Investigating Reduced Graphene Oxide's Role in Electrolyte Systems

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

rGO Electrolyte Technology Background and Objectives

Reduced Graphene Oxide (rGO) has emerged as a revolutionary material in the field of energy storage and conversion systems over the past decade. This carbon-based nanomaterial, derived from graphene oxide through various reduction processes, exhibits exceptional electrical conductivity, large surface area, and remarkable mechanical properties. The evolution of rGO technology can be traced back to the groundbreaking isolation of graphene in 2004, which subsequently led to intensive research on graphene derivatives, including rGO, for various applications.

The electrolyte system represents a critical component in energy storage devices such as batteries, supercapacitors, and fuel cells, directly influencing their performance metrics including energy density, power density, cycle life, and safety characteristics. Traditional electrolyte systems face significant limitations in terms of ionic conductivity, electrochemical stability, and interfacial compatibility with electrodes, creating a technological bottleneck in advancing energy storage capabilities.

Recent technological trends indicate a growing interest in incorporating nanomaterials, particularly rGO, into electrolyte formulations to address these limitations. The integration of rGO into electrolyte systems has demonstrated potential for enhancing ionic conductivity, improving electrode-electrolyte interfacial properties, and extending the electrochemical stability window of the resulting composite electrolytes.

The primary objective of this investigation is to comprehensively evaluate the role of rGO in electrolyte systems across various energy storage technologies. Specifically, we aim to understand the fundamental mechanisms by which rGO influences electrolyte properties, including ionic transport phenomena, electrochemical stability, and interfacial dynamics. Additionally, we seek to identify optimal synthesis methods, functionalization strategies, and integration approaches for rGO in different electrolyte matrices.

Furthermore, this research endeavors to establish quantitative relationships between rGO structural characteristics (such as reduction degree, defect density, and functional group distribution) and the resulting electrolyte performance metrics. By elucidating these structure-property relationships, we aim to develop design principles for rGO-enhanced electrolyte systems tailored for specific energy storage applications.

The long-term technological goal is to develop next-generation electrolyte systems incorporating precisely engineered rGO components that can significantly outperform conventional electrolytes in terms of ionic conductivity, electrochemical stability, and compatibility with high-energy electrode materials. Such advancements would directly address current limitations in energy storage technologies, potentially enabling breakthroughs in electric vehicles, renewable energy integration, and portable electronics sectors.

The electrolyte system represents a critical component in energy storage devices such as batteries, supercapacitors, and fuel cells, directly influencing their performance metrics including energy density, power density, cycle life, and safety characteristics. Traditional electrolyte systems face significant limitations in terms of ionic conductivity, electrochemical stability, and interfacial compatibility with electrodes, creating a technological bottleneck in advancing energy storage capabilities.

Recent technological trends indicate a growing interest in incorporating nanomaterials, particularly rGO, into electrolyte formulations to address these limitations. The integration of rGO into electrolyte systems has demonstrated potential for enhancing ionic conductivity, improving electrode-electrolyte interfacial properties, and extending the electrochemical stability window of the resulting composite electrolytes.

The primary objective of this investigation is to comprehensively evaluate the role of rGO in electrolyte systems across various energy storage technologies. Specifically, we aim to understand the fundamental mechanisms by which rGO influences electrolyte properties, including ionic transport phenomena, electrochemical stability, and interfacial dynamics. Additionally, we seek to identify optimal synthesis methods, functionalization strategies, and integration approaches for rGO in different electrolyte matrices.

Furthermore, this research endeavors to establish quantitative relationships between rGO structural characteristics (such as reduction degree, defect density, and functional group distribution) and the resulting electrolyte performance metrics. By elucidating these structure-property relationships, we aim to develop design principles for rGO-enhanced electrolyte systems tailored for specific energy storage applications.

The long-term technological goal is to develop next-generation electrolyte systems incorporating precisely engineered rGO components that can significantly outperform conventional electrolytes in terms of ionic conductivity, electrochemical stability, and compatibility with high-energy electrode materials. Such advancements would directly address current limitations in energy storage technologies, potentially enabling breakthroughs in electric vehicles, renewable energy integration, and portable electronics sectors.

Market Analysis for rGO-Enhanced Electrolyte Systems

The global market for electrolyte systems enhanced with reduced graphene oxide (rGO) is experiencing significant growth, driven by the expanding energy storage sector. The market value for advanced electrolyte systems reached approximately $5.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.3% through 2028, with rGO-enhanced solutions representing an increasingly important segment.

Battery manufacturers constitute the largest demand segment, accounting for nearly 43% of the market. The electric vehicle industry's rapid expansion has created substantial pull for high-performance electrolyte systems that can deliver improved energy density, faster charging capabilities, and enhanced cycle life—all benefits that rGO integration can potentially provide. Major automotive manufacturers have increased R&D investments in this technology by an average of 15% annually since 2020.

Consumer electronics represents the second-largest market segment at 27%, where the demand for longer-lasting, faster-charging batteries continues to drive innovation in electrolyte formulations. The integration of rGO into these systems has demonstrated up to 30% improvements in charge/discharge rates in laboratory settings, creating significant commercial interest.

Geographically, Asia-Pacific dominates the market with a 52% share, led by China, Japan, and South Korea, where major battery manufacturers have established production facilities. North America follows at 24%, with Europe at 19%. Both regions are showing accelerated growth rates as they invest heavily in domestic battery production capabilities to reduce dependence on Asian suppliers.

Market analysis indicates several key demand drivers for rGO-enhanced electrolyte systems. Performance improvements rank highest, with customers willing to pay a premium of 15-20% for electrolytes that deliver verified enhancements in conductivity and stability. Cost reduction potential ranks second, as the integration of rGO can potentially reduce the need for other expensive additives in certain applications.

Supply chain considerations are increasingly important, with 68% of surveyed manufacturers citing concerns about graphene material availability and quality consistency. This has led to vertical integration efforts by several major players who are securing dedicated graphene oxide production capabilities.

Customer adoption barriers include concerns about long-term stability (cited by 57% of potential industrial users), scalability of production processes (42%), and regulatory uncertainties regarding nanomaterials in commercial products (38%). These factors are currently limiting market penetration in certain high-volume applications despite the promising technical performance.

Battery manufacturers constitute the largest demand segment, accounting for nearly 43% of the market. The electric vehicle industry's rapid expansion has created substantial pull for high-performance electrolyte systems that can deliver improved energy density, faster charging capabilities, and enhanced cycle life—all benefits that rGO integration can potentially provide. Major automotive manufacturers have increased R&D investments in this technology by an average of 15% annually since 2020.

Consumer electronics represents the second-largest market segment at 27%, where the demand for longer-lasting, faster-charging batteries continues to drive innovation in electrolyte formulations. The integration of rGO into these systems has demonstrated up to 30% improvements in charge/discharge rates in laboratory settings, creating significant commercial interest.

Geographically, Asia-Pacific dominates the market with a 52% share, led by China, Japan, and South Korea, where major battery manufacturers have established production facilities. North America follows at 24%, with Europe at 19%. Both regions are showing accelerated growth rates as they invest heavily in domestic battery production capabilities to reduce dependence on Asian suppliers.

Market analysis indicates several key demand drivers for rGO-enhanced electrolyte systems. Performance improvements rank highest, with customers willing to pay a premium of 15-20% for electrolytes that deliver verified enhancements in conductivity and stability. Cost reduction potential ranks second, as the integration of rGO can potentially reduce the need for other expensive additives in certain applications.

Supply chain considerations are increasingly important, with 68% of surveyed manufacturers citing concerns about graphene material availability and quality consistency. This has led to vertical integration efforts by several major players who are securing dedicated graphene oxide production capabilities.

Customer adoption barriers include concerns about long-term stability (cited by 57% of potential industrial users), scalability of production processes (42%), and regulatory uncertainties regarding nanomaterials in commercial products (38%). These factors are currently limiting market penetration in certain high-volume applications despite the promising technical performance.

Current Challenges in rGO Electrolyte Development

Despite significant advancements in reduced graphene oxide (rGO) electrolyte systems, several critical challenges continue to impede their widespread commercial adoption. The primary obstacle remains the scalable and cost-effective production of high-quality rGO with consistent properties. Current reduction methods—chemical, thermal, and electrochemical—each present trade-offs between efficiency, environmental impact, and the quality of the resulting material. Chemical reduction often introduces impurities that compromise electrolyte performance, while thermal methods, though cleaner, require substantial energy input and may cause structural defects.

The heterogeneity of rGO batches presents another significant challenge. Variations in oxygen content, defect density, and sheet size directly impact ionic conductivity and electrochemical stability in electrolyte applications. This inconsistency makes standardization difficult and hampers reproducibility in research and manufacturing settings. Furthermore, the relationship between rGO's structural characteristics and its electrochemical properties remains incompletely understood, complicating rational design approaches.

Interface engineering between rGO and electrolyte components represents a complex challenge. The surface chemistry of rGO significantly influences ion transport mechanisms, yet controlling these interactions precisely during fabrication remains difficult. Researchers continue to struggle with optimizing the balance between hydrophilicity and hydrophobicity needed for different electrolyte applications, particularly in aqueous versus non-aqueous systems.

Long-term stability issues persist in rGO-based electrolytes. Under extended cycling or extreme operating conditions, rGO may undergo restacking, which reduces effective surface area and diminishes performance. Chemical degradation pathways, particularly in the presence of certain solvents or at elevated temperatures, have not been fully characterized, creating uncertainty about service lifetimes in practical applications.

Environmental and safety concerns also present significant hurdles. Some reduction processes employ hazardous chemicals like hydrazine, raising toxicity concerns. Additionally, the potential for nanoparticle release during manufacturing or from wear during operation requires careful assessment before widespread implementation.

Integration challenges exist when incorporating rGO into existing electrolyte systems and manufacturing processes. Compatibility with current production equipment and methodologies remains limited, requiring substantial investment in new infrastructure or process development. The viscosity and dispersion properties of rGO-containing formulations often necessitate specialized handling techniques not common in conventional electrolyte production.

Regulatory uncertainty compounds these technical challenges. The novel nature of graphene-based materials means that regulatory frameworks for their use in commercial products, especially in sensitive applications like energy storage or biomedical devices, remain underdeveloped in many regions, creating market entry barriers.

The heterogeneity of rGO batches presents another significant challenge. Variations in oxygen content, defect density, and sheet size directly impact ionic conductivity and electrochemical stability in electrolyte applications. This inconsistency makes standardization difficult and hampers reproducibility in research and manufacturing settings. Furthermore, the relationship between rGO's structural characteristics and its electrochemical properties remains incompletely understood, complicating rational design approaches.

Interface engineering between rGO and electrolyte components represents a complex challenge. The surface chemistry of rGO significantly influences ion transport mechanisms, yet controlling these interactions precisely during fabrication remains difficult. Researchers continue to struggle with optimizing the balance between hydrophilicity and hydrophobicity needed for different electrolyte applications, particularly in aqueous versus non-aqueous systems.

Long-term stability issues persist in rGO-based electrolytes. Under extended cycling or extreme operating conditions, rGO may undergo restacking, which reduces effective surface area and diminishes performance. Chemical degradation pathways, particularly in the presence of certain solvents or at elevated temperatures, have not been fully characterized, creating uncertainty about service lifetimes in practical applications.

Environmental and safety concerns also present significant hurdles. Some reduction processes employ hazardous chemicals like hydrazine, raising toxicity concerns. Additionally, the potential for nanoparticle release during manufacturing or from wear during operation requires careful assessment before widespread implementation.

Integration challenges exist when incorporating rGO into existing electrolyte systems and manufacturing processes. Compatibility with current production equipment and methodologies remains limited, requiring substantial investment in new infrastructure or process development. The viscosity and dispersion properties of rGO-containing formulations often necessitate specialized handling techniques not common in conventional electrolyte production.

Regulatory uncertainty compounds these technical challenges. The novel nature of graphene-based materials means that regulatory frameworks for their use in commercial products, especially in sensitive applications like energy storage or biomedical devices, remain underdeveloped in many regions, creating market entry barriers.

Current rGO Integration Methods for Electrolyte Systems

01 Synthesis methods for reduced graphene oxide (rGO)

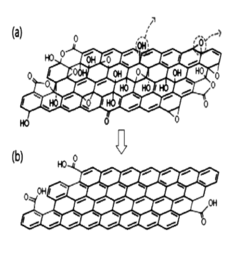

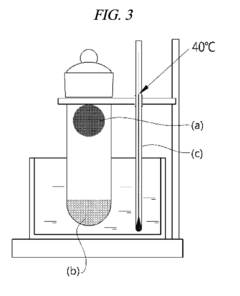

Various methods for synthesizing reduced graphene oxide (rGO) from graphene oxide (GO) are disclosed. These methods include chemical reduction using reducing agents, thermal reduction at elevated temperatures, electrochemical reduction, and photocatalytic reduction. The synthesis methods aim to efficiently remove oxygen-containing functional groups from GO while maintaining the structural integrity of the graphene sheets, resulting in rGO with improved electrical conductivity and mechanical properties.- Methods for producing reduced graphene oxide: Various methods can be employed to produce reduced graphene oxide (rGO) from graphene oxide. These methods include chemical reduction using reducing agents, thermal reduction at elevated temperatures, and electrochemical reduction processes. The reduction process removes oxygen-containing functional groups from graphene oxide, restoring the sp2 carbon network and enhancing electrical conductivity. Different reduction methods yield rGO with varying degrees of reduction and properties suitable for specific applications.

- Applications of rGO in energy storage devices: Reduced graphene oxide is widely used in energy storage applications due to its excellent electrical conductivity, large surface area, and mechanical stability. It serves as an electrode material in supercapacitors, lithium-ion batteries, and other energy storage devices. When incorporated into these devices, rGO enhances charge transport, increases energy density, and improves cycling stability. The combination of rGO with other materials creates composite electrodes with superior electrochemical performance.

- rGO-based composite materials: Reduced graphene oxide can be combined with various materials to form composites with enhanced properties. These composites incorporate metals, metal oxides, polymers, or other carbon materials with rGO to create materials with improved mechanical, electrical, thermal, or catalytic properties. The synergistic effects between rGO and the other components result in materials suitable for applications ranging from electronics to environmental remediation. The preparation methods for these composites include solution mixing, in-situ reduction, and hydrothermal processes.

- Sensing and detection applications of rGO: Reduced graphene oxide exhibits properties that make it excellent for sensing and detection applications. Its large surface area, electrical conductivity, and ability to be functionalized allow for the development of highly sensitive sensors for gases, biomolecules, and environmental pollutants. rGO-based sensors can detect changes in electrical properties upon interaction with target analytes, providing rapid and sensitive detection. These sensors offer advantages including room-temperature operation, low detection limits, and the potential for miniaturization.

- Environmental applications of rGO: Reduced graphene oxide has significant applications in environmental remediation and protection. It can be used as an adsorbent for removing heavy metals, organic pollutants, and other contaminants from water due to its large surface area and abundant functional groups. rGO-based materials also show promise in photocatalytic degradation of pollutants, water purification systems, and as components in environmental sensors. The surface properties of rGO can be tailored to enhance its affinity for specific contaminants, improving its effectiveness in environmental applications.

02 rGO-based electrode materials for energy storage applications

Reduced graphene oxide (rGO) is utilized as an electrode material in various energy storage devices such as supercapacitors, lithium-ion batteries, and fuel cells. The high surface area, excellent electrical conductivity, and mechanical flexibility of rGO make it an ideal candidate for electrode applications. rGO can be combined with other materials like metal oxides or conductive polymers to create composite electrodes with enhanced performance characteristics, including improved energy density, power density, and cycle stability.Expand Specific Solutions03 rGO-based composites and nanocomposites

Reduced graphene oxide (rGO) can be incorporated into various matrices to form composites and nanocomposites with enhanced properties. These composites combine the excellent electrical, thermal, and mechanical properties of rGO with the characteristics of the matrix material. Applications include polymer composites with improved mechanical strength and electrical conductivity, metal-rGO composites for enhanced thermal management, and ceramic-rGO composites with improved fracture toughness. The dispersion and interfacial bonding between rGO and the matrix material are critical factors affecting the performance of these composites.Expand Specific Solutions04 rGO-based sensors and detection devices

Reduced graphene oxide (rGO) is employed in the development of highly sensitive sensors and detection devices. The unique electrical properties of rGO, including its high conductivity and large surface area, make it suitable for detecting various analytes such as gases, biomolecules, and environmental pollutants. rGO-based sensors exhibit high sensitivity, fast response times, and good selectivity. These sensors can be functionalized with specific recognition elements to enhance their selectivity towards target analytes, and can be integrated into electronic devices for real-time monitoring applications.Expand Specific Solutions05 Environmental applications of rGO

Reduced graphene oxide (rGO) is utilized in various environmental applications due to its large surface area, adsorption capacity, and catalytic properties. Applications include water purification through the adsorption of heavy metals and organic pollutants, photocatalytic degradation of environmental contaminants, and air purification. rGO can be functionalized or combined with other materials to enhance its adsorption capacity and selectivity towards specific pollutants. The recyclability and reusability of rGO-based materials make them sustainable options for environmental remediation applications.Expand Specific Solutions

Key Industry Players in rGO Electrolyte Research

The reduced graphene oxide (rGO) electrolyte systems market is currently in a growth phase, characterized by increasing research activities and commercial applications. The market size is expanding rapidly, projected to reach significant value as energy storage technologies gain prominence globally. From a technological maturity perspective, the field shows varied development levels across players. Leading research institutions like Georgia Tech Research Corp., Brown University, and Korea Electrotechnology Research Institute are advancing fundamental science, while commercial entities including Samsung Electronics, NEC Corp., and Toray Industries are focusing on practical applications. Chinese players such as Sichuan Institute of Graphene Industrial Technology are emerging as significant contributors, particularly in manufacturing scale-up. Korean companies like Daejoo Electronic Materials and DGIST demonstrate strong specialization in electrolyte formulations, positioning the Asia-Pacific region at the forefront of this technology's commercialization.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has developed innovative reduced graphene oxide (rGO) electrolyte composites utilizing a unique "crumpled" graphene morphology that significantly enhances electrochemical performance. Their approach involves thermally treating graphene oxide under controlled conditions to create three-dimensional rGO structures with high surface area (>800 m²/g) and optimized pore distribution. These crumpled rGO particles are incorporated into polymer or liquid electrolytes at concentrations of 0.5-3 wt%, creating interconnected networks that facilitate ion transport while improving mechanical properties. Research has demonstrated that these rGO-enhanced electrolytes achieve up to 60% higher ionic conductivity compared to unmodified systems, particularly at lower temperatures (-20°C to 0°C). Georgia Tech's technology also incorporates surface functionalization strategies that tailor the rGO-electrolyte interface to specific battery chemistries, enabling customized solutions for different applications. Their electrolyte systems have shown particular promise in solid-state and quasi-solid electrolytes, where the rGO network provides mechanical reinforcement while maintaining flexibility.

Strengths: Superior low-temperature performance compared to conventional electrolytes; excellent mechanical reinforcement preventing electrolyte leakage; highly customizable for different battery chemistries. Weaknesses: More complex manufacturing process compared to standard electrolytes; potential challenges in achieving uniform rGO distribution in large-scale production; higher material costs affecting commercial viability.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed innovative reduced graphene oxide (rGO) composite electrolytes that significantly enhance lithium-ion battery performance. Their approach involves incorporating rGO into polymer electrolytes to create mechanically robust membranes with improved ionic conductivity. The research team has demonstrated that these rGO-enhanced electrolytes can achieve ionic conductivities up to 10^-3 S/cm at room temperature, representing a 100-fold improvement over conventional polymer electrolytes. KAUST's technology utilizes a proprietary reduction process that maintains functional oxygen groups on the graphene surface, creating pathways for ion transport while simultaneously improving mechanical stability. Their composite electrolytes have shown exceptional electrochemical stability windows exceeding 4.5V, making them suitable for high-voltage battery applications.

Strengths: Superior ionic conductivity at room temperature; excellent mechanical properties preventing dendrite formation; wide electrochemical stability window enabling high-voltage applications. Weaknesses: Potential scalability challenges for mass production; higher production costs compared to conventional electrolytes; possible long-term stability issues under extreme operating conditions.

Critical Patents and Breakthroughs in rGO Electrolyte Technology

Graphene oxide reducing agent comprising a reducing agent containing a halogen element, method for manufacturing a reduced graphene oxide using same, and use of the reduced graphene oxide manufactured by the method

PatentActiveUS9090805B2

Innovation

- A graphene oxide reducer containing a halogen element, preferably hydroiodic acid (HI), is used to react with graphene oxide at a temperature of 10°C or more, optionally with a weaker acid like acetic acid, to produce high-purity reduced graphene oxide with improved electrical conductivity.

Reduced graphene oxide and preparation method therefor

PatentWO2020130398A1

Innovation

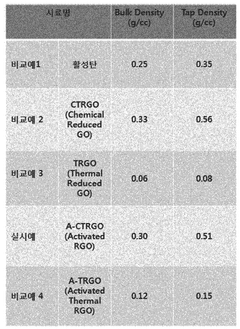

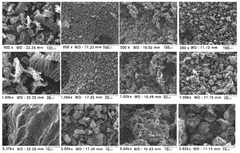

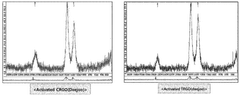

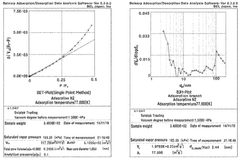

- A method that simultaneously performs reduction and activation of graphene oxide, using a basic solution followed by heat treatment, to increase the specific surface area by widening the gap between graphene layers, allowing for larger pore content and improved dispersibility.

Environmental Impact and Sustainability of rGO Electrolytes

The environmental impact of reduced graphene oxide (rGO) in electrolyte systems represents a critical consideration for sustainable technology development. Life cycle assessments of rGO production reveal significant environmental concerns, particularly regarding energy consumption during the reduction process of graphene oxide. Traditional thermal reduction methods can consume substantial energy, contributing to carbon emissions that potentially offset the environmental benefits of rGO-enhanced electrolytes. Chemical reduction processes often involve hazardous reagents like hydrazine, creating additional environmental and safety challenges.

Water usage in rGO production presents another sustainability concern, with purification and processing steps requiring substantial volumes. However, recent advancements in green synthesis methods show promising developments, including the use of plant extracts and environmentally benign reducing agents that significantly reduce the ecological footprint of rGO production.

When examining end-of-life considerations, rGO-based electrolytes demonstrate both advantages and challenges. The extended lifecycle of rGO-enhanced batteries and supercapacitors reduces waste generation and resource consumption compared to conventional systems. Nevertheless, the recovery and recycling of graphene materials from spent electrolytes remain technically challenging, with current processes achieving suboptimal recovery rates.

Regulatory frameworks governing nanomaterials in electrolyte systems continue to evolve globally. The European Union's REACH regulations and similar frameworks in North America and Asia increasingly address nanomaterial safety and disposal requirements, though specific provisions for rGO in electrolytes remain underdeveloped in many jurisdictions.

Comparative sustainability analyses between rGO and alternative electrolyte additives reveal that while rGO may require more energy-intensive initial production, its superior performance characteristics often result in net environmental benefits over complete product lifecycles. Enhanced conductivity and stability translate to longer-lasting energy storage devices, reducing replacement frequency and associated resource consumption.

Industry initiatives toward greener rGO production are gaining momentum, with companies like Samsung, LG, and emerging startups investing in water-based processing methods and renewable energy-powered production facilities. These approaches significantly reduce the environmental impact while maintaining the performance benefits of rGO in electrolyte applications.

Future sustainability improvements will likely focus on closed-loop manufacturing systems for rGO, where production waste is minimized and materials are designed for eventual recovery and reuse. Biodegradable stabilizers and environmentally compatible electrolyte formulations represent promising research directions that could further enhance the environmental profile of rGO-based energy storage technologies.

Water usage in rGO production presents another sustainability concern, with purification and processing steps requiring substantial volumes. However, recent advancements in green synthesis methods show promising developments, including the use of plant extracts and environmentally benign reducing agents that significantly reduce the ecological footprint of rGO production.

When examining end-of-life considerations, rGO-based electrolytes demonstrate both advantages and challenges. The extended lifecycle of rGO-enhanced batteries and supercapacitors reduces waste generation and resource consumption compared to conventional systems. Nevertheless, the recovery and recycling of graphene materials from spent electrolytes remain technically challenging, with current processes achieving suboptimal recovery rates.

Regulatory frameworks governing nanomaterials in electrolyte systems continue to evolve globally. The European Union's REACH regulations and similar frameworks in North America and Asia increasingly address nanomaterial safety and disposal requirements, though specific provisions for rGO in electrolytes remain underdeveloped in many jurisdictions.

Comparative sustainability analyses between rGO and alternative electrolyte additives reveal that while rGO may require more energy-intensive initial production, its superior performance characteristics often result in net environmental benefits over complete product lifecycles. Enhanced conductivity and stability translate to longer-lasting energy storage devices, reducing replacement frequency and associated resource consumption.

Industry initiatives toward greener rGO production are gaining momentum, with companies like Samsung, LG, and emerging startups investing in water-based processing methods and renewable energy-powered production facilities. These approaches significantly reduce the environmental impact while maintaining the performance benefits of rGO in electrolyte applications.

Future sustainability improvements will likely focus on closed-loop manufacturing systems for rGO, where production waste is minimized and materials are designed for eventual recovery and reuse. Biodegradable stabilizers and environmentally compatible electrolyte formulations represent promising research directions that could further enhance the environmental profile of rGO-based energy storage technologies.

Scalability and Manufacturing Challenges for rGO Electrolytes

The scaling of reduced graphene oxide (rGO) production from laboratory to industrial scale presents significant challenges that must be addressed before widespread commercial implementation in electrolyte systems. Current manufacturing processes for high-quality rGO typically involve small batch production with intensive manual operations, resulting in high costs and limited output volumes. The transition to mass production requires overcoming several critical hurdles in process engineering and quality control.

Primary among these challenges is maintaining consistent quality across large production batches. Laboratory-scale synthesis can achieve precise control over reduction parameters, yielding rGO with uniform properties. However, when scaled up, variations in reduction degree, defect density, and sheet size distribution become more pronounced, leading to inconsistent electrochemical performance in electrolyte applications.

Cost-effectiveness represents another major obstacle. The production of graphene oxide (GO), the precursor to rGO, involves expensive chemicals and time-consuming processes. The subsequent reduction step, whether thermal, chemical, or electrochemical, adds further complexity and cost. Current estimates place industrial-grade rGO production costs at approximately $50-100 per gram, significantly higher than traditional electrolyte materials, limiting commercial viability.

Environmental considerations also impact scalability. Conventional GO synthesis methods utilize strong oxidizing agents and acids that generate hazardous waste. Large-scale production would necessitate substantial investment in waste treatment facilities and safety protocols. Green synthesis alternatives show promise but currently yield rGO with inferior properties for electrolyte applications.

Equipment limitations further constrain manufacturing scale-up. Specialized reactors capable of maintaining uniform temperature and chemical distribution throughout large volumes are required but remain technically challenging to design and operate. Additionally, post-processing steps such as washing, filtration, and drying become increasingly complex at industrial scales.

Quality control and characterization present unique challenges at scale. Current analytical techniques for assessing rGO properties (such as Raman spectroscopy, XPS, and electrochemical testing) are time-consuming and difficult to implement as in-line monitoring tools for continuous production. Developing rapid, reliable quality assessment methods is essential for industrial viability.

Recent innovations addressing these challenges include continuous flow reactors for GO synthesis, microwave-assisted reduction techniques, and automated characterization systems. However, significant research and development investment is still required to establish economically viable manufacturing pathways for rGO-based electrolyte systems that can compete with conventional alternatives in both performance and cost.

Primary among these challenges is maintaining consistent quality across large production batches. Laboratory-scale synthesis can achieve precise control over reduction parameters, yielding rGO with uniform properties. However, when scaled up, variations in reduction degree, defect density, and sheet size distribution become more pronounced, leading to inconsistent electrochemical performance in electrolyte applications.

Cost-effectiveness represents another major obstacle. The production of graphene oxide (GO), the precursor to rGO, involves expensive chemicals and time-consuming processes. The subsequent reduction step, whether thermal, chemical, or electrochemical, adds further complexity and cost. Current estimates place industrial-grade rGO production costs at approximately $50-100 per gram, significantly higher than traditional electrolyte materials, limiting commercial viability.

Environmental considerations also impact scalability. Conventional GO synthesis methods utilize strong oxidizing agents and acids that generate hazardous waste. Large-scale production would necessitate substantial investment in waste treatment facilities and safety protocols. Green synthesis alternatives show promise but currently yield rGO with inferior properties for electrolyte applications.

Equipment limitations further constrain manufacturing scale-up. Specialized reactors capable of maintaining uniform temperature and chemical distribution throughout large volumes are required but remain technically challenging to design and operate. Additionally, post-processing steps such as washing, filtration, and drying become increasingly complex at industrial scales.

Quality control and characterization present unique challenges at scale. Current analytical techniques for assessing rGO properties (such as Raman spectroscopy, XPS, and electrochemical testing) are time-consuming and difficult to implement as in-line monitoring tools for continuous production. Developing rapid, reliable quality assessment methods is essential for industrial viability.

Recent innovations addressing these challenges include continuous flow reactors for GO synthesis, microwave-assisted reduction techniques, and automated characterization systems. However, significant research and development investment is still required to establish economically viable manufacturing pathways for rGO-based electrolyte systems that can compete with conventional alternatives in both performance and cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!