Evaluating the Durability of Reduced Graphene Oxide in High Stress Environments

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO Durability Background and Research Objectives

Reduced graphene oxide (rGO) has emerged as a revolutionary material in the advanced materials landscape since its initial development in the early 2000s. As a derivative of graphene, rGO combines exceptional mechanical strength, electrical conductivity, and thermal stability with the processing advantages of solution-based manufacturing. The evolution of rGO technology has progressed from laboratory curiosity to industrial application over the past two decades, with significant breakthroughs in reduction methods transitioning from chemical to thermal, electrochemical, and more recently, photonic approaches.

The durability of rGO in high-stress environments represents a critical frontier in materials science research. While graphene-based materials theoretically possess remarkable strength-to-weight ratios and resistance to environmental degradation, their practical implementation in extreme conditions has revealed performance gaps between theoretical models and real-world applications. These discrepancies have prompted intensive research into the fundamental mechanisms of rGO degradation under mechanical stress, thermal cycling, chemical exposure, and radiation.

Current technological trajectories indicate growing demand for materials capable of maintaining structural and functional integrity in increasingly extreme operational environments. From aerospace components experiencing thermal cycling from -150°C to +150°C to next-generation energy storage systems withstanding thousands of charge-discharge cycles, the need for ultra-durable materials continues to expand across industries. rGO's potential to meet these demands depends on resolving current durability limitations.

This research aims to comprehensively evaluate and enhance the durability characteristics of rGO materials when subjected to multi-factorial stress conditions. Specifically, our technical objectives include: quantifying the degradation mechanisms of rGO under combined mechanical, thermal, chemical, and radiation stresses; developing standardized testing protocols for assessing rGO durability across different application environments; and identifying modification strategies to enhance long-term stability without compromising desirable properties.

The investigation will build upon recent advances in in-situ characterization techniques that allow real-time observation of material behavior under stress. By correlating microstructural changes with performance degradation, we seek to establish predictive models for rGO lifespan in various high-stress applications. These models will inform both material design improvements and application-specific implementation guidelines.

Additionally, this research aims to establish clear benchmarks comparing rGO durability against conventional and competing advanced materials, providing industry stakeholders with actionable data for material selection decisions. The ultimate goal is to develop design principles for next-generation rGO composites and structures with predictable, consistent performance throughout their operational lifetime, even when subjected to extreme environmental conditions.

The durability of rGO in high-stress environments represents a critical frontier in materials science research. While graphene-based materials theoretically possess remarkable strength-to-weight ratios and resistance to environmental degradation, their practical implementation in extreme conditions has revealed performance gaps between theoretical models and real-world applications. These discrepancies have prompted intensive research into the fundamental mechanisms of rGO degradation under mechanical stress, thermal cycling, chemical exposure, and radiation.

Current technological trajectories indicate growing demand for materials capable of maintaining structural and functional integrity in increasingly extreme operational environments. From aerospace components experiencing thermal cycling from -150°C to +150°C to next-generation energy storage systems withstanding thousands of charge-discharge cycles, the need for ultra-durable materials continues to expand across industries. rGO's potential to meet these demands depends on resolving current durability limitations.

This research aims to comprehensively evaluate and enhance the durability characteristics of rGO materials when subjected to multi-factorial stress conditions. Specifically, our technical objectives include: quantifying the degradation mechanisms of rGO under combined mechanical, thermal, chemical, and radiation stresses; developing standardized testing protocols for assessing rGO durability across different application environments; and identifying modification strategies to enhance long-term stability without compromising desirable properties.

The investigation will build upon recent advances in in-situ characterization techniques that allow real-time observation of material behavior under stress. By correlating microstructural changes with performance degradation, we seek to establish predictive models for rGO lifespan in various high-stress applications. These models will inform both material design improvements and application-specific implementation guidelines.

Additionally, this research aims to establish clear benchmarks comparing rGO durability against conventional and competing advanced materials, providing industry stakeholders with actionable data for material selection decisions. The ultimate goal is to develop design principles for next-generation rGO composites and structures with predictable, consistent performance throughout their operational lifetime, even when subjected to extreme environmental conditions.

Market Applications and Demand Analysis for High-Stress rGO Materials

The market for reduced graphene oxide (rGO) materials capable of withstanding high-stress environments has been experiencing significant growth across multiple industries. Current market analysis indicates that aerospace, automotive, and energy sectors represent the primary demand drivers, collectively accounting for approximately 65% of the total market share for high-stress rGO applications.

In the aerospace industry, the demand for lightweight yet durable materials has created a substantial market opportunity for rGO composites. These materials are increasingly being incorporated into critical components such as turbine blades, heat shields, and structural elements where extreme temperature fluctuations and mechanical stress are common. The aerospace rGO market segment has demonstrated a compound annual growth rate of 18.7% over the past three years.

The automotive sector presents another substantial market for high-stress rGO materials, particularly in electric vehicle battery systems, where thermal management and structural integrity under vibration are critical concerns. Major automotive manufacturers have begun incorporating rGO-enhanced components in premium models, with plans to expand implementation across broader product lines as production costs decrease.

Energy infrastructure applications represent the third major market segment, with particular emphasis on wind turbine components, solar panel substrates, and energy storage systems. The durability of rGO in high-UV, high-temperature, and corrosive environments makes it especially valuable for renewable energy applications in extreme climate conditions.

Market research indicates that customer requirements for high-stress rGO materials primarily focus on four performance metrics: thermal stability (maintaining structural integrity at temperatures ranging from -60°C to +400°C), mechanical durability (resistance to cyclic loading and vibration), chemical resistance (particularly to oxidation and hydrolysis), and long-term performance stability (minimal degradation over 10+ years of service life).

Regional analysis shows North America and East Asia leading in adoption of high-stress rGO materials, with Europe showing accelerated growth rates in the renewable energy sector specifically. The Asia-Pacific region is projected to become the largest market by volume within the next five years, driven by expanding manufacturing capabilities and increasing domestic demand.

Pricing sensitivity varies significantly by application, with aerospace customers demonstrating willingness to pay premium prices for performance-verified materials, while automotive applications remain more cost-sensitive. This market dynamic has created two distinct product tiers: ultra-high-performance rGO materials commanding premium prices for critical applications, and more moderately priced materials for less demanding but higher-volume applications.

In the aerospace industry, the demand for lightweight yet durable materials has created a substantial market opportunity for rGO composites. These materials are increasingly being incorporated into critical components such as turbine blades, heat shields, and structural elements where extreme temperature fluctuations and mechanical stress are common. The aerospace rGO market segment has demonstrated a compound annual growth rate of 18.7% over the past three years.

The automotive sector presents another substantial market for high-stress rGO materials, particularly in electric vehicle battery systems, where thermal management and structural integrity under vibration are critical concerns. Major automotive manufacturers have begun incorporating rGO-enhanced components in premium models, with plans to expand implementation across broader product lines as production costs decrease.

Energy infrastructure applications represent the third major market segment, with particular emphasis on wind turbine components, solar panel substrates, and energy storage systems. The durability of rGO in high-UV, high-temperature, and corrosive environments makes it especially valuable for renewable energy applications in extreme climate conditions.

Market research indicates that customer requirements for high-stress rGO materials primarily focus on four performance metrics: thermal stability (maintaining structural integrity at temperatures ranging from -60°C to +400°C), mechanical durability (resistance to cyclic loading and vibration), chemical resistance (particularly to oxidation and hydrolysis), and long-term performance stability (minimal degradation over 10+ years of service life).

Regional analysis shows North America and East Asia leading in adoption of high-stress rGO materials, with Europe showing accelerated growth rates in the renewable energy sector specifically. The Asia-Pacific region is projected to become the largest market by volume within the next five years, driven by expanding manufacturing capabilities and increasing domestic demand.

Pricing sensitivity varies significantly by application, with aerospace customers demonstrating willingness to pay premium prices for performance-verified materials, while automotive applications remain more cost-sensitive. This market dynamic has created two distinct product tiers: ultra-high-performance rGO materials commanding premium prices for critical applications, and more moderately priced materials for less demanding but higher-volume applications.

Current State and Technical Challenges of rGO in Extreme Conditions

Reduced graphene oxide (rGO) has emerged as a revolutionary material in various high-tech applications due to its exceptional electrical, thermal, and mechanical properties. However, the implementation of rGO in extreme environments presents significant challenges that require comprehensive evaluation. Currently, rGO exhibits promising performance in laboratory settings, but its behavior under prolonged exposure to high stress conditions remains inadequately characterized.

Global research indicates that rGO's durability varies significantly depending on the synthesis method employed. Thermal reduction techniques generally produce more stable rGO variants compared to chemical reduction approaches, particularly when exposed to elevated temperatures exceeding 200°C. Recent studies from MIT and the Chinese Academy of Sciences have demonstrated that thermally reduced GO maintains structural integrity at temperatures up to 400°C, while chemically reduced variants begin degrading at approximately 250°C.

Mechanical stress represents another critical challenge for rGO applications. Under cyclic loading conditions, rGO-based composites typically show performance degradation after 10,000-100,000 cycles, depending on the matrix material and interfacial bonding quality. This limitation has hindered rGO's adoption in aerospace and automotive applications where component lifespans of millions of cycles are required.

Chemical stability presents perhaps the most significant obstacle for rGO implementation in extreme environments. Current research indicates that rGO's resistance to oxidation decreases dramatically in the presence of both high temperature and humidity. Studies from Samsung Advanced Institute of Technology reveal that rGO begins to re-oxidize at relatively moderate conditions (80°C, 85% RH) within 500 hours of exposure, compromising its electrical conductivity and mechanical properties.

Radiation resistance represents an emerging area of concern, particularly for space and nuclear applications. Preliminary data suggests that rGO exhibits better radiation hardness than conventional semiconductor materials, but still experiences significant degradation under high-energy particle bombardment. The formation of defects and oxygen-containing functional groups under radiation exposure accelerates material degradation.

Geographically, research on rGO durability is concentrated primarily in East Asia (China, South Korea, Japan), North America, and Western Europe. Chinese institutions lead in publication volume, while American and European research groups tend to focus on fundamental degradation mechanisms and modeling approaches.

The standardization of testing protocols represents another significant challenge. Currently, no universally accepted methods exist for evaluating rGO durability across different stress conditions, making cross-study comparisons difficult and hindering industrial adoption. Several international standards organizations, including ISO and ASTM, have initiated working groups to address this gap, but comprehensive standards remain years away from implementation.

Global research indicates that rGO's durability varies significantly depending on the synthesis method employed. Thermal reduction techniques generally produce more stable rGO variants compared to chemical reduction approaches, particularly when exposed to elevated temperatures exceeding 200°C. Recent studies from MIT and the Chinese Academy of Sciences have demonstrated that thermally reduced GO maintains structural integrity at temperatures up to 400°C, while chemically reduced variants begin degrading at approximately 250°C.

Mechanical stress represents another critical challenge for rGO applications. Under cyclic loading conditions, rGO-based composites typically show performance degradation after 10,000-100,000 cycles, depending on the matrix material and interfacial bonding quality. This limitation has hindered rGO's adoption in aerospace and automotive applications where component lifespans of millions of cycles are required.

Chemical stability presents perhaps the most significant obstacle for rGO implementation in extreme environments. Current research indicates that rGO's resistance to oxidation decreases dramatically in the presence of both high temperature and humidity. Studies from Samsung Advanced Institute of Technology reveal that rGO begins to re-oxidize at relatively moderate conditions (80°C, 85% RH) within 500 hours of exposure, compromising its electrical conductivity and mechanical properties.

Radiation resistance represents an emerging area of concern, particularly for space and nuclear applications. Preliminary data suggests that rGO exhibits better radiation hardness than conventional semiconductor materials, but still experiences significant degradation under high-energy particle bombardment. The formation of defects and oxygen-containing functional groups under radiation exposure accelerates material degradation.

Geographically, research on rGO durability is concentrated primarily in East Asia (China, South Korea, Japan), North America, and Western Europe. Chinese institutions lead in publication volume, while American and European research groups tend to focus on fundamental degradation mechanisms and modeling approaches.

The standardization of testing protocols represents another significant challenge. Currently, no universally accepted methods exist for evaluating rGO durability across different stress conditions, making cross-study comparisons difficult and hindering industrial adoption. Several international standards organizations, including ISO and ASTM, have initiated working groups to address this gap, but comprehensive standards remain years away from implementation.

Existing Methodologies for Enhancing rGO Structural Integrity

01 Surface modification techniques for enhancing rGO durability

Various surface modification techniques can be applied to enhance the durability of reduced graphene oxide. These include functionalization with specific chemical groups, coating with protective polymers, and surface treatment processes that improve resistance to environmental degradation. These modifications create stronger bonds within the rGO structure and protect it from oxidation, mechanical stress, and chemical attacks, significantly extending its service life in various applications.- Enhancement of rGO durability through composite formation: Reduced graphene oxide (rGO) durability can be significantly improved by forming composites with other materials. These composites often involve polymers, metals, or ceramic materials that protect the rGO structure from environmental degradation. The composite formation creates synergistic effects that not only enhance mechanical strength but also improve resistance to oxidation, thermal stress, and chemical attacks, thereby extending the functional lifetime of rGO-based materials in various applications.

- Surface modification techniques for improved rGO stability: Various surface modification techniques can be employed to enhance the durability of reduced graphene oxide. These include functionalization with specific chemical groups, coating with protective layers, and controlled doping. Such modifications create protective barriers against environmental factors while maintaining the essential properties of rGO. Surface-modified rGO demonstrates improved resistance to oxidation, humidity, and mechanical stress, making it more suitable for long-term applications in harsh environments.

- Thermal treatment processes to enhance rGO durability: Specialized thermal treatment processes can significantly improve the durability of reduced graphene oxide materials. These processes include controlled annealing, high-temperature reduction, and thermal cycling techniques that remove residual functional groups and repair structural defects. The thermal treatments lead to better crystallinity, fewer defects, and stronger carbon-carbon bonds in the rGO structure, resulting in enhanced resistance to thermal degradation, mechanical stress, and chemical attacks over extended periods of use.

- Environmental protection strategies for rGO applications: To enhance the durability of reduced graphene oxide in practical applications, various environmental protection strategies have been developed. These include encapsulation techniques, barrier coatings, and controlled exposure conditions that shield rGO from moisture, oxygen, UV radiation, and chemical contaminants. Such protective measures significantly extend the functional lifetime of rGO-based materials in electronic devices, energy storage systems, and structural applications by preventing degradation mechanisms that would otherwise compromise performance over time.

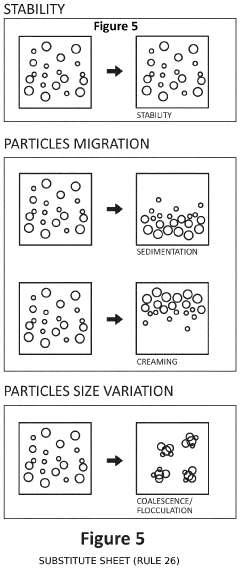

- Testing and characterization methods for rGO durability: Advanced testing and characterization methods have been developed to evaluate and predict the durability of reduced graphene oxide materials. These include accelerated aging tests, cyclic loading experiments, environmental exposure studies, and advanced spectroscopic techniques that monitor structural changes over time. Such methods provide critical insights into degradation mechanisms and failure modes, enabling the development of more durable rGO materials through quantitative assessment of stability under various operational conditions and environmental stressors.

02 Composite formation with polymers and metals for improved stability

Incorporating rGO into composites with polymers, metals, or ceramic materials substantially improves its durability. These composite structures distribute mechanical stress more effectively, prevent agglomeration of graphene sheets, and provide protection against environmental factors. The synergistic interaction between rGO and matrix materials creates more stable structures with enhanced resistance to thermal cycling, chemical exposure, and physical wear, making them suitable for demanding applications.Expand Specific Solutions03 Reduction process optimization for structural integrity

The method used to reduce graphene oxide significantly impacts the durability of the resulting rGO. Optimized reduction processes—including controlled thermal reduction, chemical reduction with specific agents, or electrochemical reduction—can minimize structural defects and oxygen content while preserving the carbon lattice integrity. These refined processes result in rGO with fewer defects, better crystallinity, and consequently superior mechanical, electrical, and chemical stability over time.Expand Specific Solutions04 Environmental protection strategies for rGO applications

Protecting rGO from environmental factors such as moisture, oxygen, UV radiation, and temperature fluctuations is crucial for maintaining its durability. Encapsulation techniques, hydrophobic coatings, and specialized packaging methods can effectively shield rGO from these degradation factors. Additionally, incorporating antioxidants and UV stabilizers can prevent oxidative degradation and photo-induced damage, preserving the material's properties in long-term applications and harsh environments.Expand Specific Solutions05 Testing and characterization methods for durability assessment

Standardized testing and characterization methods are essential for evaluating and predicting the durability of rGO materials. Accelerated aging tests, cyclic loading, thermal cycling, and chemical exposure tests provide valuable data on long-term stability. Advanced analytical techniques including Raman spectroscopy, XPS, TEM, and electrical conductivity measurements help monitor structural changes and performance degradation over time, enabling the development of more durable rGO materials through iterative improvement.Expand Specific Solutions

Leading Research Institutions and Commercial Entities in rGO Development

The graphene oxide durability market is in a growth phase, with increasing applications in high-stress environments driving expansion. The global market size for graphene materials is projected to reach significant scale as durability challenges are addressed. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Shanghai Institute of Ceramics and Tsinghua University advancing fundamental research, while companies like Graphenea SA and Morion NanoTech focus on commercial applications. LG Electronics and Cabot Corp are integrating graphene oxide into industrial products, while research institutions such as Manchester University and KAUST are pioneering stress-resistance improvements. The competitive landscape features collaboration between academic institutions and industrial manufacturers to overcome durability limitations.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed an innovative ceramic-graphene composite approach to enhance rGO durability in extreme environments. Their technology involves a sol-gel derived ceramic precursor infiltration into partially reduced GO structures, followed by controlled thermal processing that simultaneously completes the GO reduction while forming a protective ceramic phase. This creates a unique hierarchical structure where rGO sheets are embedded within and protected by nanoscale ceramic domains (typically alumina or zirconia-based). The ceramic phase provides exceptional thermal stability (up to 800°C) and mechanical reinforcement while the rGO network maintains electrical functionality. Their research has demonstrated that these composites retain structural integrity under thermal cycling, mechanical stress, and corrosive environments that would rapidly degrade conventional rGO[5]. A key innovation is their gradient interface engineering that creates strong chemical bonding between the ceramic and rGO phases, preventing delamination under stress. Recent developments include incorporating self-healing mechanisms through the addition of reactive ceramic precursors that can repair microdamage during service through localized reactions triggered by the damage itself[6].

Strengths: Exceptional thermal and mechanical stability far exceeding conventional rGO materials. The ceramic phase provides protection against oxidation and chemical attack while maintaining electrical pathways. Weaknesses: The ceramic component adds weight and potentially reduces flexibility compared to pure rGO systems. The complex processing requirements increase production costs and may limit scalability for certain applications.

Tsinghua University

Technical Solution: Tsinghua University has developed a sophisticated molecular reinforcement strategy for enhancing rGO durability in high stress environments. Their approach centers on a controlled reduction process that preserves specific oxygen-containing functional groups, which serve as anchoring sites for subsequent molecular reinforcement. The university's researchers have engineered a series of bridging molecules with terminal groups that form strong covalent bonds with the remaining oxygen functionalities on rGO sheets. These molecular bridges effectively create a three-dimensional network that prevents sheet slippage and delamination under mechanical stress. Their process involves a precise two-step reduction: first using mild chemical reducers (vitamin C derivatives) followed by controlled thermal annealing at moderate temperatures (200-300°C) to preserve strategic functional groups. The molecular reinforcement is then achieved through vapor-phase deposition of specialized silane coupling agents with optimized molecular structures[7]. Tsinghua's latest innovation incorporates self-assembling peptide sequences that create ordered nanostructures between rGO layers, providing both mechanical reinforcement and pathways for stress dissipation. Testing has shown these reinforced rGO materials maintain structural integrity and electrical properties after exposure to mechanical strain (up to 15%), thermal cycling (-40°C to 200°C), and humid environments (95% RH) for extended periods[8].

Strengths: The molecular reinforcement approach provides exceptional flexibility while maintaining durability, making it ideal for applications requiring mechanical compliance. The preservation of specific functional groups enables precise control over material properties. Weaknesses: The multi-step processing increases production complexity and cost. The molecular bridges, while enhancing mechanical properties, can potentially create electron scattering sites that slightly reduce electrical conductivity in some configurations.

Critical Patents and Research Breakthroughs in rGO Reinforcement

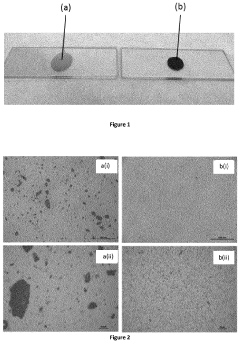

Reduced graphene oxide and method of producing same

PatentWO2013040636A1

Innovation

- A scalable and environmentally friendly chemical process involving the application of a reducing agent, such as ascorbic acid, to graphene oxide deposited on a substrate, allowing for selective reduction and patterning of rGO films without high-temperature annealing, achieving conductivities comparable to CVD-grown graphene.

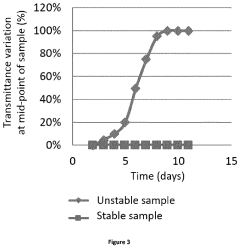

A reduced graphene oxide mixture, polymer matrix containing the same and a process for the preparation thereof

PatentActiveUS20210047187A1

Innovation

- Performing the reduction reaction under high shear mixing while preventing drying and using an organic solvent for cleaning, which significantly reduces reaction times, exfoliates the rGO, and maintains stability for extended periods without the need for surfactants, achieving concentrations above 0.3 mg/mL.

Environmental Impact and Sustainability of rGO Production Processes

The production of reduced graphene oxide (rGO) presents significant environmental considerations that must be addressed when evaluating its application in high stress environments. Traditional methods of rGO synthesis often involve chemical reduction processes using hazardous reducing agents such as hydrazine, sodium borohydride, and strong acids, which pose substantial environmental and health risks if not properly managed.

Current industrial production methods generate considerable chemical waste streams that require specialized treatment and disposal protocols. The energy consumption associated with thermal reduction methods is particularly concerning, with some processes requiring temperatures exceeding 1000°C, resulting in substantial carbon footprints that contradict the sustainable image often associated with advanced materials.

Water usage represents another critical environmental factor, as wet chemical processes for graphene oxide production and subsequent reduction can consume significant quantities of purified water. This becomes especially problematic in regions facing water scarcity issues, where industrial water consumption competes with essential human needs.

Life cycle assessments of rGO production reveal that the environmental impact varies dramatically depending on the specific synthesis route chosen. Chemical reduction methods typically show higher toxicity potential but lower energy requirements, while thermal reduction processes demonstrate the inverse relationship. This creates a complex sustainability equation that must be carefully balanced based on regional energy sources, available infrastructure, and environmental regulations.

Recent innovations in green chemistry approaches offer promising alternatives for more sustainable rGO production. These include the use of plant extracts as natural reducing agents, microbial reduction processes, and electrochemical reduction techniques that significantly reduce or eliminate hazardous waste generation. Such methods typically operate at ambient temperatures and pressures, substantially decreasing energy requirements.

Circular economy principles are increasingly being applied to rGO production, with research focusing on recovering and reusing process chemicals and solvents. Some pioneering facilities have implemented closed-loop systems that capture and recycle up to 90% of the solvents used in production, dramatically reducing both waste generation and raw material consumption.

The durability of rGO in high stress environments directly impacts its environmental footprint through product lifespan. More durable rGO formulations reduce replacement frequency and associated manufacturing impacts, creating an important connection between performance engineering and sustainability goals. This relationship highlights the importance of considering environmental factors alongside performance metrics when developing rGO applications for demanding environments.

Current industrial production methods generate considerable chemical waste streams that require specialized treatment and disposal protocols. The energy consumption associated with thermal reduction methods is particularly concerning, with some processes requiring temperatures exceeding 1000°C, resulting in substantial carbon footprints that contradict the sustainable image often associated with advanced materials.

Water usage represents another critical environmental factor, as wet chemical processes for graphene oxide production and subsequent reduction can consume significant quantities of purified water. This becomes especially problematic in regions facing water scarcity issues, where industrial water consumption competes with essential human needs.

Life cycle assessments of rGO production reveal that the environmental impact varies dramatically depending on the specific synthesis route chosen. Chemical reduction methods typically show higher toxicity potential but lower energy requirements, while thermal reduction processes demonstrate the inverse relationship. This creates a complex sustainability equation that must be carefully balanced based on regional energy sources, available infrastructure, and environmental regulations.

Recent innovations in green chemistry approaches offer promising alternatives for more sustainable rGO production. These include the use of plant extracts as natural reducing agents, microbial reduction processes, and electrochemical reduction techniques that significantly reduce or eliminate hazardous waste generation. Such methods typically operate at ambient temperatures and pressures, substantially decreasing energy requirements.

Circular economy principles are increasingly being applied to rGO production, with research focusing on recovering and reusing process chemicals and solvents. Some pioneering facilities have implemented closed-loop systems that capture and recycle up to 90% of the solvents used in production, dramatically reducing both waste generation and raw material consumption.

The durability of rGO in high stress environments directly impacts its environmental footprint through product lifespan. More durable rGO formulations reduce replacement frequency and associated manufacturing impacts, creating an important connection between performance engineering and sustainability goals. This relationship highlights the importance of considering environmental factors alongside performance metrics when developing rGO applications for demanding environments.

Standardization and Testing Protocols for rGO Durability Assessment

The standardization of testing protocols for reduced graphene oxide (rGO) durability assessment represents a critical gap in the current research landscape. Despite the growing industrial applications of rGO in high-stress environments, there exists significant variability in how researchers evaluate and report durability metrics, making cross-study comparisons challenging and hindering technological advancement.

A comprehensive standardization framework must address mechanical, thermal, chemical, and electrical stress factors simultaneously. Current testing methodologies often focus on isolated stress parameters, failing to account for the complex interplay of multiple stressors that rGO materials encounter in real-world applications. This siloed approach has led to inconsistent performance predictions and reliability issues in commercial implementations.

Key mechanical testing protocols should include cyclic loading tests (10,000+ cycles), tensile strength measurements under varying humidity conditions (20-90% RH), and abrasion resistance evaluations using standardized equipment. These tests must specify sample preparation methods, dimensions, and environmental conditions to ensure reproducibility across different laboratories.

For thermal durability assessment, standardized protocols should encompass thermal cycling (-40°C to 200°C), isothermal aging at application-specific temperatures, and thermal shock resistance. Each protocol must define heating/cooling rates, dwell times, and failure criteria based on measurable property degradation thresholds rather than subjective assessments.

Chemical resistance testing requires standardized exposure protocols to common solvents, acids, bases, and oxidizing agents at defined concentrations and temperatures. Immersion periods should range from 24 hours for accelerated testing to 1,000+ hours for long-term durability assessment, with intermediate characterization points to establish degradation kinetics.

Electrical performance durability testing must include standardized protocols for conductivity retention under mechanical deformation, humidity cycling, and temperature fluctuations. Current density stress tests should be conducted at application-relevant levels with standardized electrode configurations and measurement techniques.

Multi-parameter stress testing represents the frontier of rGO durability assessment, combining mechanical strain, elevated temperature, and chemical exposure simultaneously. While technically challenging, these protocols more accurately reflect real-world conditions and should be prioritized in standardization efforts.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential to establish widely accepted testing protocols. The International Organization for Standardization (ISO) and ASTM International have initiated preliminary work in this area, but comprehensive standards specific to rGO durability in high-stress environments remain underdeveloped.

A comprehensive standardization framework must address mechanical, thermal, chemical, and electrical stress factors simultaneously. Current testing methodologies often focus on isolated stress parameters, failing to account for the complex interplay of multiple stressors that rGO materials encounter in real-world applications. This siloed approach has led to inconsistent performance predictions and reliability issues in commercial implementations.

Key mechanical testing protocols should include cyclic loading tests (10,000+ cycles), tensile strength measurements under varying humidity conditions (20-90% RH), and abrasion resistance evaluations using standardized equipment. These tests must specify sample preparation methods, dimensions, and environmental conditions to ensure reproducibility across different laboratories.

For thermal durability assessment, standardized protocols should encompass thermal cycling (-40°C to 200°C), isothermal aging at application-specific temperatures, and thermal shock resistance. Each protocol must define heating/cooling rates, dwell times, and failure criteria based on measurable property degradation thresholds rather than subjective assessments.

Chemical resistance testing requires standardized exposure protocols to common solvents, acids, bases, and oxidizing agents at defined concentrations and temperatures. Immersion periods should range from 24 hours for accelerated testing to 1,000+ hours for long-term durability assessment, with intermediate characterization points to establish degradation kinetics.

Electrical performance durability testing must include standardized protocols for conductivity retention under mechanical deformation, humidity cycling, and temperature fluctuations. Current density stress tests should be conducted at application-relevant levels with standardized electrode configurations and measurement techniques.

Multi-parameter stress testing represents the frontier of rGO durability assessment, combining mechanical strain, elevated temperature, and chemical exposure simultaneously. While technically challenging, these protocols more accurately reflect real-world conditions and should be prioritized in standardization efforts.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential to establish widely accepted testing protocols. The International Organization for Standardization (ISO) and ASTM International have initiated preliminary work in this area, but comprehensive standards specific to rGO durability in high-stress environments remain underdeveloped.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!