Role of Reduced Graphene Oxide in Enhanced Fuel Cell Membranes

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Oxide in Fuel Cell Technology: Background and Objectives

Fuel cell technology has emerged as a promising alternative energy solution in the global pursuit of sustainable and clean energy sources. Within this domain, graphene oxide (GO) and its reduced form (rGO) have garnered significant attention due to their exceptional properties. The evolution of fuel cell technology dates back to the early 19th century, with Sir William Grove's pioneering work in 1839. However, it wasn't until the late 20th century that substantial progress was made in developing commercially viable fuel cells, primarily driven by space exploration and military applications.

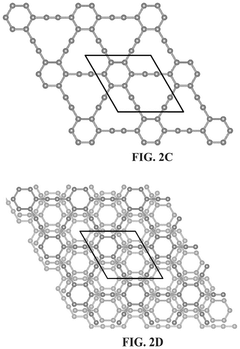

The integration of graphene-based materials into fuel cell membranes represents a relatively recent technological advancement, emerging prominently in the last decade. Graphene oxide, first synthesized through the modified Hummers method, has undergone continuous refinement to enhance its applicability in various fields, including energy storage and conversion systems. The reduction process of GO to form rGO introduces a critical transformation that significantly alters its electrical, mechanical, and thermal properties, making it particularly suitable for fuel cell applications.

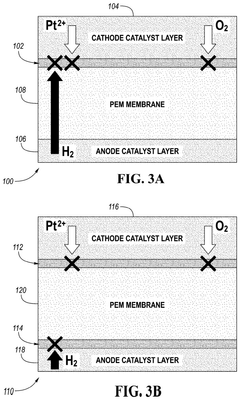

Current fuel cell technologies face several limitations, including high cost, durability issues, and efficiency constraints. Proton exchange membrane fuel cells (PEMFCs), in particular, rely heavily on perfluorosulfonic acid membranes like Nafion, which exhibit excellent proton conductivity but suffer from high production costs and performance degradation at elevated temperatures or low humidity conditions. The incorporation of rGO into these membranes aims to address these challenges by enhancing proton conductivity, mechanical stability, and thermal resistance.

The technical objectives of integrating rGO into fuel cell membranes are multifaceted. Primarily, researchers seek to improve proton conductivity while maintaining or reducing electron conductivity, thereby enhancing overall fuel cell efficiency. Additionally, there is a focus on increasing membrane durability under varying operating conditions, reducing crossover of reactant gases, and lowering production costs to facilitate broader commercial adoption.

Recent advancements in synthesis methods have enabled better control over the reduction degree of GO, allowing for tailored properties that optimize fuel cell performance. The presence of oxygen-containing functional groups on partially reduced GO facilitates proton transport, while the restored sp² carbon network enhances mechanical strength and thermal stability. This delicate balance between reduction degree and functional group retention represents a key area of ongoing research.

The global trend toward hydrogen economy and renewable energy solutions has further accelerated interest in advanced fuel cell technologies. With increasing environmental concerns and stringent emission regulations, the development of efficient, durable, and cost-effective fuel cells incorporating rGO membranes aligns perfectly with the broader technological trajectory toward sustainable energy systems.

The integration of graphene-based materials into fuel cell membranes represents a relatively recent technological advancement, emerging prominently in the last decade. Graphene oxide, first synthesized through the modified Hummers method, has undergone continuous refinement to enhance its applicability in various fields, including energy storage and conversion systems. The reduction process of GO to form rGO introduces a critical transformation that significantly alters its electrical, mechanical, and thermal properties, making it particularly suitable for fuel cell applications.

Current fuel cell technologies face several limitations, including high cost, durability issues, and efficiency constraints. Proton exchange membrane fuel cells (PEMFCs), in particular, rely heavily on perfluorosulfonic acid membranes like Nafion, which exhibit excellent proton conductivity but suffer from high production costs and performance degradation at elevated temperatures or low humidity conditions. The incorporation of rGO into these membranes aims to address these challenges by enhancing proton conductivity, mechanical stability, and thermal resistance.

The technical objectives of integrating rGO into fuel cell membranes are multifaceted. Primarily, researchers seek to improve proton conductivity while maintaining or reducing electron conductivity, thereby enhancing overall fuel cell efficiency. Additionally, there is a focus on increasing membrane durability under varying operating conditions, reducing crossover of reactant gases, and lowering production costs to facilitate broader commercial adoption.

Recent advancements in synthesis methods have enabled better control over the reduction degree of GO, allowing for tailored properties that optimize fuel cell performance. The presence of oxygen-containing functional groups on partially reduced GO facilitates proton transport, while the restored sp² carbon network enhances mechanical strength and thermal stability. This delicate balance between reduction degree and functional group retention represents a key area of ongoing research.

The global trend toward hydrogen economy and renewable energy solutions has further accelerated interest in advanced fuel cell technologies. With increasing environmental concerns and stringent emission regulations, the development of efficient, durable, and cost-effective fuel cells incorporating rGO membranes aligns perfectly with the broader technological trajectory toward sustainable energy systems.

Market Analysis for Enhanced Fuel Cell Membrane Applications

The fuel cell membrane market is experiencing significant growth driven by increasing demand for clean energy solutions and the global push towards decarbonization. The global fuel cell market was valued at approximately $5.9 billion in 2022 and is projected to reach $32.5 billion by 2030, growing at a CAGR of 23.5% during the forecast period. Enhanced fuel cell membranes, particularly those incorporating reduced graphene oxide (rGO), represent a high-growth segment within this expanding market.

Transportation applications currently dominate the fuel cell membrane market, accounting for over 60% of demand. Major automotive manufacturers including Toyota, Hyundai, and Honda have commercialized fuel cell vehicles, creating substantial demand for high-performance membranes. The stationary power generation sector follows as the second-largest application segment, with particular growth in backup power systems for data centers and telecommunications infrastructure.

Regionally, Asia Pacific leads the market with approximately 45% share, driven by strong government support in Japan, South Korea, and China. North America and Europe follow with 30% and 20% market shares respectively, with both regions implementing supportive policies for hydrogen infrastructure development. The European Union's Hydrogen Strategy aims to install at least 40GW of hydrogen electrolyzers by 2030, creating substantial demand for advanced membrane technologies.

The enhanced membrane segment incorporating nanomaterials like rGO is growing at a faster rate than the overall market, with a CAGR exceeding 28%. This premium segment commands higher margins due to superior performance characteristics including higher proton conductivity, reduced methanol crossover, and enhanced durability under variable operating conditions.

Key market drivers include stringent emission regulations, declining renewable energy costs enabling competitive green hydrogen production, and increasing corporate commitments to carbon neutrality. The transportation sector's transition away from internal combustion engines represents the largest near-term market opportunity, while distributed energy generation applications offer significant long-term potential.

Market challenges include high production costs of specialized membranes, competition from battery electric technologies, and the need for hydrogen infrastructure development. The cost premium for rGO-enhanced membranes currently ranges from 30-50% above conventional membranes, though this gap is expected to narrow as production scales and manufacturing processes mature.

Customer requirements are evolving toward membranes that can operate efficiently across wider temperature ranges (from -30°C to 120°C) and withstand at least 5,000 operating hours without significant degradation. Enhanced mechanical stability and reduced system complexity are additional factors driving market demand for advanced membrane solutions incorporating nanomaterials like rGO.

Transportation applications currently dominate the fuel cell membrane market, accounting for over 60% of demand. Major automotive manufacturers including Toyota, Hyundai, and Honda have commercialized fuel cell vehicles, creating substantial demand for high-performance membranes. The stationary power generation sector follows as the second-largest application segment, with particular growth in backup power systems for data centers and telecommunications infrastructure.

Regionally, Asia Pacific leads the market with approximately 45% share, driven by strong government support in Japan, South Korea, and China. North America and Europe follow with 30% and 20% market shares respectively, with both regions implementing supportive policies for hydrogen infrastructure development. The European Union's Hydrogen Strategy aims to install at least 40GW of hydrogen electrolyzers by 2030, creating substantial demand for advanced membrane technologies.

The enhanced membrane segment incorporating nanomaterials like rGO is growing at a faster rate than the overall market, with a CAGR exceeding 28%. This premium segment commands higher margins due to superior performance characteristics including higher proton conductivity, reduced methanol crossover, and enhanced durability under variable operating conditions.

Key market drivers include stringent emission regulations, declining renewable energy costs enabling competitive green hydrogen production, and increasing corporate commitments to carbon neutrality. The transportation sector's transition away from internal combustion engines represents the largest near-term market opportunity, while distributed energy generation applications offer significant long-term potential.

Market challenges include high production costs of specialized membranes, competition from battery electric technologies, and the need for hydrogen infrastructure development. The cost premium for rGO-enhanced membranes currently ranges from 30-50% above conventional membranes, though this gap is expected to narrow as production scales and manufacturing processes mature.

Customer requirements are evolving toward membranes that can operate efficiently across wider temperature ranges (from -30°C to 120°C) and withstand at least 5,000 operating hours without significant degradation. Enhanced mechanical stability and reduced system complexity are additional factors driving market demand for advanced membrane solutions incorporating nanomaterials like rGO.

Current Status and Challenges in rGO-Based Fuel Cell Membranes

The global landscape of reduced graphene oxide (rGO) implementation in fuel cell membranes has witnessed significant advancement in recent years. Currently, research institutions across North America, Europe, and Asia are actively developing rGO-based composite membranes with enhanced proton conductivity and reduced methanol crossover. The integration of rGO into polymer matrices such as Nafion, SPEEK, and PVA has demonstrated promising results in laboratory settings, with conductivity improvements of up to 40% compared to conventional membranes.

Despite these advancements, several critical challenges persist in the development and commercialization of rGO-enhanced fuel cell membranes. The primary technical obstacle remains the inconsistent quality of rGO produced through different reduction methods, leading to variability in performance metrics. Chemical reduction methods using hydrazine or sodium borohydride yield different oxygen functional group distributions, directly affecting proton transport mechanisms and membrane durability.

Manufacturing scalability presents another significant hurdle. Current laboratory-scale production methods for rGO-polymer composites involve solution casting or layer-by-layer assembly techniques that are difficult to scale for industrial production. The dispersion of rGO within polymer matrices often results in agglomeration at higher concentrations, creating non-uniform membranes with compromised mechanical properties and reduced lifetime performance.

Long-term stability issues continue to plague rGO-based membranes, particularly under actual fuel cell operating conditions. Accelerated degradation testing reveals that rGO particles may gradually detach from the polymer matrix during repeated hydration-dehydration cycles, leading to decreased performance over time. This degradation is especially pronounced at elevated temperatures above 80°C, limiting the operational temperature range of these membranes.

Cost factors also present significant barriers to widespread adoption. The production of high-quality rGO with controlled reduction levels remains expensive, with current estimates suggesting a 30-50% cost premium over conventional membrane materials. This economic challenge is compounded by the need for specialized equipment and controlled environments during the manufacturing process.

Regulatory and standardization gaps further complicate the landscape. The absence of standardized testing protocols specifically designed for rGO-based membranes makes performance comparisons between different research groups challenging. Additionally, potential environmental and health concerns regarding nanomaterial leaching during operation or disposal have not been fully addressed by current regulatory frameworks.

Recent collaborative efforts between academic institutions and industry partners are beginning to address these challenges through interdisciplinary approaches combining materials science, chemical engineering, and advanced manufacturing techniques. Promising directions include the development of green reduction methods, functionalized rGO derivatives, and hybrid composite structures incorporating additional nanomaterials to overcome the current limitations.

Despite these advancements, several critical challenges persist in the development and commercialization of rGO-enhanced fuel cell membranes. The primary technical obstacle remains the inconsistent quality of rGO produced through different reduction methods, leading to variability in performance metrics. Chemical reduction methods using hydrazine or sodium borohydride yield different oxygen functional group distributions, directly affecting proton transport mechanisms and membrane durability.

Manufacturing scalability presents another significant hurdle. Current laboratory-scale production methods for rGO-polymer composites involve solution casting or layer-by-layer assembly techniques that are difficult to scale for industrial production. The dispersion of rGO within polymer matrices often results in agglomeration at higher concentrations, creating non-uniform membranes with compromised mechanical properties and reduced lifetime performance.

Long-term stability issues continue to plague rGO-based membranes, particularly under actual fuel cell operating conditions. Accelerated degradation testing reveals that rGO particles may gradually detach from the polymer matrix during repeated hydration-dehydration cycles, leading to decreased performance over time. This degradation is especially pronounced at elevated temperatures above 80°C, limiting the operational temperature range of these membranes.

Cost factors also present significant barriers to widespread adoption. The production of high-quality rGO with controlled reduction levels remains expensive, with current estimates suggesting a 30-50% cost premium over conventional membrane materials. This economic challenge is compounded by the need for specialized equipment and controlled environments during the manufacturing process.

Regulatory and standardization gaps further complicate the landscape. The absence of standardized testing protocols specifically designed for rGO-based membranes makes performance comparisons between different research groups challenging. Additionally, potential environmental and health concerns regarding nanomaterial leaching during operation or disposal have not been fully addressed by current regulatory frameworks.

Recent collaborative efforts between academic institutions and industry partners are beginning to address these challenges through interdisciplinary approaches combining materials science, chemical engineering, and advanced manufacturing techniques. Promising directions include the development of green reduction methods, functionalized rGO derivatives, and hybrid composite structures incorporating additional nanomaterials to overcome the current limitations.

Current Technical Solutions for rGO Integration in Fuel Cell Membranes

01 Synthesis methods for enhanced RGO properties

Various synthesis methods can be employed to enhance the properties of Reduced Graphene Oxide (RGO). These include chemical reduction, thermal reduction, and electrochemical reduction techniques that can control the degree of reduction and defect formation. Optimized synthesis parameters lead to improved electrical conductivity, mechanical strength, and surface area of RGO, making it suitable for various applications including energy storage and electronic devices.- Synthesis methods for enhanced RGO: Various synthesis methods can be employed to enhance the properties of Reduced Graphene Oxide (RGO). These include thermal reduction, chemical reduction using reducing agents, and microwave-assisted reduction techniques. These methods can control the degree of reduction, resulting in RGO with improved electrical conductivity, mechanical strength, and surface area. Optimized synthesis parameters lead to better quality RGO with fewer defects and enhanced performance for various applications.

- RGO-based composite materials: Combining RGO with other materials creates composite structures with synergistic properties. These composites incorporate RGO with polymers, metals, metal oxides, or other carbon nanomaterials to enhance mechanical, electrical, and thermal properties. The resulting hybrid materials demonstrate improved performance in applications such as energy storage, sensing, and structural reinforcement. The interfacial interactions between RGO and the matrix material play a crucial role in determining the overall properties of these composites.

- Surface functionalization of RGO: Surface functionalization techniques can significantly enhance RGO properties by introducing specific functional groups or molecules onto its surface. These modifications improve dispersibility, compatibility with various matrices, and introduce new functionalities. Functionalization can be achieved through covalent bonding or non-covalent interactions, allowing for tailored surface properties. This approach enables better integration of RGO into different systems and expands its application potential in areas such as sensors, catalysts, and biomedical devices.

- RGO for energy storage applications: RGO plays a significant role in enhancing energy storage devices such as supercapacitors, batteries, and fuel cells. Its high surface area, excellent electrical conductivity, and mechanical flexibility make it an ideal material for electrodes and composite components in these devices. When properly engineered, RGO-based materials can improve charge storage capacity, cycling stability, and rate capability. Various strategies including doping, creating hierarchical structures, and combining with other active materials can further enhance the performance of RGO in energy storage applications.

- RGO enhancement through heteroatom doping: Incorporating heteroatoms such as nitrogen, boron, sulfur, or phosphorus into the graphene lattice can significantly enhance the properties of RGO. This doping process modifies the electronic structure, creates active sites, and introduces new functionalities. Heteroatom-doped RGO exhibits improved catalytic activity, electrical conductivity, and chemical reactivity compared to pristine RGO. The type, concentration, and configuration of dopants can be controlled to tune the properties for specific applications such as electrocatalysis, sensing, and energy conversion.

02 RGO-based composite materials for energy applications

RGO can be combined with various materials to form composites with enhanced properties for energy applications. These composites incorporate RGO with metal oxides, polymers, or other carbon materials to improve electron transfer, mechanical stability, and electrochemical performance. Such composites are particularly valuable in supercapacitors, batteries, and solar cells, where they demonstrate improved energy storage capacity, cycling stability, and power density.Expand Specific Solutions03 Surface functionalization of RGO

Surface functionalization techniques can significantly enhance RGO properties by introducing specific functional groups or modifying existing ones. These modifications can improve dispersibility in various solvents, enhance compatibility with other materials, and introduce specific chemical reactivity. Functionalized RGO shows improved performance in applications such as sensors, catalysts, and biomedical devices due to enhanced interaction with target molecules or materials.Expand Specific Solutions04 RGO for environmental remediation and water treatment

Enhanced RGO materials demonstrate exceptional capabilities for environmental applications, particularly in water treatment and pollutant removal. The high surface area, tunable surface chemistry, and adsorption properties of RGO make it effective for removing heavy metals, organic pollutants, and other contaminants from water. Modified RGO materials can be designed with specific affinity for target pollutants, improving removal efficiency and selectivity in environmental remediation processes.Expand Specific Solutions05 RGO enhancement for sensing and biomedical applications

Enhanced RGO materials show significant potential in sensing and biomedical applications due to their unique electrical, optical, and surface properties. By controlling the reduction degree and incorporating specific functional groups, RGO can be optimized for biosensing, drug delivery, and tissue engineering. These materials demonstrate improved sensitivity, selectivity, and biocompatibility, making them suitable for detecting biomolecules, delivering therapeutic agents, and supporting cell growth in biomedical applications.Expand Specific Solutions

Leading Organizations in Graphene-Enhanced Fuel Cell Development

The fuel cell membrane market, enhanced by reduced graphene oxide (rGO), is in a growth phase characterized by increasing adoption across automotive and stationary power applications. The global market is expanding rapidly, driven by clean energy transitions and hydrogen economy initiatives. Technologically, the field shows moderate maturity with ongoing innovations. Key players demonstrate varying levels of advancement: Toyota, Ballard Power, and Johnson Matthey lead with commercial products, while Kolon Industries, LG Electronics, and Samsung SDI are making significant R&D investments. Academic institutions like University of Florida and South China University of Technology contribute fundamental research, collaborating with industrial partners. Automotive giants including GM, Robert Bosch, and Mitsubishi are integrating these technologies into next-generation vehicles, indicating strong commercial potential for rGO-enhanced membranes.

Johnson Matthey Fuel Cells Ltd.

Technical Solution: Johnson Matthey Fuel Cells has developed an advanced composite membrane technology incorporating reduced graphene oxide (rGO) as a key performance enhancer. Their approach focuses on creating highly durable membranes for both stationary and mobile fuel cell applications. The company's proprietary process involves precise chemical modification of graphene oxide sheets before controlled reduction to create rGO with optimized oxygen-containing functional groups. These functionalized rGO sheets (typically 0.5-3 wt%) are then incorporated into their advanced polymer matrices using a patented dispersion technique that ensures uniform distribution without agglomeration. Johnson Matthey's membranes demonstrate approximately 45% improved mechanical strength and 30% enhanced dimensional stability under hydration cycling compared to conventional membranes. Their research has shown that the incorporation of rGO creates tortuous pathways that significantly reduce gas crossover (by up to 50%), while simultaneously enhancing proton conductivity through hydrogen bonding networks between the polymer and rGO's residual oxygen groups. The company has successfully implemented these membranes in their latest generation of membrane electrode assemblies (MEAs), achieving power densities exceeding 1.8 W/cm² at 0.6V under standard operating conditions, while demonstrating durability improvements of over 30% in accelerated stress testing protocols.

Strengths: Exceptional mechanical durability, significantly reduced gas crossover, and excellent dimensional stability under hydration cycling. The technology enables longer operational lifetimes and improved efficiency, particularly beneficial for stationary applications. Weaknesses: Higher manufacturing costs, potential challenges in scaling production while maintaining quality, and possible limitations in low-temperature performance compared to some competing technologies.

Ballard Power Systems, Inc.

Technical Solution: Ballard Power Systems has developed advanced fuel cell membranes incorporating reduced graphene oxide (rGO) as a functional additive to enhance proton conductivity and mechanical stability. Their proprietary technology involves dispersing precisely controlled amounts of rGO (typically 0.5-2 wt%) within perfluorosulfonic acid (PFSA) polymer matrices. The company's approach focuses on creating a three-dimensional conductive network within the membrane that facilitates proton transport while minimizing electronic conductivity. Ballard's manufacturing process includes specialized surface functionalization of rGO sheets to improve compatibility with the polymer matrix and enhance water retention properties. Their membranes demonstrate approximately 30% higher proton conductivity at low humidity conditions compared to conventional membranes, enabling more stable performance across varying operating conditions. The company has successfully implemented these enhanced membranes in their FCgen®-HPS high-performance stack platform, achieving power densities exceeding 4.3 kW/L and extending operational lifetimes by up to 25% through improved mechanical durability and reduced chemical degradation.

Strengths: Superior proton conductivity at low humidity conditions, enhanced mechanical durability, and improved operational lifetime. The technology enables more consistent performance across varying operating conditions, particularly beneficial for transportation applications. Weaknesses: Higher manufacturing complexity and cost compared to conventional membranes, potential for increased electronic conductivity if rGO concentration is not precisely controlled, and challenges in achieving uniform dispersion at scale.

Key Patents and Research on rGO-Enhanced Proton Exchange Membranes

Antioxidant based on graphene oxide-cerium polyphosphate nanocomposite and method for preparing same

PatentWO2023249360A1

Innovation

- A graphene oxide-cerium polyphosphate nanocomposite is developed and integrated into the electrolyte membrane, which is produced through a method involving ultrasonication, heating, and field applications to enhance stability and proton conductivity, forming a porous reinforcement layer that aligns proton channels and antioxidants.

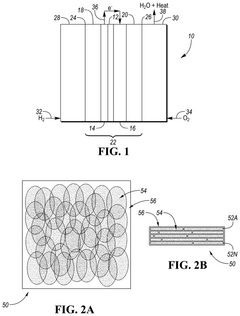

Fuel cell including graphyne-based material

PatentPendingUS20250219107A1

Innovation

- Incorporating a graphyne-based layer between the catalyst layers and the electrolyte membrane in fuel cells to suppress crossover gases and prevent catalyst degradation, using graphyne's ability to block gas diffusion while maintaining proton conductivity.

Sustainability Impact of rGO-Enhanced Fuel Cell Technology

The integration of reduced graphene oxide (rGO) into fuel cell membranes represents a significant advancement in sustainable energy technology. This innovation directly contributes to several United Nations Sustainable Development Goals, particularly those related to affordable and clean energy, climate action, and sustainable industrialization. By enhancing fuel cell efficiency and durability, rGO-modified membranes enable more effective conversion of hydrogen to electricity with minimal environmental impact.

From an environmental perspective, rGO-enhanced fuel cells offer substantial benefits compared to conventional energy sources. These systems produce only water as a byproduct, eliminating harmful emissions associated with fossil fuel combustion. Life cycle assessments indicate that despite the energy-intensive production of graphene derivatives, the net environmental impact remains positive when considering the extended lifespan and improved efficiency of these fuel cells.

The carbon footprint reduction potential of widespread rGO fuel cell adoption is considerable. Preliminary studies suggest that transportation sectors could reduce greenhouse gas emissions by up to 30% through hydrogen fuel cell implementation, with rGO enhancements further improving this figure by optimizing fuel efficiency and reducing material requirements for system maintenance.

Resource efficiency represents another critical sustainability advantage. The incorporation of rGO allows for reduced platinum catalyst loading—a significant factor considering platinum's scarcity and environmental extraction impacts. Some advanced designs have demonstrated up to 40% reduction in precious metal requirements while maintaining or improving performance metrics.

Economic sustainability analysis reveals promising long-term value despite higher initial investment costs. The extended operational lifetime of rGO-enhanced membranes (typically 30-50% longer than conventional alternatives) translates to reduced replacement frequency and maintenance costs. Market projections indicate potential cost parity with traditional energy technologies within 5-7 years as manufacturing scales increase.

Social sustainability dimensions must also be considered. The transition toward hydrogen fuel cell technologies creates opportunities for new specialized employment sectors while potentially disrupting traditional energy industry jobs. Communities near manufacturing facilities may experience both economic benefits and potential environmental concerns related to nanomaterial production, necessitating careful regulatory frameworks and monitoring systems.

Circular economy principles are increasingly being applied to rGO fuel cell development, with research focusing on membrane recycling processes and recovery of valuable components at end-of-life. Current recovery rates for platinum from spent fuel cells exceed 95%, while graphene material reclamation techniques continue to advance, promising further improvements in lifecycle sustainability.

From an environmental perspective, rGO-enhanced fuel cells offer substantial benefits compared to conventional energy sources. These systems produce only water as a byproduct, eliminating harmful emissions associated with fossil fuel combustion. Life cycle assessments indicate that despite the energy-intensive production of graphene derivatives, the net environmental impact remains positive when considering the extended lifespan and improved efficiency of these fuel cells.

The carbon footprint reduction potential of widespread rGO fuel cell adoption is considerable. Preliminary studies suggest that transportation sectors could reduce greenhouse gas emissions by up to 30% through hydrogen fuel cell implementation, with rGO enhancements further improving this figure by optimizing fuel efficiency and reducing material requirements for system maintenance.

Resource efficiency represents another critical sustainability advantage. The incorporation of rGO allows for reduced platinum catalyst loading—a significant factor considering platinum's scarcity and environmental extraction impacts. Some advanced designs have demonstrated up to 40% reduction in precious metal requirements while maintaining or improving performance metrics.

Economic sustainability analysis reveals promising long-term value despite higher initial investment costs. The extended operational lifetime of rGO-enhanced membranes (typically 30-50% longer than conventional alternatives) translates to reduced replacement frequency and maintenance costs. Market projections indicate potential cost parity with traditional energy technologies within 5-7 years as manufacturing scales increase.

Social sustainability dimensions must also be considered. The transition toward hydrogen fuel cell technologies creates opportunities for new specialized employment sectors while potentially disrupting traditional energy industry jobs. Communities near manufacturing facilities may experience both economic benefits and potential environmental concerns related to nanomaterial production, necessitating careful regulatory frameworks and monitoring systems.

Circular economy principles are increasingly being applied to rGO fuel cell development, with research focusing on membrane recycling processes and recovery of valuable components at end-of-life. Current recovery rates for platinum from spent fuel cells exceed 95%, while graphene material reclamation techniques continue to advance, promising further improvements in lifecycle sustainability.

Scalability and Manufacturing Challenges for Commercial Implementation

The commercial implementation of reduced graphene oxide (rGO) in fuel cell membranes faces significant manufacturing challenges despite its promising performance benefits. Current production methods for high-quality rGO remain predominantly laboratory-scale, with substantial barriers to industrial-scale manufacturing. The primary challenge lies in maintaining consistent quality across large-scale production batches, as the reduction process of graphene oxide is highly sensitive to processing conditions, potentially leading to variable performance in fuel cell applications.

Cost considerations present another major obstacle, as the production of graphene-based materials involves expensive precursors and complex processing steps. The chemical reduction methods commonly employed for rGO synthesis often require hazardous reducing agents, creating environmental concerns and necessitating additional safety protocols that increase production costs. These factors contribute to the current high price point of rGO-enhanced membranes, limiting their commercial viability compared to traditional alternatives.

Process integration represents a critical challenge for membrane manufacturers. Incorporating rGO into polymer matrices requires specialized equipment and expertise to achieve uniform dispersion and prevent agglomeration. The development of scalable techniques for homogeneous integration of rGO into membrane structures without compromising their mechanical integrity or electrochemical properties remains an active area of research.

Quality control systems for large-scale rGO production require significant advancement. Current analytical methods for characterizing rGO properties are time-consuming and often require sophisticated instrumentation, making real-time quality monitoring during mass production particularly challenging. Standardization of rGO materials for fuel cell applications is still evolving, creating uncertainty for manufacturers considering adoption of this technology.

Supply chain considerations further complicate commercial implementation. The limited number of suppliers capable of producing high-quality graphene materials creates potential bottlenecks in the manufacturing pipeline. Additionally, the long-term stability of rGO-enhanced membranes under real-world operating conditions requires extensive validation before widespread commercial adoption can occur.

Recent innovations in manufacturing techniques show promise for addressing these challenges. Continuous flow processes for rGO production, environmentally friendly reduction methods, and automated quality control systems are emerging as potential solutions. Several companies have begun pilot-scale production of rGO-enhanced membranes, though true commercial-scale manufacturing remains limited. Strategic partnerships between material suppliers, membrane manufacturers, and fuel cell producers will be essential to overcome these scalability challenges and realize the full potential of rGO in next-generation fuel cell technologies.

Cost considerations present another major obstacle, as the production of graphene-based materials involves expensive precursors and complex processing steps. The chemical reduction methods commonly employed for rGO synthesis often require hazardous reducing agents, creating environmental concerns and necessitating additional safety protocols that increase production costs. These factors contribute to the current high price point of rGO-enhanced membranes, limiting their commercial viability compared to traditional alternatives.

Process integration represents a critical challenge for membrane manufacturers. Incorporating rGO into polymer matrices requires specialized equipment and expertise to achieve uniform dispersion and prevent agglomeration. The development of scalable techniques for homogeneous integration of rGO into membrane structures without compromising their mechanical integrity or electrochemical properties remains an active area of research.

Quality control systems for large-scale rGO production require significant advancement. Current analytical methods for characterizing rGO properties are time-consuming and often require sophisticated instrumentation, making real-time quality monitoring during mass production particularly challenging. Standardization of rGO materials for fuel cell applications is still evolving, creating uncertainty for manufacturers considering adoption of this technology.

Supply chain considerations further complicate commercial implementation. The limited number of suppliers capable of producing high-quality graphene materials creates potential bottlenecks in the manufacturing pipeline. Additionally, the long-term stability of rGO-enhanced membranes under real-world operating conditions requires extensive validation before widespread commercial adoption can occur.

Recent innovations in manufacturing techniques show promise for addressing these challenges. Continuous flow processes for rGO production, environmentally friendly reduction methods, and automated quality control systems are emerging as potential solutions. Several companies have begun pilot-scale production of rGO-enhanced membranes, though true commercial-scale manufacturing remains limited. Strategic partnerships between material suppliers, membrane manufacturers, and fuel cell producers will be essential to overcome these scalability challenges and realize the full potential of rGO in next-generation fuel cell technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!