Directed Energy Deposition: Key Contributions to Smart Materials

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Objectives

Directed Energy Deposition (DED) has evolved significantly since its inception in the 1990s as a specialized additive manufacturing technique. Initially developed for repair applications in aerospace and defense sectors, DED technology has undergone remarkable transformation through several distinct phases of development. The early systems focused primarily on metal deposition using laser heat sources with limited material options and relatively poor dimensional accuracy.

By the early 2000s, DED technology experienced its first major evolution with the introduction of multi-axis systems and improved powder delivery mechanisms. This period marked the transition from purely repair-oriented applications to the fabrication of complex geometries and functionally graded materials. The integration of closed-loop monitoring systems during this phase represented a critical advancement in improving process stability and part quality.

The 2010s witnessed a paradigm shift in DED capabilities with the emergence of hybrid DED systems that combined additive and subtractive manufacturing processes. These integrated systems addressed the surface finish limitations of traditional DED while expanding the range of achievable geometries. Simultaneously, significant improvements in process control algorithms and thermal management strategies enabled the processing of increasingly challenging materials, including reactive metals and high-temperature alloys.

Recent technological advancements have focused on expanding DED's role in smart materials development. Modern DED systems now incorporate multiple energy sources (laser, electron beam, plasma arc), synchronized multi-material delivery systems, and advanced in-situ monitoring capabilities. These innovations have positioned DED as a key enabling technology for creating materials with embedded functionality, adaptive properties, and site-specific performance characteristics.

The current technological objective for DED in smart materials fabrication centers on achieving precise control over material composition, microstructure, and properties at the microscale. This includes developing capabilities for depositing materials with programmed responses to external stimuli, creating seamless multi-material interfaces, and embedding sensors or electronic components within structural materials during fabrication.

Looking forward, the strategic goals for DED technology evolution include enhancing deposition resolution to sub-millimeter scales, expanding the compatible material library to include ceramics, polymers, and composites alongside metals, and developing standardized approaches for qualifying DED-produced smart materials for critical applications. Additionally, there is significant focus on reducing the energy intensity of the process and minimizing material waste to align with sustainable manufacturing principles.

By the early 2000s, DED technology experienced its first major evolution with the introduction of multi-axis systems and improved powder delivery mechanisms. This period marked the transition from purely repair-oriented applications to the fabrication of complex geometries and functionally graded materials. The integration of closed-loop monitoring systems during this phase represented a critical advancement in improving process stability and part quality.

The 2010s witnessed a paradigm shift in DED capabilities with the emergence of hybrid DED systems that combined additive and subtractive manufacturing processes. These integrated systems addressed the surface finish limitations of traditional DED while expanding the range of achievable geometries. Simultaneously, significant improvements in process control algorithms and thermal management strategies enabled the processing of increasingly challenging materials, including reactive metals and high-temperature alloys.

Recent technological advancements have focused on expanding DED's role in smart materials development. Modern DED systems now incorporate multiple energy sources (laser, electron beam, plasma arc), synchronized multi-material delivery systems, and advanced in-situ monitoring capabilities. These innovations have positioned DED as a key enabling technology for creating materials with embedded functionality, adaptive properties, and site-specific performance characteristics.

The current technological objective for DED in smart materials fabrication centers on achieving precise control over material composition, microstructure, and properties at the microscale. This includes developing capabilities for depositing materials with programmed responses to external stimuli, creating seamless multi-material interfaces, and embedding sensors or electronic components within structural materials during fabrication.

Looking forward, the strategic goals for DED technology evolution include enhancing deposition resolution to sub-millimeter scales, expanding the compatible material library to include ceramics, polymers, and composites alongside metals, and developing standardized approaches for qualifying DED-produced smart materials for critical applications. Additionally, there is significant focus on reducing the energy intensity of the process and minimizing material waste to align with sustainable manufacturing principles.

Smart Materials Market Analysis

The smart materials market is experiencing significant growth, driven by advancements in manufacturing technologies like Directed Energy Deposition (DED). Current market valuations place the global smart materials sector at approximately 65.7 billion USD in 2023, with projections indicating growth to reach 125.3 billion USD by 2028, representing a compound annual growth rate (CAGR) of 13.8%.

The aerospace and defense sectors currently dominate smart materials consumption, accounting for roughly 32% of market share. This is followed by automotive applications at 24%, healthcare at 18%, and construction at 15%. The remaining 11% is distributed across various industries including consumer electronics and energy. DED technology is particularly influential in aerospace and automotive segments, where its ability to create complex geometries with smart material properties offers substantial competitive advantages.

Regional analysis reveals North America leads the market with 38% share, followed by Europe at 29%, Asia-Pacific at 27%, and the rest of the world at 6%. However, the Asia-Pacific region demonstrates the fastest growth trajectory with a 16.2% CAGR, primarily driven by rapid industrialization in China and India, alongside significant R&D investments in Japan and South Korea.

Shape memory alloys represent the largest segment within smart materials, constituting approximately 35% of the market. Piezoelectric materials follow at 28%, with magnetostrictive materials at 15%, self-healing materials at 12%, and other categories comprising the remaining 10%. DED technology has shown particular promise in the development of multi-material smart components that combine these various material types.

Customer demand patterns indicate increasing preference for materials with multi-functional capabilities, reduced environmental impact, and enhanced durability. Industries are willing to pay premium prices for smart materials that deliver significant performance improvements or enable novel functionalities. The average price premium for advanced smart materials over conventional alternatives ranges from 30% to 120%, depending on application specifics and performance characteristics.

Supply chain analysis reveals potential vulnerabilities in rare earth element availability, which affects approximately 40% of smart material production. DED manufacturing processes offer advantages in material efficiency, potentially reducing dependency on these critical materials by enabling precise deposition and minimizing waste.

Market forecasts suggest particularly strong growth in self-healing materials (18.7% CAGR) and programmable matter applications (22.3% CAGR) over the next five years, areas where DED technology's precision and multi-material capabilities provide significant competitive advantages.

The aerospace and defense sectors currently dominate smart materials consumption, accounting for roughly 32% of market share. This is followed by automotive applications at 24%, healthcare at 18%, and construction at 15%. The remaining 11% is distributed across various industries including consumer electronics and energy. DED technology is particularly influential in aerospace and automotive segments, where its ability to create complex geometries with smart material properties offers substantial competitive advantages.

Regional analysis reveals North America leads the market with 38% share, followed by Europe at 29%, Asia-Pacific at 27%, and the rest of the world at 6%. However, the Asia-Pacific region demonstrates the fastest growth trajectory with a 16.2% CAGR, primarily driven by rapid industrialization in China and India, alongside significant R&D investments in Japan and South Korea.

Shape memory alloys represent the largest segment within smart materials, constituting approximately 35% of the market. Piezoelectric materials follow at 28%, with magnetostrictive materials at 15%, self-healing materials at 12%, and other categories comprising the remaining 10%. DED technology has shown particular promise in the development of multi-material smart components that combine these various material types.

Customer demand patterns indicate increasing preference for materials with multi-functional capabilities, reduced environmental impact, and enhanced durability. Industries are willing to pay premium prices for smart materials that deliver significant performance improvements or enable novel functionalities. The average price premium for advanced smart materials over conventional alternatives ranges from 30% to 120%, depending on application specifics and performance characteristics.

Supply chain analysis reveals potential vulnerabilities in rare earth element availability, which affects approximately 40% of smart material production. DED manufacturing processes offer advantages in material efficiency, potentially reducing dependency on these critical materials by enabling precise deposition and minimizing waste.

Market forecasts suggest particularly strong growth in self-healing materials (18.7% CAGR) and programmable matter applications (22.3% CAGR) over the next five years, areas where DED technology's precision and multi-material capabilities provide significant competitive advantages.

DED Technical Challenges and Global Development Status

Despite significant advancements in Directed Energy Deposition (DED) technology for smart materials, several technical challenges persist that impede its widespread industrial adoption. Material compatibility remains a primary concern, as not all powders or wire feedstocks respond predictably to the high-energy deposition process, particularly when developing multi-material or functionally graded smart components. The thermal management during deposition creates substantial residual stresses and potential microstructural defects that can compromise the functional properties of smart materials.

Process control presents another significant hurdle, with real-time monitoring systems still struggling to provide the precision required for consistent smart material fabrication. The layer-by-layer deposition process often results in anisotropic properties that can interfere with the intended functionality of smart materials, particularly those requiring uniform response characteristics.

Globally, DED technology development shows distinct regional patterns. North America, particularly the United States, leads in research publications and patent filings, with significant contributions from national laboratories and aerospace industry partnerships. The technology readiness level (TRL) for basic DED processes reaches 7-8 in this region, though applications specifically for smart materials remain at TRL 4-6.

European development focuses on precision engineering applications, with Germany, the UK, and France establishing specialized research centers dedicated to DED technology advancement. The European approach emphasizes process standardization and certification pathways, crucial for regulated industries where smart materials show promise.

The Asia-Pacific region demonstrates rapid growth in DED technology adoption, with China investing heavily in large-scale manufacturing capabilities and Japan focusing on high-precision applications. South Korea has emerged as a significant contributor to smart material applications through DED, particularly in biomedical and electronic domains.

Recent global trends indicate increasing collaboration between academic institutions and industry partners, with open innovation consortia forming to address common technical challenges. Cross-disciplinary research combining materials science, mechanical engineering, and control systems is accelerating solutions to persistent issues.

The global market for DED equipment has grown at approximately 15% annually since 2018, with specialized systems for smart material fabrication representing a small but rapidly expanding segment. However, the fragmented nature of technical standards and certification processes across different regions creates barriers to technology transfer and commercialization.

Process control presents another significant hurdle, with real-time monitoring systems still struggling to provide the precision required for consistent smart material fabrication. The layer-by-layer deposition process often results in anisotropic properties that can interfere with the intended functionality of smart materials, particularly those requiring uniform response characteristics.

Globally, DED technology development shows distinct regional patterns. North America, particularly the United States, leads in research publications and patent filings, with significant contributions from national laboratories and aerospace industry partnerships. The technology readiness level (TRL) for basic DED processes reaches 7-8 in this region, though applications specifically for smart materials remain at TRL 4-6.

European development focuses on precision engineering applications, with Germany, the UK, and France establishing specialized research centers dedicated to DED technology advancement. The European approach emphasizes process standardization and certification pathways, crucial for regulated industries where smart materials show promise.

The Asia-Pacific region demonstrates rapid growth in DED technology adoption, with China investing heavily in large-scale manufacturing capabilities and Japan focusing on high-precision applications. South Korea has emerged as a significant contributor to smart material applications through DED, particularly in biomedical and electronic domains.

Recent global trends indicate increasing collaboration between academic institutions and industry partners, with open innovation consortia forming to address common technical challenges. Cross-disciplinary research combining materials science, mechanical engineering, and control systems is accelerating solutions to persistent issues.

The global market for DED equipment has grown at approximately 15% annually since 2018, with specialized systems for smart material fabrication representing a small but rapidly expanding segment. However, the fragmented nature of technical standards and certification processes across different regions creates barriers to technology transfer and commercialization.

Current DED Implementation for Smart Materials

01 Smart materials for directed energy deposition processes

Smart materials with specific properties can be used in directed energy deposition (DED) processes to create components with enhanced functionality. These materials can include shape memory alloys, piezoelectric materials, and other responsive materials that can change their properties in response to external stimuli. The integration of these smart materials in DED processes allows for the fabrication of components with embedded sensors, actuators, or other functional elements.- Smart materials for directed energy deposition processes: Smart materials with specific properties can be used in directed energy deposition (DED) processes to create components with enhanced functionality. These materials can include shape memory alloys, piezoelectric materials, and other responsive materials that can change their properties in response to external stimuli. The integration of these smart materials in DED processes allows for the fabrication of components with embedded sensors, actuators, or other functional elements.

- Process control and monitoring in directed energy deposition: Advanced control systems and monitoring techniques are essential for directed energy deposition of smart materials. These systems can include real-time feedback mechanisms, machine learning algorithms, and sensor networks that monitor various process parameters such as temperature, deposition rate, and material flow. By implementing sophisticated control strategies, the quality and consistency of the deposited smart materials can be significantly improved, leading to enhanced performance of the final components.

- Multi-material deposition techniques for smart structures: Multi-material deposition techniques enable the creation of complex smart structures with varying material compositions and properties. These techniques allow for the strategic placement of different materials within a single component, creating functional gradients or discrete regions with specific properties. By combining different materials in a controlled manner, it is possible to fabricate components with localized smart functionalities, such as sensing, actuation, or self-healing capabilities.

- Integration of sensors and functional elements during deposition: The integration of sensors and other functional elements during the directed energy deposition process allows for the creation of smart components with embedded monitoring capabilities. This approach involves the strategic placement of sensing elements, conductive pathways, or other functional features within the component during fabrication. The resulting smart components can provide real-time data on their condition, performance, or environment, enabling advanced monitoring and control applications.

- Post-processing techniques for smart material enhancement: Various post-processing techniques can be applied to enhance the properties and functionality of smart materials deposited using directed energy deposition. These techniques may include heat treatments, surface modifications, or additional processing steps that activate or improve the smart properties of the materials. Post-processing can be crucial for achieving the desired functional characteristics in the final component, such as improved shape memory behavior, enhanced sensing capabilities, or better mechanical properties.

02 Process control and monitoring in directed energy deposition

Advanced control and monitoring systems are essential for directed energy deposition of smart materials. These systems utilize real-time feedback mechanisms, computer vision, and machine learning algorithms to ensure precise deposition of materials. By continuously monitoring parameters such as temperature, deposition rate, and material flow, these systems can adjust process parameters in real-time to maintain optimal conditions for depositing smart materials with consistent properties.Expand Specific Solutions03 Multi-material deposition for functional gradients

Directed energy deposition techniques can be used to create functionally graded materials by depositing multiple materials with varying compositions. This approach allows for the creation of components with spatially varying properties, such as thermal conductivity, electrical conductivity, or mechanical strength. By strategically depositing different smart materials in specific patterns or gradients, components can be designed with tailored properties for specific applications.Expand Specific Solutions04 In-situ synthesis of smart materials during deposition

In-situ synthesis techniques can be integrated with directed energy deposition processes to create smart materials directly during the fabrication process. This approach involves chemical reactions or phase transformations that occur during the deposition process, resulting in the formation of smart materials with specific properties. By controlling the process parameters, such as temperature, pressure, and cooling rates, the properties of the synthesized smart materials can be tailored for specific applications.Expand Specific Solutions05 Post-processing treatments for enhanced functionality

Post-processing treatments can be applied to directed energy deposited smart materials to enhance their functionality. These treatments include heat treatment, surface modification, and other processes that can alter the microstructure, composition, or surface properties of the deposited materials. By applying specific post-processing treatments, the performance of smart materials can be optimized for various applications, such as sensing, actuation, or energy harvesting.Expand Specific Solutions

Leading DED Technology Companies and Research Institutions

Directed Energy Deposition (DED) technology for smart materials is currently in a growth phase, with an expanding market driven by aerospace, defense, and industrial applications. The global market is estimated to reach $1.5 billion by 2025, growing at approximately 15% annually. Technologically, DED is advancing rapidly with varying maturity levels across applications. Leading players include GE Avio and Rolls-Royce in aerospace applications, DM3D Technology and Lockheed Martin in large-scale metal manufacturing, Applied Materials in semiconductor applications, and academic institutions like Nanyang Technological University advancing fundamental research. Chinese universities (Jilin University, Chongqing University) are increasingly contributing to innovation, while companies like Siemens and Caterpillar are integrating DED into industrial manufacturing processes.

GE Avio Srl

Technical Solution: GE Avio has developed an advanced DED platform called ATLAS (Advanced Technology Laser Additive System) specifically designed for aerospace applications requiring smart materials. Their technology utilizes a high-power fiber laser coupled with a sophisticated powder delivery system that enables precise control over material composition during deposition. GE Avio's process incorporates real-time monitoring using multiple sensors (thermal, optical, and acoustic) to detect and correct process anomalies, ensuring consistent material properties throughout complex components. The company has pioneered techniques for creating functionally graded materials that transition between different alloys, enabling components with location-specific properties optimized for thermal management and mechanical performance. Their DED technology has been successfully applied to manufacture turbine blades with integrated cooling channels and sensor mounting features, reducing component weight by up to 30% while maintaining or improving performance characteristics. GE Avio has also developed proprietary post-processing techniques that enhance the surface finish and mechanical properties of DED-manufactured components.

Strengths: Extensive experience with aerospace-grade materials and certification processes; advanced multi-sensor monitoring systems for quality assurance. Weaknesses: Technology primarily optimized for aerospace applications; relatively high operational costs compared to conventional manufacturing methods.

DM3D Technology LLC

Technical Solution: DM3D Technology has developed a proprietary DED system called Direct Metal Deposition (DMD) specifically optimized for smart material applications. Their technology utilizes a closed-loop feedback system that monitors and controls the melt pool in real-time, allowing for precise control of material properties during deposition. The company's multi-axis deposition capability enables the creation of complex 3D structures with embedded functionality, such as conformal cooling channels and integrated sensors. DM3D has pioneered techniques for creating functionally graded materials (FGMs) that transition smoothly between different material compositions, enabling components with location-specific properties. Their hybrid manufacturing approach combines DED with in-situ machining, allowing for the production of components with tight tolerances and excellent surface finish. The company has demonstrated the ability to deposit a wide range of materials including tool steels, titanium alloys, and nickel-based superalloys with minimal porosity (<0.2%) and mechanical properties comparable to wrought materials.

Strengths: Exceptional material versatility and ability to create functionally graded components; advanced closed-loop control systems for consistent quality. Weaknesses: Lower deposition rates compared to some competing technologies; higher operational costs due to complex monitoring systems.

Critical Patents in DED-based Smart Materials

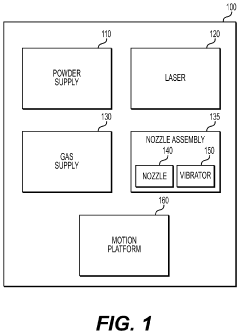

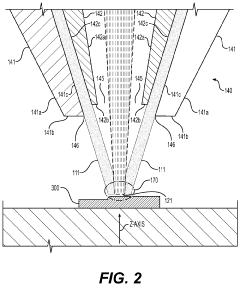

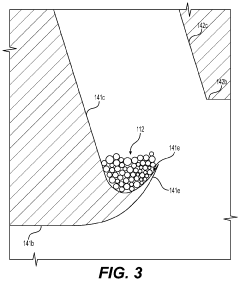

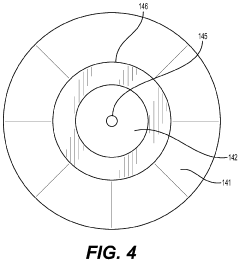

Directed energy deposition nozzle assembly with nozzle and vibrator that vibrates nozzle, and directed energy deposition apparatus having such nozzle assembly

PatentPendingUS20230090734A1

Innovation

- A nozzle assembly with a vibrator that applies a controlled vibration to the nozzle, using a ring-shaped silicone body and an electric motor to move a weight perpendicular to the nozzle's axis, which dislodges and prevents powder adhesion, reducing agglomeration and non-uniformity, and is configured with an annular orifice surrounding the energy beam opening to facilitate efficient powder and gas stream delivery.

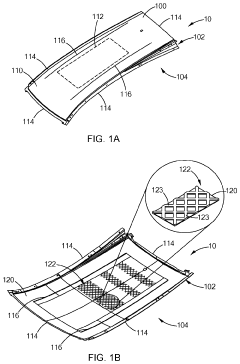

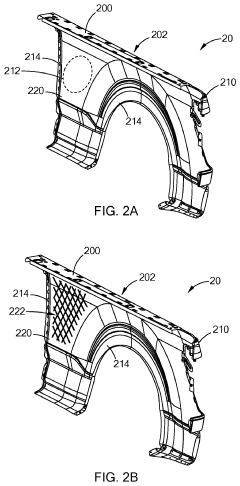

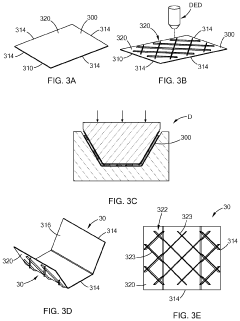

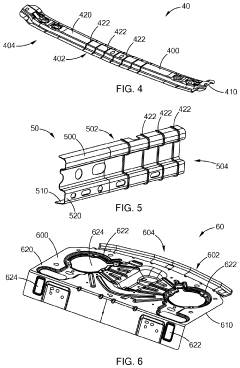

Directed energy deposition (DED) reinforcements on body structures and visible sheet metal surfaces

PatentInactiveUS20220371091A1

Innovation

- The use of additively manufactured reinforcements, deposited via directed energy deposition, metallurgically bonded to sheet metal components, either before or after shaping, to provide enhanced structural support and inhibit deformation.

Sustainability Impact of DED Manufacturing

Directed Energy Deposition (DED) manufacturing processes represent a significant advancement in sustainable manufacturing practices within the additive manufacturing landscape. The environmental footprint of DED technology demonstrates considerable advantages over conventional manufacturing methods, particularly in terms of material utilization efficiency. Studies indicate that DED processes can achieve material utilization rates exceeding 90%, substantially reducing waste compared to traditional subtractive manufacturing techniques that may waste up to 80% of raw materials.

Energy consumption analysis reveals that DED manufacturing can reduce overall energy requirements by 50-70% compared to conventional methods when producing complex geometries. This efficiency stems from the targeted energy delivery mechanism that applies thermal energy precisely where needed, minimizing excess heat generation and associated energy losses. Furthermore, the localized nature of material deposition significantly reduces the need for extensive post-processing operations.

The life cycle assessment of DED-manufactured components shows promising sustainability metrics. Carbon footprint reductions of 30-60% have been documented across various applications, particularly in aerospace and automotive sectors where lightweight, high-performance components directly contribute to operational efficiency and reduced emissions throughout product lifespans.

DED technology enables significant advancements in material circularity through its compatibility with recycled feedstock materials. Research demonstrates that certain DED systems can effectively process recycled metal powders with minimal degradation in mechanical properties, creating pathways for closed-loop material systems. This capability addresses critical raw material scarcity concerns, particularly for strategic metals used in high-performance applications.

From a supply chain perspective, DED manufacturing facilitates distributed production models that can substantially reduce transportation-related emissions. The ability to manufacture components on-demand and on-site represents a paradigm shift from traditional centralized manufacturing approaches, potentially eliminating thousands of miles in shipping distances for critical components.

Water usage in DED processes presents another sustainability advantage, with studies indicating up to 80% reduction in water consumption compared to conventional manufacturing methods that often require substantial cooling and cleaning operations. This aspect becomes increasingly significant as water scarcity emerges as a global sustainability challenge.

The integration of DED technology with renewable energy sources presents promising opportunities for further sustainability improvements. Research initiatives exploring solar-powered and renewable energy-driven DED systems demonstrate the potential for near-zero emission manufacturing capabilities, particularly relevant for remote or off-grid applications where sustainable manufacturing solutions are critically needed.

Energy consumption analysis reveals that DED manufacturing can reduce overall energy requirements by 50-70% compared to conventional methods when producing complex geometries. This efficiency stems from the targeted energy delivery mechanism that applies thermal energy precisely where needed, minimizing excess heat generation and associated energy losses. Furthermore, the localized nature of material deposition significantly reduces the need for extensive post-processing operations.

The life cycle assessment of DED-manufactured components shows promising sustainability metrics. Carbon footprint reductions of 30-60% have been documented across various applications, particularly in aerospace and automotive sectors where lightweight, high-performance components directly contribute to operational efficiency and reduced emissions throughout product lifespans.

DED technology enables significant advancements in material circularity through its compatibility with recycled feedstock materials. Research demonstrates that certain DED systems can effectively process recycled metal powders with minimal degradation in mechanical properties, creating pathways for closed-loop material systems. This capability addresses critical raw material scarcity concerns, particularly for strategic metals used in high-performance applications.

From a supply chain perspective, DED manufacturing facilitates distributed production models that can substantially reduce transportation-related emissions. The ability to manufacture components on-demand and on-site represents a paradigm shift from traditional centralized manufacturing approaches, potentially eliminating thousands of miles in shipping distances for critical components.

Water usage in DED processes presents another sustainability advantage, with studies indicating up to 80% reduction in water consumption compared to conventional manufacturing methods that often require substantial cooling and cleaning operations. This aspect becomes increasingly significant as water scarcity emerges as a global sustainability challenge.

The integration of DED technology with renewable energy sources presents promising opportunities for further sustainability improvements. Research initiatives exploring solar-powered and renewable energy-driven DED systems demonstrate the potential for near-zero emission manufacturing capabilities, particularly relevant for remote or off-grid applications where sustainable manufacturing solutions are critically needed.

Industry Standards and Certification Requirements

The standardization landscape for Directed Energy Deposition (DED) in smart materials manufacturing remains in active development, with several key organizations leading the establishment of comprehensive frameworks. ASTM International's F42 Committee on Additive Manufacturing Technologies has developed crucial standards including ASTM F3187, which specifically addresses DED processes and terminology. This standard provides essential guidelines for process classification, parameter definition, and quality control metrics specific to DED applications in smart materials production.

ISO/TC 261 complements these efforts through standards like ISO/ASTM 52900, which establishes fundamental principles and vocabulary for additive manufacturing processes including DED. For smart materials applications, the ISO/ASTM 52901 standard provides requirements for purchased parts, offering critical guidance on material specifications and performance characteristics that directly impact functional properties of smart materials produced via DED.

Certification requirements for DED processes in smart materials manufacturing typically follow a multi-tiered approach. Material certification represents the foundation, requiring suppliers to provide detailed documentation on chemical composition, particle size distribution, and flow characteristics of powders used in DED processes. These parameters significantly influence the microstructural development and functional properties of resulting smart materials.

Process certification constitutes the second tier, focusing on equipment calibration, process parameter validation, and in-process monitoring capabilities. For smart materials with specific functional requirements, such as shape memory alloys or self-healing composites, process certification must verify the equipment's ability to maintain precise thermal gradients and cooling rates that directly influence transformation temperatures and functional response.

Personnel certification forms the third critical component, requiring operators to demonstrate proficiency in DED system operation, parameter optimization, and quality assessment specific to smart materials production. Organizations like America Makes and the Additive Manufacturing Users Group offer specialized training programs focused on DED processes for functional materials applications.

Quality assurance frameworks for DED-produced smart materials increasingly incorporate non-destructive testing protocols outlined in standards like ASTM E1417 for liquid penetrant examination and ASTM E1444 for magnetic particle testing. These methods help verify the structural integrity of DED-fabricated components while preserving their functional properties. Additionally, emerging standards specifically address testing methodologies for evaluating the unique properties of smart materials, such as shape memory response, self-healing efficiency, and stimulus-responsive behavior.

ISO/TC 261 complements these efforts through standards like ISO/ASTM 52900, which establishes fundamental principles and vocabulary for additive manufacturing processes including DED. For smart materials applications, the ISO/ASTM 52901 standard provides requirements for purchased parts, offering critical guidance on material specifications and performance characteristics that directly impact functional properties of smart materials produced via DED.

Certification requirements for DED processes in smart materials manufacturing typically follow a multi-tiered approach. Material certification represents the foundation, requiring suppliers to provide detailed documentation on chemical composition, particle size distribution, and flow characteristics of powders used in DED processes. These parameters significantly influence the microstructural development and functional properties of resulting smart materials.

Process certification constitutes the second tier, focusing on equipment calibration, process parameter validation, and in-process monitoring capabilities. For smart materials with specific functional requirements, such as shape memory alloys or self-healing composites, process certification must verify the equipment's ability to maintain precise thermal gradients and cooling rates that directly influence transformation temperatures and functional response.

Personnel certification forms the third critical component, requiring operators to demonstrate proficiency in DED system operation, parameter optimization, and quality assessment specific to smart materials production. Organizations like America Makes and the Additive Manufacturing Users Group offer specialized training programs focused on DED processes for functional materials applications.

Quality assurance frameworks for DED-produced smart materials increasingly incorporate non-destructive testing protocols outlined in standards like ASTM E1417 for liquid penetrant examination and ASTM E1444 for magnetic particle testing. These methods help verify the structural integrity of DED-fabricated components while preserving their functional properties. Additionally, emerging standards specifically address testing methodologies for evaluating the unique properties of smart materials, such as shape memory response, self-healing efficiency, and stimulus-responsive behavior.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!