How Reduced Graphene Oxide Interfaces with Organic Matrixes

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO-Organic Matrix Interface Background and Objectives

Reduced graphene oxide (rGO) has emerged as a revolutionary material in the field of advanced composites and functional materials due to its exceptional electrical, thermal, and mechanical properties. The interface between rGO and organic matrices represents a critical frontier in materials science that has evolved significantly over the past decade. Initially discovered through mechanical exfoliation of graphite in 2004, graphene-based materials have transitioned from laboratory curiosities to industrially relevant components, with rGO offering a scalable alternative to pristine graphene while maintaining many of its desirable properties.

The evolution of rGO-organic matrix interface technology has been driven by the limitations of conventional composite materials in meeting increasingly demanding performance requirements across industries. Traditional fillers often suffer from poor dispersion and weak interfacial interactions, limiting their effectiveness. The unique two-dimensional structure of rGO, combined with its rich surface chemistry resulting from the reduction process, presents unprecedented opportunities for engineering interfaces with organic matrices at the molecular level.

Current technological trends in this field focus on developing precise control over the reduction degree of graphene oxide, as this directly influences the interface characteristics. The partial restoration of the sp² carbon network during reduction creates a delicate balance between electrical conductivity and functional group availability for interfacial bonding. This balance is crucial for optimizing composite performance across multiple dimensions simultaneously.

The primary technical objective of research in this domain is to establish fundamental understanding and control of the physicochemical interactions occurring at the rGO-organic matrix interface. This includes elucidating the mechanisms of load transfer, electron transport, and thermal conduction across these interfaces. Secondary objectives include developing scalable methods for interface engineering that can be implemented in industrial settings, as well as creating predictive models that can accelerate the design of tailored interfaces for specific applications.

From a broader perspective, mastering rGO-organic matrix interfaces aims to enable next-generation materials with synergistic properties that exceed the simple sum of their components. These include multifunctional composites with simultaneously enhanced mechanical strength, electrical conductivity, thermal management capabilities, and stimuli-responsive behaviors. Such materials could revolutionize applications ranging from aerospace structures and automotive components to flexible electronics and biomedical devices.

The interdisciplinary nature of this field necessitates integration of knowledge from materials science, physical chemistry, polymer engineering, and computational modeling. Recent advances in characterization techniques, particularly in situ methods that can probe interfaces under realistic conditions, have accelerated progress in understanding these complex interfacial phenomena and set the stage for transformative developments in the coming years.

The evolution of rGO-organic matrix interface technology has been driven by the limitations of conventional composite materials in meeting increasingly demanding performance requirements across industries. Traditional fillers often suffer from poor dispersion and weak interfacial interactions, limiting their effectiveness. The unique two-dimensional structure of rGO, combined with its rich surface chemistry resulting from the reduction process, presents unprecedented opportunities for engineering interfaces with organic matrices at the molecular level.

Current technological trends in this field focus on developing precise control over the reduction degree of graphene oxide, as this directly influences the interface characteristics. The partial restoration of the sp² carbon network during reduction creates a delicate balance between electrical conductivity and functional group availability for interfacial bonding. This balance is crucial for optimizing composite performance across multiple dimensions simultaneously.

The primary technical objective of research in this domain is to establish fundamental understanding and control of the physicochemical interactions occurring at the rGO-organic matrix interface. This includes elucidating the mechanisms of load transfer, electron transport, and thermal conduction across these interfaces. Secondary objectives include developing scalable methods for interface engineering that can be implemented in industrial settings, as well as creating predictive models that can accelerate the design of tailored interfaces for specific applications.

From a broader perspective, mastering rGO-organic matrix interfaces aims to enable next-generation materials with synergistic properties that exceed the simple sum of their components. These include multifunctional composites with simultaneously enhanced mechanical strength, electrical conductivity, thermal management capabilities, and stimuli-responsive behaviors. Such materials could revolutionize applications ranging from aerospace structures and automotive components to flexible electronics and biomedical devices.

The interdisciplinary nature of this field necessitates integration of knowledge from materials science, physical chemistry, polymer engineering, and computational modeling. Recent advances in characterization techniques, particularly in situ methods that can probe interfaces under realistic conditions, have accelerated progress in understanding these complex interfacial phenomena and set the stage for transformative developments in the coming years.

Market Analysis for rGO-Organic Composite Applications

The global market for reduced graphene oxide (rGO)-organic composites has experienced significant growth in recent years, driven by the exceptional properties these materials offer when properly interfaced. The market size for graphene-based composites reached approximately $23 million in 2022 and is projected to grow at a CAGR of 38.7% through 2030, with rGO-organic composites representing a substantial segment of this expansion.

Electronics and energy storage applications currently dominate the market demand, accounting for nearly 45% of rGO-organic composite applications. The superior electrical conductivity and thermal management capabilities of these composites have made them particularly valuable in flexible electronics, where the market is expanding at over 25% annually. Major electronics manufacturers have begun incorporating rGO-organic composites into next-generation devices to enhance performance while reducing weight and power consumption.

The energy storage sector represents another significant market driver, with rGO-organic composites being integrated into advanced battery and supercapacitor technologies. Market analysis indicates that the demand for high-performance energy storage solutions is expected to grow by 40% over the next five years, creating substantial opportunities for rGO-organic composite materials that can improve energy density and cycling stability.

Biomedical applications constitute an emerging market segment with exceptional growth potential. The biocompatibility of certain rGO-organic interfaces has opened new avenues in drug delivery systems, biosensors, and tissue engineering. While currently representing only about 12% of the total market share, this segment is projected to grow at the fastest rate (42% CAGR) among all application areas.

Regional market distribution shows Asia-Pacific leading with 45% market share, followed by North America (30%) and Europe (20%). China and South Korea have made substantial investments in manufacturing infrastructure for rGO-organic composites, while North American and European markets focus more on high-value applications in aerospace, defense, and medical technologies.

Market barriers include high production costs, with current manufacturing methods for quality rGO-organic composites averaging $200-300 per kilogram. Scalability challenges and inconsistent quality control in the interface between rGO and organic matrices remain significant obstacles to wider market adoption. Industry analysts predict that production costs need to decrease by at least 60% to achieve mass market penetration beyond specialized applications.

Consumer trends indicate growing demand for sustainable materials, creating opportunities for bio-based organic matrices interfaced with rGO. This eco-friendly segment is expected to grow from its current 8% market share to approximately 20% by 2028, driven by regulatory pressures and corporate sustainability initiatives.

Electronics and energy storage applications currently dominate the market demand, accounting for nearly 45% of rGO-organic composite applications. The superior electrical conductivity and thermal management capabilities of these composites have made them particularly valuable in flexible electronics, where the market is expanding at over 25% annually. Major electronics manufacturers have begun incorporating rGO-organic composites into next-generation devices to enhance performance while reducing weight and power consumption.

The energy storage sector represents another significant market driver, with rGO-organic composites being integrated into advanced battery and supercapacitor technologies. Market analysis indicates that the demand for high-performance energy storage solutions is expected to grow by 40% over the next five years, creating substantial opportunities for rGO-organic composite materials that can improve energy density and cycling stability.

Biomedical applications constitute an emerging market segment with exceptional growth potential. The biocompatibility of certain rGO-organic interfaces has opened new avenues in drug delivery systems, biosensors, and tissue engineering. While currently representing only about 12% of the total market share, this segment is projected to grow at the fastest rate (42% CAGR) among all application areas.

Regional market distribution shows Asia-Pacific leading with 45% market share, followed by North America (30%) and Europe (20%). China and South Korea have made substantial investments in manufacturing infrastructure for rGO-organic composites, while North American and European markets focus more on high-value applications in aerospace, defense, and medical technologies.

Market barriers include high production costs, with current manufacturing methods for quality rGO-organic composites averaging $200-300 per kilogram. Scalability challenges and inconsistent quality control in the interface between rGO and organic matrices remain significant obstacles to wider market adoption. Industry analysts predict that production costs need to decrease by at least 60% to achieve mass market penetration beyond specialized applications.

Consumer trends indicate growing demand for sustainable materials, creating opportunities for bio-based organic matrices interfaced with rGO. This eco-friendly segment is expected to grow from its current 8% market share to approximately 20% by 2028, driven by regulatory pressures and corporate sustainability initiatives.

Current Challenges in rGO-Organic Interface Engineering

Despite significant advancements in reduced graphene oxide (rGO) research, several critical challenges persist in the engineering of interfaces between rGO and organic matrices. The primary obstacle remains the inherent incompatibility between the predominantly hydrophilic nature of rGO and the hydrophobic character of most organic matrices. This fundamental mismatch creates weak interfacial bonding, resulting in suboptimal mechanical properties and diminished performance in composite materials.

Surface functionalization approaches, while promising, face reproducibility issues due to the heterogeneous nature of rGO sheets. The variable oxygen content and distribution across different batches of rGO lead to inconsistent surface chemistry, making standardized functionalization protocols difficult to establish. This variability significantly impacts the quality and reliability of the resulting interfaces in industrial applications.

Another significant challenge lies in the aggregation tendency of rGO sheets during processing with organic matrices. The strong π-π interactions between graphene layers promote restacking, which reduces the effective surface area available for interfacing with organic components. Current dispersion techniques often rely on harsh solvents or extensive sonication, which can damage the rGO structure or introduce unwanted impurities into the final composite.

The characterization of rGO-organic interfaces presents substantial technical difficulties. Conventional analytical methods struggle to provide accurate information about the molecular-level interactions at these interfaces. The dynamic nature of these interfaces during material processing and under various environmental conditions further complicates their study and optimization.

Scale-up challenges represent a major hurdle in transitioning from laboratory success to industrial implementation. Methods that work effectively at small scales often encounter significant barriers when applied to mass production scenarios. The cost-effectiveness of interface engineering techniques remains questionable for many potential applications, limiting commercial adoption.

Environmental stability of engineered interfaces poses another critical challenge. Many current interface modification approaches yield connections that degrade under thermal cycling, humidity, or mechanical stress. This degradation significantly reduces the long-term reliability of rGO-organic composite materials in real-world applications.

The lack of standardized testing protocols specifically designed for evaluating rGO-organic interfaces hampers progress in the field. Without consistent evaluation methods, comparing different interface engineering approaches becomes problematic, slowing the identification of optimal solutions for specific applications. This standardization gap also creates barriers for regulatory approval in sensitive application areas such as biomedical devices or food packaging.

Surface functionalization approaches, while promising, face reproducibility issues due to the heterogeneous nature of rGO sheets. The variable oxygen content and distribution across different batches of rGO lead to inconsistent surface chemistry, making standardized functionalization protocols difficult to establish. This variability significantly impacts the quality and reliability of the resulting interfaces in industrial applications.

Another significant challenge lies in the aggregation tendency of rGO sheets during processing with organic matrices. The strong π-π interactions between graphene layers promote restacking, which reduces the effective surface area available for interfacing with organic components. Current dispersion techniques often rely on harsh solvents or extensive sonication, which can damage the rGO structure or introduce unwanted impurities into the final composite.

The characterization of rGO-organic interfaces presents substantial technical difficulties. Conventional analytical methods struggle to provide accurate information about the molecular-level interactions at these interfaces. The dynamic nature of these interfaces during material processing and under various environmental conditions further complicates their study and optimization.

Scale-up challenges represent a major hurdle in transitioning from laboratory success to industrial implementation. Methods that work effectively at small scales often encounter significant barriers when applied to mass production scenarios. The cost-effectiveness of interface engineering techniques remains questionable for many potential applications, limiting commercial adoption.

Environmental stability of engineered interfaces poses another critical challenge. Many current interface modification approaches yield connections that degrade under thermal cycling, humidity, or mechanical stress. This degradation significantly reduces the long-term reliability of rGO-organic composite materials in real-world applications.

The lack of standardized testing protocols specifically designed for evaluating rGO-organic interfaces hampers progress in the field. Without consistent evaluation methods, comparing different interface engineering approaches becomes problematic, slowing the identification of optimal solutions for specific applications. This standardization gap also creates barriers for regulatory approval in sensitive application areas such as biomedical devices or food packaging.

Existing Interface Modification Strategies

01 Electrical and conductive properties of rGO interfaces

Reduced graphene oxide (rGO) exhibits excellent electrical conductivity properties at interfaces, making it suitable for various electronic applications. The reduction process significantly enhances the conductivity compared to graphene oxide by restoring the sp² carbon network. These interfaces show tunable electrical properties based on the degree of reduction and can form effective electrical contacts with various materials including metals and semiconductors. The interface conductivity can be further enhanced through doping or functionalization techniques.- Electrical and conductive properties of rGO interfaces: Reduced graphene oxide (rGO) exhibits excellent electrical conductivity properties at interfaces, making it suitable for various electronic applications. The reduction process significantly enhances the conductivity compared to graphene oxide by restoring the sp² carbon network. These interfaces show tunable electrical properties depending on the degree of reduction and can be optimized for specific applications such as sensors, supercapacitors, and flexible electronics. The interface conductivity can be further enhanced through doping or by creating hybrid structures with other conductive materials.

- Mechanical and structural characteristics of rGO interfaces: The mechanical properties of reduced graphene oxide interfaces are characterized by high strength, flexibility, and durability. These interfaces demonstrate excellent mechanical stability even under deformation, making them suitable for flexible device applications. The structural characteristics of rGO interfaces can be tailored through controlled reduction processes, affecting properties such as surface roughness, layer thickness, and defect density. The mechanical robustness of rGO interfaces allows for their integration into composite materials to enhance overall structural integrity and performance.

- Thermal and energy transfer properties at rGO interfaces: Reduced graphene oxide interfaces exhibit exceptional thermal conductivity and energy transfer capabilities, making them valuable for thermal management applications. The thermal properties can be modulated by controlling the reduction level and interface structure. These interfaces facilitate efficient heat dissipation in electronic devices and can be incorporated into thermal interface materials. The energy transfer characteristics of rGO interfaces also make them suitable for energy storage and conversion applications, including batteries and solar cells, where interface properties significantly impact overall device performance.

- Chemical and surface functionalization of rGO interfaces: The surface chemistry of reduced graphene oxide interfaces can be modified through various functionalization techniques to enhance specific properties or interactions. Functional groups on rGO surfaces enable tailored interactions with other materials, improving compatibility in composites or biological systems. Surface modifications can enhance selectivity and sensitivity in sensing applications or improve binding with specific analytes. The degree of reduction affects the density of remaining oxygen-containing groups, which influences surface energy, wettability, and chemical reactivity of the interfaces. These chemical properties can be optimized for applications ranging from catalysis to biomedical devices.

- Optical and photonic properties of rGO interfaces: Reduced graphene oxide interfaces demonstrate unique optical and photonic properties that can be tuned through the degree of reduction and structural arrangement. These interfaces exhibit controllable light absorption and transmission characteristics across a wide spectral range. The optical properties of rGO interfaces make them suitable for applications in photonics, optoelectronics, and photovoltaics. By manipulating the interface structure and composition, the photonic response can be optimized for specific wavelengths or applications. The combination of optical properties with electrical conductivity enables multifunctional devices where light-matter interactions at interfaces play a crucial role.

02 Mechanical and structural properties of rGO interfaces

The mechanical properties of reduced graphene oxide interfaces are characterized by high strength, flexibility, and durability. These interfaces demonstrate excellent adhesion to various substrates while maintaining structural integrity. The mechanical stability of rGO interfaces can be controlled through the reduction process parameters, affecting the density of defects and functional groups at the interface. The structural properties of rGO interfaces also include high surface area and tunable porosity, which contribute to their performance in composite materials and coatings.Expand Specific Solutions03 Thermal and energy transfer properties at rGO interfaces

Reduced graphene oxide interfaces demonstrate exceptional thermal conductivity and heat dissipation capabilities, making them valuable for thermal management applications. The thermal properties at these interfaces can be tuned by controlling the reduction level and interface structure. rGO interfaces facilitate efficient energy transfer across material boundaries and can be optimized for thermoelectric applications. The thermal stability of these interfaces at elevated temperatures makes them suitable for high-temperature applications in electronics and energy storage devices.Expand Specific Solutions04 Chemical and sensing properties of rGO interfaces

The chemical properties of reduced graphene oxide interfaces include tunable surface chemistry, selective adsorption capabilities, and high reactivity toward specific analytes. These interfaces contain residual oxygen functional groups that can be leveraged for chemical sensing applications. The chemical sensitivity of rGO interfaces can be enhanced through functionalization with specific molecules or nanoparticles. These properties make rGO interfaces highly effective in electrochemical sensors, gas sensors, and biosensors with improved selectivity and sensitivity compared to conventional materials.Expand Specific Solutions05 Biocompatibility and biological interface properties of rGO

Reduced graphene oxide interfaces demonstrate unique biological properties including controlled biocompatibility and cellular interactions. These interfaces can be functionalized to enhance biocompatibility or antimicrobial properties for specific biomedical applications. The surface chemistry of rGO interfaces influences protein adsorption, cell adhesion, and proliferation, making them suitable for tissue engineering and drug delivery systems. The biological response to rGO interfaces can be modulated by controlling the degree of reduction and surface functionalization, allowing for customized interactions with biological systems.Expand Specific Solutions

Leading Research Groups and Companies in rGO Composites

The reduced graphene oxide (rGO) interface with organic matrices represents a rapidly evolving field in advanced materials science, currently transitioning from early development to commercial application phases. The market is experiencing significant growth, projected to reach substantial scale as applications in electronics, composites, and energy storage expand. Technologically, research institutions like The University of Manchester, Northwestern University, and École Polytechnique Fédérale de Lausanne lead fundamental research, while companies including LG Electronics, Graphenea, and Cabot Corporation are advancing commercial applications. The Georgia Tech Research Corp and CNRS contribute significant intellectual property. Chinese institutions (Beijing University of Chemical Technology, Hunan University) are rapidly closing the technology gap, particularly in mass production techniques, creating a competitive global landscape where academic-industrial partnerships increasingly drive innovation.

The University of Manchester

Technical Solution: The University of Manchester has pioneered groundbreaking research on reduced graphene oxide (rGO) interfaces with organic matrices. Their approach involves chemical functionalization of rGO sheets through covalent and non-covalent methods to enhance compatibility with organic polymers. They've developed a proprietary thermal reduction process that preserves the structural integrity of graphene while removing oxygen-containing groups in a controlled manner[1]. Their research demonstrates that partially reduced GO maintains sufficient functional groups for effective polymer interaction while restoring electrical conductivity. Manchester's scientists have also established protocols for uniform dispersion of rGO in various polymer matrices using solvent-assisted techniques and ultrasonication, achieving enhanced mechanical properties with loadings as low as 0.5 wt%[2]. Their work has shown that the interfacial interactions between rGO and polymers can be tailored by controlling the degree of reduction and remaining oxygen functionalities.

Strengths: World-leading expertise in graphene research with access to advanced characterization techniques; established methodologies for controlled reduction processes; demonstrated improvements in mechanical and electrical properties of composites. Weaknesses: Some techniques require specialized equipment and may be challenging to scale up for industrial applications; potential batch-to-batch variations in rGO quality.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has developed innovative approaches for integrating reduced graphene oxide (rGO) with organic matrices through their patented interfacial engineering techniques. Their methodology focuses on creating strong covalent and non-covalent interactions between rGO and various polymer systems. They've pioneered a multi-step reduction process that preserves specific oxygen-containing functional groups strategically positioned to maximize polymer compatibility[3]. Their research demonstrates that controlling the spatial distribution of functional groups on rGO surfaces significantly enhances interfacial adhesion with organic matrices. Georgia Tech has also developed novel surface modification techniques using silane coupling agents and other bifunctional molecules that act as molecular bridges between rGO and polymer matrices[4]. Their work has shown remarkable improvements in load transfer efficiency across the rGO-polymer interface, resulting in composites with enhanced mechanical properties and electrical conductivity. Additionally, they've established methods for in-situ polymerization in the presence of functionalized rGO, creating more homogeneous composites with reduced agglomeration issues.

Strengths: Advanced interfacial engineering expertise; sophisticated characterization capabilities; demonstrated improvements in mechanical properties and electrical conductivity of composites; techniques applicable to a wide range of polymer systems. Weaknesses: Some methods require complex multi-step processes that may be challenging to implement at industrial scale; potential increased production costs due to specialized chemical treatments.

Key Mechanisms of rGO-Organic Matrix Interactions

A MIXTURE OF REDUCED GRAPHENE OXIDE, A POLYMERIC MATRIX CONTAINING THE SAME AND A PROCEDURE FOR ITS PREPARATION

PatentInactiveES2803957R1

Innovation

- Development of a stable suspension and wet powder of reduced graphene oxide (rGO) in organic solvent with concentration greater than 0.3 mg/ml, maintaining stability for at least 5 days as measured by Turbiscan.

- Creation of a polymeric matrix incorporating the stable rGO suspension or wet powder, enabling effective integration of graphene properties into polymer systems.

- Novel processes for preparing both the stable rGO suspension/wet powder and the polymeric matrix containing rGO.

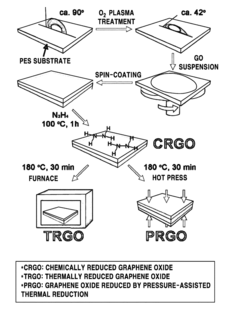

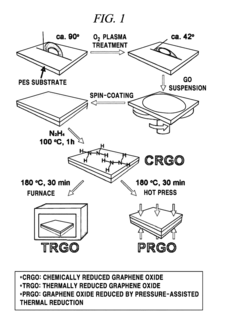

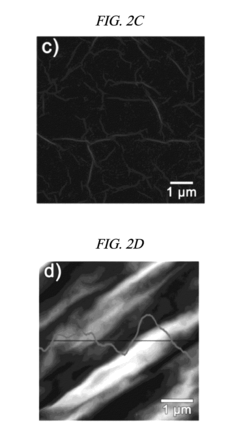

Preparing method of reduced graphene oxide film using a chemical reduction method and a pressure-assisted thermal reduction method, reduced graphene oxide film prepared by the same, and graphene electrode including the reduced graphene oxide film

PatentActiveUS9236156B2

Innovation

- A method involving the coating of a graphene oxide-dispersed solution on a substrate followed by a combination of chemical reduction and pressure-assisted thermal reduction to form a reduced graphene oxide film, allowing for efficient production at low temperatures and achieving low surface resistance and high conductivity.

Environmental Impact and Sustainability Considerations

The environmental implications of reduced graphene oxide (rGO) interfaces with organic matrices extend beyond laboratory applications to broader ecological considerations. The production processes of rGO often involve chemical reduction methods utilizing hazardous reducing agents such as hydrazine, sodium borohydride, or high-temperature thermal treatments, which can generate toxic byproducts and significant energy consumption. These environmental concerns necessitate the development of greener synthesis approaches that minimize harmful emissions and reduce the carbon footprint associated with rGO production.

Recent advances in eco-friendly reduction methods have shown promising results, including the use of natural reducing agents derived from plant extracts, which contain polyphenols and other antioxidants capable of reducing graphene oxide under mild conditions. These biomimetic approaches not only decrease the environmental impact but also enhance the biocompatibility of the resulting rGO-organic matrix composites, making them more suitable for biomedical applications.

The lifecycle assessment of rGO-organic matrix composites reveals both challenges and opportunities for sustainability. While these materials offer enhanced durability and performance that could extend product lifespans, concerns remain regarding end-of-life disposal and potential environmental persistence. The nanoscale dimensions of rGO particles raise questions about their bioaccumulation potential and long-term ecological effects if released into natural systems.

Recycling and recovery strategies for rGO-containing composites represent an emerging research area critical for circular economy implementation. Current techniques include solvent-based extraction methods and thermal decomposition processes that aim to separate and recover the graphene components from organic matrices. However, these processes often face efficiency limitations and may introduce secondary environmental impacts through solvent usage or energy requirements.

Regulatory frameworks governing nanomaterials like rGO are still evolving globally, with varying approaches to risk assessment and management. The development of standardized protocols for evaluating the environmental fate and ecotoxicological profiles of rGO-organic matrix interfaces remains crucial for responsible innovation in this field. Industry stakeholders and research institutions are increasingly collaborating to establish best practices that balance technological advancement with environmental stewardship.

Water consumption and contamination represent additional environmental considerations in rGO production and application processes. The synthesis of graphene oxide typically involves multiple washing steps that generate wastewater containing oxidizing agents and metal ions. Implementing closed-loop water systems and developing water-efficient processing techniques could significantly reduce the environmental footprint of these materials throughout their lifecycle.

Recent advances in eco-friendly reduction methods have shown promising results, including the use of natural reducing agents derived from plant extracts, which contain polyphenols and other antioxidants capable of reducing graphene oxide under mild conditions. These biomimetic approaches not only decrease the environmental impact but also enhance the biocompatibility of the resulting rGO-organic matrix composites, making them more suitable for biomedical applications.

The lifecycle assessment of rGO-organic matrix composites reveals both challenges and opportunities for sustainability. While these materials offer enhanced durability and performance that could extend product lifespans, concerns remain regarding end-of-life disposal and potential environmental persistence. The nanoscale dimensions of rGO particles raise questions about their bioaccumulation potential and long-term ecological effects if released into natural systems.

Recycling and recovery strategies for rGO-containing composites represent an emerging research area critical for circular economy implementation. Current techniques include solvent-based extraction methods and thermal decomposition processes that aim to separate and recover the graphene components from organic matrices. However, these processes often face efficiency limitations and may introduce secondary environmental impacts through solvent usage or energy requirements.

Regulatory frameworks governing nanomaterials like rGO are still evolving globally, with varying approaches to risk assessment and management. The development of standardized protocols for evaluating the environmental fate and ecotoxicological profiles of rGO-organic matrix interfaces remains crucial for responsible innovation in this field. Industry stakeholders and research institutions are increasingly collaborating to establish best practices that balance technological advancement with environmental stewardship.

Water consumption and contamination represent additional environmental considerations in rGO production and application processes. The synthesis of graphene oxide typically involves multiple washing steps that generate wastewater containing oxidizing agents and metal ions. Implementing closed-loop water systems and developing water-efficient processing techniques could significantly reduce the environmental footprint of these materials throughout their lifecycle.

Scalability and Industrial Implementation Challenges

The scaling of reduced graphene oxide (rGO) integration with organic matrices from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current production methods for high-quality rGO-organic composites are predominantly batch-based, with limited throughput and inconsistent quality across production runs. The transition to continuous manufacturing processes represents a critical hurdle, as maintaining uniform dispersion and interfacial properties at scale requires sophisticated process control systems that many manufacturers lack.

Material cost remains a substantial barrier to widespread industrial adoption. While graphene oxide production costs have decreased, the reduction processes and subsequent functionalization treatments necessary for optimal organic matrix interfacing still contribute to prohibitively high material expenses for many applications. This economic constraint is particularly evident in cost-sensitive industries where performance improvements must justify the premium price point.

Quality control and standardization present additional implementation challenges. The interfacial properties between rGO and organic matrices are highly sensitive to processing conditions, with minor variations potentially leading to significant performance differences. Current analytical techniques for characterizing these interfaces at industrial scale lack the precision and throughput necessary for real-time quality assurance, creating bottlenecks in production workflows.

Environmental and safety considerations further complicate industrial implementation. The handling of nanomaterials at scale introduces workplace exposure risks that require specialized containment systems and safety protocols. Additionally, the chemical reduction processes commonly employed generate hazardous waste streams that necessitate costly treatment procedures to meet increasingly stringent environmental regulations.

Supply chain reliability represents another significant obstacle. The commercial ecosystem for high-quality rGO remains fragmented, with few suppliers capable of delivering consistent materials at industrial volumes. This supply uncertainty complicates manufacturing planning and increases risk for potential adopters of rGO-organic composite technologies.

Regulatory frameworks governing nanomaterial incorporation into commercial products continue to evolve, creating compliance uncertainty for manufacturers. The lack of standardized testing protocols specifically designed for rGO-organic interfaces makes certification processes lengthy and unpredictable, further deterring industrial implementation despite the promising performance benefits these materials offer.

Material cost remains a substantial barrier to widespread industrial adoption. While graphene oxide production costs have decreased, the reduction processes and subsequent functionalization treatments necessary for optimal organic matrix interfacing still contribute to prohibitively high material expenses for many applications. This economic constraint is particularly evident in cost-sensitive industries where performance improvements must justify the premium price point.

Quality control and standardization present additional implementation challenges. The interfacial properties between rGO and organic matrices are highly sensitive to processing conditions, with minor variations potentially leading to significant performance differences. Current analytical techniques for characterizing these interfaces at industrial scale lack the precision and throughput necessary for real-time quality assurance, creating bottlenecks in production workflows.

Environmental and safety considerations further complicate industrial implementation. The handling of nanomaterials at scale introduces workplace exposure risks that require specialized containment systems and safety protocols. Additionally, the chemical reduction processes commonly employed generate hazardous waste streams that necessitate costly treatment procedures to meet increasingly stringent environmental regulations.

Supply chain reliability represents another significant obstacle. The commercial ecosystem for high-quality rGO remains fragmented, with few suppliers capable of delivering consistent materials at industrial volumes. This supply uncertainty complicates manufacturing planning and increases risk for potential adopters of rGO-organic composite technologies.

Regulatory frameworks governing nanomaterial incorporation into commercial products continue to evolve, creating compliance uncertainty for manufacturers. The lack of standardized testing protocols specifically designed for rGO-organic interfaces makes certification processes lengthy and unpredictable, further deterring industrial implementation despite the promising performance benefits these materials offer.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!