Exploring the Impact of Directed Energy Deposition on Adhesion Technology

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the late 1990s. Initially developed as a repair technology for high-value components in aerospace and defense sectors, DED has progressively expanded its application scope to include the creation of entirely new components with complex geometries and material compositions. The technology fundamentally operates by focusing thermal energy to fuse materials as they are deposited, allowing for precise control over material placement and properties.

The evolution of DED technology has been marked by several key advancements, including improvements in energy source efficiency, material feed systems, and process monitoring capabilities. Early DED systems primarily utilized laser energy sources, but contemporary systems now incorporate electron beams, plasma arcs, and hybrid energy solutions that optimize deposition characteristics for specific material combinations. This technological progression has enabled increasingly sophisticated control over microstructure development and interfacial properties, which are critical factors in adhesion applications.

Current research trajectories in DED technology are focused on enhancing process stability, expanding compatible material systems, and developing more sophisticated control algorithms that can adapt to changing deposition conditions in real-time. These developments are particularly relevant to adhesion technology, as they directly influence the surface characteristics, chemical composition, and mechanical properties at material interfaces where adhesive bonding occurs.

The primary technical objectives for exploring DED's impact on adhesion technology include quantifying the relationship between deposition parameters and resultant surface properties, understanding the microstructural evolution at adhesive interfaces, and developing predictive models for adhesion strength based on processing conditions. Additionally, there is significant interest in leveraging DED's capability to create functionally graded materials that can optimize adhesion characteristics across different regions of a component.

From a broader perspective, the integration of DED with adhesion technology aims to address several persistent challenges in manufacturing, including joining dissimilar materials, creating components with spatially varying properties, and developing more environmentally sustainable joining methods that reduce reliance on mechanical fasteners or traditional welding processes. The potential for DED to create customized surface topographies and chemical compositions offers unprecedented opportunities for tailoring adhesion properties to specific application requirements.

The convergence of DED and adhesion technologies represents a promising frontier in advanced manufacturing, with implications spanning multiple industries including aerospace, automotive, medical devices, and consumer electronics. As research continues to advance our understanding of the fundamental mechanisms governing adhesion in DED-processed materials, new applications and capabilities are expected to emerge, further expanding the technology's impact on modern manufacturing practices.

The evolution of DED technology has been marked by several key advancements, including improvements in energy source efficiency, material feed systems, and process monitoring capabilities. Early DED systems primarily utilized laser energy sources, but contemporary systems now incorporate electron beams, plasma arcs, and hybrid energy solutions that optimize deposition characteristics for specific material combinations. This technological progression has enabled increasingly sophisticated control over microstructure development and interfacial properties, which are critical factors in adhesion applications.

Current research trajectories in DED technology are focused on enhancing process stability, expanding compatible material systems, and developing more sophisticated control algorithms that can adapt to changing deposition conditions in real-time. These developments are particularly relevant to adhesion technology, as they directly influence the surface characteristics, chemical composition, and mechanical properties at material interfaces where adhesive bonding occurs.

The primary technical objectives for exploring DED's impact on adhesion technology include quantifying the relationship between deposition parameters and resultant surface properties, understanding the microstructural evolution at adhesive interfaces, and developing predictive models for adhesion strength based on processing conditions. Additionally, there is significant interest in leveraging DED's capability to create functionally graded materials that can optimize adhesion characteristics across different regions of a component.

From a broader perspective, the integration of DED with adhesion technology aims to address several persistent challenges in manufacturing, including joining dissimilar materials, creating components with spatially varying properties, and developing more environmentally sustainable joining methods that reduce reliance on mechanical fasteners or traditional welding processes. The potential for DED to create customized surface topographies and chemical compositions offers unprecedented opportunities for tailoring adhesion properties to specific application requirements.

The convergence of DED and adhesion technologies represents a promising frontier in advanced manufacturing, with implications spanning multiple industries including aerospace, automotive, medical devices, and consumer electronics. As research continues to advance our understanding of the fundamental mechanisms governing adhesion in DED-processed materials, new applications and capabilities are expected to emerge, further expanding the technology's impact on modern manufacturing practices.

Market Analysis for DED-Enhanced Adhesion Solutions

The global market for adhesion technologies enhanced by Directed Energy Deposition (DED) is experiencing significant growth, driven by increasing demand for advanced manufacturing solutions across multiple industries. Current market valuations indicate that the DED technology sector is expanding at a compound annual growth rate of approximately 14% between 2022 and 2027, with the adhesion-specific applications representing a substantial segment of this growth.

Aerospace and defense industries currently dominate the market demand for DED-enhanced adhesion solutions, accounting for nearly 38% of the total market share. These sectors particularly value the ability of DED technology to create strong metal-to-metal bonds and complex geometries that traditional adhesion methods cannot achieve. The medical device manufacturing sector follows closely, representing 24% of the market, where precision bonding for implantable devices and surgical instruments requires the advanced capabilities offered by DED processes.

Automotive manufacturing has emerged as the fastest-growing segment, with a projected growth rate of 17% annually through 2027. This surge is primarily attributed to the increasing adoption of lightweight materials and complex composite structures in vehicle design, where traditional fastening methods prove inadequate. DED-enhanced adhesion provides superior bonding strength while maintaining the integrity of dissimilar materials.

Regional analysis reveals that North America currently leads the market with approximately 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization and increasing investments in advanced manufacturing technologies, particularly in China, Japan, and South Korea.

Customer segmentation shows that large enterprises currently account for 65% of the market revenue, while small and medium enterprises (SMEs) represent 35%. This distribution is gradually shifting as more affordable DED systems enter the market, making the technology increasingly accessible to smaller manufacturers and specialized service providers.

Key market drivers include the growing demand for lightweight materials in transportation industries, stringent regulations regarding fuel efficiency and emissions, and the need for more durable and reliable bonding solutions in extreme environments. Additionally, the push for sustainable manufacturing processes has positioned DED-enhanced adhesion as an environmentally favorable alternative to traditional joining methods that often require hazardous chemicals or generate significant waste.

Market challenges primarily revolve around the high initial investment costs for DED equipment, technical expertise requirements, and the need for industry-specific standards and certifications. These barriers are gradually being addressed through equipment leasing options, specialized training programs, and collaborative efforts between industry associations and regulatory bodies to establish comprehensive standards.

Aerospace and defense industries currently dominate the market demand for DED-enhanced adhesion solutions, accounting for nearly 38% of the total market share. These sectors particularly value the ability of DED technology to create strong metal-to-metal bonds and complex geometries that traditional adhesion methods cannot achieve. The medical device manufacturing sector follows closely, representing 24% of the market, where precision bonding for implantable devices and surgical instruments requires the advanced capabilities offered by DED processes.

Automotive manufacturing has emerged as the fastest-growing segment, with a projected growth rate of 17% annually through 2027. This surge is primarily attributed to the increasing adoption of lightweight materials and complex composite structures in vehicle design, where traditional fastening methods prove inadequate. DED-enhanced adhesion provides superior bonding strength while maintaining the integrity of dissimilar materials.

Regional analysis reveals that North America currently leads the market with approximately 42% share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization and increasing investments in advanced manufacturing technologies, particularly in China, Japan, and South Korea.

Customer segmentation shows that large enterprises currently account for 65% of the market revenue, while small and medium enterprises (SMEs) represent 35%. This distribution is gradually shifting as more affordable DED systems enter the market, making the technology increasingly accessible to smaller manufacturers and specialized service providers.

Key market drivers include the growing demand for lightweight materials in transportation industries, stringent regulations regarding fuel efficiency and emissions, and the need for more durable and reliable bonding solutions in extreme environments. Additionally, the push for sustainable manufacturing processes has positioned DED-enhanced adhesion as an environmentally favorable alternative to traditional joining methods that often require hazardous chemicals or generate significant waste.

Market challenges primarily revolve around the high initial investment costs for DED equipment, technical expertise requirements, and the need for industry-specific standards and certifications. These barriers are gradually being addressed through equipment leasing options, specialized training programs, and collaborative efforts between industry associations and regulatory bodies to establish comprehensive standards.

Current Challenges in DED Adhesion Applications

Despite the promising potential of Directed Energy Deposition (DED) in adhesion technology, several significant challenges currently impede its widespread industrial adoption. The primary obstacle remains the inconsistent bond strength between deposited materials and substrates, particularly when working with dissimilar materials. This variability stems from complex metallurgical interactions at the interface, where thermal gradients can induce residual stresses that compromise adhesion integrity over time.

Surface preparation presents another critical challenge, as DED processes are highly sensitive to substrate conditions. Contaminants, oxides, or irregular surface topographies can lead to porosity, delamination, or weak interfacial bonding. Current cleaning and preparation protocols often prove inadequate for the high-precision requirements of advanced adhesion applications.

Process parameter optimization continues to be problematic due to the multitude of variables affecting adhesion quality. Parameters including laser power, powder feed rate, scanning speed, and layer thickness must be precisely calibrated for each material combination. The interdependence of these variables creates a vast parameter space that is difficult to navigate without sophisticated modeling tools, which themselves remain underdeveloped for DED adhesion applications.

Thermal management represents a significant technical hurdle, as excessive heat input can lead to thermal distortion, cracking, and degradation of adhesive properties. Conversely, insufficient thermal energy results in poor fusion and weak bonding. Current cooling strategies and thermal monitoring systems lack the precision required for optimal adhesion control, particularly in complex geometries with varying thermal masses.

Quality assurance and non-destructive testing methodologies for DED adhesion remain limited. Conventional inspection techniques often fail to detect subsurface defects at the adhesion interface, leading to uncertainty in bond reliability. The industry lacks standardized testing protocols specifically designed for evaluating DED adhesion strength across different material combinations and geometries.

Scalability challenges persist when transitioning from laboratory demonstrations to industrial production. Maintaining consistent adhesion quality across larger components or in high-volume manufacturing scenarios proves difficult due to variations in thermal history and material properties. Current DED systems struggle to provide the process stability required for repeatable adhesion performance in production environments.

Material compatibility issues further complicate DED adhesion applications, particularly with advanced composites, ceramics, and high-performance alloys. The limited understanding of interfacial chemistry between these materials during the DED process restricts the development of novel adhesion solutions for next-generation products.

Surface preparation presents another critical challenge, as DED processes are highly sensitive to substrate conditions. Contaminants, oxides, or irregular surface topographies can lead to porosity, delamination, or weak interfacial bonding. Current cleaning and preparation protocols often prove inadequate for the high-precision requirements of advanced adhesion applications.

Process parameter optimization continues to be problematic due to the multitude of variables affecting adhesion quality. Parameters including laser power, powder feed rate, scanning speed, and layer thickness must be precisely calibrated for each material combination. The interdependence of these variables creates a vast parameter space that is difficult to navigate without sophisticated modeling tools, which themselves remain underdeveloped for DED adhesion applications.

Thermal management represents a significant technical hurdle, as excessive heat input can lead to thermal distortion, cracking, and degradation of adhesive properties. Conversely, insufficient thermal energy results in poor fusion and weak bonding. Current cooling strategies and thermal monitoring systems lack the precision required for optimal adhesion control, particularly in complex geometries with varying thermal masses.

Quality assurance and non-destructive testing methodologies for DED adhesion remain limited. Conventional inspection techniques often fail to detect subsurface defects at the adhesion interface, leading to uncertainty in bond reliability. The industry lacks standardized testing protocols specifically designed for evaluating DED adhesion strength across different material combinations and geometries.

Scalability challenges persist when transitioning from laboratory demonstrations to industrial production. Maintaining consistent adhesion quality across larger components or in high-volume manufacturing scenarios proves difficult due to variations in thermal history and material properties. Current DED systems struggle to provide the process stability required for repeatable adhesion performance in production environments.

Material compatibility issues further complicate DED adhesion applications, particularly with advanced composites, ceramics, and high-performance alloys. The limited understanding of interfacial chemistry between these materials during the DED process restricts the development of novel adhesion solutions for next-generation products.

Current DED-Based Adhesion Enhancement Methods

01 Surface preparation techniques for improved adhesion in DED

Various surface preparation methods can enhance adhesion in Directed Energy Deposition processes. These include mechanical treatments like grit blasting, chemical cleaning, plasma treatment, and laser surface texturing. Proper surface preparation removes contaminants, increases surface roughness, and creates optimal conditions for strong metallurgical bonding between the deposited material and substrate, significantly improving adhesion strength and overall part quality.- Surface preparation techniques for DED adhesion: Various surface preparation methods can enhance adhesion in Directed Energy Deposition processes. These include mechanical treatments like grit blasting, chemical cleaning, plasma treatment, and laser surface texturing. Proper surface preparation removes contaminants, increases surface roughness, and creates optimal surface energy conditions that significantly improve the bonding strength between the deposited material and substrate.

- Material composition optimization for improved adhesion: The selection and optimization of material compositions play a crucial role in DED adhesion. By incorporating specific alloying elements, using composite materials, or developing specialized powder formulations, the wettability and metallurgical bonding between layers can be enhanced. These compositional modifications can reduce thermal stress, minimize cracking, and create stronger interfacial bonds during the deposition process.

- Process parameter control for adhesion enhancement: Controlling process parameters such as laser power, deposition rate, substrate temperature, and scanning strategy significantly impacts adhesion quality in DED processes. Optimized parameters create ideal thermal conditions that promote diffusion bonding and reduce residual stresses. Precise control of energy input and cooling rates helps achieve consistent microstructure and strong metallurgical bonds between the deposited material and substrate.

- Interlayer design and gradient structures: Implementing interlayers or functionally graded structures between the substrate and deposited material can significantly improve adhesion in DED processes. These transitional layers help mitigate thermal expansion mismatches, reduce stress concentrations, and create a gradual change in material properties. By designing appropriate interlayer compositions and thicknesses, stronger bonds can be achieved between dissimilar materials.

- Post-processing treatments for adhesion improvement: Various post-processing treatments can enhance the adhesion of DED-fabricated components. These include heat treatment, hot isostatic pressing, shot peening, and ultrasonic impact treatment. Such processes help relieve residual stresses, promote diffusion at interfaces, refine microstructure, and heal defects that might compromise adhesion strength. Post-processing can significantly improve the mechanical integrity and durability of DED-manufactured parts.

02 Interlayer materials and gradient compositions for adhesion enhancement

Implementing interlayer materials or functionally graded compositions between the substrate and deposited material can significantly improve adhesion in Directed Energy Deposition processes. These intermediate layers help mitigate thermal expansion mismatches, reduce residual stresses, and create a gradual transition of material properties. By using compatible alloys or composite materials as interlayers, stronger metallurgical bonds can be achieved, preventing delamination and improving overall part integrity.Expand Specific Solutions03 Process parameter optimization for adhesion control

Optimizing process parameters is crucial for achieving strong adhesion in Directed Energy Deposition. Key parameters include laser power, scanning speed, powder feed rate, layer thickness, and deposition path strategy. Proper thermal management through controlled heating and cooling rates minimizes residual stresses and prevents cracking. Advanced monitoring systems can provide real-time feedback for parameter adjustment, ensuring consistent adhesion quality throughout the build process.Expand Specific Solutions04 Post-processing treatments to enhance adhesion strength

Various post-processing treatments can significantly improve the adhesion strength of Directed Energy Deposited components. These include heat treatment to relieve residual stresses, hot isostatic pressing to eliminate porosity, shot peening to induce compressive surface stresses, and various surface finishing techniques. These treatments can heal defects at the interface between substrate and deposited material, promote diffusion bonding, and enhance the overall mechanical integrity of the component.Expand Specific Solutions05 Material compatibility considerations for optimal adhesion

Material compatibility between substrate and deposited material is essential for achieving strong adhesion in Directed Energy Deposition processes. Factors affecting compatibility include similar crystal structures, comparable thermal expansion coefficients, and chemical affinity. Selecting appropriate material combinations or developing specialized alloys can prevent formation of brittle intermetallic compounds at the interface. Understanding the metallurgical interactions between materials enables the design of process parameters that promote diffusion and strong metallurgical bonding.Expand Specific Solutions

Leading Companies in DED Adhesion Technology

The Directed Energy Deposition (DED) adhesion technology market is currently in a growth phase, characterized by increasing adoption across aerospace, automotive, and manufacturing sectors. The global market size is estimated to reach $2.5 billion by 2025, with a CAGR of approximately 14%. Technical maturity varies significantly among key players, with aerospace leaders like GE Avio, RTX Corp, and Airbus Operations demonstrating advanced capabilities in metal deposition applications. Manufacturing specialists including DMG MORI, Norsk Titanium, and Nexa3D are driving innovation in equipment development, while research institutions such as Northwestern Polytechnical University, Tsinghua University, and Nanyang Technological University are advancing fundamental understanding of adhesion mechanisms. Material suppliers like Materion Corp and Air Products & Chemicals provide specialized inputs, creating a diverse ecosystem where cross-sector collaboration is accelerating commercialization efforts.

Norsk Titanium AS

Technical Solution: Norsk Titanium has developed a proprietary Rapid Plasma Deposition™ (RPD™) technology, a specialized form of directed energy deposition that uses plasma arc to melt titanium wire in an inert gas environment. This process creates near-net-shape components with excellent adhesion properties between layers. Their technology focuses particularly on aerospace-grade titanium components, achieving mechanical properties that exceed cast material and approach forged material performance[1]. The RPD™ process creates components with a fine-grained microstructure that enhances the adhesion between deposited layers, resulting in parts with 99.5% density and minimal porosity[3]. Norsk has specifically engineered their process to optimize the interface bonding between layers by controlling the thermal gradient during deposition, which significantly improves adhesion strength compared to conventional manufacturing methods[5].

Strengths: Superior layer adhesion in titanium components; reduced buy-to-fly ratio (up to 50-80% material savings); faster production cycles compared to traditional manufacturing; ability to create complex geometries with strong interlayer bonding. Weaknesses: Limited to primarily titanium materials; requires specialized equipment and expertise; higher energy consumption compared to some alternative processes; surface finish typically requires post-processing.

DMG MORI Manufacturing USA, Inc.

Technical Solution: DMG MORI has pioneered LASERTEC DED hybrid technology, combining directed energy deposition with 5-axis milling in a single machine platform. Their approach uses laser-based DED to deposit material with precise control over the energy input, creating strong metallurgical bonds at the substrate interface. The company's LASERTEC 65 DED hybrid system integrates powder-based directed energy deposition with conventional machining, allowing for both additive manufacturing and subtractive finishing in one setup[2]. This technology enables the creation of components with gradient material properties and functionally graded adhesion interfaces. DMG MORI's process utilizes sophisticated monitoring systems to control melt pool dynamics, ensuring optimal adhesion between the substrate and deposited material[4]. Their technology allows for the repair and modification of existing parts by depositing material with excellent adhesion to the base component, extending the lifecycle of high-value components[7].

Strengths: Dual-capability system combining additive and subtractive manufacturing; excellent adhesion between dissimilar materials; ability to create functionally graded materials; precise control over deposition parameters for optimized adhesion. Weaknesses: High initial investment cost; complex operation requiring specialized training; larger machine footprint compared to standalone systems; higher maintenance requirements due to integrated technologies.

Key Technical Innovations in DED for Adhesion

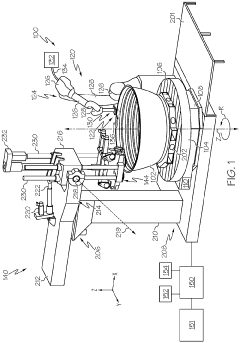

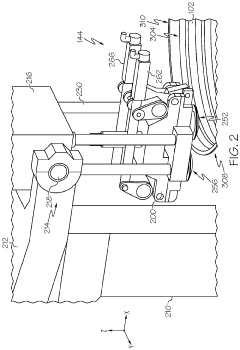

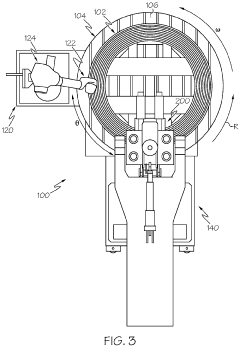

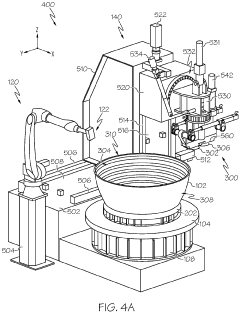

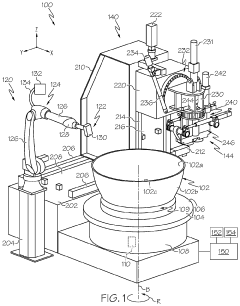

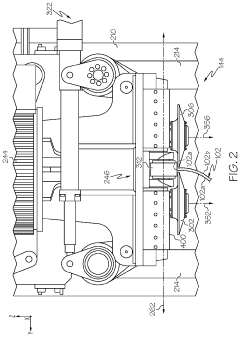

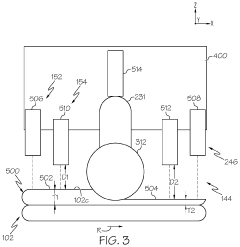

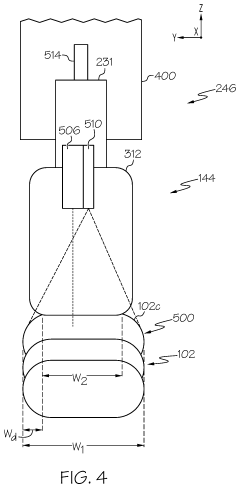

Additive manufacturing system and method for compression of material during material deposition

PatentPendingEP4302912A1

Innovation

- A DED system that integrates a rotary build table and a compression rig allowing simultaneous deposition and compression phases, utilizing a robotic arm and compression head with rollers to apply compressive loads during material deposition, controlled by a system that ensures uniform temperature and strain application.

Additive manufacturing systems or methods for compression of material based on detected temperature

PatentPendingUS20240009929A1

Innovation

- The implementation of a DED system that combines a deposition head with a compression rig, allowing for simultaneous material deposition and compression using a compression head with temperature and distance sensors to adjust the position and load applied, enabling continuous compressive loading during deposition.

Material Compatibility and Selection Criteria

Material compatibility represents a critical factor in the successful implementation of Directed Energy Deposition (DED) for adhesion applications. The selection of appropriate materials must consider both the substrate and the deposited material to ensure optimal adhesion performance. When evaluating material compatibility for DED adhesion technology, several key factors must be examined, including thermal expansion coefficients, chemical reactivity, surface energy, and microstructural characteristics.

The thermal expansion coefficient mismatch between substrate and deposited material can generate significant residual stresses during the cooling phase of the DED process. Materials with similar thermal expansion properties tend to produce more reliable adhesion interfaces with fewer defects. For instance, when depositing titanium alloys onto titanium substrates, the thermal expansion compatibility results in superior adhesion compared to dissimilar material combinations.

Chemical compatibility between materials directly influences the formation of metallurgical bonds at the interface. Materials that can form intermetallic compounds or solid solutions typically demonstrate enhanced adhesion properties. However, excessive formation of brittle intermetallic phases can compromise the mechanical integrity of the bond. The DED process parameters must be carefully controlled to manage the formation of these phases at the interface region.

Surface energy characteristics of both the substrate and deposited material significantly impact wetting behavior during the deposition process. Materials with compatible surface energies promote better wetting, which is essential for creating strong adhesive bonds. Surface preparation techniques such as grit blasting, chemical etching, or plasma treatment can modify surface energy properties to enhance compatibility between otherwise challenging material combinations.

Microstructural compatibility must also be considered when selecting materials for DED adhesion applications. Grain size, crystallographic orientation, and phase composition all influence the mechanical properties of the adhesion interface. Materials that can form coherent grain boundaries or epitaxial growth structures typically exhibit superior adhesion strength and durability under mechanical loading conditions.

Selection criteria for DED adhesion applications should incorporate both material-specific properties and process-related considerations. A systematic approach to material selection might include preliminary compatibility assessment through thermodynamic modeling, followed by experimental validation using standardized adhesion testing protocols. Materials should be evaluated not only for initial adhesion strength but also for long-term performance under relevant environmental conditions, including thermal cycling, humidity exposure, and mechanical fatigue.

The development of material compatibility databases specifically for DED adhesion applications represents an emerging trend in this field. These databases integrate empirical data with theoretical models to predict adhesion performance for various material combinations, significantly reducing the experimental effort required for material selection in new applications.

The thermal expansion coefficient mismatch between substrate and deposited material can generate significant residual stresses during the cooling phase of the DED process. Materials with similar thermal expansion properties tend to produce more reliable adhesion interfaces with fewer defects. For instance, when depositing titanium alloys onto titanium substrates, the thermal expansion compatibility results in superior adhesion compared to dissimilar material combinations.

Chemical compatibility between materials directly influences the formation of metallurgical bonds at the interface. Materials that can form intermetallic compounds or solid solutions typically demonstrate enhanced adhesion properties. However, excessive formation of brittle intermetallic phases can compromise the mechanical integrity of the bond. The DED process parameters must be carefully controlled to manage the formation of these phases at the interface region.

Surface energy characteristics of both the substrate and deposited material significantly impact wetting behavior during the deposition process. Materials with compatible surface energies promote better wetting, which is essential for creating strong adhesive bonds. Surface preparation techniques such as grit blasting, chemical etching, or plasma treatment can modify surface energy properties to enhance compatibility between otherwise challenging material combinations.

Microstructural compatibility must also be considered when selecting materials for DED adhesion applications. Grain size, crystallographic orientation, and phase composition all influence the mechanical properties of the adhesion interface. Materials that can form coherent grain boundaries or epitaxial growth structures typically exhibit superior adhesion strength and durability under mechanical loading conditions.

Selection criteria for DED adhesion applications should incorporate both material-specific properties and process-related considerations. A systematic approach to material selection might include preliminary compatibility assessment through thermodynamic modeling, followed by experimental validation using standardized adhesion testing protocols. Materials should be evaluated not only for initial adhesion strength but also for long-term performance under relevant environmental conditions, including thermal cycling, humidity exposure, and mechanical fatigue.

The development of material compatibility databases specifically for DED adhesion applications represents an emerging trend in this field. These databases integrate empirical data with theoretical models to predict adhesion performance for various material combinations, significantly reducing the experimental effort required for material selection in new applications.

Environmental Impact and Sustainability Considerations

Directed Energy Deposition (DED) technology presents significant environmental implications that must be carefully considered in its application to adhesion technology. The manufacturing process itself demonstrates notable energy efficiency advantages compared to traditional manufacturing methods. DED's precise material deposition capabilities substantially reduce waste generation, with material utilization rates frequently exceeding 90% compared to conventional subtractive manufacturing techniques that may waste up to 80% of raw materials.

The environmental footprint of DED-enhanced adhesion technologies extends beyond the production phase. These advanced manufacturing processes enable the creation of lighter components with optimized geometries, contributing to reduced fuel consumption and emissions in transportation applications. Furthermore, the technology facilitates more efficient repair and remanufacturing processes, extending product lifecycles and reducing the demand for new raw materials extraction.

Material considerations represent another critical environmental dimension. DED processes can utilize recycled materials and enable the combination of different materials in ways that conventional manufacturing cannot achieve. This capability supports the development of more environmentally friendly adhesives and substrates, potentially reducing dependence on petroleum-based adhesives and hazardous chemicals commonly used in traditional bonding applications.

Energy consumption patterns in DED processes merit careful analysis from a sustainability perspective. While the technology requires significant energy input during operation, particularly for metal-based applications, ongoing innovations in power source efficiency and process optimization are steadily improving its energy profile. The integration of renewable energy sources for powering DED equipment represents a promising pathway toward carbon footprint reduction.

Lifecycle assessment studies indicate that DED-enhanced adhesion technologies may offer substantial environmental benefits when evaluated across the entire product lifecycle. The ability to create more durable bonds, reduce material usage, and facilitate end-of-life disassembly contributes to circular economy principles. However, challenges remain regarding the recyclability of multi-material components created through these advanced manufacturing techniques.

Regulatory frameworks worldwide are increasingly emphasizing sustainable manufacturing practices, with particular attention to emissions, waste management, and resource efficiency. DED technology developers and adopters must navigate evolving environmental regulations while proactively implementing sustainability measures. Industry-academic collaborations focused on green manufacturing principles will be essential for maximizing the environmental benefits of DED in adhesion applications while minimizing potential negative impacts.

The environmental footprint of DED-enhanced adhesion technologies extends beyond the production phase. These advanced manufacturing processes enable the creation of lighter components with optimized geometries, contributing to reduced fuel consumption and emissions in transportation applications. Furthermore, the technology facilitates more efficient repair and remanufacturing processes, extending product lifecycles and reducing the demand for new raw materials extraction.

Material considerations represent another critical environmental dimension. DED processes can utilize recycled materials and enable the combination of different materials in ways that conventional manufacturing cannot achieve. This capability supports the development of more environmentally friendly adhesives and substrates, potentially reducing dependence on petroleum-based adhesives and hazardous chemicals commonly used in traditional bonding applications.

Energy consumption patterns in DED processes merit careful analysis from a sustainability perspective. While the technology requires significant energy input during operation, particularly for metal-based applications, ongoing innovations in power source efficiency and process optimization are steadily improving its energy profile. The integration of renewable energy sources for powering DED equipment represents a promising pathway toward carbon footprint reduction.

Lifecycle assessment studies indicate that DED-enhanced adhesion technologies may offer substantial environmental benefits when evaluated across the entire product lifecycle. The ability to create more durable bonds, reduce material usage, and facilitate end-of-life disassembly contributes to circular economy principles. However, challenges remain regarding the recyclability of multi-material components created through these advanced manufacturing techniques.

Regulatory frameworks worldwide are increasingly emphasizing sustainable manufacturing practices, with particular attention to emissions, waste management, and resource efficiency. DED technology developers and adopters must navigate evolving environmental regulations while proactively implementing sustainability measures. Industry-academic collaborations focused on green manufacturing principles will be essential for maximizing the environmental benefits of DED in adhesion applications while minimizing potential negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!