Comparative Analysis: Directed Energy Deposition in Competing Industries

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) emerged in the late 1990s as an advanced additive manufacturing technology capable of producing near-net-shape metal components. The technology evolved from laser cladding processes, with significant advancements occurring in the early 2000s when researchers began exploring its potential for creating functional metal parts rather than merely surface coatings. DED's distinctive capability to deposit material in any direction on existing components has positioned it as a transformative technology across multiple industries.

The evolution of DED technology has been marked by continuous improvements in process control, material compatibility, and deposition accuracy. Early systems were limited by inconsistent material properties and poor surface finish, but modern DED equipment incorporates sophisticated monitoring systems, closed-loop controls, and multi-axis deposition capabilities that have dramatically enhanced part quality and repeatability.

Current market trends indicate accelerating adoption of DED across aerospace, defense, medical, and heavy machinery sectors, with the global market projected to grow at a CAGR of approximately 14.5% through 2028. This growth is primarily driven by increasing demand for repair solutions, part customization, and the ability to process high-value materials like titanium alloys, Inconel, and tool steels.

The primary technical objectives for DED development focus on several key areas. First, improving deposition rates while maintaining or enhancing part quality remains a critical goal, as current systems still face throughput limitations compared to conventional manufacturing. Second, expanding the range of compatible materials, particularly for multi-material components, represents a significant opportunity for differentiation among competing industries.

Third, enhancing process monitoring and control systems to achieve consistent material properties throughout complex geometries continues to challenge researchers and equipment manufacturers. Fourth, reducing post-processing requirements through improved surface finish and dimensional accuracy would substantially increase DED's economic viability for end-use parts.

The competitive landscape reveals divergent approaches to these objectives, with aerospace prioritizing material qualification and certification pathways, while automotive sectors focus on cost reduction and throughput improvements. Medical device manufacturers emphasize precision and biocompatibility, whereas heavy equipment industries concentrate on repair applications and wear-resistant coatings.

Understanding these industry-specific priorities provides crucial context for evaluating the competitive positioning of different DED implementations and identifying cross-industry opportunities for technology transfer and adaptation.

The evolution of DED technology has been marked by continuous improvements in process control, material compatibility, and deposition accuracy. Early systems were limited by inconsistent material properties and poor surface finish, but modern DED equipment incorporates sophisticated monitoring systems, closed-loop controls, and multi-axis deposition capabilities that have dramatically enhanced part quality and repeatability.

Current market trends indicate accelerating adoption of DED across aerospace, defense, medical, and heavy machinery sectors, with the global market projected to grow at a CAGR of approximately 14.5% through 2028. This growth is primarily driven by increasing demand for repair solutions, part customization, and the ability to process high-value materials like titanium alloys, Inconel, and tool steels.

The primary technical objectives for DED development focus on several key areas. First, improving deposition rates while maintaining or enhancing part quality remains a critical goal, as current systems still face throughput limitations compared to conventional manufacturing. Second, expanding the range of compatible materials, particularly for multi-material components, represents a significant opportunity for differentiation among competing industries.

Third, enhancing process monitoring and control systems to achieve consistent material properties throughout complex geometries continues to challenge researchers and equipment manufacturers. Fourth, reducing post-processing requirements through improved surface finish and dimensional accuracy would substantially increase DED's economic viability for end-use parts.

The competitive landscape reveals divergent approaches to these objectives, with aerospace prioritizing material qualification and certification pathways, while automotive sectors focus on cost reduction and throughput improvements. Medical device manufacturers emphasize precision and biocompatibility, whereas heavy equipment industries concentrate on repair applications and wear-resistant coatings.

Understanding these industry-specific priorities provides crucial context for evaluating the competitive positioning of different DED implementations and identifying cross-industry opportunities for technology transfer and adaptation.

Market Demand Analysis for DED Applications

The global market for Directed Energy Deposition (DED) applications has been experiencing significant growth, driven by increasing demand across multiple industries. The aerospace sector currently represents the largest market segment, valuing DED technology for its ability to repair high-value components and manufacture complex geometries with specialized materials. This sector's demand is primarily fueled by the need to reduce buy-to-fly ratios and decrease material waste during production of critical components.

The automotive industry has emerged as another key market for DED applications, particularly as manufacturers seek lightweight solutions and rapid prototyping capabilities. The technology's ability to create multi-material parts and perform repairs on existing tooling has positioned it as a valuable asset in automotive manufacturing processes, especially as the industry transitions toward electric vehicles requiring novel component designs.

Medical device manufacturing represents a rapidly growing market segment for DED technology. The demand stems from the ability to create patient-specific implants with complex internal structures and biocompatible materials. Market research indicates that personalized medical solutions using additive manufacturing technologies like DED could grow at a compound annual rate exceeding traditional manufacturing methods in the healthcare sector.

Energy sector applications, particularly in oil and gas, power generation, and renewable energy, demonstrate substantial market potential for DED. The technology's capacity to repair and enhance the performance of turbine blades, drill bits, and other components exposed to extreme conditions drives adoption in these industries. The ability to apply wear-resistant coatings and perform on-site repairs represents significant value propositions.

Defense applications constitute another substantial market segment, with demand for rapid field repairs, spare parts manufacturing, and development of next-generation materials and components. The strategic importance of reducing supply chain vulnerabilities has accelerated interest in deployable DED systems.

Market forecasts suggest the global DED equipment and services market will continue expanding as the technology matures and becomes more accessible to small and medium enterprises. Regional analysis indicates North America currently leads in market share, followed by Europe and Asia-Pacific, though the latter is expected to demonstrate the highest growth rate in the coming years.

Customer requirements across these industries consistently emphasize several factors: improved material efficiency, reduced lead times, enhanced component performance, and cost-effectiveness compared to traditional manufacturing methods. The market increasingly demands integrated solutions that combine DED hardware with specialized software for design optimization and process control.

The automotive industry has emerged as another key market for DED applications, particularly as manufacturers seek lightweight solutions and rapid prototyping capabilities. The technology's ability to create multi-material parts and perform repairs on existing tooling has positioned it as a valuable asset in automotive manufacturing processes, especially as the industry transitions toward electric vehicles requiring novel component designs.

Medical device manufacturing represents a rapidly growing market segment for DED technology. The demand stems from the ability to create patient-specific implants with complex internal structures and biocompatible materials. Market research indicates that personalized medical solutions using additive manufacturing technologies like DED could grow at a compound annual rate exceeding traditional manufacturing methods in the healthcare sector.

Energy sector applications, particularly in oil and gas, power generation, and renewable energy, demonstrate substantial market potential for DED. The technology's capacity to repair and enhance the performance of turbine blades, drill bits, and other components exposed to extreme conditions drives adoption in these industries. The ability to apply wear-resistant coatings and perform on-site repairs represents significant value propositions.

Defense applications constitute another substantial market segment, with demand for rapid field repairs, spare parts manufacturing, and development of next-generation materials and components. The strategic importance of reducing supply chain vulnerabilities has accelerated interest in deployable DED systems.

Market forecasts suggest the global DED equipment and services market will continue expanding as the technology matures and becomes more accessible to small and medium enterprises. Regional analysis indicates North America currently leads in market share, followed by Europe and Asia-Pacific, though the latter is expected to demonstrate the highest growth rate in the coming years.

Customer requirements across these industries consistently emphasize several factors: improved material efficiency, reduced lead times, enhanced component performance, and cost-effectiveness compared to traditional manufacturing methods. The market increasingly demands integrated solutions that combine DED hardware with specialized software for design optimization and process control.

Global DED Technology Landscape and Challenges

Directed Energy Deposition (DED) technology has evolved significantly over the past decade, establishing itself as a critical additive manufacturing process across multiple industries. The global landscape of DED implementation reveals considerable variation in adoption rates, technological sophistication, and application focus across different regions. North America, particularly the United States, leads in DED research and implementation, with significant investments from aerospace, defense, and medical sectors driving innovation. The European market demonstrates strong growth in automotive and industrial applications, with countries like Germany, France, and the UK hosting advanced research centers dedicated to metal additive manufacturing technologies.

Asia-Pacific represents the fastest-growing region for DED adoption, with China making substantial investments in developing indigenous capabilities, particularly for large-scale metal components. Japan and South Korea focus on high-precision applications in electronics and automotive sectors, emphasizing process refinement and material development.

Despite its promising trajectory, DED technology faces several significant challenges that impede broader industrial adoption. Material limitations remain a primary concern, as not all metal alloys perform consistently in DED processes. The technology struggles with processing certain high-temperature materials and maintaining consistent properties throughout large builds. Process stability and repeatability issues continue to challenge manufacturers, with variations in thermal conditions leading to inconsistent mechanical properties across builds.

Quality assurance represents another major hurdle, as in-situ monitoring systems remain inadequate for real-time defect detection and process control. The lack of standardized qualification procedures further complicates industrial implementation, particularly in highly regulated sectors like aerospace and medical devices. Cost factors also present significant barriers, with high-powered laser systems and specialized powder materials driving up both capital and operational expenses.

Regulatory frameworks for DED technology vary substantially across regions, creating compliance challenges for global manufacturers. While some countries have developed comprehensive standards for additive manufacturing processes, many regions lack specific guidelines for DED implementation, creating uncertainty for industrial adopters.

The environmental impact of DED processes presents both challenges and opportunities. While the technology offers potential material efficiency improvements compared to traditional manufacturing, concerns about energy consumption, powder waste management, and workplace safety require further attention as implementation scales.

Looking forward, the global DED landscape is poised for significant transformation as hybrid manufacturing systems gain traction, combining DED capabilities with traditional machining processes to overcome current limitations. Cross-industry collaboration and knowledge sharing will be essential to address the identified challenges and accelerate the technology's maturation across diverse industrial applications.

Asia-Pacific represents the fastest-growing region for DED adoption, with China making substantial investments in developing indigenous capabilities, particularly for large-scale metal components. Japan and South Korea focus on high-precision applications in electronics and automotive sectors, emphasizing process refinement and material development.

Despite its promising trajectory, DED technology faces several significant challenges that impede broader industrial adoption. Material limitations remain a primary concern, as not all metal alloys perform consistently in DED processes. The technology struggles with processing certain high-temperature materials and maintaining consistent properties throughout large builds. Process stability and repeatability issues continue to challenge manufacturers, with variations in thermal conditions leading to inconsistent mechanical properties across builds.

Quality assurance represents another major hurdle, as in-situ monitoring systems remain inadequate for real-time defect detection and process control. The lack of standardized qualification procedures further complicates industrial implementation, particularly in highly regulated sectors like aerospace and medical devices. Cost factors also present significant barriers, with high-powered laser systems and specialized powder materials driving up both capital and operational expenses.

Regulatory frameworks for DED technology vary substantially across regions, creating compliance challenges for global manufacturers. While some countries have developed comprehensive standards for additive manufacturing processes, many regions lack specific guidelines for DED implementation, creating uncertainty for industrial adopters.

The environmental impact of DED processes presents both challenges and opportunities. While the technology offers potential material efficiency improvements compared to traditional manufacturing, concerns about energy consumption, powder waste management, and workplace safety require further attention as implementation scales.

Looking forward, the global DED landscape is poised for significant transformation as hybrid manufacturing systems gain traction, combining DED capabilities with traditional machining processes to overcome current limitations. Cross-industry collaboration and knowledge sharing will be essential to address the identified challenges and accelerate the technology's maturation across diverse industrial applications.

Current DED Implementation Solutions

01 Directed Energy Deposition Process Fundamentals

Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits melted material onto a specified surface, where it solidifies. This technology allows for the creation of complex geometries and can be used with various materials including metals, polymers, and ceramics. The process parameters such as energy source power, material feed rate, and deposition path significantly influence the quality of the final product.- Process parameters and control in DED: Directed Energy Deposition (DED) processes require precise control of various parameters to achieve optimal results. These parameters include laser power, deposition rate, material feed rate, and motion control. Advanced control systems can monitor and adjust these parameters in real-time to maintain consistent quality throughout the build process. Proper parameter optimization helps minimize defects, improve surface finish, and enhance the mechanical properties of the final parts.

- Material considerations for DED applications: The selection and preparation of materials play a crucial role in Directed Energy Deposition processes. Various metal powders, wires, and alloys can be used depending on the specific application requirements. Material properties such as particle size distribution, flowability, and thermal characteristics significantly impact the deposition quality. Multi-material deposition capabilities allow for functionally graded components with varying material compositions throughout the part, enabling customized mechanical and thermal properties.

- Equipment design and configuration for DED systems: DED systems incorporate various equipment configurations to meet different manufacturing needs. These systems typically include energy sources (lasers, electron beams, or plasma arcs), material delivery mechanisms, motion control systems, and monitoring equipment. Multi-axis deposition capabilities allow for complex geometries and overhanging features without support structures. Closed-loop feedback systems with sensors for temperature, melt pool dimensions, and layer height enable real-time adjustments to maintain quality and dimensional accuracy.

- Post-processing techniques for DED manufactured parts: Parts produced through Directed Energy Deposition often require post-processing to achieve final specifications. Common post-processing techniques include heat treatment to relieve residual stresses, machining to improve dimensional accuracy and surface finish, and hot isostatic pressing to reduce porosity. Surface treatments such as shot peening or polishing may be applied to enhance fatigue resistance and aesthetic qualities. These post-processing steps are essential for ensuring that DED-manufactured components meet industry standards and performance requirements.

- Hybrid manufacturing approaches combining DED with other processes: Hybrid manufacturing systems integrate Directed Energy Deposition with other manufacturing processes such as machining, grinding, or inspection within a single platform. This approach allows for alternating between additive and subtractive operations, enabling the production of complex components with high precision. Hybrid systems can repair or modify existing parts by selectively adding material to worn or damaged areas. The combination of technologies provides advantages in terms of reduced production time, improved material utilization, and enhanced geometric capabilities compared to standalone processes.

02 Material Considerations in DED Applications

The selection and preparation of materials play a crucial role in Directed Energy Deposition processes. Various metal powders and wire feedstocks can be used, including titanium alloys, nickel-based superalloys, stainless steels, and aluminum alloys. The material properties, such as particle size distribution, flowability, and thermal conductivity, significantly affect the deposition quality. Pre-processing treatments and post-processing heat treatments are often necessary to achieve desired mechanical properties and microstructure in the final components. Material compatibility with the energy source and substrate is also an important consideration.Expand Specific Solutions03 Energy Source Technologies for DED

Different energy sources can be employed in Directed Energy Deposition systems, each with specific advantages and limitations. Laser-based DED systems use high-power lasers to create a melt pool on the substrate where material is deposited. Electron beam systems operate in vacuum environments and offer high energy efficiency. Plasma arc and electric arc systems provide cost-effective alternatives with high deposition rates but lower precision. The selection of an appropriate energy source depends on factors such as required precision, material compatibility, production volume, and economic considerations.Expand Specific Solutions04 Process Control and Monitoring Systems

Advanced control and monitoring systems are essential for ensuring quality and repeatability in Directed Energy Deposition processes. These systems typically include real-time monitoring of process parameters such as melt pool temperature, dimensions, and cooling rates. Closed-loop control systems adjust process parameters dynamically based on sensor feedback to maintain consistent quality. Machine learning and artificial intelligence algorithms are increasingly being integrated to predict and prevent defects. Vision systems and thermal cameras provide valuable data for process optimization and quality assurance.Expand Specific Solutions05 Hybrid Manufacturing and Multi-Material DED

Hybrid manufacturing systems combine Directed Energy Deposition with traditional manufacturing processes such as machining or forming. These integrated systems allow for the repair, modification, or feature addition to existing components. Multi-material deposition capabilities enable the creation of functionally graded materials and components with varying properties throughout their structure. This approach offers advantages in terms of material efficiency, reduced processing time, and enhanced component functionality. Applications include repair of high-value components, tooling with conformal cooling channels, and parts with optimized mechanical properties.Expand Specific Solutions

Key Industrial Players in DED Manufacturing

The Directed Energy Deposition (DED) market is currently in a growth phase, characterized by increasing adoption across aerospace, defense, and manufacturing sectors. The global market size is projected to reach approximately $1.5 billion by 2027, with a CAGR of 15-20%. From a technological maturity perspective, the landscape shows varying degrees of advancement. Leading academic institutions like Tianjin University and Zhejiang University are driving fundamental research, while industrial players demonstrate different specialization levels. Aerospace companies including GE Avio, Airbus Operations, and Rolls-Royce have achieved significant commercial implementation, particularly for component repair and prototyping. Meanwhile, emerging players like Spar Systems are developing novel applications in energy recovery systems. The competitive landscape is further shaped by material suppliers like Alcoa, who are developing specialized metal powders optimized for DED processes.

Tianjin University

Technical Solution: Tianjin University has pioneered research in multi-material Directed Energy Deposition (DED) technology, developing systems capable of creating functionally graded materials with controlled composition transitions. Their approach utilizes a dual-powder feeding mechanism that can dynamically adjust material composition during deposition, enabling the creation of components with spatially varied properties. The university's research team has developed specialized nozzle designs that improve powder efficiency by up to 30% compared to conventional systems, reducing material waste in the DED process. Their technology incorporates advanced thermal modeling algorithms that predict and compensate for residual stress development during fabrication, significantly reducing part distortion. Tianjin University has also created novel post-processing techniques specifically designed for DED-manufactured components, including specialized heat treatment protocols that optimize microstructure development in deposited materials.

Strengths: Leading research in functionally graded materials; innovative powder delivery systems; strong academic foundation with extensive published research. Weaknesses: Less industrial implementation experience compared to commercial entities; technology still primarily in research phase rather than full commercial deployment; limited scale-up validation.

GE Avio Srl

Technical Solution: GE Avio has developed an integrated Directed Energy Deposition (DED) platform specifically designed for aviation components, focusing on high-temperature superalloys and titanium alloys. Their technology employs a multi-axis deposition system with advanced path planning algorithms that optimize material deposition strategies based on part geometry and thermal considerations. GE Avio's DED system incorporates in-situ monitoring using multiple sensor types, including thermal cameras, pyrometers, and spectrometers, creating a comprehensive process signature that enables real-time quality verification. The company has pioneered the use of DED for repair applications in aviation, developing specialized techniques for restoring damaged turbine components with material properties equivalent to original specifications. Their technology includes proprietary powder formulations specifically engineered for DED processes, with optimized flow characteristics and particle size distributions that enhance deposition consistency and reduce porosity.

Strengths: Deep integration with aviation certification processes; comprehensive in-situ monitoring capabilities; established repair protocols for critical components. Weaknesses: Technology primarily optimized for aerospace applications with less flexibility for other industries; higher operational costs; complex system requiring specialized operator training.

Critical DED Patents and Technical Innovations

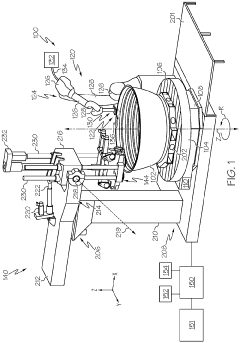

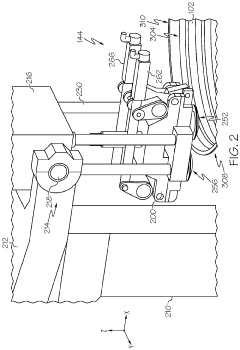

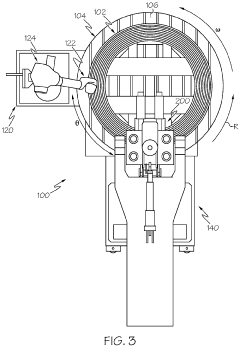

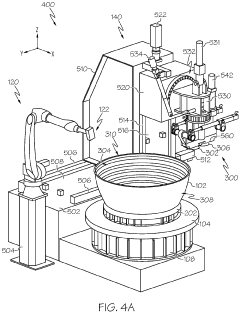

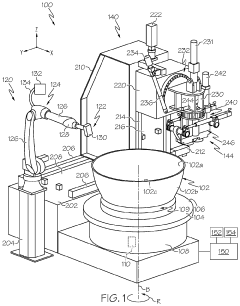

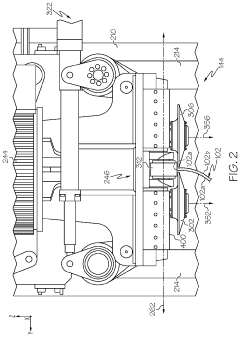

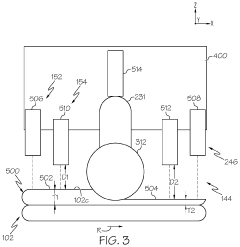

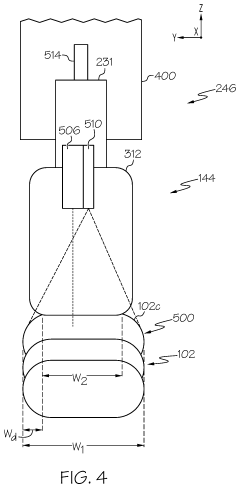

Additive manufacturing system and method for compression of material during material deposition

PatentPendingEP4302912A1

Innovation

- A DED system that integrates a rotary build table and a compression rig allowing simultaneous deposition and compression phases, utilizing a robotic arm and compression head with rollers to apply compressive loads during material deposition, controlled by a system that ensures uniform temperature and strain application.

Additive manufacturing systems or methods for compression of material based on detected temperature

PatentPendingUS20240009929A1

Innovation

- The implementation of a DED system that combines a deposition head with a compression rig, allowing for simultaneous material deposition and compression using a compression head with temperature and distance sensors to adjust the position and load applied, enabling continuous compressive loading during deposition.

Cross-Industry DED Application Comparison

Directed Energy Deposition (DED) technology has been adopted across multiple industries with varying degrees of implementation and success. The aerospace sector leads in DED adoption, utilizing the technology primarily for component repair and manufacturing of complex geometries with high-value materials such as titanium alloys and nickel-based superalloys. Aerospace applications benefit from DED's ability to create near-net-shape parts with minimal material waste, which is particularly advantageous when working with expensive materials.

In contrast, the automotive industry has implemented DED technology more selectively, focusing on tooling applications and rapid prototyping rather than end-use components. The cost-sensitive nature of automotive manufacturing has limited widespread adoption, though recent advancements in process control and material efficiency are gradually increasing implementation rates, particularly for high-performance vehicles and specialized components.

The medical device industry presents another distinct application profile, where DED is employed for creating customized implants and surgical instruments. The technology's ability to work with biocompatible materials like titanium makes it particularly valuable in this sector. However, regulatory requirements and certification processes have created a more measured adoption curve compared to other industries.

Energy sector applications of DED technology focus primarily on repair and refurbishment of high-value components such as turbine blades and drilling equipment. The harsh operating environments of these components demand materials with exceptional mechanical properties, which DED can deliver through controlled deposition and microstructure development.

Defense applications represent perhaps the most advanced implementation of DED technology, with significant investments in mobile manufacturing capabilities and field repair systems. The strategic advantage of on-demand manufacturing in remote locations has driven substantial research and development in this sector, resulting in more robust and versatile DED systems.

Cross-industry analysis reveals that material compatibility remains a universal challenge, though each industry has developed specialized approaches based on their specific requirements. Process monitoring and quality control systems show significant variation across industries, with aerospace and medical applications implementing the most stringent protocols. Cost justification models differ substantially, with high-value, low-volume industries achieving faster return on investment compared to mass production environments.

Knowledge transfer between industries has been limited by proprietary concerns and industry-specific requirements, suggesting an opportunity for more collaborative development approaches that could accelerate technology maturation across all sectors.

In contrast, the automotive industry has implemented DED technology more selectively, focusing on tooling applications and rapid prototyping rather than end-use components. The cost-sensitive nature of automotive manufacturing has limited widespread adoption, though recent advancements in process control and material efficiency are gradually increasing implementation rates, particularly for high-performance vehicles and specialized components.

The medical device industry presents another distinct application profile, where DED is employed for creating customized implants and surgical instruments. The technology's ability to work with biocompatible materials like titanium makes it particularly valuable in this sector. However, regulatory requirements and certification processes have created a more measured adoption curve compared to other industries.

Energy sector applications of DED technology focus primarily on repair and refurbishment of high-value components such as turbine blades and drilling equipment. The harsh operating environments of these components demand materials with exceptional mechanical properties, which DED can deliver through controlled deposition and microstructure development.

Defense applications represent perhaps the most advanced implementation of DED technology, with significant investments in mobile manufacturing capabilities and field repair systems. The strategic advantage of on-demand manufacturing in remote locations has driven substantial research and development in this sector, resulting in more robust and versatile DED systems.

Cross-industry analysis reveals that material compatibility remains a universal challenge, though each industry has developed specialized approaches based on their specific requirements. Process monitoring and quality control systems show significant variation across industries, with aerospace and medical applications implementing the most stringent protocols. Cost justification models differ substantially, with high-value, low-volume industries achieving faster return on investment compared to mass production environments.

Knowledge transfer between industries has been limited by proprietary concerns and industry-specific requirements, suggesting an opportunity for more collaborative development approaches that could accelerate technology maturation across all sectors.

Material Compatibility and Sustainability in DED

Material compatibility represents a critical dimension in the advancement of Directed Energy Deposition (DED) technology across competing industries. The versatility of DED processes allows for the processing of a wide spectrum of materials, including metals, ceramics, polymers, and composites, though with varying degrees of success and application-specific challenges. Metals remain the most extensively utilized material category in DED applications, with particular emphasis on titanium alloys, nickel-based superalloys, and stainless steels due to their favorable thermal properties and industrial relevance.

The sustainability aspects of DED technology present both opportunities and challenges. On the positive side, DED offers significant material efficiency advantages compared to traditional subtractive manufacturing methods, with material utilization rates typically exceeding 90% versus 20-30% for conventional machining processes. This reduction in material waste translates directly to decreased environmental impact and resource consumption, particularly significant for rare or expensive materials commonly used in aerospace and medical applications.

Energy consumption patterns in DED processes vary considerably across different industrial implementations. While the high-energy requirements for material melting represent a sustainability concern, the overall life-cycle assessment often demonstrates net positive environmental impacts when considering reduced transportation needs, decreased inventory requirements, and extended component lifespans through repair capabilities. Recent technological innovations have focused on improving energy efficiency through optimized process parameters and advanced power management systems.

Material recyclability within DED systems presents another dimension of sustainability consideration. Unused powder materials can typically be reclaimed and reprocessed, though degradation concerns exist after multiple recycling iterations. The aerospace industry has pioneered closed-loop material systems that maximize reusability while maintaining stringent quality requirements, establishing benchmarks for other sectors to follow.

Cross-industry compatibility challenges persist, particularly regarding certification and standardization of materials processed via DED. The medical industry demands biocompatibility and strict regulatory compliance, while aerospace applications prioritize fatigue resistance and thermal stability. These divergent requirements have led to industry-specific material development pathways, sometimes limiting knowledge transfer and technological cross-pollination between sectors.

Future sustainability improvements in DED technology will likely emerge from interdisciplinary approaches combining materials science, process engineering, and environmental assessment methodologies. Promising research directions include development of biodegradable support structures, integration of renewable energy sources for DED systems, and creation of comprehensive material lifecycle management protocols tailored to additive manufacturing environments.

The sustainability aspects of DED technology present both opportunities and challenges. On the positive side, DED offers significant material efficiency advantages compared to traditional subtractive manufacturing methods, with material utilization rates typically exceeding 90% versus 20-30% for conventional machining processes. This reduction in material waste translates directly to decreased environmental impact and resource consumption, particularly significant for rare or expensive materials commonly used in aerospace and medical applications.

Energy consumption patterns in DED processes vary considerably across different industrial implementations. While the high-energy requirements for material melting represent a sustainability concern, the overall life-cycle assessment often demonstrates net positive environmental impacts when considering reduced transportation needs, decreased inventory requirements, and extended component lifespans through repair capabilities. Recent technological innovations have focused on improving energy efficiency through optimized process parameters and advanced power management systems.

Material recyclability within DED systems presents another dimension of sustainability consideration. Unused powder materials can typically be reclaimed and reprocessed, though degradation concerns exist after multiple recycling iterations. The aerospace industry has pioneered closed-loop material systems that maximize reusability while maintaining stringent quality requirements, establishing benchmarks for other sectors to follow.

Cross-industry compatibility challenges persist, particularly regarding certification and standardization of materials processed via DED. The medical industry demands biocompatibility and strict regulatory compliance, while aerospace applications prioritize fatigue resistance and thermal stability. These divergent requirements have led to industry-specific material development pathways, sometimes limiting knowledge transfer and technological cross-pollination between sectors.

Future sustainability improvements in DED technology will likely emerge from interdisciplinary approaches combining materials science, process engineering, and environmental assessment methodologies. Promising research directions include development of biodegradable support structures, integration of renewable energy sources for DED systems, and creation of comprehensive material lifecycle management protocols tailored to additive manufacturing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!