The Role of Reduced Graphene Oxide in Modern Electronics

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Oxide Evolution and Research Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of electronics since its initial discovery. The journey of graphene began with the groundbreaking work of Andre Geim and Konstantin Novoselov in 2004, who isolated single-layer graphene through mechanical exfoliation, earning them the Nobel Prize in Physics in 2010. This discovery catalyzed intensive research into graphene derivatives, with graphene oxide becoming particularly significant due to its unique properties and processing advantages.

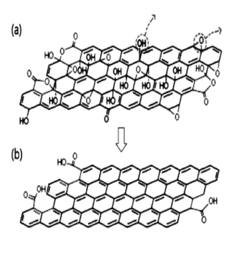

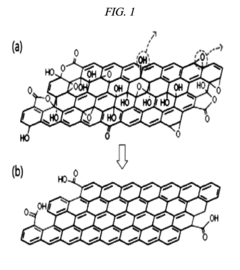

The evolution of graphene oxide research has progressed through several distinct phases. Initially, researchers focused on fundamental characterization and understanding the structural and chemical properties of GO. This was followed by the development of various synthesis methods, including modified Hummers method, which remains the most widely used approach for GO production. The third phase saw the emergence of reduction techniques to convert GO to reduced graphene oxide (rGO), which exhibits electrical properties closer to pristine graphene while maintaining some of GO's processability advantages.

Recent years have witnessed a shift toward application-oriented research, with particular emphasis on electronics integration. The trajectory of GO research has been marked by continuous improvements in production scalability, reduction efficiency, and functional customization to meet specific electronic applications requirements. The development of environmentally friendly reduction methods represents another significant trend in GO evolution.

The primary research objectives in the field of reduced graphene oxide for modern electronics encompass several interconnected goals. First, researchers aim to develop more efficient and controlled reduction processes that can precisely tune the electrical, thermal, and mechanical properties of rGO. This includes exploring novel reduction agents and techniques that minimize defects while maximizing conductivity restoration.

Second, there is a focused effort to enhance the integration compatibility of rGO with conventional semiconductor manufacturing processes. This involves developing techniques for precise deposition, patterning, and interface engineering that enable seamless incorporation into existing electronic fabrication workflows.

Third, researchers are working to understand and exploit the unique properties of partially reduced GO, where the degree of reduction can be strategically controlled to create materials with tailored functionalities for specific electronic applications, from flexible displays to energy storage devices.

Finally, sustainability objectives have gained prominence, with research directed toward developing eco-friendly production and reduction methods that minimize environmental impact while maintaining economic viability for large-scale production. These objectives collectively drive the field toward realizing the full potential of reduced graphene oxide in transforming next-generation electronic technologies.

The evolution of graphene oxide research has progressed through several distinct phases. Initially, researchers focused on fundamental characterization and understanding the structural and chemical properties of GO. This was followed by the development of various synthesis methods, including modified Hummers method, which remains the most widely used approach for GO production. The third phase saw the emergence of reduction techniques to convert GO to reduced graphene oxide (rGO), which exhibits electrical properties closer to pristine graphene while maintaining some of GO's processability advantages.

Recent years have witnessed a shift toward application-oriented research, with particular emphasis on electronics integration. The trajectory of GO research has been marked by continuous improvements in production scalability, reduction efficiency, and functional customization to meet specific electronic applications requirements. The development of environmentally friendly reduction methods represents another significant trend in GO evolution.

The primary research objectives in the field of reduced graphene oxide for modern electronics encompass several interconnected goals. First, researchers aim to develop more efficient and controlled reduction processes that can precisely tune the electrical, thermal, and mechanical properties of rGO. This includes exploring novel reduction agents and techniques that minimize defects while maximizing conductivity restoration.

Second, there is a focused effort to enhance the integration compatibility of rGO with conventional semiconductor manufacturing processes. This involves developing techniques for precise deposition, patterning, and interface engineering that enable seamless incorporation into existing electronic fabrication workflows.

Third, researchers are working to understand and exploit the unique properties of partially reduced GO, where the degree of reduction can be strategically controlled to create materials with tailored functionalities for specific electronic applications, from flexible displays to energy storage devices.

Finally, sustainability objectives have gained prominence, with research directed toward developing eco-friendly production and reduction methods that minimize environmental impact while maintaining economic viability for large-scale production. These objectives collectively drive the field toward realizing the full potential of reduced graphene oxide in transforming next-generation electronic technologies.

Market Applications and Demand Analysis for rGO

The market for reduced graphene oxide (rGO) in electronics has witnessed substantial growth in recent years, driven primarily by its exceptional electrical, thermal, and mechanical properties. The global market for graphene-based materials, including rGO, was valued at approximately $620 million in 2022 and is projected to reach $2.5 billion by 2030, with a compound annual growth rate of 19.4% during this forecast period.

Consumer electronics represents the largest application segment for rGO, accounting for nearly 35% of the total market share. This dominance stems from the increasing demand for flexible displays, wearable devices, and high-performance smartphones. Major manufacturers like Samsung, LG, and Apple have invested significantly in graphene-based technologies to enhance product performance and introduce innovative features.

Energy storage applications constitute another rapidly growing market segment for rGO. The material's high surface area and excellent conductivity make it ideal for supercapacitors and lithium-ion batteries. Market analysis indicates that the energy storage sector for rGO is expanding at 22.3% annually, outpacing the overall market growth rate. This acceleration is largely attributed to the global push toward renewable energy systems and electric vehicles.

Semiconductor and integrated circuit manufacturers have also shown increasing interest in rGO as a potential replacement for traditional materials. The demand is particularly strong in applications requiring high thermal conductivity and electrical performance in miniaturized formats. Industry reports suggest that approximately 28% of semiconductor companies are currently conducting R&D activities involving graphene-based materials.

Regional analysis reveals that Asia-Pacific dominates the rGO market with a 45% share, followed by North America (30%) and Europe (20%). China, South Korea, and Japan lead in production capacity and consumption, while the United States maintains leadership in research innovation. The European market is characterized by strong governmental support for graphene commercialization through initiatives like the Graphene Flagship program.

Market challenges include high production costs, scalability issues, and quality consistency. The average production cost of high-quality rGO remains approximately 5-10 times higher than conventional materials, creating a significant barrier to widespread adoption. However, recent technological advancements have reduced production costs by nearly 40% compared to 2018 levels.

Customer demand analysis indicates that performance enhancement is the primary driver (65% of customers), followed by miniaturization capabilities (22%) and energy efficiency improvements (13%). Industries are increasingly willing to pay premium prices for rGO-based solutions that deliver substantial performance advantages over conventional alternatives.

Consumer electronics represents the largest application segment for rGO, accounting for nearly 35% of the total market share. This dominance stems from the increasing demand for flexible displays, wearable devices, and high-performance smartphones. Major manufacturers like Samsung, LG, and Apple have invested significantly in graphene-based technologies to enhance product performance and introduce innovative features.

Energy storage applications constitute another rapidly growing market segment for rGO. The material's high surface area and excellent conductivity make it ideal for supercapacitors and lithium-ion batteries. Market analysis indicates that the energy storage sector for rGO is expanding at 22.3% annually, outpacing the overall market growth rate. This acceleration is largely attributed to the global push toward renewable energy systems and electric vehicles.

Semiconductor and integrated circuit manufacturers have also shown increasing interest in rGO as a potential replacement for traditional materials. The demand is particularly strong in applications requiring high thermal conductivity and electrical performance in miniaturized formats. Industry reports suggest that approximately 28% of semiconductor companies are currently conducting R&D activities involving graphene-based materials.

Regional analysis reveals that Asia-Pacific dominates the rGO market with a 45% share, followed by North America (30%) and Europe (20%). China, South Korea, and Japan lead in production capacity and consumption, while the United States maintains leadership in research innovation. The European market is characterized by strong governmental support for graphene commercialization through initiatives like the Graphene Flagship program.

Market challenges include high production costs, scalability issues, and quality consistency. The average production cost of high-quality rGO remains approximately 5-10 times higher than conventional materials, creating a significant barrier to widespread adoption. However, recent technological advancements have reduced production costs by nearly 40% compared to 2018 levels.

Customer demand analysis indicates that performance enhancement is the primary driver (65% of customers), followed by miniaturization capabilities (22%) and energy efficiency improvements (13%). Industries are increasingly willing to pay premium prices for rGO-based solutions that deliver substantial performance advantages over conventional alternatives.

Current Challenges in rGO Production and Implementation

Despite significant advancements in reduced graphene oxide (rGO) research, several critical challenges persist in its production and implementation for electronic applications. The primary obstacle remains the scalable and cost-effective production of high-quality rGO with consistent properties. Current reduction methods, including chemical, thermal, and electrochemical approaches, often result in structural defects and residual oxygen-containing groups that compromise electrical conductivity and overall performance.

Chemical reduction methods using hydrazine or other reducing agents face environmental and safety concerns, while thermal reduction processes require high energy consumption and often lead to structural damage. Electrochemical reduction offers better control but struggles with scalability for industrial applications. The lack of standardized production protocols further exacerbates quality inconsistencies across different batches and manufacturers.

Another significant challenge is the restoration of the sp² carbon network during the reduction process. The ideal reduction would completely remove oxygen functionalities while perfectly restoring the graphene lattice, but in practice, this remains elusive. The resulting rGO typically contains residual defects that act as electron scattering sites, limiting its theoretical electrical conductivity potential.

Integration challenges also persist when incorporating rGO into existing electronic manufacturing processes. The material's compatibility with standard semiconductor fabrication techniques remains problematic, particularly regarding uniform deposition, patterning precision, and interface engineering with other materials. These integration issues have limited rGO's widespread adoption in commercial electronic devices despite its promising properties.

Stability represents another critical concern, as rGO-based devices often exhibit performance degradation over time due to re-oxidation or structural changes when exposed to environmental conditions. This instability affects long-term reliability, particularly in applications requiring consistent performance under varying environmental conditions.

Reproducibility issues further complicate industrial implementation, as slight variations in production parameters can significantly alter rGO's properties. The lack of standardized characterization methods makes quality control particularly challenging, hindering the establishment of reliable supply chains for electronic manufacturers.

Addressing these challenges requires interdisciplinary approaches combining materials science, chemical engineering, and electronics manufacturing expertise. Recent research has focused on developing hybrid reduction methods, in-situ characterization techniques, and novel integration strategies to overcome these limitations, but significant work remains before rGO can fulfill its potential as a transformative material in modern electronics.

Chemical reduction methods using hydrazine or other reducing agents face environmental and safety concerns, while thermal reduction processes require high energy consumption and often lead to structural damage. Electrochemical reduction offers better control but struggles with scalability for industrial applications. The lack of standardized production protocols further exacerbates quality inconsistencies across different batches and manufacturers.

Another significant challenge is the restoration of the sp² carbon network during the reduction process. The ideal reduction would completely remove oxygen functionalities while perfectly restoring the graphene lattice, but in practice, this remains elusive. The resulting rGO typically contains residual defects that act as electron scattering sites, limiting its theoretical electrical conductivity potential.

Integration challenges also persist when incorporating rGO into existing electronic manufacturing processes. The material's compatibility with standard semiconductor fabrication techniques remains problematic, particularly regarding uniform deposition, patterning precision, and interface engineering with other materials. These integration issues have limited rGO's widespread adoption in commercial electronic devices despite its promising properties.

Stability represents another critical concern, as rGO-based devices often exhibit performance degradation over time due to re-oxidation or structural changes when exposed to environmental conditions. This instability affects long-term reliability, particularly in applications requiring consistent performance under varying environmental conditions.

Reproducibility issues further complicate industrial implementation, as slight variations in production parameters can significantly alter rGO's properties. The lack of standardized characterization methods makes quality control particularly challenging, hindering the establishment of reliable supply chains for electronic manufacturers.

Addressing these challenges requires interdisciplinary approaches combining materials science, chemical engineering, and electronics manufacturing expertise. Recent research has focused on developing hybrid reduction methods, in-situ characterization techniques, and novel integration strategies to overcome these limitations, but significant work remains before rGO can fulfill its potential as a transformative material in modern electronics.

Contemporary rGO Integration Methods in Electronics

01 Methods for producing reduced graphene oxide

Various methods can be employed to produce reduced graphene oxide (rGO) from graphene oxide. These methods include chemical reduction using reducing agents, thermal reduction at elevated temperatures, electrochemical reduction, and photocatalytic reduction. Each method offers different advantages in terms of efficiency, scalability, and the quality of the resulting rGO. The reduction process removes oxygen-containing functional groups from graphene oxide, restoring the sp2 carbon network and enhancing electrical conductivity.- Methods for producing reduced graphene oxide (rGO): Various methods have been developed for the production of reduced graphene oxide, including chemical reduction, thermal reduction, and electrochemical reduction processes. These methods aim to efficiently remove oxygen-containing functional groups from graphene oxide to restore the sp2 carbon network and enhance electrical conductivity. The reduction processes can be optimized to control the degree of reduction and tailor the properties of rGO for specific applications.

- rGO-based energy storage applications: Reduced graphene oxide is widely used in energy storage devices such as supercapacitors, lithium-ion batteries, and fuel cells due to its high surface area, excellent electrical conductivity, and mechanical stability. rGO can be incorporated as an electrode material, conductive additive, or composite component to enhance energy density, power density, and cycling stability. The unique properties of rGO allow for improved electron transport and ion diffusion in energy storage systems.

- rGO-based composite materials: Reduced graphene oxide can be combined with various materials including polymers, metals, metal oxides, and other carbon materials to form composite structures with enhanced properties. These composites leverage the mechanical strength, thermal conductivity, and electrical properties of rGO while addressing limitations such as restacking and agglomeration. rGO-based composites find applications in structural materials, conductive films, sensors, and catalysts.

- rGO for sensing and detection applications: Reduced graphene oxide is utilized in various sensing platforms due to its large surface area, excellent electrical conductivity, and ease of functionalization. rGO-based sensors can detect gases, biomolecules, heavy metals, and other analytes with high sensitivity and selectivity. The sensing mechanisms often involve changes in electrical properties, optical characteristics, or electrochemical responses upon interaction with target molecules, making rGO valuable for environmental monitoring, medical diagnostics, and security applications.

- Surface modification and functionalization of rGO: The surface of reduced graphene oxide can be modified and functionalized to enhance its properties and expand its applications. Functionalization strategies include covalent attachment of organic molecules, doping with heteroatoms, and decoration with nanoparticles. These modifications can improve dispersibility, biocompatibility, catalytic activity, and selectivity toward specific interactions. Controlled functionalization enables the tailoring of rGO properties for targeted applications in electronics, catalysis, biomedicine, and environmental remediation.

02 Applications of rGO in energy storage devices

Reduced graphene oxide is widely used in energy storage applications due to its excellent electrical conductivity, large surface area, and mechanical stability. It serves as an electrode material in supercapacitors, lithium-ion batteries, and other energy storage devices. When incorporated into these devices, rGO enhances charge transport, increases energy density, and improves cycling stability. The unique properties of rGO make it an ideal candidate for next-generation energy storage solutions.Expand Specific Solutions03 rGO-based composite materials

Reduced graphene oxide can be combined with various materials to form composites with enhanced properties. These composites include rGO with metal oxides, polymers, or other carbon materials. The resulting materials exhibit synergistic effects, such as improved mechanical strength, electrical conductivity, and thermal stability. rGO-based composites find applications in sensors, catalysts, and structural materials, offering superior performance compared to their individual components.Expand Specific Solutions04 Environmental applications of rGO

Reduced graphene oxide has significant potential in environmental remediation and protection. It can be used as an adsorbent for removing pollutants from water, including heavy metals and organic contaminants. rGO-based materials also show promise in air purification, waste treatment, and as photocatalysts for degrading environmental pollutants. The high surface area and tunable surface chemistry of rGO make it effective for various environmental applications.Expand Specific Solutions05 rGO in electronic and sensing devices

Reduced graphene oxide is increasingly being utilized in electronic devices and sensors due to its excellent electrical properties and large surface area. Applications include field-effect transistors, transparent conductive films, flexible electronics, and various types of sensors for detecting gases, biomolecules, and environmental parameters. The sensitivity of rGO-based sensors can be further enhanced by functionalization or incorporation into composite structures, enabling detection of analytes at very low concentrations.Expand Specific Solutions

Leading Companies and Research Institutions in rGO Field

The reduced graphene oxide (rGO) market in modern electronics is currently in a growth phase, characterized by increasing adoption across various applications due to its exceptional electrical, thermal, and mechanical properties. The global market is expanding rapidly, with projections indicating significant growth as industries seek more efficient and sustainable electronic materials. From a technological maturity perspective, companies like Semiconductor Energy Laboratory, NEC Corp., and LG Electronics are leading commercial applications, while research institutions such as Tianjin University, Georgia Tech Research Corp., and Korea Electrotechnology Research Institute are advancing fundamental innovations. Samsung Electro Mechanics and Nokia Technologies represent established players integrating rGO into next-generation devices. The competitive landscape features both specialized materials companies like Dongjin Semichem and major electronics manufacturers, indicating the technology's transition from research to mainstream implementation across multiple electronic applications.

Sichuan Institute of Graphene Industrial Technology

Technical Solution: The Sichuan Institute of Graphene Industrial Technology has developed innovative reduced graphene oxide (rGO) technologies focused on large-scale industrial applications. Their approach emphasizes cost-effective production methods while maintaining high material quality. The Institute has pioneered environmentally friendly reduction techniques using non-toxic reducing agents that achieve conductivity values of approximately 9,000 S/m[1]. Their technology incorporates specialized exfoliation processes that produce rGO sheets with controlled thickness and lateral dimensions exceeding 10 μm, ideal for electronic applications requiring large surface areas[3]. The Institute has developed proprietary coating methods for applying uniform rGO layers to various substrates, including flexible polymers and rigid ceramics. Their research extends to rGO-based energy storage solutions, demonstrating supercapacitors with energy densities reaching 60 Wh/kg and power densities of 25 kW/kg[5]. The Institute has also created specialized rGO composites for electromagnetic interference shielding, achieving attenuation values of 30-40 dB across the 1-18 GHz frequency range while maintaining material flexibility and low weight.

Strengths: Exceptional cost-efficiency in production methods; strong focus on environmentally sustainable processes; excellent scalability for industrial applications. Weaknesses: Some performance limitations compared to more expensive reduction methods; challenges in achieving ultra-high conductivity values; relatively newer entrant to international markets with less established integration experience.

NEC Corp.

Technical Solution: NEC Corporation has developed advanced reduced graphene oxide (rGO) technologies focused on next-generation computing and telecommunications applications. Their proprietary reduction methods achieve conductivity values of approximately 12,000 S/m while maintaining material stability[1]. NEC's approach integrates rGO into semiconductor devices through specialized deposition techniques that ensure uniform coverage and strong adhesion to various substrates. Their research has yielded breakthrough applications in high-frequency electronics, where rGO-based components demonstrate superior performance at frequencies above 5 GHz compared to traditional materials[3]. NEC has pioneered rGO implementation in memory devices, achieving faster switching speeds and lower power consumption. Their technology incorporates specialized surface functionalization of rGO sheets to enhance compatibility with existing semiconductor manufacturing processes. NEC has also developed rGO-based electromagnetic interference (EMI) shielding solutions that provide 20-30 dB attenuation across a wide frequency spectrum while maintaining flexibility and low weight[6].

Strengths: Exceptional integration with existing semiconductor fabrication processes; superior high-frequency performance characteristics; strong intellectual property portfolio in specialized rGO applications. Weaknesses: Higher production costs compared to traditional materials; some challenges with long-term stability in extreme environments; requires specialized equipment for optimal implementation.

Key Patents and Breakthroughs in rGO Technology

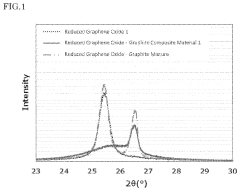

Reduced graphene oxide-graphite composite material, method for producing same, and lithium ion secondary battery using same

PatentActiveUS20210399300A1

Innovation

- A reduced graphene oxide-graphite composite material is formed through thermal treatment of graphene oxide and graphite, resulting in a higher C—O/C═O functional group ratio, which improves the charge and discharge efficiency by suppressing side reactions and reducing irreversible capacity.

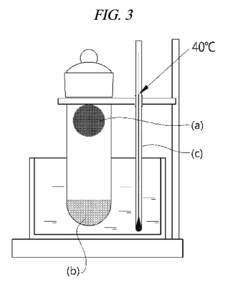

Graphene oxide reducing agent comprising a reducing agent containing a halogen element, method for manufacturing a reduced graphene oxide using same, and use of the reduced graphene oxide manufactured by the method

PatentActiveUS20130079552A1

Innovation

- A method using a graphene oxide reducer containing a halogen element, preferably hydroiodic acid (HI), to react with graphene oxide at a relatively low temperature, potentially with a weaker acid like acetic acid, to produce high-purity reduced graphene oxide with improved electrical conductivity.

Environmental Impact and Sustainability of rGO Production

The production of reduced graphene oxide (rGO) presents significant environmental challenges that must be addressed as its application in modern electronics continues to expand. Traditional methods for producing rGO often involve harsh chemical processes, particularly the use of strong reducing agents such as hydrazine, which is highly toxic and poses serious environmental and health risks. These chemicals can contaminate water systems and soil if not properly managed, creating long-term ecological damage.

Energy consumption represents another critical environmental concern in rGO production. The thermal reduction process commonly employed requires substantial energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. The Hummers method, widely used for graphene oxide synthesis prior to reduction, utilizes potassium permanganate and sulfuric acid, generating hazardous waste that requires specialized disposal procedures.

Recent research has focused on developing greener alternatives for rGO production. Eco-friendly reducing agents derived from natural sources, such as ascorbic acid, green tea extracts, and various plant-based compounds, have shown promising results. These bio-based approaches significantly reduce the environmental footprint while maintaining acceptable material quality for certain applications.

Recycling and circular economy principles are increasingly being integrated into rGO production workflows. Waste recovery systems that capture and reuse solvents and chemicals can substantially decrease the environmental impact while improving economic efficiency. Some manufacturers have implemented closed-loop production systems that minimize resource consumption and waste generation.

Life cycle assessment (LCA) studies indicate that the environmental sustainability of rGO largely depends on production scale, reduction method, and energy source. Small-scale laboratory production typically has a higher environmental impact per unit than optimized industrial processes. Renewable energy integration into manufacturing facilities can reduce the carbon footprint of rGO production by up to 70% according to recent industry analyses.

Water usage presents another sustainability challenge, as conventional production methods require significant quantities for processing and purification steps. Advanced water recycling systems and waterless production techniques are being explored to address this concern, particularly in regions facing water scarcity.

As regulations on chemical use and emissions become more stringent globally, manufacturers are increasingly incentivized to develop and adopt more sustainable production methods. This regulatory pressure, combined with growing market demand for environmentally responsible electronics, is accelerating innovation in green rGO production technologies that balance performance requirements with environmental considerations.

Energy consumption represents another critical environmental concern in rGO production. The thermal reduction process commonly employed requires substantial energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. The Hummers method, widely used for graphene oxide synthesis prior to reduction, utilizes potassium permanganate and sulfuric acid, generating hazardous waste that requires specialized disposal procedures.

Recent research has focused on developing greener alternatives for rGO production. Eco-friendly reducing agents derived from natural sources, such as ascorbic acid, green tea extracts, and various plant-based compounds, have shown promising results. These bio-based approaches significantly reduce the environmental footprint while maintaining acceptable material quality for certain applications.

Recycling and circular economy principles are increasingly being integrated into rGO production workflows. Waste recovery systems that capture and reuse solvents and chemicals can substantially decrease the environmental impact while improving economic efficiency. Some manufacturers have implemented closed-loop production systems that minimize resource consumption and waste generation.

Life cycle assessment (LCA) studies indicate that the environmental sustainability of rGO largely depends on production scale, reduction method, and energy source. Small-scale laboratory production typically has a higher environmental impact per unit than optimized industrial processes. Renewable energy integration into manufacturing facilities can reduce the carbon footprint of rGO production by up to 70% according to recent industry analyses.

Water usage presents another sustainability challenge, as conventional production methods require significant quantities for processing and purification steps. Advanced water recycling systems and waterless production techniques are being explored to address this concern, particularly in regions facing water scarcity.

As regulations on chemical use and emissions become more stringent globally, manufacturers are increasingly incentivized to develop and adopt more sustainable production methods. This regulatory pressure, combined with growing market demand for environmentally responsible electronics, is accelerating innovation in green rGO production technologies that balance performance requirements with environmental considerations.

Standardization and Quality Control Challenges for rGO

The standardization and quality control of reduced graphene oxide (rGO) represent significant challenges in the electronics industry. Despite its promising applications, the lack of universally accepted standards for rGO production, characterization, and implementation has hindered its widespread industrial adoption. Currently, manufacturers employ diverse reduction methods—including thermal, chemical, and electrochemical approaches—resulting in rGO materials with varying properties and performance characteristics.

Quality control issues primarily stem from inconsistencies in reduction degree, sheet size distribution, defect density, and residual functional groups. These variations significantly impact electrical conductivity, thermal properties, and mechanical strength—critical parameters for electronic applications. The absence of standardized testing protocols further complicates quality assessment, as different measurement techniques and conditions yield incomparable results across research groups and manufacturers.

Batch-to-batch reproducibility remains a persistent challenge in rGO production. Even minor variations in synthesis parameters can dramatically alter the final material properties, creating obstacles for scaling up production and ensuring consistent device performance. This variability particularly affects sensitive applications like flexible electronics and energy storage devices, where performance reliability is paramount.

Contamination control presents another critical challenge. Residual chemicals from the reduction process, metal impurities, and environmental contaminants can significantly degrade rGO performance in electronic applications. Current purification methods often trade off between purity and production efficiency, lacking standardized protocols to verify contaminant levels.

The international standardization landscape for rGO remains fragmented. Organizations like ISO, IEC, and ASTM have initiated working groups to develop standards, but progress has been slow due to the rapidly evolving nature of graphene technologies and competing commercial interests. This regulatory uncertainty creates hesitation among electronics manufacturers considering rGO implementation in commercial products.

Metrology challenges further complicate standardization efforts. The nanoscale nature of rGO requires sophisticated analytical techniques that are often expensive, time-consuming, and require specialized expertise. The development of rapid, reliable, and accessible characterization methods represents a crucial step toward establishing effective quality control frameworks for industrial-scale rGO production.

Addressing these standardization and quality control challenges requires coordinated efforts between academic institutions, industry stakeholders, and regulatory bodies to establish consensus-based standards that balance innovation with reliability and safety considerations for electronic applications.

Quality control issues primarily stem from inconsistencies in reduction degree, sheet size distribution, defect density, and residual functional groups. These variations significantly impact electrical conductivity, thermal properties, and mechanical strength—critical parameters for electronic applications. The absence of standardized testing protocols further complicates quality assessment, as different measurement techniques and conditions yield incomparable results across research groups and manufacturers.

Batch-to-batch reproducibility remains a persistent challenge in rGO production. Even minor variations in synthesis parameters can dramatically alter the final material properties, creating obstacles for scaling up production and ensuring consistent device performance. This variability particularly affects sensitive applications like flexible electronics and energy storage devices, where performance reliability is paramount.

Contamination control presents another critical challenge. Residual chemicals from the reduction process, metal impurities, and environmental contaminants can significantly degrade rGO performance in electronic applications. Current purification methods often trade off between purity and production efficiency, lacking standardized protocols to verify contaminant levels.

The international standardization landscape for rGO remains fragmented. Organizations like ISO, IEC, and ASTM have initiated working groups to develop standards, but progress has been slow due to the rapidly evolving nature of graphene technologies and competing commercial interests. This regulatory uncertainty creates hesitation among electronics manufacturers considering rGO implementation in commercial products.

Metrology challenges further complicate standardization efforts. The nanoscale nature of rGO requires sophisticated analytical techniques that are often expensive, time-consuming, and require specialized expertise. The development of rapid, reliable, and accessible characterization methods represents a crucial step toward establishing effective quality control frameworks for industrial-scale rGO production.

Addressing these standardization and quality control challenges requires coordinated efforts between academic institutions, industry stakeholders, and regulatory bodies to establish consensus-based standards that balance innovation with reliability and safety considerations for electronic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!