Assessing Directed Energy Deposition's Role in Advanced Manufacturing

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Objectives

Directed Energy Deposition (DED) has evolved significantly since its inception in the 1990s, transforming from experimental technology to a vital component in advanced manufacturing. Initially developed as a laser cladding process, DED has expanded to encompass various energy sources including electron beams, plasma arcs, and high-powered lasers, each offering unique capabilities for material deposition and part fabrication.

The evolutionary trajectory of DED technology has been marked by several key milestones. Early systems focused primarily on repair applications and simple geometries, while contemporary systems demonstrate remarkable precision in creating complex, multi-material components with functionally graded properties. This progression has been enabled by advances in process control, monitoring systems, and computational modeling that allow for real-time adjustments during fabrication.

Material compatibility has expanded dramatically throughout DED's development. Initial applications were limited to a narrow range of metals, whereas modern systems can process a diverse array of materials including titanium alloys, nickel-based superalloys, stainless steels, and increasingly, ceramic and composite materials. This material flexibility represents one of DED's most significant technological advances.

The primary objective of DED technology development has been to establish a reliable, repeatable manufacturing process capable of producing components with mechanical properties comparable or superior to traditionally manufactured parts. Secondary objectives include increasing deposition rates, improving surface finish quality, and enhancing geometric accuracy to reduce post-processing requirements.

Current research and development efforts are focused on several critical areas: expanding the process envelope to accommodate larger build volumes, increasing deposition rates without sacrificing quality, developing hybrid manufacturing systems that combine DED with subtractive processes, and implementing advanced in-situ monitoring for closed-loop control systems.

Looking forward, DED technology aims to achieve greater integration with digital manufacturing ecosystems, enabling seamless implementation of Industry 4.0 principles. This includes developing more sophisticated process models that can predict and compensate for thermal distortion, residual stress, and microstructural variations. Additionally, there is significant interest in expanding DED capabilities for repair and remanufacturing applications, particularly in aerospace, defense, and energy sectors where component restoration offers substantial economic and sustainability benefits.

The ultimate technological goal for DED is to establish it as a mainstream manufacturing process with standardized parameters, certified materials, and validated quality assurance protocols that enable widespread industrial adoption across diverse sectors requiring high-performance, customized metal components.

The evolutionary trajectory of DED technology has been marked by several key milestones. Early systems focused primarily on repair applications and simple geometries, while contemporary systems demonstrate remarkable precision in creating complex, multi-material components with functionally graded properties. This progression has been enabled by advances in process control, monitoring systems, and computational modeling that allow for real-time adjustments during fabrication.

Material compatibility has expanded dramatically throughout DED's development. Initial applications were limited to a narrow range of metals, whereas modern systems can process a diverse array of materials including titanium alloys, nickel-based superalloys, stainless steels, and increasingly, ceramic and composite materials. This material flexibility represents one of DED's most significant technological advances.

The primary objective of DED technology development has been to establish a reliable, repeatable manufacturing process capable of producing components with mechanical properties comparable or superior to traditionally manufactured parts. Secondary objectives include increasing deposition rates, improving surface finish quality, and enhancing geometric accuracy to reduce post-processing requirements.

Current research and development efforts are focused on several critical areas: expanding the process envelope to accommodate larger build volumes, increasing deposition rates without sacrificing quality, developing hybrid manufacturing systems that combine DED with subtractive processes, and implementing advanced in-situ monitoring for closed-loop control systems.

Looking forward, DED technology aims to achieve greater integration with digital manufacturing ecosystems, enabling seamless implementation of Industry 4.0 principles. This includes developing more sophisticated process models that can predict and compensate for thermal distortion, residual stress, and microstructural variations. Additionally, there is significant interest in expanding DED capabilities for repair and remanufacturing applications, particularly in aerospace, defense, and energy sectors where component restoration offers substantial economic and sustainability benefits.

The ultimate technological goal for DED is to establish it as a mainstream manufacturing process with standardized parameters, certified materials, and validated quality assurance protocols that enable widespread industrial adoption across diverse sectors requiring high-performance, customized metal components.

Market Analysis for DED Manufacturing Solutions

The global market for Directed Energy Deposition (DED) manufacturing solutions is experiencing robust growth, driven by increasing demand for advanced manufacturing technologies across various industrial sectors. Current market valuations place the DED segment at approximately $500 million, with projections indicating a compound annual growth rate of 14-16% over the next five years. This growth trajectory positions DED as one of the fastest-expanding segments within the broader additive manufacturing market.

Key industries adopting DED technology include aerospace, defense, automotive, medical devices, and energy sectors. The aerospace industry represents the largest market share, accounting for nearly 30% of total DED applications, primarily for component repair and manufacturing of complex titanium structures. Defense applications follow closely, with significant investments in DED for field repair capabilities and rapid prototyping of critical components.

Regional market analysis reveals North America as the dominant market for DED solutions, holding approximately 40% of the global market share. This leadership position stems from substantial defense spending and the presence of major aerospace manufacturers. Europe represents the second-largest market at 30%, with particularly strong adoption in Germany, France, and the UK. The Asia-Pacific region, while currently accounting for 25% of the market, is expected to demonstrate the highest growth rate, driven by rapid industrialization in China, Japan, and South Korea.

Customer segmentation within the DED market reveals three primary buyer categories: large original equipment manufacturers (OEMs), specialized service bureaus, and research institutions. OEMs typically invest in DED for in-house production capabilities, while service bureaus offer DED as part of broader manufacturing services. Research institutions continue to drive innovation in DED applications and materials compatibility.

Market challenges include high equipment costs, with industrial-grade DED systems ranging from $500,000 to over $1.5 million, creating significant barriers to entry for smaller manufacturers. Additionally, the specialized technical expertise required for operation and the ongoing development of industry standards represent obstacles to wider market penetration.

Competitive analysis indicates a moderately concentrated market with approximately 15 major equipment manufacturers. Market leaders include established players from traditional manufacturing backgrounds who have expanded into additive manufacturing, alongside specialized DED technology startups. Recent market trends show increasing consolidation through strategic acquisitions, as larger manufacturing conglomerates seek to incorporate DED capabilities into their technology portfolios.

Key industries adopting DED technology include aerospace, defense, automotive, medical devices, and energy sectors. The aerospace industry represents the largest market share, accounting for nearly 30% of total DED applications, primarily for component repair and manufacturing of complex titanium structures. Defense applications follow closely, with significant investments in DED for field repair capabilities and rapid prototyping of critical components.

Regional market analysis reveals North America as the dominant market for DED solutions, holding approximately 40% of the global market share. This leadership position stems from substantial defense spending and the presence of major aerospace manufacturers. Europe represents the second-largest market at 30%, with particularly strong adoption in Germany, France, and the UK. The Asia-Pacific region, while currently accounting for 25% of the market, is expected to demonstrate the highest growth rate, driven by rapid industrialization in China, Japan, and South Korea.

Customer segmentation within the DED market reveals three primary buyer categories: large original equipment manufacturers (OEMs), specialized service bureaus, and research institutions. OEMs typically invest in DED for in-house production capabilities, while service bureaus offer DED as part of broader manufacturing services. Research institutions continue to drive innovation in DED applications and materials compatibility.

Market challenges include high equipment costs, with industrial-grade DED systems ranging from $500,000 to over $1.5 million, creating significant barriers to entry for smaller manufacturers. Additionally, the specialized technical expertise required for operation and the ongoing development of industry standards represent obstacles to wider market penetration.

Competitive analysis indicates a moderately concentrated market with approximately 15 major equipment manufacturers. Market leaders include established players from traditional manufacturing backgrounds who have expanded into additive manufacturing, alongside specialized DED technology startups. Recent market trends show increasing consolidation through strategic acquisitions, as larger manufacturing conglomerates seek to incorporate DED capabilities into their technology portfolios.

DED Technical Landscape and Barriers

Directed Energy Deposition (DED) technology has evolved significantly over the past two decades, transitioning from experimental applications to becoming an integral component of advanced manufacturing systems. The current technical landscape reveals a technology that offers unique capabilities for producing complex metal components with high material efficiency, but still faces considerable implementation barriers.

The global DED market is characterized by a diverse ecosystem of equipment manufacturers, with major players concentrated in North America, Europe, and East Asia. Leading systems typically employ either laser, electron beam, or plasma arc as energy sources, with laser-based systems dominating commercial applications due to their precision and versatility across material types.

Current DED systems demonstrate impressive capabilities in producing large-format metal components with relatively high deposition rates (typically 2-10 kg/h), making them particularly valuable for aerospace, defense, and heavy machinery applications. However, the technology faces significant technical barriers that limit broader industrial adoption.

Process stability remains a primary challenge, with thermal management issues causing inconsistent material properties across complex geometries. Temperature gradients during deposition can lead to residual stresses, warping, and unpredictable microstructural development. This variability compromises mechanical performance and makes quality assurance difficult, particularly for critical applications requiring certification.

Real-time monitoring and closed-loop control systems represent another technical frontier. While some advanced systems incorporate thermal imaging and layer geometry verification, truly adaptive process control remains elusive. The complex interaction between process parameters (power, feed rate, travel speed) and material properties creates a multidimensional optimization problem that current control algorithms struggle to manage effectively.

Material compatibility presents additional constraints, as not all metal alloys perform consistently in DED processes. High-value materials like titanium alloys, nickel superalloys, and specialized steels show promising results, but many common engineering alloys exhibit porosity, cracking, or inconsistent properties when processed via DED.

Surface finish and dimensional accuracy limitations necessitate post-processing operations, reducing the economic advantages of the technology. Typical as-deposited surfaces exhibit roughness values (Ra) between 15-40 μm, requiring secondary machining to achieve functional tolerances for most applications.

The integration of DED into existing manufacturing workflows presents both technical and organizational challenges. Current systems lack standardized interfaces for data exchange with CAD/CAM environments, and process planning tools remain relatively immature compared to conventional manufacturing methods.

The global DED market is characterized by a diverse ecosystem of equipment manufacturers, with major players concentrated in North America, Europe, and East Asia. Leading systems typically employ either laser, electron beam, or plasma arc as energy sources, with laser-based systems dominating commercial applications due to their precision and versatility across material types.

Current DED systems demonstrate impressive capabilities in producing large-format metal components with relatively high deposition rates (typically 2-10 kg/h), making them particularly valuable for aerospace, defense, and heavy machinery applications. However, the technology faces significant technical barriers that limit broader industrial adoption.

Process stability remains a primary challenge, with thermal management issues causing inconsistent material properties across complex geometries. Temperature gradients during deposition can lead to residual stresses, warping, and unpredictable microstructural development. This variability compromises mechanical performance and makes quality assurance difficult, particularly for critical applications requiring certification.

Real-time monitoring and closed-loop control systems represent another technical frontier. While some advanced systems incorporate thermal imaging and layer geometry verification, truly adaptive process control remains elusive. The complex interaction between process parameters (power, feed rate, travel speed) and material properties creates a multidimensional optimization problem that current control algorithms struggle to manage effectively.

Material compatibility presents additional constraints, as not all metal alloys perform consistently in DED processes. High-value materials like titanium alloys, nickel superalloys, and specialized steels show promising results, but many common engineering alloys exhibit porosity, cracking, or inconsistent properties when processed via DED.

Surface finish and dimensional accuracy limitations necessitate post-processing operations, reducing the economic advantages of the technology. Typical as-deposited surfaces exhibit roughness values (Ra) between 15-40 μm, requiring secondary machining to achieve functional tolerances for most applications.

The integration of DED into existing manufacturing workflows presents both technical and organizational challenges. Current systems lack standardized interfaces for data exchange with CAD/CAM environments, and process planning tools remain relatively immature compared to conventional manufacturing methods.

Current DED Implementation Approaches

01 DED process optimization and control

Directed Energy Deposition (DED) processes can be optimized through various control mechanisms to improve build quality and efficiency. This includes real-time monitoring systems, feedback control loops, and parameter optimization for different materials. Advanced control strategies help maintain consistent deposition rates, thermal conditions, and material properties throughout the build process, resulting in higher quality parts with improved mechanical properties and reduced defects.- DED process optimization and control: Directed Energy Deposition processes can be optimized through various control mechanisms to improve build quality and efficiency. This includes real-time monitoring systems, feedback control loops, and parameter optimization techniques that adjust power, feed rate, and scanning strategies. Advanced control systems can detect and correct defects during the build process, resulting in improved material properties and reduced post-processing requirements.

- Multi-material and functionally graded components via DED: Directed Energy Deposition enables the fabrication of multi-material and functionally graded components by precisely controlling material composition during the deposition process. This capability allows for the creation of parts with tailored properties in specific regions, such as wear resistance in one area and heat resistance in another. The technology can seamlessly transition between different materials or create composite structures with unique property combinations not achievable through conventional manufacturing methods.

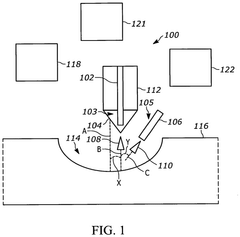

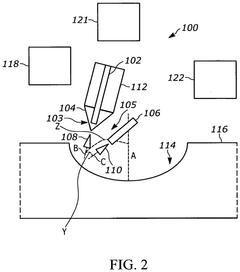

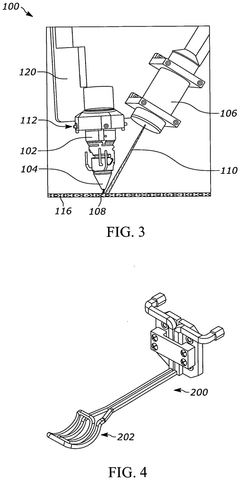

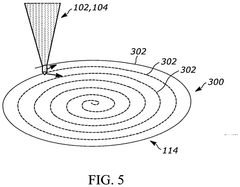

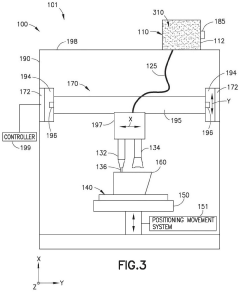

- DED equipment and system configurations: Various equipment configurations and system designs are employed in Directed Energy Deposition, including different energy sources (laser, electron beam, plasma arc), delivery mechanisms, and motion systems. These systems can be customized with multiple deposition heads, integrated sensors, and specialized atmosphere control chambers. Advanced DED systems may incorporate robotic arms for complex geometries or hybrid manufacturing capabilities that combine additive and subtractive processes in a single setup.

- Material development for DED applications: Specialized materials and powder formulations are being developed specifically for Directed Energy Deposition processes. These materials are engineered for optimal flowability, energy absorption, and solidification characteristics. Research focuses on expanding the range of compatible materials, including high-performance alloys, ceramics, and composites. Material development also addresses challenges such as cracking susceptibility, thermal stress management, and microstructure control during the rapid solidification conditions typical in DED processes.

- Repair and remanufacturing using DED technology: Directed Energy Deposition is particularly effective for repair and remanufacturing applications, allowing for the restoration of damaged or worn components. The process can selectively add material to specific areas of existing parts, extending their service life and reducing replacement costs. This approach is especially valuable for high-value components in aerospace, defense, and industrial sectors. The technology enables precise material addition with minimal heat-affected zones and good metallurgical bonding to the substrate material.

02 Multi-material DED applications

Multi-material Directed Energy Deposition enables the fabrication of components with functionally graded properties or distinct material zones. This approach allows for the strategic placement of different materials within a single component to optimize performance characteristics such as wear resistance, thermal conductivity, or corrosion resistance. The technology enables the creation of novel material combinations that would be difficult or impossible to achieve using conventional manufacturing methods.Expand Specific Solutions03 DED equipment and system design

Specialized equipment designs for Directed Energy Deposition include various energy source configurations (laser, electron beam, plasma arc), multi-axis deposition systems, and integrated monitoring capabilities. These systems may incorporate multiple powder feeders, gas shielding mechanisms, and cooling systems to control the deposition environment. Advanced DED systems may also feature hybrid manufacturing capabilities that combine additive and subtractive processes in a single machine.Expand Specific Solutions04 Material development for DED processes

Materials specifically formulated for Directed Energy Deposition processes include specialized metal powders, alloys, and composites with optimized particle size distribution, flowability, and thermal properties. These materials are designed to enhance deposition efficiency, reduce defects, and achieve desired microstructural characteristics in the final parts. Research focuses on expanding the range of compatible materials for DED, including high-performance alloys, ceramics, and metal matrix composites.Expand Specific Solutions05 Post-processing techniques for DED parts

Post-processing methods for Directed Energy Deposition manufactured components include heat treatment, surface finishing, machining, and hot isostatic pressing to improve mechanical properties and surface quality. These techniques help address common DED challenges such as residual stress, porosity, and surface roughness. Advanced post-processing approaches may be tailored to specific materials or applications to optimize final part performance and dimensional accuracy.Expand Specific Solutions

Leading DED Technology Providers and Competitors

Directed Energy Deposition (DED) is currently in a growth phase within the advanced manufacturing landscape, with the market expanding as industries recognize its potential for complex part production and repair applications. The global market size for DED technology is projected to reach significant scale as adoption increases across aerospace, defense, and industrial sectors. From a technological maturity perspective, key players demonstrate varying levels of advancement: GE Avio and Norsk Titanium lead commercial implementation in aerospace applications, while RTX, Lockheed Martin, and Airbus are driving defense-oriented innovations. Academic institutions like Tsinghua University, Nanyang Technological University, and Huazhong University are advancing fundamental research, while specialized manufacturers such as DMG MORI and Stratasys are developing integrated DED systems for industrial applications, indicating a technology approaching mainstream industrial adoption but with significant room for optimization.

GE Avio Srl

Technical Solution: GE Avio has developed an advanced hybrid DED system that combines laser-based directed energy deposition with high-precision 5-axis machining capabilities. Their technology, known as STREAM (Selective Titanium Repair and Additive Manufacturing), is specifically optimized for aerospace engine components using titanium and nickel-based superalloys. The system features a proprietary powder delivery mechanism that achieves near-100% material utilization, significantly reducing waste compared to traditional powder bed systems. GE Avio's implementation includes sophisticated thermal monitoring using infrared cameras that create a detailed thermal history for each component, ensuring consistent microstructure and mechanical properties. The company has successfully implemented this technology for both manufacturing new components and repairing high-value engine parts, demonstrating a 70% reduction in repair cycle time and 40% cost reduction compared to conventional repair methods. Their process has been qualified for critical rotating components in aircraft engines, meeting stringent aerospace certification requirements[9][10].

Strengths: Exceptional material efficiency; qualified for critical aerospace applications; dual capability for both manufacturing and repair; significant cost and time savings for complex components. Weaknesses: Limited material portfolio; high initial investment costs; complex qualification process for new applications; requires specialized operator training.

Norsk Titanium AS

Technical Solution: Norsk Titanium has developed a proprietary Rapid Plasma Deposition™ (RPD™) technology, a specialized form of directed energy deposition that uses plasma torches to melt titanium wire in an inert gas environment. Their process enables near-net-shape manufacturing of structural titanium components with up to 80% reduced time and material waste compared to traditional forging methods. The company has achieved significant milestones in aerospace manufacturing, becoming the first to receive FAA approval for additive manufactured structural titanium components for commercial aircraft. Their RPD™ technology allows for the production of large structural parts (up to 900mm) with mechanical properties that meet or exceed traditional forged titanium specifications, while maintaining precise control over microstructure through their patented thermal management systems[1][2].

Strengths: Superior material efficiency with up to 80% reduction in buy-to-fly ratios; FAA certification for critical aerospace components; ability to produce large structural parts with consistent mechanical properties. Weaknesses: Limited to titanium alloys; high initial capital investment; requires specialized expertise for operation and quality control.

Critical DED Patents and Technical Innovations

Directed energy deposition system and methods for component repairs

PatentPendingEP4609971A1

Innovation

- A DED system employing multiple energy sources and a bi-directional spiral deposition pattern, combined with induction heating, to melt and uniformly fill concave cavities with angled walls, using titanium aluminide powder, ensuring thermal distribution and adhesion.

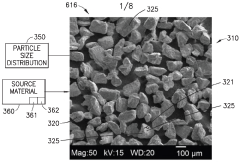

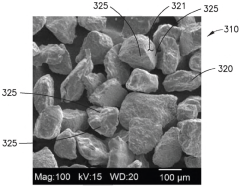

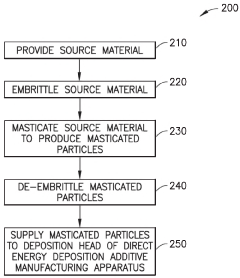

Methods for additive manufacturing with masticated particles

PatentInactiveAU2019283964A1

Innovation

- The use of masticated particles with angular facets, produced by grinding and crushing source materials, which are then fed through a deposition nozzle and melted by a directed energy source to form parts, significantly reducing production costs by 75% to 90% compared to traditional spherical powders.

Material Compatibility and Process Parameters

Material compatibility represents a critical factor in the successful implementation of Directed Energy Deposition (DED) processes. The technology demonstrates remarkable versatility across various metallic materials, including titanium alloys, nickel-based superalloys, stainless steels, and tool steels. However, each material category presents unique challenges that require specific process parameter adjustments to achieve optimal results. For instance, titanium alloys demand stringent atmospheric control to prevent oxidation, while nickel superalloys require precise thermal management to avoid detrimental microstructural changes.

Process parameters in DED technology form an intricate network of interdependent variables that significantly influence the final part quality. Laser power density, material feed rate, traverse speed, and layer thickness constitute the primary parameters requiring careful calibration. Research indicates that laser power typically ranges from 500W to 4kW depending on material properties and desired deposition rates. The powder feed rate, generally between 2-15 g/min, must be synchronized with the energy input to ensure complete melting without excessive heat accumulation.

The relationship between process parameters and resultant material properties exhibits complex non-linear behavior. Studies reveal that cooling rates, which directly affect microstructure formation, can vary from 10³ to 10⁶ K/s depending on parameter combinations. This variability enables tailored microstructures but simultaneously introduces challenges in process repeatability. Recent investigations have demonstrated that parameter optimization can reduce porosity levels to below 0.1% in most engineering alloys, significantly enhancing mechanical performance.

Environmental factors, particularly shielding gas composition and flow dynamics, play a crucial role in material compatibility. Argon remains the predominant choice for reactive materials, while helium offers advantages for high thermal conductivity applications despite its higher cost. Hybrid gas solutions combining both elements have shown promising results in balancing oxidation prevention and heat transfer efficiency.

Multi-material compatibility represents an emerging frontier in DED technology, with research focusing on functionally graded materials and novel alloy combinations. The transition zones between dissimilar materials present particular challenges regarding residual stress management and intermetallic compound formation. Parameter modulation strategies, including power ramping and composition gradient control, have demonstrated effectiveness in mitigating these issues, enabling previously impossible material combinations.

Computational modeling approaches have advanced significantly, allowing predictive parameter selection based on material-specific properties. Machine learning algorithms trained on extensive parameter-property datasets are increasingly employed to optimize process parameters, reducing the traditional trial-and-error approach. These developments are accelerating the integration of new materials into DED manufacturing workflows, expanding the technology's application potential across industries.

Process parameters in DED technology form an intricate network of interdependent variables that significantly influence the final part quality. Laser power density, material feed rate, traverse speed, and layer thickness constitute the primary parameters requiring careful calibration. Research indicates that laser power typically ranges from 500W to 4kW depending on material properties and desired deposition rates. The powder feed rate, generally between 2-15 g/min, must be synchronized with the energy input to ensure complete melting without excessive heat accumulation.

The relationship between process parameters and resultant material properties exhibits complex non-linear behavior. Studies reveal that cooling rates, which directly affect microstructure formation, can vary from 10³ to 10⁶ K/s depending on parameter combinations. This variability enables tailored microstructures but simultaneously introduces challenges in process repeatability. Recent investigations have demonstrated that parameter optimization can reduce porosity levels to below 0.1% in most engineering alloys, significantly enhancing mechanical performance.

Environmental factors, particularly shielding gas composition and flow dynamics, play a crucial role in material compatibility. Argon remains the predominant choice for reactive materials, while helium offers advantages for high thermal conductivity applications despite its higher cost. Hybrid gas solutions combining both elements have shown promising results in balancing oxidation prevention and heat transfer efficiency.

Multi-material compatibility represents an emerging frontier in DED technology, with research focusing on functionally graded materials and novel alloy combinations. The transition zones between dissimilar materials present particular challenges regarding residual stress management and intermetallic compound formation. Parameter modulation strategies, including power ramping and composition gradient control, have demonstrated effectiveness in mitigating these issues, enabling previously impossible material combinations.

Computational modeling approaches have advanced significantly, allowing predictive parameter selection based on material-specific properties. Machine learning algorithms trained on extensive parameter-property datasets are increasingly employed to optimize process parameters, reducing the traditional trial-and-error approach. These developments are accelerating the integration of new materials into DED manufacturing workflows, expanding the technology's application potential across industries.

Sustainability and Cost-Efficiency Analysis

Directed Energy Deposition (DED) technology demonstrates significant sustainability advantages compared to traditional manufacturing methods. The process utilizes materials more efficiently, with powder utilization rates typically reaching 90-95% compared to 40-60% in powder bed fusion systems. This dramatic reduction in material waste directly translates to lower environmental impact and resource consumption across the manufacturing lifecycle.

Energy efficiency analysis reveals that DED processes can reduce overall energy consumption by 15-30% compared to conventional subtractive manufacturing for complex components. This efficiency stems from the additive nature of the process, which eliminates energy-intensive material removal steps and reduces the need for multiple manufacturing operations. The localized energy application in DED further minimizes heat-affected zones and unnecessary material heating.

From a cost perspective, DED offers compelling advantages for medium to large-scale components. Initial investment costs for industrial DED systems range from $500,000 to $1.5 million, representing a significant capital expenditure. However, the technology demonstrates favorable economics through reduced material costs, decreased tooling requirements, and shortened production cycles.

Life cycle assessment (LCA) studies indicate that DED manufacturing can reduce the carbon footprint by up to 25% for certain aerospace and defense components when compared to traditional manufacturing routes. This reduction stems primarily from material savings, energy efficiency, and the ability to repair rather than replace components.

The repair and remanufacturing capabilities of DED technology present perhaps its most significant sustainability advantage. Components that would traditionally be scrapped can be restored to original specifications, extending product lifecycles and reducing the demand for new raw materials. Case studies from the aerospace sector demonstrate cost savings of 40-70% when using DED for repair versus component replacement.

Economic analysis shows that while DED typically has higher hourly operational costs than conventional manufacturing, the total cost of ownership often becomes favorable for complex geometries and specialized materials. The break-even point varies by application but generally occurs at lower production volumes for high-value components made from expensive materials like titanium alloys or nickel superalloys.

Future sustainability improvements are anticipated through process optimization, increased energy efficiency of laser sources, and the development of closed-loop material recycling systems. These advancements could further enhance the already favorable sustainability profile of DED technology in advanced manufacturing applications.

Energy efficiency analysis reveals that DED processes can reduce overall energy consumption by 15-30% compared to conventional subtractive manufacturing for complex components. This efficiency stems from the additive nature of the process, which eliminates energy-intensive material removal steps and reduces the need for multiple manufacturing operations. The localized energy application in DED further minimizes heat-affected zones and unnecessary material heating.

From a cost perspective, DED offers compelling advantages for medium to large-scale components. Initial investment costs for industrial DED systems range from $500,000 to $1.5 million, representing a significant capital expenditure. However, the technology demonstrates favorable economics through reduced material costs, decreased tooling requirements, and shortened production cycles.

Life cycle assessment (LCA) studies indicate that DED manufacturing can reduce the carbon footprint by up to 25% for certain aerospace and defense components when compared to traditional manufacturing routes. This reduction stems primarily from material savings, energy efficiency, and the ability to repair rather than replace components.

The repair and remanufacturing capabilities of DED technology present perhaps its most significant sustainability advantage. Components that would traditionally be scrapped can be restored to original specifications, extending product lifecycles and reducing the demand for new raw materials. Case studies from the aerospace sector demonstrate cost savings of 40-70% when using DED for repair versus component replacement.

Economic analysis shows that while DED typically has higher hourly operational costs than conventional manufacturing, the total cost of ownership often becomes favorable for complex geometries and specialized materials. The break-even point varies by application but generally occurs at lower production volumes for high-value components made from expensive materials like titanium alloys or nickel superalloys.

Future sustainability improvements are anticipated through process optimization, increased energy efficiency of laser sources, and the development of closed-loop material recycling systems. These advancements could further enhance the already favorable sustainability profile of DED technology in advanced manufacturing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!