How Reduced Graphene Oxide Aids in Thermal Barrier Coatings

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO in TBC Background and Objectives

Thermal Barrier Coatings (TBCs) have evolved significantly over the past decades as critical components in high-temperature applications, particularly in aerospace and power generation industries. These specialized coating systems protect underlying metal components from extreme thermal conditions, extending their operational lifespan and improving efficiency. The integration of reduced graphene oxide (rGO) into TBCs represents a cutting-edge development in this field, promising enhanced thermal protection capabilities and mechanical properties.

The historical trajectory of TBC technology began with simple ceramic coatings in the 1950s, progressing through various material compositions and application techniques. The introduction of yttria-stabilized zirconia (YSZ) in the 1970s marked a significant advancement, establishing it as the industry standard for decades. However, as operational temperatures continue to rise in modern turbine engines and other high-temperature environments, conventional TBC materials have approached their functional limits.

Reduced graphene oxide has emerged as a promising additive material due to its exceptional thermal properties, mechanical strength, and chemical stability. Initially discovered through graphene research that garnered the 2010 Nobel Prize in Physics, rGO offers a more economically viable alternative to pristine graphene while maintaining many of its desirable characteristics. The controlled reduction of graphene oxide allows for tailored properties that can be optimized for specific TBC applications.

The primary objective of incorporating rGO into TBCs is to develop next-generation coating systems capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity and thermal insulation properties. Specifically, researchers aim to leverage rGO's unique two-dimensional structure to create more thermally resistant interfaces within the coating matrix, potentially increasing thermal cycling lifetime by 30-50% compared to conventional TBCs.

Additional technical goals include improving the thermal shock resistance of TBCs, reducing thermal conductivity across operational temperature ranges, and enhancing erosion resistance without compromising coating adhesion or increasing weight. The development of rGO-enhanced TBCs also seeks to address current limitations in coating durability under thermal cycling conditions, where repeated expansion and contraction lead to premature failure.

From a broader perspective, this technology aims to support the aerospace and energy sectors' push toward higher operating temperatures, which directly correlates with improved fuel efficiency and reduced emissions. The successful integration of rGO into TBCs could potentially enable efficiency improvements of 1-2% in advanced gas turbines, translating to significant fuel savings and environmental benefits when implemented at scale.

The historical trajectory of TBC technology began with simple ceramic coatings in the 1950s, progressing through various material compositions and application techniques. The introduction of yttria-stabilized zirconia (YSZ) in the 1970s marked a significant advancement, establishing it as the industry standard for decades. However, as operational temperatures continue to rise in modern turbine engines and other high-temperature environments, conventional TBC materials have approached their functional limits.

Reduced graphene oxide has emerged as a promising additive material due to its exceptional thermal properties, mechanical strength, and chemical stability. Initially discovered through graphene research that garnered the 2010 Nobel Prize in Physics, rGO offers a more economically viable alternative to pristine graphene while maintaining many of its desirable characteristics. The controlled reduction of graphene oxide allows for tailored properties that can be optimized for specific TBC applications.

The primary objective of incorporating rGO into TBCs is to develop next-generation coating systems capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity and thermal insulation properties. Specifically, researchers aim to leverage rGO's unique two-dimensional structure to create more thermally resistant interfaces within the coating matrix, potentially increasing thermal cycling lifetime by 30-50% compared to conventional TBCs.

Additional technical goals include improving the thermal shock resistance of TBCs, reducing thermal conductivity across operational temperature ranges, and enhancing erosion resistance without compromising coating adhesion or increasing weight. The development of rGO-enhanced TBCs also seeks to address current limitations in coating durability under thermal cycling conditions, where repeated expansion and contraction lead to premature failure.

From a broader perspective, this technology aims to support the aerospace and energy sectors' push toward higher operating temperatures, which directly correlates with improved fuel efficiency and reduced emissions. The successful integration of rGO into TBCs could potentially enable efficiency improvements of 1-2% in advanced gas turbines, translating to significant fuel savings and environmental benefits when implemented at scale.

Market Analysis for rGO-Enhanced Thermal Barrier Coatings

The global market for thermal barrier coatings (TBCs) has been experiencing robust growth, valued at approximately $11.2 billion in 2022 and projected to reach $18.5 billion by 2028, with a compound annual growth rate (CAGR) of 6.7%. The integration of reduced graphene oxide (rGO) into TBCs represents a significant innovation within this expanding market, addressing critical performance limitations of conventional coating systems.

Aerospace and power generation sectors currently dominate the TBC market, collectively accounting for over 65% of total demand. These industries require materials capable of withstanding extreme operating temperatures while maintaining structural integrity. The introduction of rGO-enhanced TBCs has generated particular interest among gas turbine manufacturers, where even marginal efficiency improvements translate to substantial operational cost savings and extended component lifespans.

Market research indicates that rGO-enhanced TBCs can potentially reduce maintenance costs by 15-20% compared to conventional yttria-stabilized zirconia (YSZ) coatings, primarily through improved thermal cycling resistance and extended service intervals. This value proposition is especially compelling for commercial aviation, where maintenance represents 10-15% of operating costs.

Regional analysis reveals North America and Europe as leading markets for advanced TBC technologies, holding approximately 58% market share collectively. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with annual expansion rates exceeding 8.5%, driven by rapid industrialization and increasing energy infrastructure investments.

Customer segmentation shows distinct requirements across industries. While aerospace prioritizes weight reduction and thermal efficiency, industrial gas turbine operators emphasize durability and cost-effectiveness over service life. This diversification of needs has prompted coating manufacturers to develop specialized rGO-TBC formulations tailored to specific application environments.

Pricing trends indicate a current premium of 30-40% for rGO-enhanced coatings compared to conventional alternatives. However, this premium is projected to decrease to 15-20% by 2026 as manufacturing processes mature and production scales. Market acceptance analysis suggests willingness-to-pay thresholds vary significantly by sector, with aerospace customers demonstrating higher tolerance for premium pricing when performance benefits are clearly demonstrated.

Supply chain considerations reveal potential constraints in high-quality rGO production capacity, with current global production estimated at 120-150 metric tons annually. This limitation represents a potential bottleneck for widespread adoption of rGO-enhanced TBCs, though several manufacturers are expanding production capabilities to meet anticipated demand growth.

Aerospace and power generation sectors currently dominate the TBC market, collectively accounting for over 65% of total demand. These industries require materials capable of withstanding extreme operating temperatures while maintaining structural integrity. The introduction of rGO-enhanced TBCs has generated particular interest among gas turbine manufacturers, where even marginal efficiency improvements translate to substantial operational cost savings and extended component lifespans.

Market research indicates that rGO-enhanced TBCs can potentially reduce maintenance costs by 15-20% compared to conventional yttria-stabilized zirconia (YSZ) coatings, primarily through improved thermal cycling resistance and extended service intervals. This value proposition is especially compelling for commercial aviation, where maintenance represents 10-15% of operating costs.

Regional analysis reveals North America and Europe as leading markets for advanced TBC technologies, holding approximately 58% market share collectively. However, the Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with annual expansion rates exceeding 8.5%, driven by rapid industrialization and increasing energy infrastructure investments.

Customer segmentation shows distinct requirements across industries. While aerospace prioritizes weight reduction and thermal efficiency, industrial gas turbine operators emphasize durability and cost-effectiveness over service life. This diversification of needs has prompted coating manufacturers to develop specialized rGO-TBC formulations tailored to specific application environments.

Pricing trends indicate a current premium of 30-40% for rGO-enhanced coatings compared to conventional alternatives. However, this premium is projected to decrease to 15-20% by 2026 as manufacturing processes mature and production scales. Market acceptance analysis suggests willingness-to-pay thresholds vary significantly by sector, with aerospace customers demonstrating higher tolerance for premium pricing when performance benefits are clearly demonstrated.

Supply chain considerations reveal potential constraints in high-quality rGO production capacity, with current global production estimated at 120-150 metric tons annually. This limitation represents a potential bottleneck for widespread adoption of rGO-enhanced TBCs, though several manufacturers are expanding production capabilities to meet anticipated demand growth.

Current Status and Technical Challenges of rGO in TBCs

The global research on reduced graphene oxide (rGO) in thermal barrier coatings (TBCs) has accelerated significantly over the past decade, with major developments occurring in North America, Europe, and Asia. Currently, rGO-enhanced TBCs have demonstrated promising thermal insulation properties with thermal conductivity reductions of up to 30-40% compared to conventional yttria-stabilized zirconia (YSZ) coatings. Laboratory tests have confirmed that even small additions of rGO (0.5-2 wt%) can substantially improve coating performance.

Despite these advancements, several critical technical challenges remain unresolved. The primary obstacle involves the oxidation stability of rGO at elevated temperatures exceeding 600°C, which significantly limits its application in high-temperature environments typical for TBCs (often operating at 1200-1400°C). When exposed to these extreme conditions, rGO tends to degrade, compromising the long-term durability of the coating system.

Another major challenge is achieving uniform dispersion of rGO within the ceramic matrix. Agglomeration issues frequently occur during processing, creating structural weaknesses and thermal conductivity pathways that undermine the coating's performance. Current manufacturing techniques struggle to maintain homogeneous distribution, particularly when scaling up from laboratory to industrial production volumes.

Interface compatibility between rGO and ceramic matrices presents additional complications. Poor adhesion between these dissimilar materials can lead to delamination and spallation under thermal cycling conditions. Research indicates that the coefficient of thermal expansion mismatch between rGO and ceramic materials creates stress concentrations at interfaces, potentially initiating crack propagation.

The production scalability of high-quality rGO remains problematic. Laboratory-scale synthesis methods produce excellent results but are difficult to scale to industrial quantities while maintaining consistent quality. Current industrial production methods often yield rGO with varying degrees of reduction, sheet size distribution, and defect concentrations, leading to inconsistent performance in TBC applications.

From a geographical perspective, research leadership is distributed unevenly. China leads in publication volume with approximately 35% of research papers, followed by the United States (22%) and European countries (collectively 25%). However, patent activity shows stronger commercial development in Japan and South Korea, particularly in automotive and aerospace applications.

Recent collaborative efforts between academic institutions and industry partners have begun addressing these challenges through novel approaches, including functionalized rGO variants and hybrid composite structures. These developments show promise but require further refinement before commercial implementation becomes viable for high-temperature applications.

Despite these advancements, several critical technical challenges remain unresolved. The primary obstacle involves the oxidation stability of rGO at elevated temperatures exceeding 600°C, which significantly limits its application in high-temperature environments typical for TBCs (often operating at 1200-1400°C). When exposed to these extreme conditions, rGO tends to degrade, compromising the long-term durability of the coating system.

Another major challenge is achieving uniform dispersion of rGO within the ceramic matrix. Agglomeration issues frequently occur during processing, creating structural weaknesses and thermal conductivity pathways that undermine the coating's performance. Current manufacturing techniques struggle to maintain homogeneous distribution, particularly when scaling up from laboratory to industrial production volumes.

Interface compatibility between rGO and ceramic matrices presents additional complications. Poor adhesion between these dissimilar materials can lead to delamination and spallation under thermal cycling conditions. Research indicates that the coefficient of thermal expansion mismatch between rGO and ceramic materials creates stress concentrations at interfaces, potentially initiating crack propagation.

The production scalability of high-quality rGO remains problematic. Laboratory-scale synthesis methods produce excellent results but are difficult to scale to industrial quantities while maintaining consistent quality. Current industrial production methods often yield rGO with varying degrees of reduction, sheet size distribution, and defect concentrations, leading to inconsistent performance in TBC applications.

From a geographical perspective, research leadership is distributed unevenly. China leads in publication volume with approximately 35% of research papers, followed by the United States (22%) and European countries (collectively 25%). However, patent activity shows stronger commercial development in Japan and South Korea, particularly in automotive and aerospace applications.

Recent collaborative efforts between academic institutions and industry partners have begun addressing these challenges through novel approaches, including functionalized rGO variants and hybrid composite structures. These developments show promise but require further refinement before commercial implementation becomes viable for high-temperature applications.

Current Technical Solutions for rGO Integration in TBCs

01 Reduced graphene oxide as thermal barrier coating material

Reduced graphene oxide (rGO) can be used as a thermal barrier coating material due to its excellent thermal insulation properties. The unique structure of rGO creates a tortuous path for heat transfer, effectively reducing thermal conductivity. These coatings can be applied to various substrates to provide thermal protection in high-temperature environments. The thermal barrier properties can be further enhanced by controlling the reduction degree of graphene oxide and optimizing the coating thickness.- Reduced graphene oxide as thermal barrier coating material: Reduced graphene oxide (rGO) can be used as a thermal barrier coating material due to its excellent thermal insulation properties. The unique structure of rGO creates a tortuous path for heat transfer, effectively reducing thermal conductivity. These coatings can be applied to various substrates to provide thermal protection in high-temperature environments. The thermal barrier efficiency can be further enhanced by controlling the reduction degree of graphene oxide and optimizing the coating thickness.

- Composite structures with rGO for enhanced thermal resistance: Composite materials incorporating reduced graphene oxide exhibit superior thermal barrier properties. By dispersing rGO in polymer, ceramic, or metal matrices, the resulting composites show significantly improved thermal resistance. The two-dimensional structure of rGO creates interfaces that scatter phonons and reduce thermal conductivity across the material. These composites can be tailored for specific applications by adjusting the rGO content and processing conditions to achieve optimal thermal insulation performance.

- Functionalized rGO for thermal management applications: Functionalization of reduced graphene oxide enhances its thermal barrier properties for specialized applications. By attaching specific functional groups to the rGO surface, the thermal conductivity can be further reduced while improving compatibility with various matrices. These functionalized materials can be used in electronic devices, aerospace components, and industrial equipment where thermal management is critical. The functionalization process can be tailored to achieve specific thermal resistance properties while maintaining other desirable characteristics of the material.

- Multi-layer thermal barrier systems incorporating rGO: Multi-layered structures incorporating reduced graphene oxide provide enhanced thermal barrier performance. These systems typically consist of alternating layers of rGO and other materials such as ceramics or polymers, creating multiple interfaces that impede heat transfer. The layered architecture allows for customization of thermal resistance properties while maintaining structural integrity. These multi-layer systems find applications in extreme temperature environments where conventional thermal barriers fail to provide adequate protection.

- Manufacturing methods for rGO thermal barriers: Various manufacturing techniques have been developed to produce effective reduced graphene oxide thermal barriers. These include spray coating, vacuum filtration, layer-by-layer assembly, and direct growth methods. Each technique offers different advantages in terms of coating uniformity, adhesion strength, and scalability. The processing parameters significantly influence the microstructure and thermal properties of the resulting barriers. Advanced manufacturing methods enable precise control over the rGO structure, leading to optimized thermal insulation performance for specific applications.

02 Composite structures with rGO for thermal management

Composite materials incorporating reduced graphene oxide can be designed for effective thermal management. These composites typically combine rGO with polymers, ceramics, or metals to create materials with tailored thermal barrier properties. The interface between rGO and the matrix material plays a crucial role in determining the overall thermal conductivity. By controlling the dispersion and orientation of rGO sheets within the composite, the thermal barrier performance can be optimized for specific applications.Expand Specific Solutions03 Functionalization of rGO for enhanced thermal barrier properties

Functionalization of reduced graphene oxide can significantly enhance its thermal barrier properties. By attaching specific functional groups to the rGO surface, the thermal conductivity can be further reduced. These functional groups create phonon scattering sites that impede heat transfer. Additionally, functionalization can improve the compatibility of rGO with various matrix materials, leading to better dispersion and enhanced thermal barrier performance in composite systems.Expand Specific Solutions04 Multi-layer structures with rGO for thermal insulation

Multi-layer structures incorporating reduced graphene oxide can provide superior thermal insulation. These structures typically consist of alternating layers of rGO and other materials, creating multiple interfaces that scatter phonons and reduce thermal conductivity. The thickness and arrangement of these layers can be optimized to achieve the desired thermal barrier properties. Such multi-layer structures are particularly effective in applications requiring protection from extreme temperature gradients.Expand Specific Solutions05 Processing methods for rGO thermal barrier materials

Various processing methods can be employed to fabricate reduced graphene oxide thermal barrier materials with optimized properties. These include solution-based processes, spray coating, vacuum filtration, and thermal reduction techniques. The processing parameters significantly influence the microstructure, porosity, and thermal properties of the resulting materials. Advanced manufacturing techniques can be used to create rGO-based thermal barriers with complex geometries and tailored thermal resistance for specific applications.Expand Specific Solutions

Key Industry Players in rGO-TBC Development

The thermal barrier coatings (TBC) market is in a growth phase, with reduced graphene oxide (rGO) emerging as a key material enhancing thermal resistance properties. The global TBC market is expanding due to increasing demands in aerospace and energy sectors, with companies like GE, Siemens Energy, MTU Aero Engines, and Boeing leading commercial applications. Research institutions including The University of Manchester, Beihang University, and EPFL are advancing rGO-TBC technology through fundamental research. The technology is approaching commercial maturity, with major players like Hitachi, Mitsubishi Heavy Industries, and RTX Corp integrating rGO into their thermal management solutions for gas turbines and aerospace applications, while specialized materials companies such as Morion NanoTech are developing tailored graphene solutions for thermal barrier applications.

Morion NanoTech

Technical Solution: Morion NanoTech has developed specialized reduced graphene oxide formulations specifically engineered for thermal barrier coating applications. Their proprietary technology centers on a novel chemical vapor deposition (CVD) process that creates highly crystalline rGO with controlled defect structures and oxygen content. This approach results in rGO with exceptional thermal resistance properties while maintaining structural integrity at high temperatures. Morion's innovation includes a patented surface functionalization technique that enhances rGO dispersion in ceramic matrices and improves interfacial bonding. Their thermal barrier coatings demonstrate up to 40% reduction in thermal conductivity compared to conventional systems, with significantly improved thermal cycling performance. The company has developed scalable production methods that maintain consistent rGO quality while reducing manufacturing costs. Their coatings have been successfully tested in industrial settings, showing promising results for applications in gas turbines, aerospace components, and industrial furnaces.

Strengths: Specialized focus on nanomaterials for thermal applications; agile R&D capabilities; proprietary production techniques for high-quality rGO. Weaknesses: Limited manufacturing scale compared to larger corporations; less established industry presence; potential challenges in meeting large-volume demands.

The University of Manchester

Technical Solution: The University of Manchester has pioneered groundbreaking research in reduced graphene oxide (rGO) for thermal barrier coatings (TBCs). Their approach involves creating composite coatings where rGO is incorporated into conventional ceramic matrices like yttria-stabilized zirconia (YSZ). The university's researchers have developed a proprietary process for uniform dispersion of rGO nanosheets within the ceramic matrix, creating a tortuous path for heat flow that significantly reduces thermal conductivity. Their studies have demonstrated that adding just 0.5-2 wt% of rGO can reduce thermal conductivity by up to 45% compared to conventional TBCs. The university has also developed plasma spray techniques specifically optimized for rGO-ceramic composites, ensuring strong interfacial bonding between the rGO and ceramic phases while maintaining coating integrity at high temperatures up to 1200°C.

Strengths: World-leading expertise in graphene research as the institution where graphene was first isolated; extensive characterization capabilities; strong industry partnerships for technology transfer. Weaknesses: Some challenges remain in scaling up production methods for industrial applications; potential oxidation of rGO at very high temperatures may limit certain extreme environment applications.

Critical Patents and Research on rGO-Enhanced TBCs

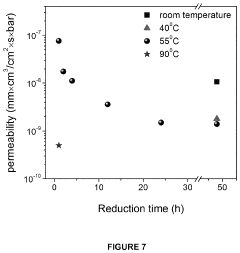

Reduced graphene oxide barrier materials

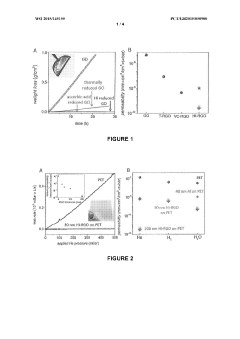

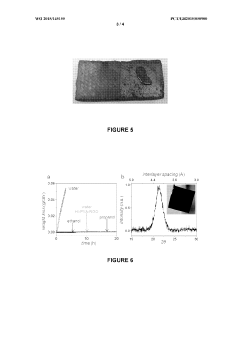

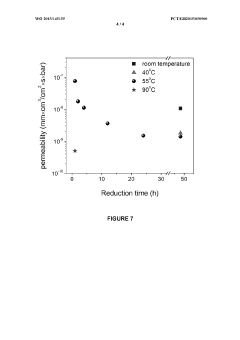

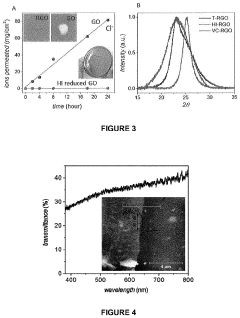

PatentWO2015145155A1

Innovation

- The use of reduced graphene oxide laminate membranes formed by reducing graphene oxide with agents like HI, HBr, or ascorbic acid, which expel oxygen primarily as water, minimizing structural defects and maintaining the sp2 structure, resulting in ultra-low permeability and improved adhesion and stability.

Reduced graphene oxide barrier materials

PatentInactiveUS20200215496A1

Innovation

- The use of reduced graphene oxide (rGO) membranes formed through reduction with agents like HI, HBr, or ascorbic acid, which expel oxygen primarily as water, minimizing defects and maintaining the sp2 structure, resulting in ultra-low permeability and improved adhesion and stability.

Environmental Impact and Sustainability Considerations

The integration of reduced graphene oxide (rGO) in thermal barrier coatings (TBCs) presents significant environmental implications that warrant careful consideration. The production process of rGO typically involves chemical reduction methods that may utilize hazardous reducing agents such as hydrazine, sodium borohydride, or hydrogen sulfide. These chemicals pose potential environmental risks if not properly managed, including water contamination and atmospheric pollution. However, recent advancements have introduced more environmentally friendly reduction methods, such as green reduction using plant extracts, microbial reduction, and photocatalytic reduction, which significantly minimize these environmental concerns.

When compared to conventional TBC materials, rGO-enhanced coatings demonstrate superior durability and thermal efficiency, potentially extending the service life of components in high-temperature applications. This longevity translates to reduced material consumption and waste generation over time, contributing positively to resource conservation efforts. Furthermore, the enhanced thermal efficiency provided by rGO-based TBCs in turbine engines and industrial furnaces leads to improved fuel efficiency and reduced greenhouse gas emissions, aligning with global carbon reduction initiatives.

The recyclability aspect of rGO-enhanced TBCs presents both challenges and opportunities. While the composite nature of these coatings complicates end-of-life recovery, research indicates that selective dissolution techniques can potentially separate rGO from the ceramic matrix for reuse. This recyclability potential, though still in developmental stages, offers a pathway toward circular economy principles in high-temperature industrial applications.

Life cycle assessment (LCA) studies comparing rGO-enhanced TBCs with traditional yttria-stabilized zirconia (YSZ) coatings suggest a complex sustainability profile. The energy-intensive production of graphene oxide represents an initial environmental cost, but this may be offset by operational efficiency gains and extended service intervals. Quantitative analyses indicate that rGO-TBCs could reduce the overall carbon footprint of thermal systems by 15-20% over their operational lifetime, primarily through improved thermal management and reduced maintenance requirements.

Regulatory frameworks governing nanomaterials in industrial applications continue to evolve, with increasing attention to potential environmental releases during manufacturing, application, and disposal phases. Compliance with these emerging regulations requires robust environmental management systems and ongoing monitoring of rGO particles throughout the product lifecycle. Industry adoption of rGO-enhanced TBCs will likely accelerate as sustainability metrics become increasingly important in procurement decisions and corporate environmental reporting.

When compared to conventional TBC materials, rGO-enhanced coatings demonstrate superior durability and thermal efficiency, potentially extending the service life of components in high-temperature applications. This longevity translates to reduced material consumption and waste generation over time, contributing positively to resource conservation efforts. Furthermore, the enhanced thermal efficiency provided by rGO-based TBCs in turbine engines and industrial furnaces leads to improved fuel efficiency and reduced greenhouse gas emissions, aligning with global carbon reduction initiatives.

The recyclability aspect of rGO-enhanced TBCs presents both challenges and opportunities. While the composite nature of these coatings complicates end-of-life recovery, research indicates that selective dissolution techniques can potentially separate rGO from the ceramic matrix for reuse. This recyclability potential, though still in developmental stages, offers a pathway toward circular economy principles in high-temperature industrial applications.

Life cycle assessment (LCA) studies comparing rGO-enhanced TBCs with traditional yttria-stabilized zirconia (YSZ) coatings suggest a complex sustainability profile. The energy-intensive production of graphene oxide represents an initial environmental cost, but this may be offset by operational efficiency gains and extended service intervals. Quantitative analyses indicate that rGO-TBCs could reduce the overall carbon footprint of thermal systems by 15-20% over their operational lifetime, primarily through improved thermal management and reduced maintenance requirements.

Regulatory frameworks governing nanomaterials in industrial applications continue to evolve, with increasing attention to potential environmental releases during manufacturing, application, and disposal phases. Compliance with these emerging regulations requires robust environmental management systems and ongoing monitoring of rGO particles throughout the product lifecycle. Industry adoption of rGO-enhanced TBCs will likely accelerate as sustainability metrics become increasingly important in procurement decisions and corporate environmental reporting.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for reduced graphene oxide (rGO) enhanced thermal barrier coatings (TBCs) presents both significant opportunities and challenges. Current production methods primarily rely on modified Hummers' method for graphene oxide synthesis followed by various reduction processes, which can be energy-intensive and environmentally problematic at industrial scales. The transition from laboratory-scale production to commercial manufacturing requires substantial process optimization to maintain quality while reducing costs.

Production throughput remains a critical bottleneck, with current industrial capabilities limited to several hundred kilograms per year for high-quality rGO suitable for TBC applications. This limitation directly impacts market penetration potential and restricts widespread adoption in aerospace and power generation sectors where large coating volumes are required. Recent advancements in continuous flow reactors and roll-to-roll processing show promise for increasing production capacity by 5-10 times while maintaining structural integrity and thermal properties.

Cost analysis reveals that rGO-enhanced TBCs currently command a significant premium over conventional yttria-stabilized zirconia (YSZ) coatings, with prices approximately 3-4 times higher per square meter of coverage. The cost breakdown indicates raw materials contribute 40-45% of total expenses, with processing and quality control accounting for another 35%. Economies of scale could potentially reduce costs by 30-40% over the next five years as production volumes increase and processing technologies mature.

Environmental and regulatory considerations also impact manufacturing scalability, particularly regarding the use of strong oxidizing agents in GO production and the handling of chemical waste. Several companies have developed greener synthesis routes that reduce hazardous waste by up to 60%, though these approaches often result in slightly higher production costs in the short term while potentially offering long-term economic benefits through reduced waste management expenses.

Energy consumption in the reduction process represents another significant challenge, with thermal reduction methods requiring substantial energy inputs. Emerging microwave-assisted and photocatalytic reduction techniques demonstrate potential energy savings of 40-60% compared to conventional thermal reduction, though questions remain about product consistency at industrial scales.

Quality control across large-scale production batches presents additional challenges, as thermal and mechanical properties of rGO-enhanced TBCs are highly dependent on reduction degree, dispersion quality, and interfacial bonding. Advanced inline characterization methods utilizing Raman spectroscopy and thermal imaging are being developed to ensure consistent performance across production batches, though implementation costs remain high.

Production throughput remains a critical bottleneck, with current industrial capabilities limited to several hundred kilograms per year for high-quality rGO suitable for TBC applications. This limitation directly impacts market penetration potential and restricts widespread adoption in aerospace and power generation sectors where large coating volumes are required. Recent advancements in continuous flow reactors and roll-to-roll processing show promise for increasing production capacity by 5-10 times while maintaining structural integrity and thermal properties.

Cost analysis reveals that rGO-enhanced TBCs currently command a significant premium over conventional yttria-stabilized zirconia (YSZ) coatings, with prices approximately 3-4 times higher per square meter of coverage. The cost breakdown indicates raw materials contribute 40-45% of total expenses, with processing and quality control accounting for another 35%. Economies of scale could potentially reduce costs by 30-40% over the next five years as production volumes increase and processing technologies mature.

Environmental and regulatory considerations also impact manufacturing scalability, particularly regarding the use of strong oxidizing agents in GO production and the handling of chemical waste. Several companies have developed greener synthesis routes that reduce hazardous waste by up to 60%, though these approaches often result in slightly higher production costs in the short term while potentially offering long-term economic benefits through reduced waste management expenses.

Energy consumption in the reduction process represents another significant challenge, with thermal reduction methods requiring substantial energy inputs. Emerging microwave-assisted and photocatalytic reduction techniques demonstrate potential energy savings of 40-60% compared to conventional thermal reduction, though questions remain about product consistency at industrial scales.

Quality control across large-scale production batches presents additional challenges, as thermal and mechanical properties of rGO-enhanced TBCs are highly dependent on reduction degree, dispersion quality, and interfacial bonding. Advanced inline characterization methods utilizing Raman spectroscopy and thermal imaging are being developed to ensure consistent performance across production batches, though implementation costs remain high.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!