Applications and Developments in Directed Energy Deposition Techniques

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology over the past three decades, evolving from its origins in laser cladding processes developed in the 1980s. This technology represents a significant advancement in metal manufacturing capabilities, allowing for direct fabrication of complex metal components through the precise deposition of material using focused thermal energy.

The fundamental principle of DED involves the simultaneous delivery of energy and feedstock material to create a melt pool that solidifies to form the desired structure. This approach differs significantly from traditional manufacturing methods and other additive manufacturing techniques, offering unique capabilities for both component fabrication and repair applications.

DED technologies have progressed through several developmental phases, beginning with basic laser cladding systems and evolving into sophisticated multi-axis deposition platforms capable of producing complex geometries with controlled microstructures. The integration of advanced control systems, real-time monitoring capabilities, and multi-material processing represents key evolutionary milestones in this technological progression.

Current technological objectives for DED development focus on several critical areas. First, enhancing deposition precision and surface finish quality to reduce or eliminate post-processing requirements. Second, expanding the range of compatible materials, particularly for high-performance alloys and multi-material structures. Third, improving process stability and repeatability through advanced sensing and control systems to ensure consistent mechanical properties across builds.

Additionally, there is significant emphasis on increasing deposition rates while maintaining quality, as productivity remains a limiting factor for broader industrial adoption. The development of hybrid manufacturing systems that combine DED with subtractive processes represents another important objective, allowing for comprehensive manufacturing solutions within a single platform.

From a materials science perspective, research aims to better understand and control microstructural development during the rapid solidification conditions characteristic of DED processes. This includes managing residual stresses, minimizing defects such as porosity and cracking, and developing tailored microstructures for specific performance requirements.

The ultimate technological goal for DED is to establish it as a mature, reliable manufacturing process capable of producing certified components for critical applications across industries including aerospace, defense, medical, and energy sectors. This requires not only technical advancements but also the development of comprehensive standards, qualification procedures, and design methodologies specific to DED processes.

The fundamental principle of DED involves the simultaneous delivery of energy and feedstock material to create a melt pool that solidifies to form the desired structure. This approach differs significantly from traditional manufacturing methods and other additive manufacturing techniques, offering unique capabilities for both component fabrication and repair applications.

DED technologies have progressed through several developmental phases, beginning with basic laser cladding systems and evolving into sophisticated multi-axis deposition platforms capable of producing complex geometries with controlled microstructures. The integration of advanced control systems, real-time monitoring capabilities, and multi-material processing represents key evolutionary milestones in this technological progression.

Current technological objectives for DED development focus on several critical areas. First, enhancing deposition precision and surface finish quality to reduce or eliminate post-processing requirements. Second, expanding the range of compatible materials, particularly for high-performance alloys and multi-material structures. Third, improving process stability and repeatability through advanced sensing and control systems to ensure consistent mechanical properties across builds.

Additionally, there is significant emphasis on increasing deposition rates while maintaining quality, as productivity remains a limiting factor for broader industrial adoption. The development of hybrid manufacturing systems that combine DED with subtractive processes represents another important objective, allowing for comprehensive manufacturing solutions within a single platform.

From a materials science perspective, research aims to better understand and control microstructural development during the rapid solidification conditions characteristic of DED processes. This includes managing residual stresses, minimizing defects such as porosity and cracking, and developing tailored microstructures for specific performance requirements.

The ultimate technological goal for DED is to establish it as a mature, reliable manufacturing process capable of producing certified components for critical applications across industries including aerospace, defense, medical, and energy sectors. This requires not only technical advancements but also the development of comprehensive standards, qualification procedures, and design methodologies specific to DED processes.

Market Analysis for DED Applications

The global market for Directed Energy Deposition (DED) technologies has experienced significant growth in recent years, driven by increasing demand for advanced manufacturing solutions across various industrial sectors. The current market size for DED technologies is estimated at $500 million, with projections indicating a compound annual growth rate (CAGR) of 14.5% over the next five years, potentially reaching $1 billion by 2028.

Aerospace and defense sectors currently represent the largest market segments for DED applications, accounting for approximately 35% of the total market share. These industries particularly value DED for its ability to repair high-value components and manufacture complex geometries with specialized materials. The automotive industry follows closely, representing about 25% of the market, where DED is increasingly utilized for rapid prototyping and tooling applications.

Medical device manufacturing has emerged as the fastest-growing segment, with a growth rate exceeding 18% annually. This surge is attributed to DED's capability to produce patient-specific implants and complex medical instruments using biocompatible materials. The technology's ability to work with titanium alloys and other medical-grade materials has positioned it as a transformative force in personalized healthcare solutions.

Regionally, North America dominates the DED market with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth, particularly in countries like China, Japan, and South Korea, where substantial investments in advanced manufacturing technologies are being made. These countries are actively developing domestic capabilities in DED technologies to support their aerospace, automotive, and medical industries.

From an economic perspective, the return on investment (ROI) for DED implementations has improved significantly. Early adopters reported breakeven periods of 3-4 years, but technological advancements and increased efficiency have reduced this to 18-24 months for most industrial applications. This improved ROI has been a critical factor driving wider adoption across various industries.

Supply chain considerations are increasingly influencing market dynamics. The ability of DED to enable on-demand manufacturing and reduce dependency on complex supply chains has become particularly valuable following global supply disruptions. Companies are increasingly viewing DED not just as a manufacturing technology but as a strategic tool for supply chain resilience, with 62% of surveyed manufacturers citing this as a primary adoption driver.

Aerospace and defense sectors currently represent the largest market segments for DED applications, accounting for approximately 35% of the total market share. These industries particularly value DED for its ability to repair high-value components and manufacture complex geometries with specialized materials. The automotive industry follows closely, representing about 25% of the market, where DED is increasingly utilized for rapid prototyping and tooling applications.

Medical device manufacturing has emerged as the fastest-growing segment, with a growth rate exceeding 18% annually. This surge is attributed to DED's capability to produce patient-specific implants and complex medical instruments using biocompatible materials. The technology's ability to work with titanium alloys and other medical-grade materials has positioned it as a transformative force in personalized healthcare solutions.

Regionally, North America dominates the DED market with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the most rapid growth, particularly in countries like China, Japan, and South Korea, where substantial investments in advanced manufacturing technologies are being made. These countries are actively developing domestic capabilities in DED technologies to support their aerospace, automotive, and medical industries.

From an economic perspective, the return on investment (ROI) for DED implementations has improved significantly. Early adopters reported breakeven periods of 3-4 years, but technological advancements and increased efficiency have reduced this to 18-24 months for most industrial applications. This improved ROI has been a critical factor driving wider adoption across various industries.

Supply chain considerations are increasingly influencing market dynamics. The ability of DED to enable on-demand manufacturing and reduce dependency on complex supply chains has become particularly valuable following global supply disruptions. Companies are increasingly viewing DED not just as a manufacturing technology but as a strategic tool for supply chain resilience, with 62% of surveyed manufacturers citing this as a primary adoption driver.

Current DED Technical Challenges

Despite significant advancements in Directed Energy Deposition (DED) technology, several critical technical challenges continue to impede its widespread industrial adoption. Material feedstock inconsistency remains a primary concern, as variations in powder or wire characteristics can lead to unpredictable mechanical properties and microstructural defects in the final components. The industry still lacks standardized feedstock specifications tailored specifically for DED processes, resulting in quality control issues across different manufacturing batches.

Process stability represents another significant hurdle, particularly in complex geometries with overhanging features. The thermal management during deposition creates residual stresses that can cause warping, cracking, or dimensional inaccuracies. Real-time monitoring systems, while improving, still struggle to provide comprehensive feedback for closed-loop control adjustments during the build process.

Surface finish quality continues to challenge DED applications, with as-deposited components typically requiring extensive post-processing. The characteristic layer-by-layer deposition creates stair-stepping effects and surface roughness that falls short of requirements for many high-performance applications, necessitating additional machining operations that increase production costs and lead times.

Microstructural control presents complex challenges due to the unique thermal history experienced during DED processes. The repeated heating and cooling cycles create anisotropic properties and potential defects such as porosity, lack of fusion, or undesired phase transformations. Current process parameters often require extensive empirical testing for each material-geometry combination, lacking robust predictive models.

Multi-material deposition capabilities, while theoretically promising, face significant implementation barriers including managing dissimilar thermal properties, preventing brittle intermetallic formation, and ensuring strong interfacial bonding. The industry lacks comprehensive material compatibility databases and process parameters for functionally graded materials.

Qualification and certification frameworks remain underdeveloped for DED-manufactured components, particularly for safety-critical applications in aerospace and medical sectors. Non-destructive testing methods struggle to reliably detect subsurface defects specific to DED processes, creating regulatory hurdles for implementation in highly regulated industries.

Computational modeling tools, while advancing rapidly, still fail to accurately predict material behavior during the complex DED process, limiting the ability to optimize parameters without extensive physical testing. The multi-physics nature of the process—involving fluid dynamics, heat transfer, phase transformations, and mechanical stresses—creates significant computational challenges that current simulation capabilities cannot fully address.

Process stability represents another significant hurdle, particularly in complex geometries with overhanging features. The thermal management during deposition creates residual stresses that can cause warping, cracking, or dimensional inaccuracies. Real-time monitoring systems, while improving, still struggle to provide comprehensive feedback for closed-loop control adjustments during the build process.

Surface finish quality continues to challenge DED applications, with as-deposited components typically requiring extensive post-processing. The characteristic layer-by-layer deposition creates stair-stepping effects and surface roughness that falls short of requirements for many high-performance applications, necessitating additional machining operations that increase production costs and lead times.

Microstructural control presents complex challenges due to the unique thermal history experienced during DED processes. The repeated heating and cooling cycles create anisotropic properties and potential defects such as porosity, lack of fusion, or undesired phase transformations. Current process parameters often require extensive empirical testing for each material-geometry combination, lacking robust predictive models.

Multi-material deposition capabilities, while theoretically promising, face significant implementation barriers including managing dissimilar thermal properties, preventing brittle intermetallic formation, and ensuring strong interfacial bonding. The industry lacks comprehensive material compatibility databases and process parameters for functionally graded materials.

Qualification and certification frameworks remain underdeveloped for DED-manufactured components, particularly for safety-critical applications in aerospace and medical sectors. Non-destructive testing methods struggle to reliably detect subsurface defects specific to DED processes, creating regulatory hurdles for implementation in highly regulated industries.

Computational modeling tools, while advancing rapidly, still fail to accurately predict material behavior during the complex DED process, limiting the ability to optimize parameters without extensive physical testing. The multi-physics nature of the process—involving fluid dynamics, heat transfer, phase transformations, and mechanical stresses—creates significant computational challenges that current simulation capabilities cannot fully address.

Current DED Implementation Solutions

01 DED process optimization and control

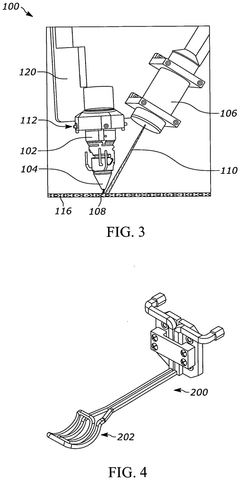

Directed Energy Deposition (DED) processes can be optimized through various control mechanisms to improve build quality and efficiency. This includes real-time monitoring systems, feedback control loops, and parameter optimization for different materials. Advanced control strategies help maintain consistent deposition rates, minimize defects, and ensure dimensional accuracy of the printed parts. Process optimization also involves adjusting laser power, feed rate, and other parameters based on material properties and desired part characteristics.- DED process fundamentals and equipment: Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits material (powder or wire) which is simultaneously melted by a heat source such as a laser, electron beam, or plasma arc. This technology allows for the creation of complex geometries and can be used for both new part manufacturing and repair applications.

- Material innovations for DED applications: Various materials have been developed specifically for DED processes, including metal alloys, composites, and functionally graded materials. These specialized materials are designed to optimize build quality, mechanical properties, and process efficiency. Innovations include powder formulations with improved flowability, wire feedstock with enhanced deposition characteristics, and multi-material systems that enable the creation of parts with varying properties throughout their structure.

- Process monitoring and control systems: Advanced monitoring and control systems have been developed to improve the quality and reliability of DED processes. These systems utilize sensors, cameras, and real-time data analysis to monitor parameters such as melt pool temperature, deposition rate, and layer geometry. Closed-loop control algorithms adjust process parameters dynamically to maintain consistent quality throughout the build, reducing defects and improving dimensional accuracy. Machine learning approaches are also being implemented to predict and prevent process anomalies.

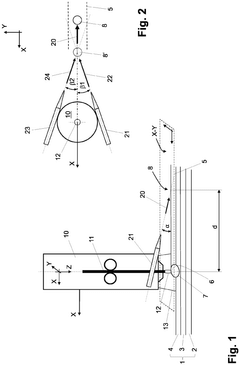

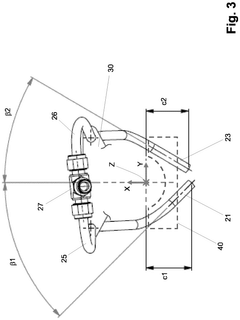

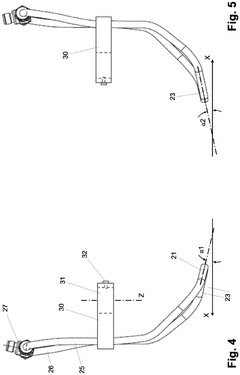

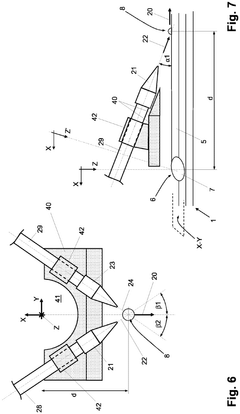

- Multi-axis and hybrid DED systems: Multi-axis DED systems combine traditional 3-axis movement with additional rotational capabilities, allowing for the deposition of material from multiple angles. This enables the creation of complex overhanging structures without support materials and improves access to intricate geometries. Hybrid systems integrate DED technology with conventional manufacturing processes such as CNC machining, enabling both additive and subtractive operations on the same platform. These hybrid approaches can significantly reduce production time and improve surface finish quality.

- Repair and remanufacturing applications: DED technology has been widely applied for repair and remanufacturing of high-value components, particularly in aerospace, defense, and heavy industry sectors. The process allows for precise deposition of material onto damaged areas, restoring original dimensions and properties. Advanced repair strategies include automated defect detection, optimized tool path generation for material deposition, and post-process treatments to ensure mechanical integrity. This approach extends component lifecycle, reduces waste, and offers significant cost savings compared to replacement.

02 Multi-material DED applications

Multi-material Directed Energy Deposition enables the fabrication of components with varying material compositions and functionally graded properties. This approach allows for the strategic placement of different materials within a single component to optimize mechanical properties, thermal performance, or corrosion resistance. The technology enables the creation of composite structures, bimetallic components, and parts with tailored material transitions that would be difficult or impossible to produce using conventional manufacturing methods.Expand Specific Solutions03 DED equipment and hardware innovations

Innovations in DED hardware focus on improving deposition heads, energy sources, and material delivery systems. Advanced nozzle designs enable more precise material deposition, while improved energy sources (lasers, electron beams, or plasma arcs) provide better control over the melt pool. Multi-axis systems allow for complex geometries without support structures, and integrated cooling systems help manage thermal gradients. These hardware innovations collectively enhance build quality, surface finish, and the overall capabilities of DED systems.Expand Specific Solutions04 DED for repair and remanufacturing

Directed Energy Deposition is particularly valuable for repair and remanufacturing applications, allowing for the restoration of damaged or worn components. The process can deposit material precisely onto existing parts to rebuild worn surfaces, repair cracks, or add features. This approach extends component lifespan, reduces waste, and offers cost savings compared to replacement. The technology is especially beneficial for high-value components in aerospace, defense, and industrial equipment where replacement costs are significant.Expand Specific Solutions05 Material development for DED processes

Material development for DED focuses on creating specialized powders and wire feedstock with properties optimized for the deposition process. This includes tailored particle size distributions, flow characteristics, and compositions that minimize defects and improve build quality. Research in this area also addresses the development of novel alloys specifically designed for DED processing, with controlled microstructures and enhanced mechanical properties. Advanced materials for DED enable applications in extreme environments and specialized industries like aerospace and medical implants.Expand Specific Solutions

Leading DED Industry Players

Directed Energy Deposition (DED) technology is currently in a growth phase, with the market expected to expand significantly due to increasing applications in aerospace, automotive, and medical sectors. The global DED market is projected to reach substantial size by 2030, driven by demand for complex metal components and repair solutions. Technologically, the field shows varying maturity levels across different players. Academic institutions like MIT, Zhejiang University, and Harbin Engineering University are advancing fundamental research, while industrial leaders such as Rolls-Royce, GE Avio, and IBM are implementing practical applications. Companies like AddUp and NRGTEK are developing specialized DED solutions, with established manufacturers like ABB Group integrating DED into production systems. National research organizations including Lawrence Livermore National Security and National Research Council of Canada are bridging the gap between research and commercialization through collaborative industry partnerships.

Zhejiang University

Technical Solution: Zhejiang University has developed innovative DED technologies focusing on multi-material and functionally graded materials (FGM) fabrication. Their research team has created a novel DED system that utilizes multiple powder feeders with precise flow control, enabling the creation of components with continuously varying material compositions. This system incorporates advanced nozzle designs that achieve optimal powder efficiency while minimizing material waste[7]. Their technology features a specialized thermal management system that controls cooling rates during deposition, allowing for tailored microstructure development throughout the build. Zhejiang University researchers have also pioneered techniques for in-situ alloying during the DED process, creating custom material compositions with enhanced properties not achievable through conventional manufacturing methods[8]. Their work has demonstrated successful fabrication of components with gradient transitions between dissimilar metals, solving traditional challenges related to thermal expansion mismatches and brittle intermetallic formation.

Strengths: World-leading expertise in functionally graded materials, innovative powder delivery systems, and advanced in-situ alloying capabilities. Weaknesses: Some technologies remain at research scale with ongoing challenges for industrial implementation and standardization.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed a sophisticated DED platform specifically tailored for aerospace component manufacturing and repair. Their technology utilizes a hybrid approach combining wire-fed and powder-based DED processes, allowing for both high deposition rates and precision finishing within the same system. Rolls-Royce's DED technology incorporates proprietary alloy formulations designed specifically for high-temperature applications in jet engines, with material properties that meet or exceed those of traditionally manufactured components[2]. Their system features adaptive path planning that automatically adjusts deposition strategies based on part geometry and thermal history, minimizing residual stress in complex aerospace components. Rolls-Royce has successfully implemented closed-loop control systems that monitor melt pool dynamics and adjust process parameters in real-time, achieving consistent material properties across large structural components[4].

Strengths: Industry-leading expertise in high-value aerospace applications, proprietary alloy development specifically for DED processes, and advanced hybrid manufacturing capabilities. Weaknesses: Technology primarily optimized for aerospace materials and applications, with potentially limited versatility for other industries.

Key DED Patents and Innovations

Method and apparatus for direct energy deposition of metal

PatentPendingEP4603213A1

Innovation

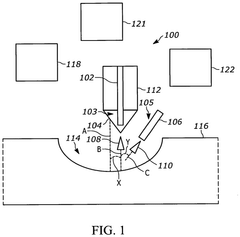

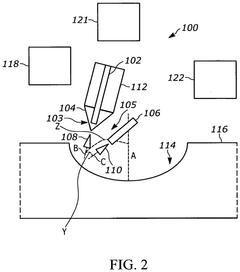

- A method and apparatus for direct energy deposition using cryogenic coolant jets directed at an acute angle to the deposition path, combining multiple jets to form a narrow coolant stream that efficiently cools the freshly deposited metal layers, reducing interference with the energy input and shielding gas, thereby minimizing stress development and enhancing cooling efficiency.

Directed energy deposition system and methods for component repairs

PatentPendingEP4609971A1

Innovation

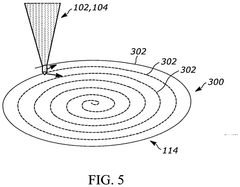

- A DED system employing multiple energy sources and a bi-directional spiral deposition pattern, combined with induction heating, to melt and uniformly fill concave cavities with angled walls, using titanium aluminide powder, ensuring thermal distribution and adhesion.

Material Compatibility in DED Processes

Material compatibility represents a critical factor in the successful implementation of Directed Energy Deposition (DED) processes. The technology's versatility in processing various materials constitutes one of its primary advantages, yet this versatility also introduces significant challenges regarding material selection and compatibility considerations.

DED processes can accommodate a wide spectrum of metallic materials, including titanium alloys, nickel-based superalloys, stainless steels, tool steels, and cobalt-chrome alloys. Each material category exhibits distinct thermal properties, melting points, and solidification behaviors that directly influence process parameters and final part quality. For instance, titanium alloys require stringent atmospheric control due to their high reactivity with oxygen at elevated temperatures, while nickel-based superalloys demand precise thermal management to prevent detrimental microstructural formations.

Multi-material compatibility has emerged as a particularly promising research direction within DED applications. The technology enables functionally graded materials (FGMs) through controlled deposition of different materials within a single build, creating components with spatially varying properties. However, this capability introduces additional complexity regarding interfacial phenomena between dissimilar materials, including potential formation of brittle intermetallic compounds, residual stress development, and thermal expansion mismatches.

Powder characteristics significantly impact material compatibility in DED processes. Particle size distribution, morphology, flowability, and chemical composition all influence process stability and resultant material properties. Spherical particles with narrow size distributions typically yield optimal results, though material-specific requirements may necessitate customized powder specifications. Additionally, powder recyclability varies substantially between materials, affecting process economics and sustainability.

Thermal management represents another crucial aspect of material compatibility. Different materials exhibit varying thermal conductivities, specific heat capacities, and thermal expansion coefficients, necessitating tailored process parameters. Inadequate thermal management can result in excessive residual stresses, distortion, cracking, or undesirable microstructural features. Advanced thermal modeling and in-process monitoring systems have become essential tools for addressing these challenges.

Recent advancements in material compatibility research include development of specialized alloys specifically formulated for DED processes, computational tools for predicting material behavior during deposition, and novel pre/post-processing techniques to enhance material performance. These developments continue to expand the range of compatible materials and enable increasingly complex multi-material structures with optimized properties for specific applications.

DED processes can accommodate a wide spectrum of metallic materials, including titanium alloys, nickel-based superalloys, stainless steels, tool steels, and cobalt-chrome alloys. Each material category exhibits distinct thermal properties, melting points, and solidification behaviors that directly influence process parameters and final part quality. For instance, titanium alloys require stringent atmospheric control due to their high reactivity with oxygen at elevated temperatures, while nickel-based superalloys demand precise thermal management to prevent detrimental microstructural formations.

Multi-material compatibility has emerged as a particularly promising research direction within DED applications. The technology enables functionally graded materials (FGMs) through controlled deposition of different materials within a single build, creating components with spatially varying properties. However, this capability introduces additional complexity regarding interfacial phenomena between dissimilar materials, including potential formation of brittle intermetallic compounds, residual stress development, and thermal expansion mismatches.

Powder characteristics significantly impact material compatibility in DED processes. Particle size distribution, morphology, flowability, and chemical composition all influence process stability and resultant material properties. Spherical particles with narrow size distributions typically yield optimal results, though material-specific requirements may necessitate customized powder specifications. Additionally, powder recyclability varies substantially between materials, affecting process economics and sustainability.

Thermal management represents another crucial aspect of material compatibility. Different materials exhibit varying thermal conductivities, specific heat capacities, and thermal expansion coefficients, necessitating tailored process parameters. Inadequate thermal management can result in excessive residual stresses, distortion, cracking, or undesirable microstructural features. Advanced thermal modeling and in-process monitoring systems have become essential tools for addressing these challenges.

Recent advancements in material compatibility research include development of specialized alloys specifically formulated for DED processes, computational tools for predicting material behavior during deposition, and novel pre/post-processing techniques to enhance material performance. These developments continue to expand the range of compatible materials and enable increasingly complex multi-material structures with optimized properties for specific applications.

Sustainability Aspects of DED Manufacturing

Directed Energy Deposition (DED) manufacturing processes are increasingly being evaluated through the lens of sustainability, as industries worldwide shift towards more environmentally responsible production methods. The environmental impact of DED technologies presents a complex picture with both significant advantages and challenges compared to conventional manufacturing techniques.

DED processes demonstrate notable sustainability benefits through material efficiency. Unlike traditional subtractive manufacturing methods that can waste up to 90% of raw materials, DED's additive approach typically achieves material utilization rates of 90-95%. This dramatic reduction in material waste directly translates to conservation of natural resources and reduced environmental footprint associated with material extraction and processing.

Energy consumption analysis reveals that DED technologies generally require 50-70% less energy than conventional manufacturing for certain applications, particularly in aerospace and medical device production. This efficiency stems from the elimination of multiple processing steps and the ability to create near-net-shape components that require minimal post-processing.

The localized nature of DED processes contributes to sustainability through reduced transportation emissions. By enabling on-site manufacturing and repair capabilities, particularly in remote locations such as offshore platforms or military deployments, DED significantly reduces the carbon footprint associated with logistics and transportation of replacement parts.

Life cycle assessment (LCA) studies indicate that DED-manufactured components often demonstrate extended service life due to superior material properties and the ability to incorporate functionally graded materials. This longevity factor represents a critical sustainability advantage that is frequently overlooked in comparative analyses.

However, challenges remain in several areas. The high-energy laser or electron beam sources used in DED processes require substantial electrical input, raising concerns about overall carbon footprint in regions dependent on fossil fuel energy generation. Additionally, metal powders used in many DED applications present potential health and environmental hazards if not properly managed throughout their lifecycle.

Recycling considerations present both opportunities and challenges. While unused metal powders can theoretically be reclaimed and reused, contamination issues and changes in powder morphology after processing can complicate recycling efforts. Advanced powder management systems are being developed to address these concerns, with closed-loop recycling showing promise for improving the sustainability profile of DED manufacturing.

Regulatory frameworks are evolving to address the unique sustainability aspects of DED technologies. The European Union's Eco-Design Directive and various international standards organizations are developing specific guidelines for additive manufacturing sustainability, which will likely shape the future implementation and assessment of DED processes across industries.

DED processes demonstrate notable sustainability benefits through material efficiency. Unlike traditional subtractive manufacturing methods that can waste up to 90% of raw materials, DED's additive approach typically achieves material utilization rates of 90-95%. This dramatic reduction in material waste directly translates to conservation of natural resources and reduced environmental footprint associated with material extraction and processing.

Energy consumption analysis reveals that DED technologies generally require 50-70% less energy than conventional manufacturing for certain applications, particularly in aerospace and medical device production. This efficiency stems from the elimination of multiple processing steps and the ability to create near-net-shape components that require minimal post-processing.

The localized nature of DED processes contributes to sustainability through reduced transportation emissions. By enabling on-site manufacturing and repair capabilities, particularly in remote locations such as offshore platforms or military deployments, DED significantly reduces the carbon footprint associated with logistics and transportation of replacement parts.

Life cycle assessment (LCA) studies indicate that DED-manufactured components often demonstrate extended service life due to superior material properties and the ability to incorporate functionally graded materials. This longevity factor represents a critical sustainability advantage that is frequently overlooked in comparative analyses.

However, challenges remain in several areas. The high-energy laser or electron beam sources used in DED processes require substantial electrical input, raising concerns about overall carbon footprint in regions dependent on fossil fuel energy generation. Additionally, metal powders used in many DED applications present potential health and environmental hazards if not properly managed throughout their lifecycle.

Recycling considerations present both opportunities and challenges. While unused metal powders can theoretically be reclaimed and reused, contamination issues and changes in powder morphology after processing can complicate recycling efforts. Advanced powder management systems are being developed to address these concerns, with closed-loop recycling showing promise for improving the sustainability profile of DED manufacturing.

Regulatory frameworks are evolving to address the unique sustainability aspects of DED technologies. The European Union's Eco-Design Directive and various international standards organizations are developing specific guidelines for additive manufacturing sustainability, which will likely shape the future implementation and assessment of DED processes across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!