Directed Energy Deposition: Advances in Additive Manufacturing Technology

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Objectives

Directed Energy Deposition (DED) technology has evolved significantly since its inception in the late 1990s, transforming from experimental prototyping methods to sophisticated manufacturing processes. Initially developed as a repair technique for high-value components in aerospace and defense sectors, DED has undergone substantial refinement in terms of precision, material compatibility, and process control. The technology's evolution has been marked by the transition from single-material deposition to multi-material capabilities, enabling the creation of functionally graded components with tailored properties.

The fundamental principle of DED involves the simultaneous delivery of energy and feedstock material to create three-dimensional structures. Early systems primarily utilized laser energy sources, but technological diversification has led to the development of electron beam, plasma arc, and hybrid energy systems. This diversification has expanded the application scope of DED technology across various industries, including aerospace, automotive, medical, and energy sectors.

Material science advancements have played a crucial role in DED's evolution, with the technology now capable of processing a wide range of metals, including titanium alloys, nickel-based superalloys, stainless steels, and increasingly, refractory metals and metal matrix composites. The progression from powder-based to wire-based feedstock systems has further enhanced material efficiency and deposition rates, addressing earlier limitations in production speed and cost-effectiveness.

Process monitoring and control systems have evolved from basic open-loop configurations to sophisticated closed-loop systems incorporating real-time monitoring and adaptive control algorithms. This advancement has significantly improved build quality, repeatability, and reliability, addressing critical challenges in quality assurance and certification for industrial applications. The integration of machine learning and artificial intelligence has further enhanced process optimization and defect prediction capabilities.

The primary objectives of current DED technology development focus on several key areas: increasing deposition rates while maintaining or improving part quality; enhancing process stability for complex geometries; expanding the range of compatible materials, particularly for high-performance applications; reducing post-processing requirements through improved surface finish and dimensional accuracy; and developing standardized qualification and certification protocols to facilitate broader industrial adoption.

Future technological objectives include the seamless integration of DED with subtractive manufacturing processes in hybrid manufacturing systems, development of multi-process capabilities combining different additive manufacturing techniques, and the creation of digital twins for process simulation and optimization. These advancements aim to position DED as a mainstream manufacturing technology capable of addressing the increasing demand for complex, customized, and high-performance components across various industrial sectors.

The fundamental principle of DED involves the simultaneous delivery of energy and feedstock material to create three-dimensional structures. Early systems primarily utilized laser energy sources, but technological diversification has led to the development of electron beam, plasma arc, and hybrid energy systems. This diversification has expanded the application scope of DED technology across various industries, including aerospace, automotive, medical, and energy sectors.

Material science advancements have played a crucial role in DED's evolution, with the technology now capable of processing a wide range of metals, including titanium alloys, nickel-based superalloys, stainless steels, and increasingly, refractory metals and metal matrix composites. The progression from powder-based to wire-based feedstock systems has further enhanced material efficiency and deposition rates, addressing earlier limitations in production speed and cost-effectiveness.

Process monitoring and control systems have evolved from basic open-loop configurations to sophisticated closed-loop systems incorporating real-time monitoring and adaptive control algorithms. This advancement has significantly improved build quality, repeatability, and reliability, addressing critical challenges in quality assurance and certification for industrial applications. The integration of machine learning and artificial intelligence has further enhanced process optimization and defect prediction capabilities.

The primary objectives of current DED technology development focus on several key areas: increasing deposition rates while maintaining or improving part quality; enhancing process stability for complex geometries; expanding the range of compatible materials, particularly for high-performance applications; reducing post-processing requirements through improved surface finish and dimensional accuracy; and developing standardized qualification and certification protocols to facilitate broader industrial adoption.

Future technological objectives include the seamless integration of DED with subtractive manufacturing processes in hybrid manufacturing systems, development of multi-process capabilities combining different additive manufacturing techniques, and the creation of digital twins for process simulation and optimization. These advancements aim to position DED as a mainstream manufacturing technology capable of addressing the increasing demand for complex, customized, and high-performance components across various industrial sectors.

Market Applications and Industry Demand

The Directed Energy Deposition (DED) market has experienced significant growth in recent years, driven by increasing demand across multiple industrial sectors. The global DED market was valued at approximately $137 million in 2022 and is projected to reach $392 million by 2028, representing a compound annual growth rate of 19.2%. This growth trajectory reflects the expanding applications of DED technology beyond its traditional use in repair and remanufacturing.

Aerospace and defense sectors currently dominate the DED market, accounting for nearly 35% of the total market share. These industries leverage DED's capabilities for manufacturing complex components with high-performance materials, including titanium alloys and nickel-based superalloys. The ability to produce parts with gradient material properties has proven particularly valuable for components exposed to extreme operating conditions, such as turbine blades and combustion chambers.

The medical industry represents another rapidly growing application area for DED technology. The market for DED-manufactured medical implants and devices is expanding at a rate of 22% annually, outpacing the overall market growth. This acceleration is primarily attributed to DED's ability to create patient-specific implants with biocompatible materials like titanium alloys, which offer superior osseointegration properties compared to traditionally manufactured implants.

Energy sector applications, particularly in oil and gas, have emerged as a significant market segment for DED technology. The demand for on-site repair capabilities in remote locations has driven adoption, with companies reporting up to 70% reduction in downtime and maintenance costs when implementing DED-based repair solutions for critical equipment components.

Automotive manufacturers have begun integrating DED into their production processes, focusing primarily on tooling applications and low-volume specialty parts. While currently representing only about 12% of the DED market, automotive applications are expected to grow substantially as the technology matures and becomes more cost-effective for higher-volume production scenarios.

The geographical distribution of DED market demand shows North America leading with approximately 42% market share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24% annually, driven by significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Material suppliers have responded to the growing DED market by developing specialized metal powders optimized for the process, with the metal powder market for DED applications growing at 17% annually. This supplier ecosystem development is crucial for addressing industry-specific requirements and enabling broader adoption across various sectors.

Aerospace and defense sectors currently dominate the DED market, accounting for nearly 35% of the total market share. These industries leverage DED's capabilities for manufacturing complex components with high-performance materials, including titanium alloys and nickel-based superalloys. The ability to produce parts with gradient material properties has proven particularly valuable for components exposed to extreme operating conditions, such as turbine blades and combustion chambers.

The medical industry represents another rapidly growing application area for DED technology. The market for DED-manufactured medical implants and devices is expanding at a rate of 22% annually, outpacing the overall market growth. This acceleration is primarily attributed to DED's ability to create patient-specific implants with biocompatible materials like titanium alloys, which offer superior osseointegration properties compared to traditionally manufactured implants.

Energy sector applications, particularly in oil and gas, have emerged as a significant market segment for DED technology. The demand for on-site repair capabilities in remote locations has driven adoption, with companies reporting up to 70% reduction in downtime and maintenance costs when implementing DED-based repair solutions for critical equipment components.

Automotive manufacturers have begun integrating DED into their production processes, focusing primarily on tooling applications and low-volume specialty parts. While currently representing only about 12% of the DED market, automotive applications are expected to grow substantially as the technology matures and becomes more cost-effective for higher-volume production scenarios.

The geographical distribution of DED market demand shows North America leading with approximately 42% market share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 24% annually, driven by significant investments in advanced manufacturing technologies in countries like China, Japan, and South Korea.

Material suppliers have responded to the growing DED market by developing specialized metal powders optimized for the process, with the metal powder market for DED applications growing at 17% annually. This supplier ecosystem development is crucial for addressing industry-specific requirements and enabling broader adoption across various sectors.

Global DED Development Status and Barriers

Directed Energy Deposition (DED) technology has witnessed significant global advancement in recent years, with varying levels of development across different regions. North America, particularly the United States, leads in DED innovation with substantial investments from both government agencies and private corporations. The U.S. Department of Defense and NASA have been instrumental in pushing the boundaries of DED applications for aerospace and defense sectors, resulting in numerous patents and commercial implementations.

Europe follows closely, with countries like Germany, the United Kingdom, and France demonstrating strong research capabilities in DED technology. The European Union's Horizon 2020 program has allocated considerable funding for additive manufacturing research, fostering collaborative efforts between academic institutions and industry partners. This has led to notable advancements in multi-material DED processes and hybrid manufacturing systems.

In Asia, China has rapidly accelerated its DED development through its "Made in China 2025" initiative, focusing on indigenous innovation and reducing dependency on foreign technology. Japan and South Korea have established specialized research centers dedicated to DED technology, particularly for applications in automotive and electronics industries.

Despite these advancements, several significant barriers impede the global adoption and further development of DED technology. Process stability and repeatability remain major challenges, as variations in material properties, environmental conditions, and equipment parameters can lead to inconsistent build quality. The complex thermal management during deposition processes often results in residual stresses and distortions that affect the final product's dimensional accuracy and mechanical properties.

Material limitations constitute another substantial barrier. While DED excels with certain metal alloys, its application with advanced materials such as ceramics, composites, and functionally graded materials remains challenging. The development of specialized powders and wires with consistent properties specifically designed for DED processes is still evolving.

Standardization and certification present regulatory hurdles that slow industry adoption. The lack of universally accepted standards for DED processes, materials, and quality assurance protocols creates uncertainty for potential adopters, particularly in highly regulated industries like aerospace and medical devices.

Cost factors also inhibit widespread implementation, as high-power laser or electron beam systems require significant capital investment. Additionally, the specialized knowledge required for operation and maintenance creates workforce development challenges that many organizations struggle to overcome.

Environmental and safety concerns related to metal powders, high-energy beams, and process emissions necessitate sophisticated containment and monitoring systems, adding complexity and cost to DED implementations.

Europe follows closely, with countries like Germany, the United Kingdom, and France demonstrating strong research capabilities in DED technology. The European Union's Horizon 2020 program has allocated considerable funding for additive manufacturing research, fostering collaborative efforts between academic institutions and industry partners. This has led to notable advancements in multi-material DED processes and hybrid manufacturing systems.

In Asia, China has rapidly accelerated its DED development through its "Made in China 2025" initiative, focusing on indigenous innovation and reducing dependency on foreign technology. Japan and South Korea have established specialized research centers dedicated to DED technology, particularly for applications in automotive and electronics industries.

Despite these advancements, several significant barriers impede the global adoption and further development of DED technology. Process stability and repeatability remain major challenges, as variations in material properties, environmental conditions, and equipment parameters can lead to inconsistent build quality. The complex thermal management during deposition processes often results in residual stresses and distortions that affect the final product's dimensional accuracy and mechanical properties.

Material limitations constitute another substantial barrier. While DED excels with certain metal alloys, its application with advanced materials such as ceramics, composites, and functionally graded materials remains challenging. The development of specialized powders and wires with consistent properties specifically designed for DED processes is still evolving.

Standardization and certification present regulatory hurdles that slow industry adoption. The lack of universally accepted standards for DED processes, materials, and quality assurance protocols creates uncertainty for potential adopters, particularly in highly regulated industries like aerospace and medical devices.

Cost factors also inhibit widespread implementation, as high-power laser or electron beam systems require significant capital investment. Additionally, the specialized knowledge required for operation and maintenance creates workforce development challenges that many organizations struggle to overcome.

Environmental and safety concerns related to metal powders, high-energy beams, and process emissions necessitate sophisticated containment and monitoring systems, adding complexity and cost to DED implementations.

Current DED Process Solutions

01 Process parameters and control in Directed Energy Deposition

Directed Energy Deposition (DED) processes require precise control of various parameters to achieve optimal results. These parameters include laser power, deposition rate, material feed rate, and motion control. Advanced control systems can monitor and adjust these parameters in real-time to maintain consistent quality throughout the build process. Proper parameter optimization helps minimize defects, improve surface finish, and enhance the mechanical properties of the final parts.- Directed Energy Deposition Process Fundamentals: Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials by melting as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits melted material onto a specified surface, where it solidifies. This technology allows for the creation of complex geometries and can be used with various materials including metals, polymers, and ceramics. The process parameters such as energy source power, material feed rate, and deposition path significantly influence the final product quality.

- Materials and Powder Characteristics for DED: The selection and characteristics of materials used in Directed Energy Deposition significantly impact the quality of the final product. Various metal powders, including titanium alloys, nickel-based superalloys, and stainless steels, are commonly used. The powder properties such as particle size distribution, flowability, and chemical composition are critical factors that affect the deposition process. Advanced material combinations and composite powders can be utilized to achieve specific mechanical properties or functional characteristics in the fabricated parts.

- Energy Source Technologies in DED Systems: Different energy sources can be employed in Directed Energy Deposition systems, including lasers, electron beams, plasma arcs, and other focused heat sources. Laser-based DED systems offer high precision and are suitable for complex geometries, while electron beam systems operate in vacuum environments and provide high energy efficiency. Plasma arc-based systems are often more cost-effective but may offer lower resolution. The selection of energy source depends on the specific application requirements, material compatibility, and desired part characteristics.

- Process Control and Monitoring Systems: Advanced process control and monitoring systems are essential for ensuring quality and consistency in Directed Energy Deposition. These systems may include real-time thermal imaging, melt pool monitoring, layer height detection, and feedback control mechanisms. Machine learning algorithms can be implemented to analyze process data and make adjustments during fabrication. Closed-loop control systems help maintain optimal processing parameters throughout the build, compensating for variations in material properties or environmental conditions, thereby improving part quality and reproducibility.

- Multi-Material and Functionally Graded Components: Directed Energy Deposition enables the fabrication of multi-material and functionally graded components, where material composition can be varied continuously throughout the part. This capability allows for the creation of components with location-specific properties, such as wear resistance in certain areas or heat resistance in others. The technology can be used to produce parts with embedded sensors, thermal management features, or mechanical property gradients. This approach offers significant advantages for aerospace, automotive, and medical applications where optimized performance characteristics are required in different regions of the same component.

02 Materials and powder handling for DED applications

The selection and handling of materials play a crucial role in Directed Energy Deposition processes. Various metal powders, wire feedstock, and composite materials can be used depending on the application requirements. Proper powder delivery systems ensure consistent material flow during deposition, while powder recycling and management systems help reduce waste and cost. Material compatibility with the energy source and substrate is essential for achieving strong metallurgical bonds and desired material properties in the final components.Expand Specific Solutions03 Energy source innovations for Directed Energy Deposition

Different energy sources can be employed in Directed Energy Deposition processes, including lasers, electron beams, plasma arcs, and hybrid systems. Recent innovations focus on improving energy efficiency, beam quality, and power distribution. Multi-beam systems allow for more complex deposition patterns and thermal management. Advanced energy source control enables precise heating of the deposition zone, resulting in better microstructure control and reduced thermal stress in the fabricated parts.Expand Specific Solutions04 Multi-axis systems and motion control for complex geometries

Advanced multi-axis motion systems enable the fabrication of complex geometries using Directed Energy Deposition. These systems typically incorporate 5-axis or more degrees of freedom to allow deposition at various angles and orientations. Sophisticated path planning algorithms optimize the deposition strategy based on part geometry, material properties, and process constraints. Integrated sensors and feedback systems ensure accurate positioning and consistent layer thickness throughout the build process, enabling the production of intricate features and internal structures.Expand Specific Solutions05 Hybrid manufacturing combining DED with other processes

Hybrid manufacturing systems integrate Directed Energy Deposition with other manufacturing processes such as machining, grinding, or inspection within a single platform. This combination allows for in-process finishing operations, reducing the need for secondary processing and improving dimensional accuracy. Hybrid approaches can also combine different additive manufacturing techniques to leverage their respective advantages. These integrated systems offer enhanced flexibility, reduced production time, and improved part quality compared to standalone DED processes.Expand Specific Solutions

Leading Companies and Competitive Landscape

Directed Energy Deposition (DED) technology is currently in a growth phase within the additive manufacturing market, with an expanding global footprint across aerospace, defense, and industrial sectors. The market size is projected to reach significant scale as adoption increases, particularly for high-value metal components. From a technological maturity perspective, DED has evolved from experimental to commercial applications, with key players driving innovation. Companies like GE Avio, Rolls-Royce, and Safran Aircraft Engines are leading aerospace implementations, while FormAlloy Technologies and Norsk Titanium have developed specialized DED systems. DMG MORI and JTEKT are integrating DED into hybrid manufacturing solutions, with research support from institutions like Northwestern Polytechnical University and Tianjin University advancing material science applications and process optimization.

GE Avio Srl

Technical Solution: GE Avio has developed an advanced Directed Energy Deposition (DED) technology specifically optimized for aerospace engine components. Their approach combines laser-based DED with sophisticated process monitoring systems that utilize multiple sensors to track melt pool dynamics, thermal gradients, and material deposition rates in real-time. GE Avio's technology incorporates proprietary algorithms that adjust process parameters dynamically to maintain consistent material properties throughout complex geometries[5]. The company has successfully implemented a hybrid manufacturing approach that integrates DED with traditional machining in a single platform, allowing for the production of near-net-shape components that require minimal post-processing. GE Avio has focused particularly on high-temperature superalloys used in turbine components, developing specialized process parameters that ensure optimal microstructure development during deposition. Their technology has been validated for critical aerospace applications, demonstrating mechanical properties comparable to traditionally manufactured components while reducing lead times by up to 60%[6] and material waste by up to 75% for complex geometries.

Strengths: Highly refined process parameters for aerospace-grade superalloys; integrated quality control systems with comprehensive monitoring capabilities; proven implementation in critical aerospace applications with regulatory approval. Weaknesses: Technology optimized primarily for aerospace applications with less flexibility for other industries; requires significant expertise to operate and maintain; higher capital investment compared to conventional manufacturing methods.

DMG MORI Manufacturing USA, Inc.

Technical Solution: DMG MORI has developed an innovative hybrid manufacturing approach that integrates Directed Energy Deposition (DED) with 5-axis CNC machining in a single platform. Their LASERTEC 3D hybrid series combines powder-based laser deposition with precision machining capabilities, allowing for alternating between additive manufacturing and subtractive finishing operations without part reclamping[9]. This technology enables the creation of complex geometries with excellent surface finishes and tight tolerances that would be difficult to achieve with DED alone. DMG MORI's system utilizes a coaxial powder nozzle design that enables omnidirectional deposition, facilitating the creation of overhanging features without support structures. Their process control system incorporates multiple feedback mechanisms including melt pool monitoring, thermal imaging, and layer height verification to ensure consistent material properties throughout the build. The company has developed specialized software that optimizes tool paths for both the additive and subtractive processes, automatically determining the most efficient manufacturing strategy for complex components[10]. Their technology supports a wide range of materials including tool steels, stainless steels, nickel-based alloys, and titanium alloys, with the ability to create multi-material components through controlled material transitions.

Strengths: Seamless integration of additive and subtractive manufacturing in a single platform; excellent dimensional accuracy and surface finish compared to pure DED processes; flexibility to work with a wide range of materials. Weaknesses: Higher initial investment cost compared to standalone DED systems; larger footprint requiring more shop floor space; complexity of operation requiring specialized training for both additive and subtractive processes.

Key Patents and Technical Innovations

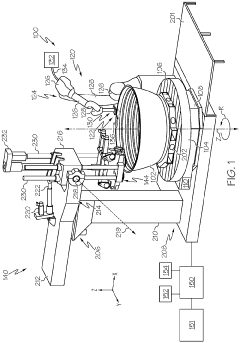

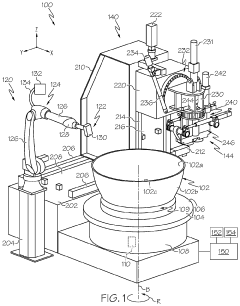

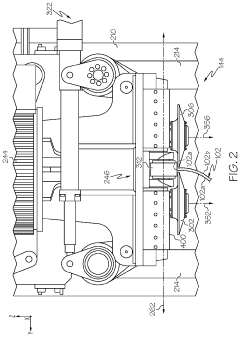

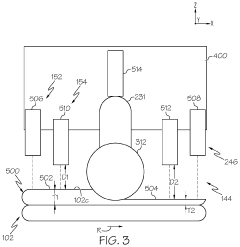

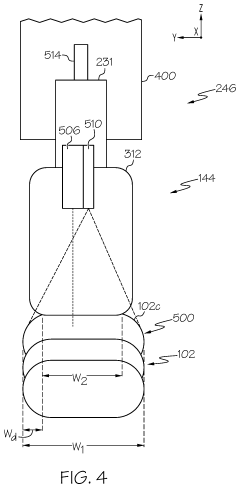

Additive manufacturing system and method for compression of material during material deposition

PatentPendingEP4302912A1

Innovation

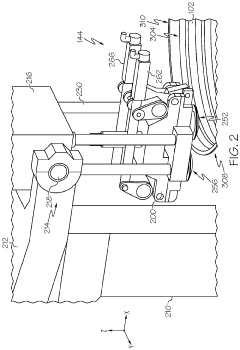

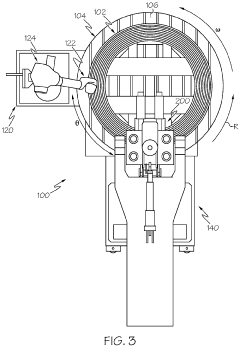

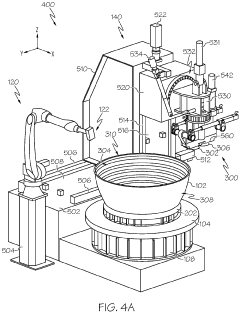

- A DED system that integrates a rotary build table and a compression rig allowing simultaneous deposition and compression phases, utilizing a robotic arm and compression head with rollers to apply compressive loads during material deposition, controlled by a system that ensures uniform temperature and strain application.

Additive manufacturing systems or methods for compression of material based on detected temperature

PatentPendingUS20240009929A1

Innovation

- The implementation of a DED system that combines a deposition head with a compression rig, allowing for simultaneous material deposition and compression using a compression head with temperature and distance sensors to adjust the position and load applied, enabling continuous compressive loading during deposition.

Material Compatibility and Development

Material compatibility represents a critical frontier in the advancement of Directed Energy Deposition (DED) technology. The process's high-energy nature creates unique material interaction dynamics that both enable novel applications and present significant challenges. Currently, DED systems demonstrate compatibility with a diverse range of materials including various metal alloys, ceramics, and increasingly, composite materials. Titanium alloys, nickel-based superalloys, and stainless steels have shown particularly promising results due to their favorable thermal properties and mechanical characteristics under high-energy deposition conditions.

Recent developments have expanded the material palette for DED processes through innovative powder formulations and wire feedstock engineering. Researchers have achieved significant breakthroughs in processing traditionally difficult materials such as refractory metals and high-entropy alloys, which offer exceptional high-temperature performance crucial for aerospace and energy sector applications. The ability to process these advanced materials represents a substantial competitive advantage for DED compared to other additive manufacturing technologies.

Material development efforts have increasingly focused on creating specialized alloys optimized specifically for DED processing parameters. These tailored materials account for the unique thermal cycles, cooling rates, and solidification behaviors characteristic of DED processes. Gradient materials, which feature controlled compositional variation throughout a single component, have emerged as a particularly promising application area, enabling components with location-specific properties that cannot be achieved through conventional manufacturing methods.

Powder characteristics have proven instrumental in determining process outcomes, with particle size distribution, morphology, and flowability directly impacting deposition quality. Advanced powder production techniques, including plasma spheroidization and gas atomization refinements, have yielded significant improvements in material consistency and performance. Concurrent developments in real-time powder flow monitoring systems have enhanced process control capabilities, allowing for adaptive adjustments during fabrication.

The interface between dissimilar materials represents another critical research domain, with significant progress made in understanding and controlling the metallurgical bonding mechanisms at these junctions. This has enabled the reliable production of multi-material components that leverage the specific advantages of different materials within a single part. Such capabilities open new design possibilities across industries ranging from biomedical implants to high-performance turbomachinery components.

Despite these advances, challenges persist in predicting and controlling microstructural development during deposition, particularly for novel material combinations. Computational modeling approaches, including multi-physics simulations that account for complex thermal, mechanical, and metallurgical interactions, are increasingly employed to accelerate material development cycles and optimize processing parameters for specific material systems.

Recent developments have expanded the material palette for DED processes through innovative powder formulations and wire feedstock engineering. Researchers have achieved significant breakthroughs in processing traditionally difficult materials such as refractory metals and high-entropy alloys, which offer exceptional high-temperature performance crucial for aerospace and energy sector applications. The ability to process these advanced materials represents a substantial competitive advantage for DED compared to other additive manufacturing technologies.

Material development efforts have increasingly focused on creating specialized alloys optimized specifically for DED processing parameters. These tailored materials account for the unique thermal cycles, cooling rates, and solidification behaviors characteristic of DED processes. Gradient materials, which feature controlled compositional variation throughout a single component, have emerged as a particularly promising application area, enabling components with location-specific properties that cannot be achieved through conventional manufacturing methods.

Powder characteristics have proven instrumental in determining process outcomes, with particle size distribution, morphology, and flowability directly impacting deposition quality. Advanced powder production techniques, including plasma spheroidization and gas atomization refinements, have yielded significant improvements in material consistency and performance. Concurrent developments in real-time powder flow monitoring systems have enhanced process control capabilities, allowing for adaptive adjustments during fabrication.

The interface between dissimilar materials represents another critical research domain, with significant progress made in understanding and controlling the metallurgical bonding mechanisms at these junctions. This has enabled the reliable production of multi-material components that leverage the specific advantages of different materials within a single part. Such capabilities open new design possibilities across industries ranging from biomedical implants to high-performance turbomachinery components.

Despite these advances, challenges persist in predicting and controlling microstructural development during deposition, particularly for novel material combinations. Computational modeling approaches, including multi-physics simulations that account for complex thermal, mechanical, and metallurgical interactions, are increasingly employed to accelerate material development cycles and optimize processing parameters for specific material systems.

Sustainability and Energy Efficiency

Directed Energy Deposition (DED) technology demonstrates significant advantages in sustainability and energy efficiency compared to traditional manufacturing methods. The process utilizes focused thermal energy to melt materials precisely where needed, substantially reducing material waste. Studies indicate that DED can achieve material utilization rates of up to 95%, compared to only 20-30% in conventional subtractive manufacturing processes, representing a dramatic improvement in resource efficiency.

Energy consumption analysis reveals that DED systems, while energy-intensive during operation, offer lifecycle energy savings through reduced raw material processing requirements and decreased transportation needs. Recent advancements in laser and electron beam technologies have improved energy transfer efficiency by approximately 30% over the past five years, with further optimization expected as the technology matures.

The closed-loop material systems being developed for DED processes enable the recycling of unused powder directly within the manufacturing cell, minimizing waste streams and associated environmental impacts. This represents a significant step toward circular manufacturing principles in industrial production environments.

Carbon footprint assessments of DED manufacturing show potential reductions of 25-40% compared to traditional methods when considering the entire product lifecycle. These gains stem primarily from reduced material consumption, localized production capabilities, and the ability to repair rather than replace components.

Thermal management innovations have emerged as a critical focus area for improving DED energy efficiency. Advanced cooling systems and thermal modeling algorithms now enable more precise energy delivery, reducing excess heat generation and improving overall process efficiency by up to 20% in newer system designs.

Multi-material DED capabilities further enhance sustainability by allowing functional gradation within components, optimizing material use based on specific performance requirements rather than overengineering entire parts with premium materials. This approach not only conserves critical resources but also improves component performance and longevity.

Industry adoption of DED technology is increasingly driven by sustainability metrics, with aerospace and energy sectors leading implementation due to their focus on lightweight, high-performance components that reduce operational energy consumption throughout product lifecycles. The technology's ability to extend component service life through repair applications represents perhaps its most significant sustainability contribution.

Energy consumption analysis reveals that DED systems, while energy-intensive during operation, offer lifecycle energy savings through reduced raw material processing requirements and decreased transportation needs. Recent advancements in laser and electron beam technologies have improved energy transfer efficiency by approximately 30% over the past five years, with further optimization expected as the technology matures.

The closed-loop material systems being developed for DED processes enable the recycling of unused powder directly within the manufacturing cell, minimizing waste streams and associated environmental impacts. This represents a significant step toward circular manufacturing principles in industrial production environments.

Carbon footprint assessments of DED manufacturing show potential reductions of 25-40% compared to traditional methods when considering the entire product lifecycle. These gains stem primarily from reduced material consumption, localized production capabilities, and the ability to repair rather than replace components.

Thermal management innovations have emerged as a critical focus area for improving DED energy efficiency. Advanced cooling systems and thermal modeling algorithms now enable more precise energy delivery, reducing excess heat generation and improving overall process efficiency by up to 20% in newer system designs.

Multi-material DED capabilities further enhance sustainability by allowing functional gradation within components, optimizing material use based on specific performance requirements rather than overengineering entire parts with premium materials. This approach not only conserves critical resources but also improves component performance and longevity.

Industry adoption of DED technology is increasingly driven by sustainability metrics, with aerospace and energy sectors leading implementation due to their focus on lightweight, high-performance components that reduce operational energy consumption throughout product lifecycles. The technology's ability to extend component service life through repair applications represents perhaps its most significant sustainability contribution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!