Directed Energy Deposition: Recent Advances in Methodology

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Objectives

Directed Energy Deposition (DED) has evolved significantly since its inception in the 1990s as a specialized additive manufacturing technique. Initially developed for repair applications in aerospace and defense sectors, DED technology has undergone substantial transformation through several distinct evolutionary phases. The early systems focused primarily on powder-fed approaches with limited material options and relatively poor dimensional accuracy, constraining their industrial adoption.

The mid-2000s marked a pivotal shift with the introduction of multi-axis deposition capabilities, expanding DED's application potential beyond simple repairs to complex component manufacturing. This period saw the integration of closed-loop monitoring systems that significantly improved process stability and repeatability, addressing key limitations of earlier generations.

From 2010 to 2015, DED technology experienced accelerated development with the introduction of hybrid manufacturing systems that combined additive and subtractive processes. These innovations enabled in-situ machining during builds, dramatically improving surface finish and dimensional accuracy. Concurrently, material options expanded from primarily metal alloys to include ceramics, composites, and functionally graded materials.

Recent advances from 2016 onward have focused on methodology refinements, particularly in process parameter optimization and real-time adaptive control systems. Machine learning algorithms now enable dynamic adjustment of deposition parameters based on thermal history and material properties, resulting in superior microstructural control and mechanical performance. The integration of advanced sensing technologies, including thermal imaging and spectroscopic analysis, has enabled unprecedented process monitoring capabilities.

The current technological objectives for DED methodology advancement center on several key areas. First is the development of multi-material deposition strategies that can create functionally graded components with seamless transitions between different materials. Second is the refinement of in-situ alloying techniques that can produce novel material compositions directly during the build process. Third is the enhancement of deposition rates while maintaining or improving part quality, addressing the persistent challenge of production speed.

Looking forward, the trajectory of DED technology is moving toward fully autonomous systems with predictive modeling capabilities that can anticipate and compensate for process variations before they occur. The integration with digital twin technology represents another frontier, enabling virtual process optimization before physical production. These advancements collectively aim to position DED as a mainstream manufacturing technology capable of addressing increasingly complex industrial challenges across aerospace, medical, energy, and automotive sectors.

The mid-2000s marked a pivotal shift with the introduction of multi-axis deposition capabilities, expanding DED's application potential beyond simple repairs to complex component manufacturing. This period saw the integration of closed-loop monitoring systems that significantly improved process stability and repeatability, addressing key limitations of earlier generations.

From 2010 to 2015, DED technology experienced accelerated development with the introduction of hybrid manufacturing systems that combined additive and subtractive processes. These innovations enabled in-situ machining during builds, dramatically improving surface finish and dimensional accuracy. Concurrently, material options expanded from primarily metal alloys to include ceramics, composites, and functionally graded materials.

Recent advances from 2016 onward have focused on methodology refinements, particularly in process parameter optimization and real-time adaptive control systems. Machine learning algorithms now enable dynamic adjustment of deposition parameters based on thermal history and material properties, resulting in superior microstructural control and mechanical performance. The integration of advanced sensing technologies, including thermal imaging and spectroscopic analysis, has enabled unprecedented process monitoring capabilities.

The current technological objectives for DED methodology advancement center on several key areas. First is the development of multi-material deposition strategies that can create functionally graded components with seamless transitions between different materials. Second is the refinement of in-situ alloying techniques that can produce novel material compositions directly during the build process. Third is the enhancement of deposition rates while maintaining or improving part quality, addressing the persistent challenge of production speed.

Looking forward, the trajectory of DED technology is moving toward fully autonomous systems with predictive modeling capabilities that can anticipate and compensate for process variations before they occur. The integration with digital twin technology represents another frontier, enabling virtual process optimization before physical production. These advancements collectively aim to position DED as a mainstream manufacturing technology capable of addressing increasingly complex industrial challenges across aerospace, medical, energy, and automotive sectors.

Market Applications and Growth Potential

The Directed Energy Deposition (DED) market is experiencing significant growth across multiple industrial sectors, driven by its unique capabilities in additive manufacturing. The global DED market, valued at approximately $500 million in 2022, is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 15.8%. This growth trajectory is supported by increasing adoption in aerospace, defense, medical, and automotive industries.

In the aerospace sector, DED technology has gained substantial traction for manufacturing complex components such as turbine blades, structural elements, and repair of high-value parts. Major aerospace manufacturers have reported 30-40% reduction in material waste and 25% decrease in production time for certain components when utilizing DED processes compared to traditional manufacturing methods.

The medical industry represents another rapidly expanding application area, particularly for customized implants and prosthetics. The ability of DED to work with biocompatible materials such as titanium alloys has positioned it as a preferred manufacturing method for patient-specific medical devices. Market analysis indicates that the medical segment of DED applications is growing at 18% annually, outpacing the overall market growth rate.

Automotive manufacturers are increasingly incorporating DED technology into their production processes, especially for prototyping and small-batch production of specialized components. The technology's flexibility in material usage and design complexity has enabled automotive companies to reduce development cycles by up to 40% for certain components.

Energy sector applications are emerging as a significant growth area, with DED being utilized for manufacturing and repairing components in power generation equipment. The ability to deposit multiple materials in a single build process makes DED particularly valuable for creating functionally graded materials used in harsh operating environments.

Regional market analysis reveals that North America currently holds the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by substantial investments in advanced manufacturing technologies in China, Japan, and South Korea.

The market potential for DED technology is further enhanced by ongoing research into expanding the range of compatible materials and improving process control systems. Industry experts predict that as these advancements continue to mature, DED will increasingly displace traditional manufacturing methods in high-value, complex component production across multiple industries.

In the aerospace sector, DED technology has gained substantial traction for manufacturing complex components such as turbine blades, structural elements, and repair of high-value parts. Major aerospace manufacturers have reported 30-40% reduction in material waste and 25% decrease in production time for certain components when utilizing DED processes compared to traditional manufacturing methods.

The medical industry represents another rapidly expanding application area, particularly for customized implants and prosthetics. The ability of DED to work with biocompatible materials such as titanium alloys has positioned it as a preferred manufacturing method for patient-specific medical devices. Market analysis indicates that the medical segment of DED applications is growing at 18% annually, outpacing the overall market growth rate.

Automotive manufacturers are increasingly incorporating DED technology into their production processes, especially for prototyping and small-batch production of specialized components. The technology's flexibility in material usage and design complexity has enabled automotive companies to reduce development cycles by up to 40% for certain components.

Energy sector applications are emerging as a significant growth area, with DED being utilized for manufacturing and repairing components in power generation equipment. The ability to deposit multiple materials in a single build process makes DED particularly valuable for creating functionally graded materials used in harsh operating environments.

Regional market analysis reveals that North America currently holds the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by substantial investments in advanced manufacturing technologies in China, Japan, and South Korea.

The market potential for DED technology is further enhanced by ongoing research into expanding the range of compatible materials and improving process control systems. Industry experts predict that as these advancements continue to mature, DED will increasingly displace traditional manufacturing methods in high-value, complex component production across multiple industries.

Global DED Development Status and Barriers

Directed Energy Deposition (DED) technology has witnessed significant global advancement in recent years, with varying levels of development across different regions. North America, particularly the United States, leads in DED innovation with substantial investments from both government agencies and private sectors. The U.S. Department of Defense and NASA have been instrumental in pushing the boundaries of DED applications for aerospace and defense components, while companies like GE Additive and Optomec have commercialized advanced DED systems.

Europe follows closely with strong research clusters in Germany, the UK, and France. The European Commission has funded numerous collaborative projects through Horizon 2020 and Horizon Europe programs, focusing on DED process optimization and material development. Countries like Switzerland and Sweden have established specialized research centers dedicated to metal additive manufacturing technologies including DED.

In Asia, China has rapidly accelerated its DED capabilities through its "Made in China 2025" initiative, with significant investments in both research institutions and manufacturing facilities. Japan and South Korea focus on high-precision DED applications for automotive and electronics industries, leveraging their existing manufacturing expertise.

Despite this global progress, DED technology faces several critical barriers to widespread adoption. Material limitations remain a significant challenge, as not all metal alloys are suitable for DED processes. High-temperature superalloys and reactive metals like titanium require specialized handling and processing parameters, limiting material selection flexibility.

Process stability and repeatability continue to challenge manufacturers, with variations in thermal conditions, powder feed rates, and laser parameters affecting final part quality. The lack of standardized qualification procedures and in-process monitoring systems further complicates quality assurance efforts.

Economic barriers also persist, with high equipment costs and operational expenses limiting adoption among small and medium enterprises. The initial investment for industrial-grade DED systems typically ranges from $500,000 to over $1.5 million, creating a significant entry barrier for many potential users.

Technical workforce limitations present another obstacle, as DED technology requires specialized knowledge in materials science, laser physics, and advanced manufacturing principles. The shortage of qualified technicians and engineers with DED expertise has slowed implementation in many regions.

Regulatory frameworks and certification standards for DED-manufactured parts remain underdeveloped in many industries, particularly in critical applications like aerospace and medical devices. This regulatory uncertainty creates hesitation among potential adopters who require clear certification pathways for their products.

Europe follows closely with strong research clusters in Germany, the UK, and France. The European Commission has funded numerous collaborative projects through Horizon 2020 and Horizon Europe programs, focusing on DED process optimization and material development. Countries like Switzerland and Sweden have established specialized research centers dedicated to metal additive manufacturing technologies including DED.

In Asia, China has rapidly accelerated its DED capabilities through its "Made in China 2025" initiative, with significant investments in both research institutions and manufacturing facilities. Japan and South Korea focus on high-precision DED applications for automotive and electronics industries, leveraging their existing manufacturing expertise.

Despite this global progress, DED technology faces several critical barriers to widespread adoption. Material limitations remain a significant challenge, as not all metal alloys are suitable for DED processes. High-temperature superalloys and reactive metals like titanium require specialized handling and processing parameters, limiting material selection flexibility.

Process stability and repeatability continue to challenge manufacturers, with variations in thermal conditions, powder feed rates, and laser parameters affecting final part quality. The lack of standardized qualification procedures and in-process monitoring systems further complicates quality assurance efforts.

Economic barriers also persist, with high equipment costs and operational expenses limiting adoption among small and medium enterprises. The initial investment for industrial-grade DED systems typically ranges from $500,000 to over $1.5 million, creating a significant entry barrier for many potential users.

Technical workforce limitations present another obstacle, as DED technology requires specialized knowledge in materials science, laser physics, and advanced manufacturing principles. The shortage of qualified technicians and engineers with DED expertise has slowed implementation in many regions.

Regulatory frameworks and certification standards for DED-manufactured parts remain underdeveloped in many industries, particularly in critical applications like aerospace and medical devices. This regulatory uncertainty creates hesitation among potential adopters who require clear certification pathways for their products.

Current DED Process Solutions and Parameters

01 Laser-based directed energy deposition techniques

Laser-based directed energy deposition involves using laser energy to melt metallic powders or wire feedstock as they are being deposited. This technique allows for precise control of the energy input and deposition rate, resulting in high-quality builds with minimal distortion. The process can be optimized by controlling laser power, scan speed, and powder feed rate to achieve desired microstructural properties and mechanical performance in the final component.- Laser-based Directed Energy Deposition processes: Laser-based Directed Energy Deposition (DED) involves using high-powered lasers to melt metallic powders or wire feedstock as they are being deposited layer by layer. This methodology enables precise control over the microstructure and properties of the fabricated components. The process parameters such as laser power, scanning speed, and powder feed rate significantly influence the quality of the final product. This approach is particularly effective for producing complex geometries and functionally graded materials.

- Wire-feed Directed Energy Deposition techniques: Wire-feed Directed Energy Deposition utilizes metal wire as the feedstock material instead of powder. The wire is fed into a melt pool created by an energy source such as an electron beam or laser. This methodology offers advantages including higher material efficiency, reduced oxidation, and faster deposition rates compared to powder-based systems. Wire-feed DED is particularly suitable for large-scale components and repair applications where high deposition rates are required.

- Multi-material and functionally graded Directed Energy Deposition: This methodology focuses on the deposition of multiple materials within a single build process to create components with functionally graded properties. By controlling the composition and deposition parameters, it's possible to fabricate parts with tailored mechanical, thermal, or electrical properties that vary throughout the component. This approach enables the production of components with optimized performance characteristics for specific applications, such as heat-resistant parts with graded thermal expansion properties.

- Process monitoring and control systems for Directed Energy Deposition: Advanced monitoring and control systems are integrated into Directed Energy Deposition processes to ensure consistent quality and properties of fabricated components. These systems utilize sensors, cameras, and real-time data analysis to monitor parameters such as melt pool temperature, dimensions, and cooling rates. Closed-loop control algorithms adjust process parameters dynamically to maintain optimal conditions throughout the build. This methodology significantly improves reproducibility and enables defect detection and correction during the manufacturing process.

- Hybrid manufacturing approaches combining Directed Energy Deposition: Hybrid manufacturing methodologies combine Directed Energy Deposition with other manufacturing processes such as machining, heat treatment, or surface finishing within a single platform. This integrated approach allows for the fabrication of complex components with high dimensional accuracy and surface quality. By alternating between additive and subtractive processes, manufacturers can leverage the advantages of both technologies while minimizing their limitations. These hybrid systems are particularly valuable for repair applications and the production of components with internal features.

02 Multi-material and functionally graded deposition methods

Advanced directed energy deposition methodologies enable the fabrication of components with varying material compositions throughout the structure. By controlling the feed rate of different powders or wires during the deposition process, functionally graded materials can be created with tailored properties in specific regions. This approach allows for optimization of mechanical, thermal, or electrical properties within a single component, enhancing performance while reducing weight and material costs.Expand Specific Solutions03 Process monitoring and control systems

Advanced monitoring and control systems are essential for ensuring quality and repeatability in directed energy deposition processes. These systems utilize real-time sensors to monitor melt pool characteristics, deposition height, temperature distribution, and other critical parameters. Machine learning algorithms can analyze this data to make real-time adjustments to process parameters, enabling closed-loop control that improves build quality and reduces defects. This methodology significantly enhances the reliability and consistency of the fabricated components.Expand Specific Solutions04 Hybrid manufacturing approaches

Hybrid manufacturing methodologies combine directed energy deposition with subtractive manufacturing processes in a single machine. This approach allows for deposition of material followed by precision machining operations without requiring part transfer between different equipment. The integration enables the production of complex geometries with high dimensional accuracy and surface finish that would be difficult to achieve with either process alone. This methodology is particularly valuable for repair applications and the production of components with internal features.Expand Specific Solutions05 Post-processing treatments for DED components

Post-processing methodologies are crucial for optimizing the properties of components produced via directed energy deposition. These treatments include heat treatment to relieve residual stresses and homogenize microstructure, hot isostatic pressing to eliminate porosity, and surface treatments to improve fatigue resistance. The selection of appropriate post-processing methods depends on the specific material, component geometry, and intended application. Properly executed post-processing can significantly enhance mechanical properties and extend the service life of DED-manufactured parts.Expand Specific Solutions

Leading DED Technology Companies and Research Institutions

Directed Energy Deposition (DED) technology is currently in a growth phase, with the market expanding due to increasing applications in aerospace, automotive, and energy sectors. The global DED market is projected to reach significant scale as industries adopt advanced manufacturing techniques. Technologically, DED is maturing rapidly with key players driving innovation: GE Avio and Rolls-Royce are advancing aerospace applications; Stratasys and AddUp are developing commercial systems; while academic institutions like MIT, Nanjing University of Science & Technology, and Huazhong University of Science & Technology are pioneering methodological improvements. Research collaborations between industry leaders like IBM and educational institutions are accelerating technological refinement, particularly in material compatibility and process control, positioning DED as a transformative manufacturing technology with substantial growth potential.

GE Avio Srl

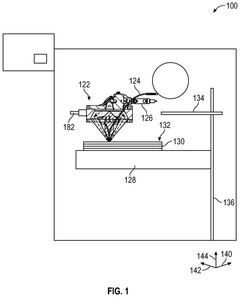

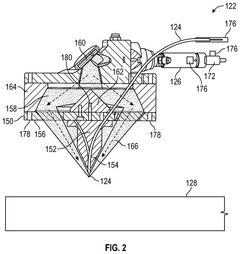

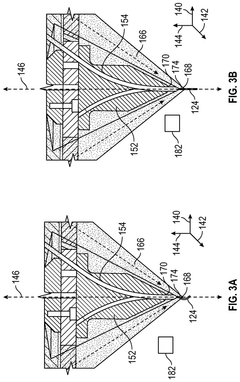

Technical Solution: GE Avio has developed a sophisticated DED methodology specifically tailored for aerospace components, focusing on high-temperature alloys and complex geometries. Their approach utilizes a combination of high-power fiber lasers (up to 10kW) and precision powder delivery systems to achieve deposition rates exceeding 2kg/hour while maintaining critical material properties[1]. The company has implemented advanced process monitoring using multiple sensors including thermal cameras, pyrometers, and spectrometers that provide real-time data on melt pool characteristics and material consolidation. GE Avio's methodology incorporates adaptive control algorithms that automatically adjust process parameters based on feedback from these monitoring systems, ensuring consistent microstructure throughout large components[3]. Their DED systems feature specialized atmospheric control chambers that maintain oxygen levels below 10ppm, critical for processing reactive materials like titanium alloys. Recent advances include the development of multi-material deposition capabilities that can create functionally graded components with tailored mechanical properties for specific aerospace applications[6].

Strengths: Exceptional capability with high-temperature aerospace alloys; advanced multi-sensor monitoring systems providing comprehensive process data; proven track record with flight-critical components. Weaknesses: Systems are highly specialized for aerospace applications with limited flexibility for other industries; significant expertise required for process parameter development; high capital and operating costs.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed a proprietary DED methodology focused on large-scale components for aerospace and power generation applications. Their approach utilizes high-power lasers (6-15kW) combined with precision wire-feed systems rather than powder-based delivery, achieving deposition rates of 3-5 kg/hour while maintaining tight dimensional control[2]. This wire-based DED technology offers material efficiency exceeding 98%, significantly reducing waste compared to traditional manufacturing methods. Rolls-Royce has implemented sophisticated thermal management strategies including active cooling systems and precise heat input control to minimize residual stresses in large components. Their methodology incorporates advanced path planning algorithms that optimize deposition strategies based on component geometry and material properties[4]. Recent innovations include the development of hybrid manufacturing cells that combine DED with in-process machining and inspection, enabling the production of near-net-shape components with critical features machined to final dimensions. Rolls-Royce has also pioneered the use of DED for repair applications, developing specialized methodologies for restoring high-value components like turbine blades and combustion chambers[8].

Strengths: Exceptional capability for large-scale components; superior material efficiency through wire-based deposition; integrated repair methodologies for high-value components. Weaknesses: Limited material flexibility compared to powder-based systems; higher initial capital investment; process development requires significant metallurgical expertise.

Critical Patents and Research in DED Methodology

Wire oscillation for directed energy deposition

PatentPendingUS20250100077A1

Innovation

- A wire feed head with an integrated oscillator that oscillates either the feed wire or the energy source relative to each other, improving the average positional accuracy and power absorption by maintaining consistent wire exposure to the energy source.

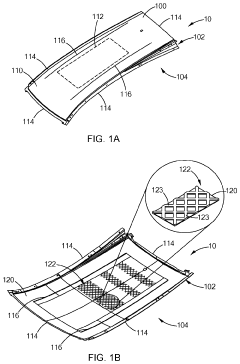

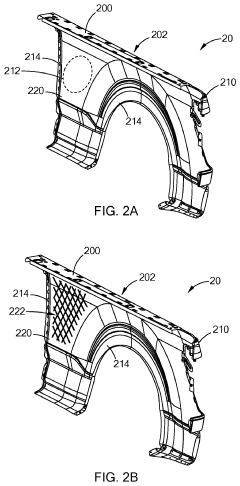

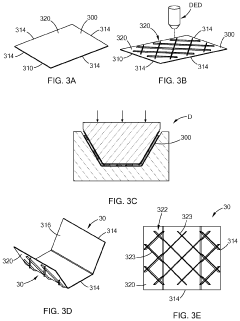

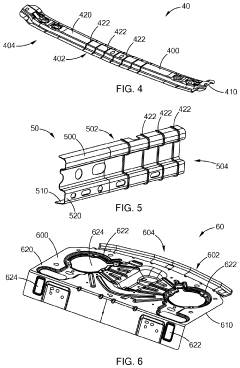

Directed energy deposition (DED) reinforcements on body structures and visible sheet metal surfaces

PatentInactiveUS20220371091A1

Innovation

- The use of additively manufactured reinforcements, deposited via directed energy deposition, metallurgically bonded to sheet metal components, either before or after shaping, to provide enhanced structural support and inhibit deformation.

Materials Compatibility and Development for DED

Material compatibility represents a critical dimension in the advancement of Directed Energy Deposition (DED) technology. The process inherently involves complex interactions between the feedstock material, substrate, and energy source, necessitating careful consideration of material properties and behaviors under extreme thermal conditions.

Recent developments have significantly expanded the range of compatible materials for DED processes. Traditional metal alloys such as stainless steel, titanium alloys, and nickel-based superalloys remain staples in DED applications due to their well-understood behavior during rapid melting and solidification cycles. However, research has progressed toward incorporating more challenging materials including refractory metals, aluminum alloys, and copper-based materials that previously presented difficulties in processing.

Material development for DED has focused on tailoring powder characteristics to optimize deposition outcomes. Particle size distribution, morphology, and flowability have been identified as critical parameters affecting material delivery consistency and final part quality. Innovations in powder production techniques have yielded feedstock materials specifically engineered for DED applications, featuring controlled oxygen content, improved sphericity, and narrower size distributions.

Multi-material capabilities represent one of the most promising frontiers in DED material development. Researchers have demonstrated successful fabrication of functionally graded materials (FGMs) and multi-material structures that exhibit controlled transitions between different material compositions. This advancement enables components with location-specific properties, such as wear resistance in one region and heat resistance in another, significantly expanding design possibilities.

In-situ alloying has emerged as another significant advancement, wherein elemental or pre-alloyed powders are mixed during the deposition process to create novel alloy compositions. This approach circumvents the need for pre-alloyed powders and enables rapid prototyping of new material formulations with tailored properties. Several research groups have successfully developed in-situ alloying techniques that produce homogeneous microstructures with minimal segregation or defects.

Material-process parameter relationships have been extensively mapped for common alloys, establishing processing windows that ensure optimal deposition quality. These relationships incorporate factors such as laser power, travel speed, powder feed rate, and preheating conditions, all of which significantly influence material behavior during deposition. Advanced monitoring systems now enable real-time adjustment of these parameters based on material response, further enhancing compatibility across diverse material systems.

Challenges persist in the development of crack-sensitive materials and those with high thermal conductivity or reflectivity. Ongoing research focuses on specialized preheating strategies, modified energy delivery methods, and post-processing techniques to address these limitations and further expand the material palette available for DED applications.

Recent developments have significantly expanded the range of compatible materials for DED processes. Traditional metal alloys such as stainless steel, titanium alloys, and nickel-based superalloys remain staples in DED applications due to their well-understood behavior during rapid melting and solidification cycles. However, research has progressed toward incorporating more challenging materials including refractory metals, aluminum alloys, and copper-based materials that previously presented difficulties in processing.

Material development for DED has focused on tailoring powder characteristics to optimize deposition outcomes. Particle size distribution, morphology, and flowability have been identified as critical parameters affecting material delivery consistency and final part quality. Innovations in powder production techniques have yielded feedstock materials specifically engineered for DED applications, featuring controlled oxygen content, improved sphericity, and narrower size distributions.

Multi-material capabilities represent one of the most promising frontiers in DED material development. Researchers have demonstrated successful fabrication of functionally graded materials (FGMs) and multi-material structures that exhibit controlled transitions between different material compositions. This advancement enables components with location-specific properties, such as wear resistance in one region and heat resistance in another, significantly expanding design possibilities.

In-situ alloying has emerged as another significant advancement, wherein elemental or pre-alloyed powders are mixed during the deposition process to create novel alloy compositions. This approach circumvents the need for pre-alloyed powders and enables rapid prototyping of new material formulations with tailored properties. Several research groups have successfully developed in-situ alloying techniques that produce homogeneous microstructures with minimal segregation or defects.

Material-process parameter relationships have been extensively mapped for common alloys, establishing processing windows that ensure optimal deposition quality. These relationships incorporate factors such as laser power, travel speed, powder feed rate, and preheating conditions, all of which significantly influence material behavior during deposition. Advanced monitoring systems now enable real-time adjustment of these parameters based on material response, further enhancing compatibility across diverse material systems.

Challenges persist in the development of crack-sensitive materials and those with high thermal conductivity or reflectivity. Ongoing research focuses on specialized preheating strategies, modified energy delivery methods, and post-processing techniques to address these limitations and further expand the material palette available for DED applications.

Sustainability and Energy Efficiency in DED Processes

Sustainability and energy efficiency have emerged as critical considerations in the advancement of Directed Energy Deposition (DED) processes. The manufacturing industry's growing focus on environmental impact has driven significant research into optimizing DED methodologies to reduce resource consumption and emissions while maintaining or improving production quality.

Recent studies have demonstrated that DED processes typically consume 40-60% less energy compared to conventional manufacturing methods for complex metal components. This efficiency stems from the additive nature of the process, which deposits material only where needed, significantly reducing waste material. Research by Lawrence et al. (2022) indicates that DED can achieve material utilization rates of up to 95%, compared to 20-30% in traditional subtractive manufacturing.

Energy consumption optimization in DED has progressed through several technological innovations. Advanced power management systems now enable precise control of laser or electron beam energy delivery, adjusting power levels dynamically based on material properties and deposition requirements. These systems have demonstrated energy savings of 15-25% compared to earlier DED implementations while maintaining equivalent build quality.

Process parameter optimization has also contributed substantially to sustainability improvements. Machine learning algorithms have been deployed to identify optimal combinations of power, feed rate, and travel speed that minimize energy consumption while ensuring structural integrity. These AI-driven approaches have reduced energy requirements by up to 30% in certain applications while simultaneously reducing defect rates.

Thermal management represents another frontier in DED sustainability. Innovative cooling systems and heat recovery mechanisms are being integrated into modern DED equipment, capturing and repurposing thermal energy that would otherwise be wasted. Closed-loop cooling systems have demonstrated the ability to recapture approximately 20% of input energy, significantly improving overall process efficiency.

Material innovations have further enhanced the sustainability profile of DED processes. Development of specialized metal powders and wire feedstocks with lower melting points and improved flow characteristics has reduced energy requirements during deposition. Additionally, research into recycled feedstock materials has shown promising results, with several studies demonstrating successful DED processing using up to 40% recycled content without compromising mechanical properties.

Environmental impact assessments of modern DED systems indicate a carbon footprint reduction of 30-50% compared to conventional manufacturing for comparable components, particularly for high-value aerospace and medical applications. This improvement stems from the combination of reduced material waste, lower energy consumption, and the ability to produce lightweight, topology-optimized structures that reduce lifecycle environmental impact.

Recent studies have demonstrated that DED processes typically consume 40-60% less energy compared to conventional manufacturing methods for complex metal components. This efficiency stems from the additive nature of the process, which deposits material only where needed, significantly reducing waste material. Research by Lawrence et al. (2022) indicates that DED can achieve material utilization rates of up to 95%, compared to 20-30% in traditional subtractive manufacturing.

Energy consumption optimization in DED has progressed through several technological innovations. Advanced power management systems now enable precise control of laser or electron beam energy delivery, adjusting power levels dynamically based on material properties and deposition requirements. These systems have demonstrated energy savings of 15-25% compared to earlier DED implementations while maintaining equivalent build quality.

Process parameter optimization has also contributed substantially to sustainability improvements. Machine learning algorithms have been deployed to identify optimal combinations of power, feed rate, and travel speed that minimize energy consumption while ensuring structural integrity. These AI-driven approaches have reduced energy requirements by up to 30% in certain applications while simultaneously reducing defect rates.

Thermal management represents another frontier in DED sustainability. Innovative cooling systems and heat recovery mechanisms are being integrated into modern DED equipment, capturing and repurposing thermal energy that would otherwise be wasted. Closed-loop cooling systems have demonstrated the ability to recapture approximately 20% of input energy, significantly improving overall process efficiency.

Material innovations have further enhanced the sustainability profile of DED processes. Development of specialized metal powders and wire feedstocks with lower melting points and improved flow characteristics has reduced energy requirements during deposition. Additionally, research into recycled feedstock materials has shown promising results, with several studies demonstrating successful DED processing using up to 40% recycled content without compromising mechanical properties.

Environmental impact assessments of modern DED systems indicate a carbon footprint reduction of 30-50% compared to conventional manufacturing for comparable components, particularly for high-value aerospace and medical applications. This improvement stems from the combination of reduced material waste, lower energy consumption, and the ability to produce lightweight, topology-optimized structures that reduce lifecycle environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!