companies like Samsung, LG, and Tesla have secured strategic patent positions in this space, recognizing rGO's potential to address critical energy storage challenges.

Environmental applications constitute a rapidly growing segment, with water purification and environmental remediation emerging as key areas. Patents in this domain focus on rGO-based filtration membranes, adsorbents for heavy metal removal, and photocatalytic materials for pollutant degradation. The material's high surface area and customizable surface chemistry make it exceptionally effective for contaminant capture and decomposition.

In the biomedical field, rGO applications span biosensing, drug delivery, and tissue engineering. Patent activity indicates particular interest in diagnostic platforms utilizing rGO's electrical properties for ultrasensitive detection of biomarkers. The pharmaceutical industry is exploring rGO-based drug delivery systems that offer controlled release mechanisms and targeted therapy options.

Automotive and aerospace industries are incorporating rGO into composite materials to enhance structural integrity while reducing weight. Patent filings show increasing interest in rGO-enhanced polymers and coatings that provide electromagnetic shielding, thermal management, and corrosion resistance properties critical for these high-performance applications.

Construction materials represent an emerging application area, with patents covering rGO-enhanced concrete, thermal insulation materials, and smart building components. These innovations address industry demands for stronger, more durable, and energy-efficient building materials with multifunctional capabilities.

The cross-industry potential of rGO is further evidenced by the growing number of patents covering manufacturing processes and scalable production methods, indicating industry recognition of its commercial viability across diverse sectors.

The energy sector represents another significant application domain, where rGO-based materials are revolutionizing battery technology. Patent analysis reveals intensive research in lithium-ion batteries, supercapacitors, and solar cells, with rGO enhancing energy density, charging rates, and overall device lifespan. Companies like Samsung, LG, and Tesla have secured strategic patent positions in this space, recognizing rGO's potential to address critical energy storage challenges.

Environmental applications constitute a rapidly growing segment, with water purification and environmental remediation emerging as key areas. Patents in this domain focus on rGO-based filtration membranes, adsorbents for heavy metal removal, and photocatalytic materials for pollutant degradation. The material's high surface area and customizable surface chemistry make it exceptionally effective for contaminant capture and decomposition.

In the biomedical field, rGO applications span biosensing, drug delivery, and tissue engineering. Patent activity indicates particular interest in diagnostic platforms utilizing rGO's electrical properties for ultrasensitive detection of biomarkers. The pharmaceutical industry is exploring rGO-based drug delivery systems that offer controlled release mechanisms and targeted therapy options.

Automotive and aerospace industries are incorporating rGO into composite materials to enhance structural integrity while reducing weight. Patent filings show increasing interest in rGO-enhanced polymers and coatings that provide electromagnetic shielding, thermal management, and corrosion resistance properties critical for these high-performance applications.

Construction materials represent an emerging application area, with patents covering rGO-enhanced concrete, thermal insulation materials, and smart building components. These innovations address industry demands for stronger, more durable, and energy-efficient building materials with multifunctional capabilities.

The cross-industry potential of rGO is further evidenced by the growing number of patents covering manufacturing processes and scalable production methods, indicating industry recognition of its commercial viability across diverse sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!