A Review of Directed Energy Deposition's Impact on Manufacturing Costs

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Cost Reduction Goals

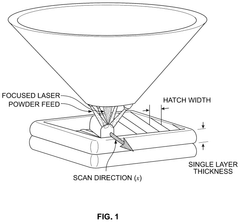

Directed Energy Deposition (DED) technology has evolved significantly since its inception in the 1990s, transforming from experimental prototyping methods to sophisticated manufacturing processes. The early iterations of DED systems were characterized by limited material options, inconsistent quality, and prohibitively high operational costs, restricting their application primarily to research environments and specialized aerospace components.

The evolution trajectory of DED technology has been marked by several key technological breakthroughs. The development of more precise laser control systems in the early 2000s enabled better deposition accuracy and reduced material waste. Subsequently, advancements in powder delivery mechanisms and real-time monitoring capabilities further enhanced process stability and part quality, while simultaneously reducing post-processing requirements.

A critical milestone in DED's evolution was the integration of multi-axis deposition capabilities, which expanded the geometric complexity achievable and opened new application domains. This was followed by the development of hybrid DED systems that combined additive and subtractive manufacturing processes, significantly improving surface finish quality and dimensional accuracy without additional processing steps.

From a cost perspective, DED technology has demonstrated a consistent downward trend in both capital investment and operational expenses. Initial systems required investments exceeding $1 million, whereas modern configurations can be acquired for approximately 30-50% less, depending on specifications. Material utilization efficiency has improved from 50-60% to 80-90% in advanced systems, substantially reducing waste and associated costs.

The primary cost reduction goals for DED technology focus on several interconnected areas. Energy efficiency improvements aim to reduce the power consumption per deposited volume by 40% within the next five years. Material development initiatives target the expansion of compatible material portfolios while reducing powder costs through improved manufacturing processes and increased market competition.

Process optimization represents another significant cost reduction vector, with objectives to increase deposition rates by 200% without compromising quality, thereby reducing production time and labor costs. Automation and integration goals seek to minimize human intervention requirements, potentially reducing operational labor costs by 60-70% for standard applications.

Looking forward, the technology roadmap for DED includes the development of multi-material deposition capabilities, in-situ quality assurance systems, and enhanced process modeling tools. These advancements are projected to further reduce manufacturing costs by 25-35% over the next decade while simultaneously expanding the application scope of DED technology across industries including aerospace, automotive, medical, and energy sectors.

The evolution trajectory of DED technology has been marked by several key technological breakthroughs. The development of more precise laser control systems in the early 2000s enabled better deposition accuracy and reduced material waste. Subsequently, advancements in powder delivery mechanisms and real-time monitoring capabilities further enhanced process stability and part quality, while simultaneously reducing post-processing requirements.

A critical milestone in DED's evolution was the integration of multi-axis deposition capabilities, which expanded the geometric complexity achievable and opened new application domains. This was followed by the development of hybrid DED systems that combined additive and subtractive manufacturing processes, significantly improving surface finish quality and dimensional accuracy without additional processing steps.

From a cost perspective, DED technology has demonstrated a consistent downward trend in both capital investment and operational expenses. Initial systems required investments exceeding $1 million, whereas modern configurations can be acquired for approximately 30-50% less, depending on specifications. Material utilization efficiency has improved from 50-60% to 80-90% in advanced systems, substantially reducing waste and associated costs.

The primary cost reduction goals for DED technology focus on several interconnected areas. Energy efficiency improvements aim to reduce the power consumption per deposited volume by 40% within the next five years. Material development initiatives target the expansion of compatible material portfolios while reducing powder costs through improved manufacturing processes and increased market competition.

Process optimization represents another significant cost reduction vector, with objectives to increase deposition rates by 200% without compromising quality, thereby reducing production time and labor costs. Automation and integration goals seek to minimize human intervention requirements, potentially reducing operational labor costs by 60-70% for standard applications.

Looking forward, the technology roadmap for DED includes the development of multi-material deposition capabilities, in-situ quality assurance systems, and enhanced process modeling tools. These advancements are projected to further reduce manufacturing costs by 25-35% over the next decade while simultaneously expanding the application scope of DED technology across industries including aerospace, automotive, medical, and energy sectors.

Market Analysis for DED Manufacturing Solutions

The Directed Energy Deposition (DED) manufacturing solutions market is experiencing significant growth, driven by increasing demand for advanced manufacturing technologies across various industries. The global DED market was valued at approximately $500 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 15.8%. This growth trajectory is supported by the technology's unique capabilities in addressing complex manufacturing challenges.

Aerospace and defense sectors currently dominate the DED market, accounting for nearly 40% of the total market share. These industries leverage DED technology for manufacturing complex components, repairing high-value parts, and producing specialized structures that would be difficult or impossible to create using conventional manufacturing methods. The medical device industry is emerging as another significant market segment, with an estimated growth rate of 18% annually, particularly for customized implants and prosthetics.

Regional analysis indicates that North America holds the largest market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 17.2% during the forecast period, primarily due to rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market is segmented by material type, with metal-based DED solutions commanding approximately 75% of the market. Among metals, titanium alloys, nickel-based superalloys, and stainless steel are the most commonly used materials in DED applications, collectively accounting for over 60% of the metal segment.

Customer demand is increasingly focused on integrated DED solutions that offer enhanced process control, monitoring capabilities, and compatibility with existing manufacturing systems. According to industry surveys, 68% of potential adopters cite cost reduction and production efficiency as primary motivators for implementing DED technology, while 52% emphasize the importance of part quality and material properties.

Market challenges include high initial investment costs, with industrial-grade DED systems ranging from $250,000 to over $1 million, and technical barriers to adoption such as process parameter optimization and quality control. However, the market is responding with innovations in hybrid manufacturing systems, multi-material deposition capabilities, and improved software solutions that address these challenges while expanding the application scope of DED technology.

Aerospace and defense sectors currently dominate the DED market, accounting for nearly 40% of the total market share. These industries leverage DED technology for manufacturing complex components, repairing high-value parts, and producing specialized structures that would be difficult or impossible to create using conventional manufacturing methods. The medical device industry is emerging as another significant market segment, with an estimated growth rate of 18% annually, particularly for customized implants and prosthetics.

Regional analysis indicates that North America holds the largest market share at 35%, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 17.2% during the forecast period, primarily due to rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

The market is segmented by material type, with metal-based DED solutions commanding approximately 75% of the market. Among metals, titanium alloys, nickel-based superalloys, and stainless steel are the most commonly used materials in DED applications, collectively accounting for over 60% of the metal segment.

Customer demand is increasingly focused on integrated DED solutions that offer enhanced process control, monitoring capabilities, and compatibility with existing manufacturing systems. According to industry surveys, 68% of potential adopters cite cost reduction and production efficiency as primary motivators for implementing DED technology, while 52% emphasize the importance of part quality and material properties.

Market challenges include high initial investment costs, with industrial-grade DED systems ranging from $250,000 to over $1 million, and technical barriers to adoption such as process parameter optimization and quality control. However, the market is responding with innovations in hybrid manufacturing systems, multi-material deposition capabilities, and improved software solutions that address these challenges while expanding the application scope of DED technology.

Current DED Technology Limitations and Cost Barriers

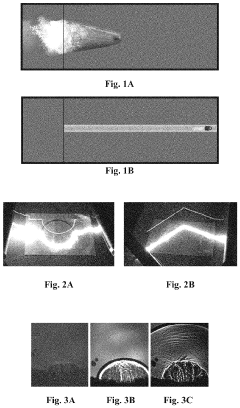

Despite the promising capabilities of Directed Energy Deposition (DED), several technological limitations and cost barriers currently impede its widespread industrial adoption. The primary technical challenge remains process stability and repeatability. DED systems often struggle with maintaining consistent material deposition rates and thermal conditions, resulting in variable part quality that necessitates extensive post-processing. This inconsistency directly translates to higher production costs and reduced economic viability for mass manufacturing applications.

Equipment costs represent a significant barrier to entry, with industrial-grade DED systems typically ranging from $500,000 to over $1.5 million, depending on capabilities and specifications. This substantial capital investment creates a high financial threshold that many small and medium enterprises cannot overcome, limiting technology democratization across the manufacturing sector.

Material efficiency presents another critical limitation. Current DED processes exhibit material utilization rates between 70-85%, significantly lower than traditional manufacturing methods. The wasted material, particularly when working with expensive metal powders such as titanium alloys or nickel-based superalloys, substantially increases per-part costs. For instance, titanium powder can cost $200-400 per kilogram, making waste reduction economically imperative.

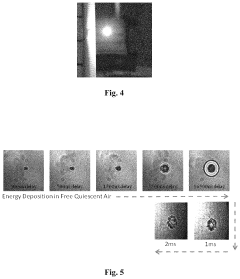

Energy consumption during DED operations constitutes another substantial cost factor. The high-power lasers or electron beams required for material melting typically consume 5-15 kW of power during operation, resulting in significant operational expenses. This energy intensity not only increases direct manufacturing costs but also raises environmental concerns regarding carbon footprint.

Quality assurance and certification processes further compound cost challenges. The complex thermal history of DED-manufactured parts necessitates comprehensive testing and validation protocols, including CT scanning, mechanical testing, and microstructural analysis. These quality control requirements can account for 15-25% of total production costs, particularly in highly regulated industries like aerospace and medical devices.

Skilled labor requirements present both technical and economic barriers. DED systems demand operators with specialized training in CAD/CAM software, materials science, and process parameter optimization. The limited availability of such expertise commands premium wages and increases operational costs, while potentially creating production bottlenecks.

Software limitations also impact cost-effectiveness. Current design and simulation tools are not fully optimized for DED processes, leading to inefficient design iterations and suboptimal part geometries. This software gap results in longer development cycles and increased engineering costs that ultimately affect product pricing and market competitiveness.

Equipment costs represent a significant barrier to entry, with industrial-grade DED systems typically ranging from $500,000 to over $1.5 million, depending on capabilities and specifications. This substantial capital investment creates a high financial threshold that many small and medium enterprises cannot overcome, limiting technology democratization across the manufacturing sector.

Material efficiency presents another critical limitation. Current DED processes exhibit material utilization rates between 70-85%, significantly lower than traditional manufacturing methods. The wasted material, particularly when working with expensive metal powders such as titanium alloys or nickel-based superalloys, substantially increases per-part costs. For instance, titanium powder can cost $200-400 per kilogram, making waste reduction economically imperative.

Energy consumption during DED operations constitutes another substantial cost factor. The high-power lasers or electron beams required for material melting typically consume 5-15 kW of power during operation, resulting in significant operational expenses. This energy intensity not only increases direct manufacturing costs but also raises environmental concerns regarding carbon footprint.

Quality assurance and certification processes further compound cost challenges. The complex thermal history of DED-manufactured parts necessitates comprehensive testing and validation protocols, including CT scanning, mechanical testing, and microstructural analysis. These quality control requirements can account for 15-25% of total production costs, particularly in highly regulated industries like aerospace and medical devices.

Skilled labor requirements present both technical and economic barriers. DED systems demand operators with specialized training in CAD/CAM software, materials science, and process parameter optimization. The limited availability of such expertise commands premium wages and increases operational costs, while potentially creating production bottlenecks.

Software limitations also impact cost-effectiveness. Current design and simulation tools are not fully optimized for DED processes, leading to inefficient design iterations and suboptimal part geometries. This software gap results in longer development cycles and increased engineering costs that ultimately affect product pricing and market competitiveness.

Cost-Effective DED Implementation Strategies

01 Cost optimization in DED process parameters

Optimizing process parameters in Directed Energy Deposition (DED) manufacturing can significantly reduce costs. This includes adjusting laser power, deposition rate, material feed rate, and travel speed to minimize material waste and energy consumption. Advanced control systems can monitor and adjust these parameters in real-time to maintain optimal efficiency while ensuring quality standards are met. These optimizations can lead to substantial cost savings in both material usage and production time.- Cost optimization in DED processes: Directed Energy Deposition (DED) manufacturing costs can be optimized through various process improvements. These include optimizing energy consumption, reducing material waste, and implementing efficient path planning strategies. Advanced control systems can monitor and adjust parameters in real-time to maintain optimal deposition conditions, thereby reducing operational costs and improving material utilization efficiency.

- Material selection and cost implications: The choice of materials significantly impacts the overall cost of DED manufacturing. Different metal powders and wire feedstocks vary in price, processability, and final part properties. Cost-effective material selection strategies include using recycled powders, developing custom alloys with improved processability, and implementing closed-loop material recovery systems to minimize waste and reduce raw material costs.

- Equipment and maintenance cost considerations: The initial investment in DED equipment represents a significant portion of manufacturing costs. This includes laser or electron beam sources, powder delivery systems, motion control platforms, and monitoring equipment. Additionally, ongoing maintenance costs, including replacement of consumables, calibration, and repair of components subject to wear, contribute to the total cost of ownership. Strategies for reducing these costs include modular system designs and predictive maintenance approaches.

- Hybrid manufacturing approaches for cost reduction: Combining DED with conventional manufacturing methods can optimize costs by leveraging the strengths of each process. Hybrid approaches include using DED for adding features to conventionally manufactured components, integrating subtractive processes for finishing operations, and employing DED for repair applications. These strategies can reduce material waste, processing time, and overall manufacturing costs compared to using DED exclusively.

- Production scale and economic considerations: The economics of DED manufacturing vary significantly with production volume and part complexity. For low-volume production of complex parts, DED can offer cost advantages over traditional manufacturing methods by eliminating tooling costs and reducing material waste. However, for higher production volumes, the relatively slow deposition rates and high equipment costs may become limiting factors. Cost modeling tools and simulation software can help optimize process parameters and production planning to achieve the most economical outcomes.

02 Material efficiency and recycling strategies

Improving material efficiency in DED processes involves strategies to reduce waste and implement effective recycling systems. Unused powder materials can be collected, filtered, and reused in subsequent builds, significantly reducing raw material costs. Advanced powder handling systems can minimize contamination and maintain material properties through multiple recycling cycles. Additionally, optimizing part design and build orientation can reduce the need for support structures, further decreasing material consumption and post-processing requirements.Expand Specific Solutions03 Equipment and maintenance cost reduction

Strategies to reduce equipment and maintenance costs in DED manufacturing include developing more energy-efficient laser systems, implementing predictive maintenance protocols, and designing modular equipment components that can be easily replaced or upgraded. Automated calibration systems can reduce setup time and operator intervention. Additionally, multi-purpose DED systems that can process various materials with minimal reconfiguration can improve equipment utilization rates and distribute fixed costs across more production runs.Expand Specific Solutions04 Hybrid manufacturing approaches

Hybrid manufacturing approaches combine DED with conventional manufacturing methods to optimize costs. These systems integrate additive and subtractive processes in a single setup, reducing handling time, improving dimensional accuracy, and minimizing post-processing requirements. By strategically applying DED only where needed and using traditional methods elsewhere, manufacturers can achieve significant cost savings while maintaining or improving part quality. This approach is particularly effective for repair applications and complex geometries with specific performance requirements.Expand Specific Solutions05 Software solutions for cost estimation and process planning

Advanced software solutions can significantly reduce DED manufacturing costs through improved process planning, simulation, and cost estimation. These tools can predict material consumption, processing time, and energy requirements before production begins. By simulating the build process, potential issues can be identified and resolved virtually, preventing costly errors during actual production. Additionally, AI-based optimization algorithms can suggest the most cost-effective build strategies based on part geometry, material properties, and production requirements.Expand Specific Solutions

Leading DED Technology Providers and Adopters

Directed Energy Deposition (DED) technology is currently in a growth phase within the additive manufacturing landscape, with the market expected to expand significantly as industries recognize its cost-reduction potential. The global market size for DED is projected to reach approximately $1.2 billion by 2027, driven by aerospace and defense applications. Leading players like GE Avio, Norsk Titanium, and Lockheed Martin are advancing the technology's maturity through significant R&D investments, while academic institutions such as Tsinghua University and Nanyang Technological University are contributing fundamental research. The technology is transitioning from early adoption to mainstream implementation, with companies like RTX Corp. and Airbus Operations integrating DED into production workflows to achieve 50-75% cost reductions compared to traditional manufacturing methods.

GE Avio Srl

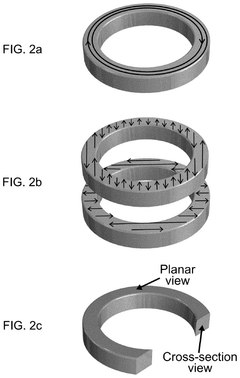

Technical Solution: GE Avio has implemented an advanced DED manufacturing ecosystem specifically optimized for aerospace propulsion components. Their approach integrates laser-based DED systems with sophisticated thermal management to enable the production of complex geometries in high-performance alloys. GE Avio's cost analysis demonstrates that for certain turbine components, DED manufacturing reduces material waste by up to 75% compared to conventional machining processes. Their implementation includes proprietary process monitoring systems that track over 20 parameters in real-time, enabling adaptive control that has reduced defect rates by approximately 40%. GE Avio has developed specialized hybrid manufacturing cells that combine DED with precision machining, reducing production cycle times by up to 65% for complex components. Their research indicates that for certain engine parts, the total manufacturing cost reduction can reach 30-45% when accounting for material savings, reduced tooling requirements, and decreased lead times.

Strengths: Exceptional capability with high-temperature superalloys critical for aerospace applications; advanced process monitoring and quality control systems; established certification pathways for flight-critical components. Weaknesses: High initial equipment investment costs; process sensitivity to environmental conditions requiring controlled manufacturing environments; challenges with consistent mechanical properties across large build volumes.

Norsk Titanium AS

Technical Solution: Norsk Titanium has pioneered Rapid Plasma Deposition (RPD), a specialized form of DED technology optimized for titanium aerospace components. Their proprietary process utilizes plasma arc energy sources rather than lasers, enabling deposition rates up to 10kg/hour while maintaining precise control over microstructure. Norsk's implementation focuses on near-net-shape manufacturing of structural titanium components, demonstrating buy-to-fly ratio improvements from 12:1 with conventional methods to approximately 3:1 with RPD. Their cost analysis shows material cost reductions of 50-70% for typical aerospace components, with additional savings from reduced machining requirements and shorter lead times. Norsk has developed a comprehensive digital thread connecting design, manufacturing, and quality assurance, enabling automated production planning that optimizes deposition strategies for cost efficiency. Their technology has been qualified for structural aerospace components by major OEMs, with documented manufacturing cost reductions of 30-40% compared to traditional titanium manufacturing methods.

Strengths: Industry-leading deposition rates for titanium components; established aerospace qualification and certification processes; significant material utilization improvements for large structural parts. Weaknesses: Technology primarily optimized for titanium alloys with limited application to other materials; larger heat-affected zones compared to laser-based systems; challenges with very fine feature resolution.

Key Patents and Research in DED Cost Optimization

High silicon electrical steel alloys using directed energy deposition

PatentPendingUS20250262669A1

Innovation

- Laser beam-directed energy deposition (LB-DED) is used to create bulk geometries of high-silicon content Fe—Si alloys through layer-by-layer printing and heat treatment, minimizing residual stresses and enabling near-net-shape manufacturing.

Directed energy deposition to facilitate high speed applications

PatentActiveUS10669653B2

Innovation

- The method involves impulsively heating a portion of a fluid to create a lower density region within a higher density region, synchronized with detonating a reactant in a pulsed propulsion unit, using techniques like laser filamentation or electrical discharges to form a low-density tube through which objects can travel with reduced drag and acoustic signature.

Material Science Advancements for DED Economics

Material science advancements have significantly influenced the economic viability of Directed Energy Deposition (DED) processes. Recent developments in powder and wire feedstock materials have led to enhanced material properties while simultaneously reducing raw material costs. Specialized alloys designed specifically for DED applications now demonstrate improved flowability, reduced oxidation tendencies, and more consistent particle size distribution, resulting in higher deposition efficiency and reduced waste.

The emergence of multi-material capabilities represents a breakthrough in DED economics. Advanced material science has enabled the seamless transition between different materials during a single build process, allowing for functionally graded components that optimize performance while minimizing expensive material usage. This capability reduces the need for costly post-processing steps and enables more efficient material utilization strategies.

Thermal management innovations derived from material science research have addressed one of DED's primary economic challenges: thermal stress and distortion. New substrate materials with tailored thermal properties help manage heat dissipation more effectively, reducing the need for extensive post-processing and repair of thermally-induced defects. These advancements directly translate to cost savings in quality control and finishing operations.

Microstructure control through material science has enhanced the repeatability and reliability of DED processes. By developing materials with predictable solidification behaviors, manufacturers can now achieve consistent mechanical properties with fewer iterations and quality control steps. This predictability reduces scrap rates and testing requirements, contributing significantly to overall cost reduction.

Surface science advancements have improved the interaction between deposited materials and laser or electron beam energy sources. Enhanced absorption coatings and surface treatments optimize energy transfer efficiency, reducing power requirements and processing time. These improvements directly impact operational costs through reduced energy consumption and increased throughput.

Recycling technologies specifically designed for DED waste materials represent another economic breakthrough. Advanced separation and purification methods now allow for the recovery and reuse of expensive metal powders that would otherwise be discarded. Material scientists have developed processes that maintain the critical properties of recycled powders, ensuring they meet specifications for subsequent manufacturing cycles.

The integration of computational materials science with DED processes has enabled more accurate prediction of material behavior during deposition. These simulation capabilities reduce the need for costly physical testing and allow for virtual optimization of process parameters before actual production begins, significantly reducing development costs and time-to-market for new applications.

The emergence of multi-material capabilities represents a breakthrough in DED economics. Advanced material science has enabled the seamless transition between different materials during a single build process, allowing for functionally graded components that optimize performance while minimizing expensive material usage. This capability reduces the need for costly post-processing steps and enables more efficient material utilization strategies.

Thermal management innovations derived from material science research have addressed one of DED's primary economic challenges: thermal stress and distortion. New substrate materials with tailored thermal properties help manage heat dissipation more effectively, reducing the need for extensive post-processing and repair of thermally-induced defects. These advancements directly translate to cost savings in quality control and finishing operations.

Microstructure control through material science has enhanced the repeatability and reliability of DED processes. By developing materials with predictable solidification behaviors, manufacturers can now achieve consistent mechanical properties with fewer iterations and quality control steps. This predictability reduces scrap rates and testing requirements, contributing significantly to overall cost reduction.

Surface science advancements have improved the interaction between deposited materials and laser or electron beam energy sources. Enhanced absorption coatings and surface treatments optimize energy transfer efficiency, reducing power requirements and processing time. These improvements directly impact operational costs through reduced energy consumption and increased throughput.

Recycling technologies specifically designed for DED waste materials represent another economic breakthrough. Advanced separation and purification methods now allow for the recovery and reuse of expensive metal powders that would otherwise be discarded. Material scientists have developed processes that maintain the critical properties of recycled powders, ensuring they meet specifications for subsequent manufacturing cycles.

The integration of computational materials science with DED processes has enabled more accurate prediction of material behavior during deposition. These simulation capabilities reduce the need for costly physical testing and allow for virtual optimization of process parameters before actual production begins, significantly reducing development costs and time-to-market for new applications.

Sustainability Impact of DED Manufacturing

Directed Energy Deposition (DED) manufacturing processes offer significant sustainability advantages over traditional manufacturing methods, positioning this technology as a key contributor to environmentally responsible industrial practices. The sustainability impact of DED extends across multiple dimensions of environmental stewardship, resource efficiency, and long-term ecological footprint reduction.

From an energy consumption perspective, DED demonstrates notable efficiency improvements compared to conventional manufacturing techniques. The targeted energy application inherent to DED processes results in reduced overall energy requirements, with studies indicating potential energy savings of 15-40% depending on the specific application and material being processed. This efficiency stems from DED's ability to deposit material precisely where needed, eliminating the extensive material removal operations common in subtractive manufacturing.

Material utilization represents another critical sustainability advantage of DED manufacturing. Traditional manufacturing methods often generate substantial waste, with material removal rates sometimes exceeding 70% of the initial stock. In contrast, DED processes typically achieve material utilization rates of 90-98%, dramatically reducing raw material consumption and associated extraction impacts. This near-net-shape production capability significantly diminishes the environmental burden associated with mining, refining, and transporting excess materials.

The environmental impact assessment of DED manufacturing reveals reduced carbon emissions throughout the product lifecycle. When considering the complete manufacturing chain, DED processes can reduce carbon footprints by 25-60% compared to conventional methods. This reduction stems from decreased transportation requirements, lower energy consumption, and minimized waste generation. Additionally, the localized nature of DED manufacturing supports distributed production models that further reduce logistics-related emissions.

DED technology also contributes to sustainability through enhanced product lifecycles. The ability to repair and remanufacture components using DED processes extends product lifespans significantly, reducing the demand for new raw materials and delaying end-of-life disposal. This repair capability is particularly valuable in industries such as aerospace and heavy machinery, where component restoration can avoid the environmental impacts associated with complete replacement.

Water conservation represents an often-overlooked sustainability benefit of DED manufacturing. Compared to traditional manufacturing processes that may require substantial cooling and cleaning operations, DED typically requires minimal water usage. This characteristic becomes increasingly important as water scarcity concerns grow globally, positioning DED as a manufacturing technology aligned with responsible water stewardship principles.

From an energy consumption perspective, DED demonstrates notable efficiency improvements compared to conventional manufacturing techniques. The targeted energy application inherent to DED processes results in reduced overall energy requirements, with studies indicating potential energy savings of 15-40% depending on the specific application and material being processed. This efficiency stems from DED's ability to deposit material precisely where needed, eliminating the extensive material removal operations common in subtractive manufacturing.

Material utilization represents another critical sustainability advantage of DED manufacturing. Traditional manufacturing methods often generate substantial waste, with material removal rates sometimes exceeding 70% of the initial stock. In contrast, DED processes typically achieve material utilization rates of 90-98%, dramatically reducing raw material consumption and associated extraction impacts. This near-net-shape production capability significantly diminishes the environmental burden associated with mining, refining, and transporting excess materials.

The environmental impact assessment of DED manufacturing reveals reduced carbon emissions throughout the product lifecycle. When considering the complete manufacturing chain, DED processes can reduce carbon footprints by 25-60% compared to conventional methods. This reduction stems from decreased transportation requirements, lower energy consumption, and minimized waste generation. Additionally, the localized nature of DED manufacturing supports distributed production models that further reduce logistics-related emissions.

DED technology also contributes to sustainability through enhanced product lifecycles. The ability to repair and remanufacture components using DED processes extends product lifespans significantly, reducing the demand for new raw materials and delaying end-of-life disposal. This repair capability is particularly valuable in industries such as aerospace and heavy machinery, where component restoration can avoid the environmental impacts associated with complete replacement.

Water conservation represents an often-overlooked sustainability benefit of DED manufacturing. Compared to traditional manufacturing processes that may require substantial cooling and cleaning operations, DED typically requires minimal water usage. This characteristic becomes increasingly important as water scarcity concerns grow globally, positioning DED as a manufacturing technology aligned with responsible water stewardship principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!