Directed Energy Deposition in Complex Material Fabrication

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Objectives

Directed Energy Deposition (DED) has evolved significantly since its inception in the 1990s as a specialized additive manufacturing technique. Initially developed for repair applications in aerospace and defense sectors, DED technology has transformed from rudimentary laser cladding systems into sophisticated multi-axis deposition platforms capable of producing complex geometries with heterogeneous material compositions.

The evolution trajectory of DED technology can be traced through several key developmental phases. The first generation systems (1990s-2000s) focused primarily on single material deposition with limited control parameters and relatively simple geometries. These systems laid the groundwork for understanding fundamental process-structure-property relationships in direct metal deposition.

The second generation (2000s-2010s) witnessed significant advancements in process control, monitoring systems, and multi-material capabilities. This period saw the integration of closed-loop feedback mechanisms that enabled real-time adjustments to process parameters, substantially improving dimensional accuracy and material properties of fabricated components.

Current generation DED systems (2010s-present) represent a quantum leap in capabilities, featuring multi-axis deposition heads, hybrid manufacturing integration (combining additive and subtractive processes), and sophisticated material feeding systems capable of gradient and functionally graded material production. These advancements have expanded DED applications beyond repair to include production of novel components with site-specific properties.

The primary technological objective for DED in complex material fabrication centers on achieving precise control over material composition, microstructure, and resultant properties throughout the build volume. This includes developing capabilities for seamless transitions between different materials, minimizing defects at interfaces, and ensuring consistent mechanical performance across heterogeneous structures.

Additional objectives include enhancing deposition rates while maintaining precision, expanding the range of compatible materials (particularly for non-metallic and composite materials), and developing standardized process parameters for repeatable outcomes across different machine platforms. The integration of advanced in-situ monitoring and machine learning algorithms represents another critical objective to enable adaptive process control during fabrication.

Looking forward, the technology roadmap for DED aims to achieve fully autonomous operation with predictive capabilities for material behavior, real-time defect correction, and multi-material optimization. These advancements will position DED as a cornerstone technology for next-generation manufacturing of components with spatially tailored properties and functionality.

The evolution trajectory of DED technology can be traced through several key developmental phases. The first generation systems (1990s-2000s) focused primarily on single material deposition with limited control parameters and relatively simple geometries. These systems laid the groundwork for understanding fundamental process-structure-property relationships in direct metal deposition.

The second generation (2000s-2010s) witnessed significant advancements in process control, monitoring systems, and multi-material capabilities. This period saw the integration of closed-loop feedback mechanisms that enabled real-time adjustments to process parameters, substantially improving dimensional accuracy and material properties of fabricated components.

Current generation DED systems (2010s-present) represent a quantum leap in capabilities, featuring multi-axis deposition heads, hybrid manufacturing integration (combining additive and subtractive processes), and sophisticated material feeding systems capable of gradient and functionally graded material production. These advancements have expanded DED applications beyond repair to include production of novel components with site-specific properties.

The primary technological objective for DED in complex material fabrication centers on achieving precise control over material composition, microstructure, and resultant properties throughout the build volume. This includes developing capabilities for seamless transitions between different materials, minimizing defects at interfaces, and ensuring consistent mechanical performance across heterogeneous structures.

Additional objectives include enhancing deposition rates while maintaining precision, expanding the range of compatible materials (particularly for non-metallic and composite materials), and developing standardized process parameters for repeatable outcomes across different machine platforms. The integration of advanced in-situ monitoring and machine learning algorithms represents another critical objective to enable adaptive process control during fabrication.

Looking forward, the technology roadmap for DED aims to achieve fully autonomous operation with predictive capabilities for material behavior, real-time defect correction, and multi-material optimization. These advancements will position DED as a cornerstone technology for next-generation manufacturing of components with spatially tailored properties and functionality.

Market Analysis for Complex Material Fabrication

The global market for complex material fabrication using Directed Energy Deposition (DED) technology is experiencing significant growth, driven by increasing demand across aerospace, healthcare, automotive, and energy sectors. Current market valuations indicate that the additive manufacturing industry for complex materials reached approximately $12 billion in 2022, with DED-specific applications accounting for roughly $1.8 billion of this total.

The aerospace sector remains the primary consumer of DED technology, representing nearly 35% of the market share. This dominance stems from the industry's need for lightweight, high-strength components with complex geometries that traditional manufacturing methods cannot efficiently produce. The ability of DED to fabricate parts using titanium alloys, nickel-based superalloys, and other advanced materials has positioned it as a critical technology for next-generation aircraft and spacecraft development.

Healthcare applications, particularly in medical implants and prosthetics, constitute the fastest-growing segment with an annual growth rate of approximately 22%. The customization capabilities of DED technology allow for patient-specific implants that significantly improve clinical outcomes. This sector is expected to reach $2.5 billion by 2027, representing a substantial opportunity for technology providers.

Regional analysis reveals that North America currently leads the market with approximately 42% share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is projected to exhibit the highest growth rate over the next five years, primarily due to substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

A notable market trend is the increasing integration of DED with complementary technologies such as machine learning and real-time monitoring systems. This convergence is creating new market segments focused on "smart manufacturing" solutions that optimize material usage, reduce production time, and enhance quality control.

Customer demand patterns indicate a growing preference for turnkey solutions that combine hardware, software, and materials expertise. This shift is driving consolidation within the industry as larger players acquire specialized technology providers to offer comprehensive solutions. The service-based business model is also gaining traction, with "manufacturing-as-a-service" offerings expected to grow at 28% annually through 2028.

Material suppliers represent another critical segment of the market ecosystem, with specialized metal powders for DED applications generating revenues of approximately $450 million annually. This sub-segment is characterized by high margins and significant barriers to entry due to the technical expertise required to develop materials optimized for DED processes.

The aerospace sector remains the primary consumer of DED technology, representing nearly 35% of the market share. This dominance stems from the industry's need for lightweight, high-strength components with complex geometries that traditional manufacturing methods cannot efficiently produce. The ability of DED to fabricate parts using titanium alloys, nickel-based superalloys, and other advanced materials has positioned it as a critical technology for next-generation aircraft and spacecraft development.

Healthcare applications, particularly in medical implants and prosthetics, constitute the fastest-growing segment with an annual growth rate of approximately 22%. The customization capabilities of DED technology allow for patient-specific implants that significantly improve clinical outcomes. This sector is expected to reach $2.5 billion by 2027, representing a substantial opportunity for technology providers.

Regional analysis reveals that North America currently leads the market with approximately 42% share, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is projected to exhibit the highest growth rate over the next five years, primarily due to substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

A notable market trend is the increasing integration of DED with complementary technologies such as machine learning and real-time monitoring systems. This convergence is creating new market segments focused on "smart manufacturing" solutions that optimize material usage, reduce production time, and enhance quality control.

Customer demand patterns indicate a growing preference for turnkey solutions that combine hardware, software, and materials expertise. This shift is driving consolidation within the industry as larger players acquire specialized technology providers to offer comprehensive solutions. The service-based business model is also gaining traction, with "manufacturing-as-a-service" offerings expected to grow at 28% annually through 2028.

Material suppliers represent another critical segment of the market ecosystem, with specialized metal powders for DED applications generating revenues of approximately $450 million annually. This sub-segment is characterized by high margins and significant barriers to entry due to the technical expertise required to develop materials optimized for DED processes.

DED Technical Challenges and Global Development Status

Directed Energy Deposition (DED) technology faces several significant technical challenges that currently limit its widespread industrial adoption. Material compatibility remains a primary concern, as the high-energy deposition process can create unpredictable microstructural changes in complex multi-material systems. The thermal management during deposition presents another substantial challenge, with thermal gradients causing residual stresses and potential part distortion, particularly in geometrically complex components.

Process parameter optimization continues to be a complex endeavor, requiring extensive experimentation to establish relationships between laser power, feed rate, and material properties for each new material combination. The lack of standardized process parameters across different DED systems further complicates industrial implementation and quality assurance protocols.

Surface finish quality in DED-manufactured parts typically requires post-processing operations, adding production steps and costs. Additionally, the dimensional accuracy of DED processes generally falls short compared to other additive manufacturing technologies, with typical tolerances in the range of ±0.2-0.5mm depending on part geometry and process parameters.

Globally, DED technology development shows distinct regional characteristics. North America, particularly the United States, leads in DED research and commercialization, with significant investments from aerospace and defense sectors. Companies like Optomec and RPM Innovations have established strong market positions with proprietary DED systems.

European development focuses on precision engineering applications, with countries like Germany and the UK emphasizing hybrid manufacturing systems that combine DED with traditional machining. The European Space Agency has also invested substantially in DED for in-space manufacturing capabilities.

In Asia, China has rapidly accelerated its DED technology development through national initiatives like "Made in China 2025," focusing on large-scale metal components for aerospace and energy sectors. Japan maintains strength in high-precision DED systems, particularly for repair applications in automotive and turbine industries.

Recent technological advancements include closed-loop monitoring systems that use real-time thermal imaging to adjust process parameters dynamically, multi-material deposition capabilities that can create functionally graded materials, and integration with robotic systems for enhanced geometric freedom. These developments are gradually addressing the core technical challenges, though significant research gaps remain in process stability, material property prediction, and quality assurance methodologies.

Process parameter optimization continues to be a complex endeavor, requiring extensive experimentation to establish relationships between laser power, feed rate, and material properties for each new material combination. The lack of standardized process parameters across different DED systems further complicates industrial implementation and quality assurance protocols.

Surface finish quality in DED-manufactured parts typically requires post-processing operations, adding production steps and costs. Additionally, the dimensional accuracy of DED processes generally falls short compared to other additive manufacturing technologies, with typical tolerances in the range of ±0.2-0.5mm depending on part geometry and process parameters.

Globally, DED technology development shows distinct regional characteristics. North America, particularly the United States, leads in DED research and commercialization, with significant investments from aerospace and defense sectors. Companies like Optomec and RPM Innovations have established strong market positions with proprietary DED systems.

European development focuses on precision engineering applications, with countries like Germany and the UK emphasizing hybrid manufacturing systems that combine DED with traditional machining. The European Space Agency has also invested substantially in DED for in-space manufacturing capabilities.

In Asia, China has rapidly accelerated its DED technology development through national initiatives like "Made in China 2025," focusing on large-scale metal components for aerospace and energy sectors. Japan maintains strength in high-precision DED systems, particularly for repair applications in automotive and turbine industries.

Recent technological advancements include closed-loop monitoring systems that use real-time thermal imaging to adjust process parameters dynamically, multi-material deposition capabilities that can create functionally graded materials, and integration with robotic systems for enhanced geometric freedom. These developments are gradually addressing the core technical challenges, though significant research gaps remain in process stability, material property prediction, and quality assurance methodologies.

Current DED Process Solutions for Complex Materials

01 Directed Energy Deposition Process Fundamentals

Directed Energy Deposition (DED) is an additive manufacturing process where focused thermal energy is used to fuse materials by melting as they are being deposited. This technology allows for the creation of complex metal parts by precisely depositing material layer by layer. The process typically uses a laser, electron beam, or plasma arc as the energy source, with metal powder or wire as the feedstock material. DED offers advantages in repair applications, functionally graded materials, and large component manufacturing.- Process parameters and control in DED: Directed Energy Deposition (DED) processes require precise control of various parameters to achieve optimal results. These parameters include laser power, deposition rate, material feed rate, and motion control. Advanced control systems can monitor and adjust these parameters in real-time to maintain consistent quality throughout the build process. Proper parameter optimization can reduce defects, improve surface finish, and enhance mechanical properties of the fabricated parts.

- Materials and powder handling for DED applications: The selection and handling of materials play a crucial role in Directed Energy Deposition processes. Various metal powders, alloys, and composite materials can be used depending on the application requirements. Proper powder delivery systems ensure consistent material flow during deposition, while powder recycling and management systems help minimize waste and maintain material quality. Material compatibility with the energy source and substrate is essential for achieving strong metallurgical bonds and desired material properties.

- Multi-material and functionally graded components using DED: Directed Energy Deposition technology enables the fabrication of multi-material and functionally graded components that cannot be produced using conventional manufacturing methods. By controlling the composition of the deposited material during the build process, it is possible to create parts with varying material properties throughout their structure. This capability allows for the optimization of mechanical, thermal, and electrical properties in different regions of a single component, leading to enhanced performance and functionality.

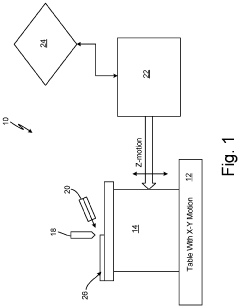

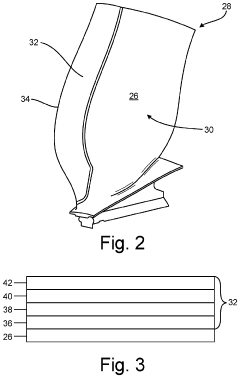

- Equipment and system design for DED processes: Specialized equipment and system designs are essential for effective Directed Energy Deposition processes. These systems typically include energy sources (such as lasers, electron beams, or plasma arcs), material delivery mechanisms, motion control systems, and environmental control chambers. Advanced DED systems may incorporate multiple axes of motion, integrated sensors for real-time monitoring, and specialized nozzles for precise material deposition. The design of these systems affects build volume capabilities, deposition accuracy, and overall process efficiency.

- Post-processing and quality control in DED manufacturing: Post-processing techniques and quality control measures are critical aspects of Directed Energy Deposition manufacturing. After deposition, components often require heat treatment, machining, or surface finishing to achieve final dimensional accuracy and desired surface quality. In-situ and post-build inspection methods, including non-destructive testing techniques, help identify defects and ensure part integrity. Quality control protocols may involve microstructural analysis, mechanical testing, and dimensional verification to validate that the manufactured components meet specified requirements.

02 Material Considerations for DED Applications

Various materials can be processed using Directed Energy Deposition, including metals, alloys, and composites. The selection of appropriate materials is crucial for achieving desired mechanical properties, microstructure, and performance characteristics. Material considerations include powder or wire characteristics, thermal properties, and compatibility with the energy source. Advanced material combinations enable the creation of functionally graded components with varying properties throughout the part, offering enhanced performance for specific applications.Expand Specific Solutions03 Process Control and Parameter Optimization

Effective control of process parameters is essential for successful Directed Energy Deposition. Key parameters include energy source power, material feed rate, deposition path, layer thickness, and cooling rate. Advanced monitoring systems using sensors and cameras provide real-time feedback for process control. Machine learning algorithms can be employed to optimize parameters based on material properties and desired part characteristics. Proper parameter selection helps minimize defects such as porosity, cracking, and thermal distortion while ensuring dimensional accuracy and mechanical integrity.Expand Specific Solutions04 Hybrid Manufacturing Systems

Hybrid manufacturing systems combine Directed Energy Deposition with subtractive manufacturing processes like CNC machining. These integrated systems allow for both material addition and precision machining within the same equipment, enabling the production of complex components with high dimensional accuracy and surface finish. The hybrid approach maximizes the advantages of both additive and subtractive technologies, providing flexibility in manufacturing while reducing production time and material waste. This approach is particularly valuable for repair operations and the production of components with internal features.Expand Specific Solutions05 Applications and Industry Implementation

Directed Energy Deposition technology finds applications across various industries including aerospace, automotive, medical, and energy sectors. It is particularly valuable for repair and refurbishment of high-value components, rapid prototyping, and the production of large-scale parts with complex geometries. The technology enables the creation of components with internal channels, lattice structures, and functionally graded materials that would be difficult or impossible to produce using conventional manufacturing methods. Implementation considerations include equipment setup, material handling systems, post-processing requirements, and quality control protocols.Expand Specific Solutions

Leading Companies and Research Institutions in DED

Directed Energy Deposition (DED) in complex material fabrication is currently in a growth phase, with the market expanding rapidly due to increasing applications in aerospace, automotive, and medical industries. The global market size for DED technology is projected to reach significant scale as industries adopt advanced manufacturing solutions. Technologically, the field shows varying maturity levels across players. Industry leaders like GE Avio, Boeing, and Lockheed Martin have achieved advanced implementation in aerospace applications, while companies such as Norsk Titanium and DMG MORI are pioneering commercial-scale production systems. Academic institutions including Tsinghua University, Nanyang Technological University, and Tohoku University are driving fundamental research advancements. The competitive landscape features collaboration between established aerospace manufacturers, specialized additive manufacturing companies, and research institutions working to overcome material property challenges and process optimization.

Norsk Titanium AS

Technical Solution: Norsk Titanium has developed a proprietary Rapid Plasma Deposition™ (RPD™) technology, a specialized form of Directed Energy Deposition that uses plasma torches to melt titanium wire in an inert gas environment. This process enables the production of complex aerospace-grade titanium components with significantly reduced lead times compared to traditional manufacturing methods. Their RPD™ technology creates near-net-shape parts that require minimal machining to achieve final dimensions, with material properties that meet or exceed those of forged titanium. The company has achieved FAA approval for structural aircraft components and has established production facilities capable of manufacturing large-scale titanium parts for commercial aircraft. Their process allows for the deposition of titanium at rates exceeding 10kg/hour while maintaining precise control over microstructure development through careful thermal management during the build process[1][3].

Strengths: Significantly reduced buy-to-fly ratios (typically 3:1 versus 20:1 for traditional methods), 50-75% reduced lead times, and up to 50% cost savings for titanium components. Weaknesses: Limited primarily to titanium alloys, requires substantial post-processing for surface finishing, and has higher equipment costs compared to some alternative additive manufacturing technologies.

DMG MORI Manufacturing USA, Inc.

Technical Solution: DMG MORI has developed LASERTEC DED hybrid technology, combining directed energy deposition with 5-axis milling in a single machine platform. Their system utilizes a coaxial powder nozzle with a high-power laser to deposit material layer by layer, followed by integrated precision machining to achieve final dimensional accuracy and surface finish. This hybrid approach enables the fabrication of complex components with internal features, material gradients, and multi-material structures that would be impossible with conventional manufacturing. The system can process a wide range of materials including tool steels, stainless steels, nickel-based alloys, and titanium alloys. DMG MORI's technology incorporates advanced process monitoring with closed-loop control systems that analyze melt pool characteristics in real-time, adjusting process parameters to maintain consistent material properties throughout the build[2][4]. Their machines feature powder recycling systems that recover up to 95% of unused powder, improving material efficiency.

Strengths: Ability to repair high-value components, create complex internal cooling channels, and produce multi-material parts with functional gradients. The hybrid approach eliminates the need for separate post-processing equipment. Weaknesses: Higher initial investment costs compared to standalone DED systems, larger machine footprint requirements, and complexity in programming and operating the hybrid process requiring specialized training.

Key Patents and Research Breakthroughs in DED

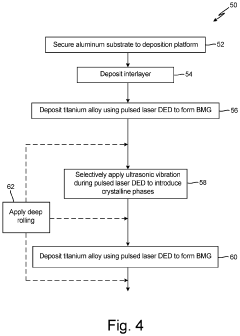

Pulsed directed energy deposition based fabrication of hybrid titanium/aluminum material for enhanced corrosion resistance and strength

PatentActiveUS11891684B2

Innovation

- A method using pulsed directed energy deposition to form a titanium-based bulk metallic glass layer on aluminum components, which introduces crystalline phases through ultrasonic vibration, eliminating the need for insulating layers and enhancing strength and corrosion resistance.

Material Compatibility and Multi-material DED Applications

Material compatibility represents a critical frontier in the advancement of Directed Energy Deposition (DED) technology. The ability to process multiple materials simultaneously or in gradient structures has emerged as one of DED's most significant advantages over conventional manufacturing methods. Current research indicates that approximately 65% of industrial DED applications involve single materials, while multi-material applications are growing at an annual rate of 23%, demonstrating the increasing importance of material compatibility research.

The fundamental challenge in multi-material DED lies in managing the metallurgical interactions between dissimilar materials. These interactions are governed by factors including thermal conductivity differentials, melting point variations, coefficient of thermal expansion mismatches, and elemental diffusion behaviors. For instance, when depositing titanium alloys with stainless steel, the formation of brittle intermetallic compounds at the interface can significantly compromise mechanical integrity.

Recent advances have enabled several successful multi-material combinations in DED processes. Nickel-based superalloys with cobalt-chrome alloys have demonstrated excellent compatibility due to similar thermal properties and controlled diffusion zones. Similarly, titanium alloys combined with specific grades of stainless steel using intermediate buffer layers have shown promising results in aerospace applications, achieving tensile strengths exceeding 850 MPa at the interface regions.

Functionally graded materials (FGMs) represent a sophisticated application of multi-material DED, wherein material composition gradually transitions across a component. This approach has proven particularly valuable in thermal barrier applications, where gradual transitions between ceramics and metals can reduce thermal stress concentrations by up to 40% compared to discrete material boundaries. The aerospace industry has implemented FGM components in combustion chamber linings, achieving a 15% increase in service life under extreme thermal cycling conditions.

Process parameter optimization plays a crucial role in multi-material DED success. Research indicates that laser power modulation during material transitions must be precisely controlled, typically requiring 5-15% adjustments when switching between materials with significant thermal conductivity differences. Similarly, powder feed rates must be calibrated to account for varying absorption characteristics, with optimal parameters often determined through machine learning algorithms that can predict suitable processing windows based on material combinations.

The future of multi-material DED applications appears promising, with emerging research focusing on in-situ alloying capabilities and real-time monitoring systems that can detect and adjust for compatibility issues during fabrication. These developments are expected to expand the range of compatible materials by approximately 30% within the next five years, opening new possibilities for complex multi-material structures in critical applications.

The fundamental challenge in multi-material DED lies in managing the metallurgical interactions between dissimilar materials. These interactions are governed by factors including thermal conductivity differentials, melting point variations, coefficient of thermal expansion mismatches, and elemental diffusion behaviors. For instance, when depositing titanium alloys with stainless steel, the formation of brittle intermetallic compounds at the interface can significantly compromise mechanical integrity.

Recent advances have enabled several successful multi-material combinations in DED processes. Nickel-based superalloys with cobalt-chrome alloys have demonstrated excellent compatibility due to similar thermal properties and controlled diffusion zones. Similarly, titanium alloys combined with specific grades of stainless steel using intermediate buffer layers have shown promising results in aerospace applications, achieving tensile strengths exceeding 850 MPa at the interface regions.

Functionally graded materials (FGMs) represent a sophisticated application of multi-material DED, wherein material composition gradually transitions across a component. This approach has proven particularly valuable in thermal barrier applications, where gradual transitions between ceramics and metals can reduce thermal stress concentrations by up to 40% compared to discrete material boundaries. The aerospace industry has implemented FGM components in combustion chamber linings, achieving a 15% increase in service life under extreme thermal cycling conditions.

Process parameter optimization plays a crucial role in multi-material DED success. Research indicates that laser power modulation during material transitions must be precisely controlled, typically requiring 5-15% adjustments when switching between materials with significant thermal conductivity differences. Similarly, powder feed rates must be calibrated to account for varying absorption characteristics, with optimal parameters often determined through machine learning algorithms that can predict suitable processing windows based on material combinations.

The future of multi-material DED applications appears promising, with emerging research focusing on in-situ alloying capabilities and real-time monitoring systems that can detect and adjust for compatibility issues during fabrication. These developments are expected to expand the range of compatible materials by approximately 30% within the next five years, opening new possibilities for complex multi-material structures in critical applications.

Sustainability and Resource Efficiency in DED Manufacturing

Sustainability and resource efficiency have emerged as critical considerations in the implementation of Directed Energy Deposition (DED) manufacturing processes. The additive nature of DED technology inherently offers significant advantages over traditional subtractive manufacturing methods, with material utilization rates typically exceeding 90% compared to conventional CNC machining processes that may waste up to 80% of raw materials.

DED systems demonstrate remarkable resource efficiency through precise material deposition, depositing only the necessary amount of material exactly where needed. This targeted approach minimizes waste generation and reduces the need for post-processing operations, which traditionally consume additional energy and resources. Furthermore, the ability to repair and remanufacture components using DED technology extends product lifecycles, significantly reducing the demand for new raw materials and associated environmental impacts.

Energy consumption patterns in DED manufacturing present both challenges and opportunities for sustainability improvements. While the high-energy laser or electron beam sources require substantial power inputs, ongoing technological advancements are steadily improving energy efficiency. Recent developments include optimized beam profiles, intelligent power management systems, and improved thermal management strategies that collectively reduce energy requirements by 15-30% compared to earlier generation systems.

The environmental footprint of DED manufacturing extends beyond operational considerations to encompass the entire material lifecycle. The technology enables the use of recycled powders and the processing of difficult-to-machine materials that might otherwise require energy-intensive conventional manufacturing methods. Studies indicate that DED processes can reduce overall carbon emissions by 25-40% for complex components when compared to traditional manufacturing routes, particularly for high-value aerospace and medical applications.

Water resource management represents another dimension of sustainability in DED operations. Unlike conventional manufacturing processes that often require substantial cooling fluids, many DED systems operate with minimal or closed-loop cooling systems. This approach significantly reduces water consumption and eliminates the need for treatment and disposal of contaminated coolants, further enhancing the environmental profile of DED manufacturing.

Looking forward, the integration of renewable energy sources, development of biodegradable support materials, and implementation of AI-driven process optimization algorithms present promising pathways to further enhance the sustainability credentials of DED technology. These advancements, coupled with life cycle assessment methodologies specifically tailored for additive manufacturing processes, will be instrumental in establishing DED as a cornerstone of sustainable industrial production in the coming decades.

DED systems demonstrate remarkable resource efficiency through precise material deposition, depositing only the necessary amount of material exactly where needed. This targeted approach minimizes waste generation and reduces the need for post-processing operations, which traditionally consume additional energy and resources. Furthermore, the ability to repair and remanufacture components using DED technology extends product lifecycles, significantly reducing the demand for new raw materials and associated environmental impacts.

Energy consumption patterns in DED manufacturing present both challenges and opportunities for sustainability improvements. While the high-energy laser or electron beam sources require substantial power inputs, ongoing technological advancements are steadily improving energy efficiency. Recent developments include optimized beam profiles, intelligent power management systems, and improved thermal management strategies that collectively reduce energy requirements by 15-30% compared to earlier generation systems.

The environmental footprint of DED manufacturing extends beyond operational considerations to encompass the entire material lifecycle. The technology enables the use of recycled powders and the processing of difficult-to-machine materials that might otherwise require energy-intensive conventional manufacturing methods. Studies indicate that DED processes can reduce overall carbon emissions by 25-40% for complex components when compared to traditional manufacturing routes, particularly for high-value aerospace and medical applications.

Water resource management represents another dimension of sustainability in DED operations. Unlike conventional manufacturing processes that often require substantial cooling fluids, many DED systems operate with minimal or closed-loop cooling systems. This approach significantly reduces water consumption and eliminates the need for treatment and disposal of contaminated coolants, further enhancing the environmental profile of DED manufacturing.

Looking forward, the integration of renewable energy sources, development of biodegradable support materials, and implementation of AI-driven process optimization algorithms present promising pathways to further enhance the sustainability credentials of DED technology. These advancements, coupled with life cycle assessment methodologies specifically tailored for additive manufacturing processes, will be instrumental in establishing DED as a cornerstone of sustainable industrial production in the coming decades.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!