Optimizing Directed Energy Deposition Parameters for Enhanced Performance

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) emerged in the late 1990s as an advanced additive manufacturing technology capable of producing near-net-shape metal components with complex geometries. This technology evolved from laser cladding processes and has since developed into a sophisticated manufacturing method that enables direct fabrication of functional metal parts from digital designs. The fundamental principle involves creating a melt pool on a substrate using a focused energy source, typically a laser, electron beam, or plasma arc, while simultaneously feeding material in the form of powder or wire.

Over the past decade, DED technology has experienced significant advancements in process control, material compatibility, and system integration. The evolution trajectory shows a clear shift from primarily repair applications to full-scale production of critical components for aerospace, defense, and medical industries. This progression has been driven by increasing demands for reduced material waste, shorter lead times, and the ability to process difficult-to-machine materials.

Current DED systems operate with power sources ranging from 500W to 4kW for precision applications, and up to 20kW for high deposition rate processes. Material deposition rates have improved from early systems capable of 10-50 g/h to modern systems achieving 300-500 g/h while maintaining dimensional accuracy within ±0.2mm. These improvements represent critical milestones in making DED commercially viable for industrial applications.

The primary technical objective in optimizing DED parameters is to establish robust process-structure-property relationships that enable predictable and repeatable material performance. This includes enhancing deposition efficiency, reducing thermal distortion, minimizing residual stresses, and achieving desired microstructural characteristics. Parameter optimization aims to balance deposition rate with part quality, addressing the inherent trade-offs between productivity and precision.

Secondary objectives include expanding the range of compatible materials, particularly for high-performance alloys such as nickel-based superalloys, titanium alloys, and refractory metals. Additionally, there is significant interest in developing multi-material capabilities to create functionally graded components with tailored properties throughout the part volume.

The long-term technological goal is to develop intelligent DED systems with closed-loop control mechanisms that can dynamically adjust process parameters in real-time based on in-situ monitoring data. This would enable adaptive manufacturing processes capable of compensating for variations in material properties, environmental conditions, and geometric complexities, ultimately leading to consistent part quality regardless of production variables.

Over the past decade, DED technology has experienced significant advancements in process control, material compatibility, and system integration. The evolution trajectory shows a clear shift from primarily repair applications to full-scale production of critical components for aerospace, defense, and medical industries. This progression has been driven by increasing demands for reduced material waste, shorter lead times, and the ability to process difficult-to-machine materials.

Current DED systems operate with power sources ranging from 500W to 4kW for precision applications, and up to 20kW for high deposition rate processes. Material deposition rates have improved from early systems capable of 10-50 g/h to modern systems achieving 300-500 g/h while maintaining dimensional accuracy within ±0.2mm. These improvements represent critical milestones in making DED commercially viable for industrial applications.

The primary technical objective in optimizing DED parameters is to establish robust process-structure-property relationships that enable predictable and repeatable material performance. This includes enhancing deposition efficiency, reducing thermal distortion, minimizing residual stresses, and achieving desired microstructural characteristics. Parameter optimization aims to balance deposition rate with part quality, addressing the inherent trade-offs between productivity and precision.

Secondary objectives include expanding the range of compatible materials, particularly for high-performance alloys such as nickel-based superalloys, titanium alloys, and refractory metals. Additionally, there is significant interest in developing multi-material capabilities to create functionally graded components with tailored properties throughout the part volume.

The long-term technological goal is to develop intelligent DED systems with closed-loop control mechanisms that can dynamically adjust process parameters in real-time based on in-situ monitoring data. This would enable adaptive manufacturing processes capable of compensating for variations in material properties, environmental conditions, and geometric complexities, ultimately leading to consistent part quality regardless of production variables.

Market Applications and Demand Analysis

The Directed Energy Deposition (DED) market has experienced significant growth in recent years, driven by increasing demand across multiple industrial sectors. The global market for DED technology was valued at approximately $500 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 15.7%. This growth trajectory underscores the expanding applications and market penetration of DED technology.

Aerospace and defense sectors currently constitute the largest market segment for DED applications, accounting for nearly 40% of the total market share. These industries leverage DED for manufacturing complex components, repairing high-value parts, and producing specialized structures that would be difficult or impossible to create using conventional manufacturing methods. The ability to optimize DED parameters directly translates to improved performance metrics critical in aerospace applications, including weight reduction, enhanced mechanical properties, and superior thermal resistance.

The medical device industry represents another rapidly growing market for optimized DED technology, with a projected growth rate of 18.3% through 2028. Applications include the production of customized implants, prosthetics, and surgical instruments. The demand for patient-specific medical devices with complex geometries and biocompatible materials has created a significant market opportunity for parameter-optimized DED processes.

Automotive manufacturing has begun adopting DED technology at an accelerating pace, particularly for rapid prototyping and the production of specialized components. Market analysis indicates that automotive applications of DED are expected to grow by 22% annually over the next five years, driven by the industry's push toward lightweight materials and complex geometrical designs that optimize fuel efficiency and performance.

Energy sector applications, particularly in oil and gas, power generation, and renewable energy, represent an emerging market segment with substantial growth potential. The repair and refurbishment of turbine blades, drill bits, and other high-wear components using optimized DED parameters can extend component lifespans by 30-50%, resulting in significant cost savings and reduced downtime.

Consumer demand for customized products has also created niche markets for DED technology in luxury goods, sporting equipment, and consumer electronics. While currently representing less than 10% of the total market, these applications are expected to grow as DED parameter optimization enables improved surface finishes and aesthetic qualities alongside functional performance.

Market research indicates that the primary drivers for DED adoption include reduced material waste (compared to traditional subtractive manufacturing), decreased lead times for complex components, and the ability to create parts with gradient material properties. As parameter optimization techniques continue to advance, these market advantages are expected to strengthen, further accelerating industry adoption across diverse sectors.

Aerospace and defense sectors currently constitute the largest market segment for DED applications, accounting for nearly 40% of the total market share. These industries leverage DED for manufacturing complex components, repairing high-value parts, and producing specialized structures that would be difficult or impossible to create using conventional manufacturing methods. The ability to optimize DED parameters directly translates to improved performance metrics critical in aerospace applications, including weight reduction, enhanced mechanical properties, and superior thermal resistance.

The medical device industry represents another rapidly growing market for optimized DED technology, with a projected growth rate of 18.3% through 2028. Applications include the production of customized implants, prosthetics, and surgical instruments. The demand for patient-specific medical devices with complex geometries and biocompatible materials has created a significant market opportunity for parameter-optimized DED processes.

Automotive manufacturing has begun adopting DED technology at an accelerating pace, particularly for rapid prototyping and the production of specialized components. Market analysis indicates that automotive applications of DED are expected to grow by 22% annually over the next five years, driven by the industry's push toward lightweight materials and complex geometrical designs that optimize fuel efficiency and performance.

Energy sector applications, particularly in oil and gas, power generation, and renewable energy, represent an emerging market segment with substantial growth potential. The repair and refurbishment of turbine blades, drill bits, and other high-wear components using optimized DED parameters can extend component lifespans by 30-50%, resulting in significant cost savings and reduced downtime.

Consumer demand for customized products has also created niche markets for DED technology in luxury goods, sporting equipment, and consumer electronics. While currently representing less than 10% of the total market, these applications are expected to grow as DED parameter optimization enables improved surface finishes and aesthetic qualities alongside functional performance.

Market research indicates that the primary drivers for DED adoption include reduced material waste (compared to traditional subtractive manufacturing), decreased lead times for complex components, and the ability to create parts with gradient material properties. As parameter optimization techniques continue to advance, these market advantages are expected to strengthen, further accelerating industry adoption across diverse sectors.

Current DED Technical Challenges

Despite significant advancements in Directed Energy Deposition (DED) technology, several critical technical challenges persist that impede its widespread industrial adoption and optimal performance. Process parameter optimization remains one of the most formidable obstacles, as the complex interrelationships between laser power, powder feed rate, scanning speed, and layer thickness create a vast parametric space that is difficult to navigate without sophisticated modeling tools or extensive experimentation.

Material-specific challenges present another significant hurdle, particularly when processing high-performance alloys such as titanium, nickel-based superalloys, and refractory metals. These materials often exhibit poor weldability, high susceptibility to oxidation, and significant thermal gradients during processing, leading to residual stresses, distortion, and potential cracking in the final components.

Thermal management during the DED process remains inadequately addressed, with rapid heating and cooling cycles generating undesirable microstructural features, including coarse grain structures, segregation of alloying elements, and formation of brittle intermetallic phases. These microstructural defects directly compromise the mechanical properties and performance of fabricated components.

Geometric accuracy and surface finish quality continue to fall short of requirements for many high-precision applications. The layer-by-layer deposition process inherently produces the "stair-stepping effect," while melt pool dynamics and material flow behavior contribute to surface roughness that often necessitates extensive post-processing operations, reducing the cost-effectiveness of the technology.

Process monitoring and control systems lack the sophistication needed for real-time quality assurance. Current sensor technologies and feedback mechanisms are insufficient for detecting and correcting process anomalies during deposition, resulting in inconsistent part quality and limited reproducibility across builds.

Porosity and inclusion formation remain persistent issues, particularly at inter-layer boundaries and in regions with complex geometries. These defects act as stress concentrators and crack initiation sites, significantly reducing fatigue life and overall mechanical performance of DED-manufactured components.

The absence of standardized qualification and certification protocols presents a regulatory challenge that limits DED adoption in safety-critical industries such as aerospace and medical device manufacturing. Without established testing methodologies and acceptance criteria, manufacturers struggle to validate the integrity and reliability of DED-produced parts for demanding applications.

Material-specific challenges present another significant hurdle, particularly when processing high-performance alloys such as titanium, nickel-based superalloys, and refractory metals. These materials often exhibit poor weldability, high susceptibility to oxidation, and significant thermal gradients during processing, leading to residual stresses, distortion, and potential cracking in the final components.

Thermal management during the DED process remains inadequately addressed, with rapid heating and cooling cycles generating undesirable microstructural features, including coarse grain structures, segregation of alloying elements, and formation of brittle intermetallic phases. These microstructural defects directly compromise the mechanical properties and performance of fabricated components.

Geometric accuracy and surface finish quality continue to fall short of requirements for many high-precision applications. The layer-by-layer deposition process inherently produces the "stair-stepping effect," while melt pool dynamics and material flow behavior contribute to surface roughness that often necessitates extensive post-processing operations, reducing the cost-effectiveness of the technology.

Process monitoring and control systems lack the sophistication needed for real-time quality assurance. Current sensor technologies and feedback mechanisms are insufficient for detecting and correcting process anomalies during deposition, resulting in inconsistent part quality and limited reproducibility across builds.

Porosity and inclusion formation remain persistent issues, particularly at inter-layer boundaries and in regions with complex geometries. These defects act as stress concentrators and crack initiation sites, significantly reducing fatigue life and overall mechanical performance of DED-manufactured components.

The absence of standardized qualification and certification protocols presents a regulatory challenge that limits DED adoption in safety-critical industries such as aerospace and medical device manufacturing. Without established testing methodologies and acceptance criteria, manufacturers struggle to validate the integrity and reliability of DED-produced parts for demanding applications.

Parameter Optimization Methodologies

01 Process optimization for Directed Energy Deposition

Optimization of process parameters is crucial for enhancing the performance of Directed Energy Deposition (DED). This includes controlling laser power, deposition rate, scanning speed, and powder feed rate to achieve desired material properties. Advanced control systems can monitor and adjust these parameters in real-time to maintain consistent quality throughout the build process, resulting in improved mechanical properties and reduced defects in the final components.- Process optimization for Directed Energy Deposition: Various process parameters can be optimized to enhance the performance of Directed Energy Deposition (DED) processes. These parameters include laser power, deposition rate, material feed rate, and scanning strategies. Optimization of these parameters leads to improved material properties, reduced defects, and enhanced overall quality of the fabricated components. Advanced control systems can be implemented to monitor and adjust these parameters in real-time during the deposition process.

- Material selection and preparation for DED applications: The selection and preparation of materials significantly impact the performance of Directed Energy Deposition processes. Various metal powders, alloys, and composite materials can be used in DED applications, each offering specific advantages. Proper material preparation, including powder size distribution, morphology, and chemical composition, is crucial for achieving optimal deposition results. Pre-processing treatments of materials can enhance flowability and deposition characteristics, leading to improved build quality.

- Monitoring and quality control systems for DED: Advanced monitoring and quality control systems are essential for ensuring high performance in Directed Energy Deposition processes. These systems include in-situ monitoring technologies that can detect defects, measure dimensional accuracy, and assess material properties during the deposition process. Thermal imaging, optical sensors, and acoustic monitoring can be integrated to provide real-time feedback on the build quality. Data analytics and machine learning algorithms can be employed to predict and prevent potential issues before they occur.

- Post-processing techniques for DED components: Various post-processing techniques can be applied to enhance the performance of components manufactured using Directed Energy Deposition. These techniques include heat treatment, surface finishing, machining, and hot isostatic pressing. Post-processing can improve mechanical properties, reduce residual stresses, enhance surface quality, and ensure dimensional accuracy of the fabricated parts. The selection of appropriate post-processing methods depends on the specific application requirements and the materials used in the DED process.

- Hybrid manufacturing approaches combining DED with other processes: Hybrid manufacturing approaches that combine Directed Energy Deposition with other manufacturing processes can significantly enhance overall performance. These hybrid approaches include integrating DED with subtractive manufacturing methods, such as CNC machining, or combining DED with other additive manufacturing techniques. Such integration allows for the fabrication of complex geometries with improved surface finish, dimensional accuracy, and mechanical properties. Hybrid systems can also reduce production time and material waste while expanding the range of achievable component designs.

02 Material selection and characterization for DED applications

The selection and characterization of materials significantly impact the performance of Directed Energy Deposition processes. Various metal powders, alloys, and composite materials can be used in DED, each offering different mechanical, thermal, and chemical properties. Material characterization techniques help in understanding the microstructure, grain size, and phase composition of deposited materials, which directly influence the strength, durability, and functionality of the fabricated components.Expand Specific Solutions03 Equipment design and configuration for enhanced DED performance

The design and configuration of DED equipment play a vital role in determining process performance. This includes the development of specialized nozzles, powder delivery systems, and motion control platforms. Multi-axis deposition systems allow for complex geometries and improved surface finish, while integrated monitoring systems provide real-time feedback on build quality. Advanced cooling systems and environmental controls help maintain optimal conditions during the deposition process.Expand Specific Solutions04 Post-processing techniques for DED manufactured components

Post-processing techniques are essential for enhancing the performance of components manufactured using Directed Energy Deposition. These techniques include heat treatment to relieve residual stresses, hot isostatic pressing to reduce porosity, and surface finishing operations to improve dimensional accuracy and surface quality. Machining operations may be required to achieve final tolerances, while various surface treatments can enhance wear resistance, corrosion protection, and other functional properties.Expand Specific Solutions05 Quality control and defect detection in DED processes

Implementing robust quality control and defect detection systems is critical for ensuring high performance in Directed Energy Deposition manufacturing. In-situ monitoring techniques using sensors, cameras, and spectroscopy can detect defects during the build process. Machine learning algorithms can analyze this data to predict and prevent defects before they occur. Non-destructive testing methods such as ultrasonic testing, X-ray computed tomography, and infrared thermography help verify the integrity of completed components and ensure they meet performance requirements.Expand Specific Solutions

Leading DED Technology Providers

Directed Energy Deposition (DED) technology is currently in a growth phase, with the market expanding rapidly due to increasing applications in aerospace, automotive, and energy sectors. The global market size for DED is projected to reach significant scale as industries adopt additive manufacturing technologies for complex components. Technologically, DED is advancing toward maturity with key players driving innovation across different sectors. Companies like Siemens AG and Rolls-Royce Corp. are leading industrial applications, while research institutions such as North Carolina State University and Dalian University of Technology are advancing parameter optimization research. Academic-industrial collaborations between entities like Huazhong University of Science & Technology and State Grid Corp. of China are accelerating the technology's development, focusing on process stability, material efficiency, and performance enhancement.

Siemens AG

Technical Solution: Siemens has developed an advanced digital twin approach to DED parameter optimization that integrates process simulation, in-process monitoring, and post-build analysis into a comprehensive optimization framework. Their ADDITIVE Manufacturing Optimizer (ADMO) platform creates physics-based models of the DED process that predict thermal history, residual stress development, and resulting microstructure based on input parameters[7]. The system employs machine learning algorithms trained on extensive experimental data to refine these models and establish correlations between process parameters and part quality metrics. Siemens' approach includes multi-scale modeling that addresses both macroscopic build characteristics and microscopic features like grain structure and precipitation behavior. Their parameter optimization strategy incorporates adaptive scan strategies that modify deposition patterns based on local geometry, with specialized approaches for overhangs, thin walls, and intersections. The company has also developed parameter sets specifically for their hybrid manufacturing systems that combine DED with 5-axis milling, with optimized transitions between additive and subtractive operations[8].

Strengths: Comprehensive digital twin approach enables accurate prediction of process outcomes before physical builds. Their integration with CAD/CAM systems allows for geometry-specific parameter optimization. Weaknesses: The system requires extensive computational resources and detailed material models, making rapid implementation for new materials challenging. The complexity of their full optimization approach may be excessive for simpler applications.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed a proprietary DED parameter optimization system specifically tailored for aerospace components requiring exceptional mechanical properties and reliability. Their approach integrates physics-based modeling with extensive empirical testing to create material-specific processing maps that guide parameter selection. The company's ACCEL (Advanced Component Cooling and Energy Laser) system employs a dual-laser configuration with independent power control, allowing for precise thermal management during deposition[2]. This system incorporates adaptive layer height control that adjusts deposition parameters based on real-time measurements of previous layer characteristics, maintaining consistent build quality throughout tall structures. Rolls-Royce has also pioneered the use of localized inert gas shielding techniques that optimize gas flow patterns around the melt pool, reducing oxygen content to below 10 ppm in critical areas[4]. Their parameter optimization includes specialized scan strategies for thin-walled structures and overhanging features, with toolpath planning algorithms that adjust travel speed and power based on geometric considerations.

Strengths: Exceptional control over microstructure and mechanical properties in high-performance alloys, with demonstrated success in flight-critical components. Their dual-laser system provides superior thermal management for complex geometries. Weaknesses: The system is highly specialized for aerospace materials (primarily nickel superalloys and titanium alloys) and may require significant adaptation for other material systems. The proprietary nature of their parameter optimization algorithms limits broader industry adoption.

Critical Process Variables Analysis

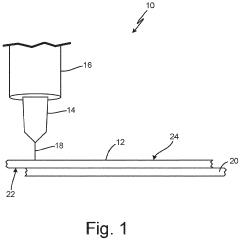

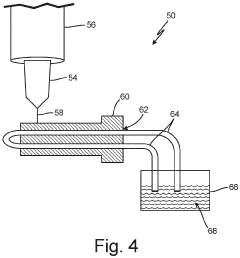

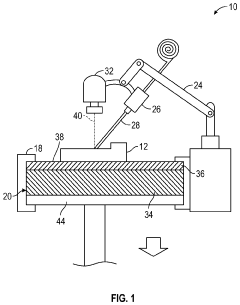

Systems and methods for in process heating for direct energy deposition applications

PatentActiveEP3885065A1

Innovation

- Conductive heating of the base during the DED process, where the base is heated to a temperature 100 to 200 degrees Celsius above ambient, reduces thermal stresses and improves weldability by controlling the additive manufacturing process, thereby enhancing the properties of the finished object.

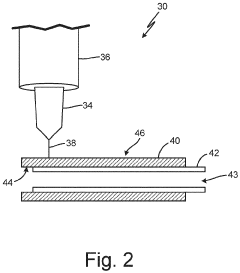

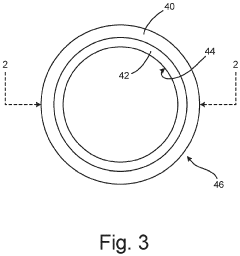

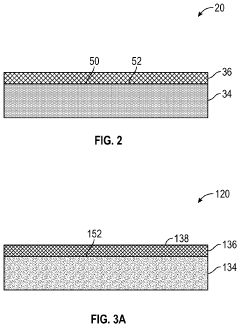

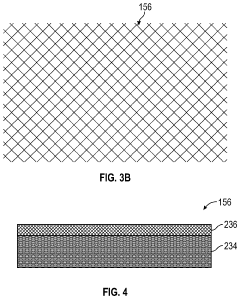

Build substrate for directed energy deposition additive manufacturing

PatentPendingUS20230415238A1

Innovation

- A build substrate with a clad metal layer that supports stresses and temperatures during deposition, allowing the article to be fused to the substrate and easily removed without additional cutting equipment, featuring a support substrate with a clad metal layer that can be dissolved or patterned for facilitated separation.

Material Compatibility Assessment

Material compatibility represents a critical factor in the optimization of Directed Energy Deposition (DED) processes. The selection of appropriate materials significantly impacts the overall performance, quality, and reliability of fabricated components. Current DED technologies demonstrate varying degrees of compatibility with different material classes, including metals, alloys, ceramics, and composites. Notably, nickel-based superalloys, titanium alloys, and stainless steels exhibit excellent processability through DED methods, while refractory metals and certain ceramic materials present considerable challenges.

The compatibility assessment must consider multiple factors including thermal properties, melting points, thermal expansion coefficients, and chemical reactivity. Materials with similar thermal expansion characteristics tend to produce components with fewer residual stresses and reduced susceptibility to cracking. Additionally, the powder particle size distribution significantly influences material flowability and deposition quality, with optimal ranges typically between 45-150 μm depending on the specific DED system configuration.

Interfacial reactions between dissimilar materials during multi-material deposition represent another critical aspect of compatibility assessment. These reactions can lead to the formation of intermetallic compounds or brittle phases that may compromise mechanical properties. Recent research has demonstrated successful gradient structures between titanium alloys and stainless steels through carefully controlled process parameters, highlighting the potential for expanding material compatibility boundaries.

Environmental factors also play a substantial role in material compatibility. Oxygen-sensitive materials such as titanium and aluminum require stringent atmospheric control during deposition to prevent oxidation and subsequent degradation of mechanical properties. Advanced DED systems incorporate localized shielding gas delivery or enclosed processing chambers to maintain inert atmospheres, thereby expanding the range of compatible materials.

Post-processing requirements must be considered within the compatibility assessment framework. Materials that require extensive heat treatment or hot isostatic pressing to achieve desired properties may present economic or practical limitations. The development of in-situ heat treatment strategies during deposition has shown promise in reducing post-processing requirements for certain material systems, particularly for precipitation-hardening alloys.

Recent advances in computational modeling have enhanced material compatibility predictions, allowing for rapid assessment of new material combinations without extensive experimental trials. These models incorporate thermodynamic databases, kinetic parameters, and process physics to simulate microstructural evolution during deposition. Such predictive capabilities accelerate the identification of optimal processing windows for novel material systems and facilitate the development of tailored parameter sets for specific applications.

The compatibility assessment must consider multiple factors including thermal properties, melting points, thermal expansion coefficients, and chemical reactivity. Materials with similar thermal expansion characteristics tend to produce components with fewer residual stresses and reduced susceptibility to cracking. Additionally, the powder particle size distribution significantly influences material flowability and deposition quality, with optimal ranges typically between 45-150 μm depending on the specific DED system configuration.

Interfacial reactions between dissimilar materials during multi-material deposition represent another critical aspect of compatibility assessment. These reactions can lead to the formation of intermetallic compounds or brittle phases that may compromise mechanical properties. Recent research has demonstrated successful gradient structures between titanium alloys and stainless steels through carefully controlled process parameters, highlighting the potential for expanding material compatibility boundaries.

Environmental factors also play a substantial role in material compatibility. Oxygen-sensitive materials such as titanium and aluminum require stringent atmospheric control during deposition to prevent oxidation and subsequent degradation of mechanical properties. Advanced DED systems incorporate localized shielding gas delivery or enclosed processing chambers to maintain inert atmospheres, thereby expanding the range of compatible materials.

Post-processing requirements must be considered within the compatibility assessment framework. Materials that require extensive heat treatment or hot isostatic pressing to achieve desired properties may present economic or practical limitations. The development of in-situ heat treatment strategies during deposition has shown promise in reducing post-processing requirements for certain material systems, particularly for precipitation-hardening alloys.

Recent advances in computational modeling have enhanced material compatibility predictions, allowing for rapid assessment of new material combinations without extensive experimental trials. These models incorporate thermodynamic databases, kinetic parameters, and process physics to simulate microstructural evolution during deposition. Such predictive capabilities accelerate the identification of optimal processing windows for novel material systems and facilitate the development of tailored parameter sets for specific applications.

Quality Control and Certification Standards

Quality control and certification standards play a pivotal role in the industrial adoption of Directed Energy Deposition (DED) technology. As the optimization of DED parameters directly impacts product quality, establishing robust quality assurance frameworks becomes essential for consistent manufacturing outcomes. Currently, several international standards organizations, including ASTM International, ISO, and AWS, have developed preliminary guidelines for additive manufacturing processes, though specific standards for DED parameter optimization remain under development.

The quality control ecosystem for DED encompasses both in-process monitoring systems and post-build inspection protocols. Advanced monitoring technologies such as thermal imaging cameras, high-speed photography, and spectroscopic analysis enable real-time assessment of melt pool dynamics, layer formation, and material deposition rates. These systems can detect anomalies during fabrication, allowing for immediate parameter adjustments to maintain quality thresholds.

Post-processing inspection methods include non-destructive testing (NDT) techniques such as X-ray computed tomography, ultrasonic testing, and dye penetrant inspection to identify internal defects, porosity, and lack-of-fusion issues. Mechanical testing protocols assess tensile strength, fatigue resistance, and hardness properties to ensure compliance with application-specific requirements. Surface metrology tools evaluate dimensional accuracy and surface roughness, which are directly influenced by DED parameter selection.

Certification pathways for DED-manufactured components vary by industry sector. Aerospace applications follow stringent certification frameworks such as those established by the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA), requiring extensive material qualification and process validation. Medical device manufacturers must adhere to FDA and equivalent regulatory guidelines, emphasizing biocompatibility and mechanical reliability.

Emerging digital certification approaches incorporate blockchain technology and digital twins to create immutable records of manufacturing parameters, material properties, and quality inspection results. These systems establish traceability throughout the product lifecycle and facilitate regulatory compliance documentation.

Standardization efforts are increasingly focusing on parameter-specific quality metrics, including correlations between energy density, scan strategy, and resultant material properties. The development of process-parameter envelopes that define acceptable operating ranges for specific material systems represents a significant advancement toward industry-wide standardization.

Future certification frameworks will likely incorporate machine learning algorithms that can predict part quality based on historical parameter-quality relationships, enabling predictive quality assurance rather than reactive inspection methodologies. This shift toward data-driven certification will accelerate the industrial adoption of optimized DED processes across critical manufacturing sectors.

The quality control ecosystem for DED encompasses both in-process monitoring systems and post-build inspection protocols. Advanced monitoring technologies such as thermal imaging cameras, high-speed photography, and spectroscopic analysis enable real-time assessment of melt pool dynamics, layer formation, and material deposition rates. These systems can detect anomalies during fabrication, allowing for immediate parameter adjustments to maintain quality thresholds.

Post-processing inspection methods include non-destructive testing (NDT) techniques such as X-ray computed tomography, ultrasonic testing, and dye penetrant inspection to identify internal defects, porosity, and lack-of-fusion issues. Mechanical testing protocols assess tensile strength, fatigue resistance, and hardness properties to ensure compliance with application-specific requirements. Surface metrology tools evaluate dimensional accuracy and surface roughness, which are directly influenced by DED parameter selection.

Certification pathways for DED-manufactured components vary by industry sector. Aerospace applications follow stringent certification frameworks such as those established by the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA), requiring extensive material qualification and process validation. Medical device manufacturers must adhere to FDA and equivalent regulatory guidelines, emphasizing biocompatibility and mechanical reliability.

Emerging digital certification approaches incorporate blockchain technology and digital twins to create immutable records of manufacturing parameters, material properties, and quality inspection results. These systems establish traceability throughout the product lifecycle and facilitate regulatory compliance documentation.

Standardization efforts are increasingly focusing on parameter-specific quality metrics, including correlations between energy density, scan strategy, and resultant material properties. The development of process-parameter envelopes that define acceptable operating ranges for specific material systems represents a significant advancement toward industry-wide standardization.

Future certification frameworks will likely incorporate machine learning algorithms that can predict part quality based on historical parameter-quality relationships, enabling predictive quality assurance rather than reactive inspection methodologies. This shift toward data-driven certification will accelerate the industrial adoption of optimized DED processes across critical manufacturing sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!