Directed Energy Deposition in Automotive Innovations and Analysis

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the 1990s. Initially developed for repair applications in aerospace, DED has undergone substantial refinement to become a versatile manufacturing process capable of producing complex metal components with exceptional material properties. The technology operates by focusing thermal energy to fuse materials as they are deposited, creating structures layer by layer with minimal waste.

The automotive industry has historically relied on conventional manufacturing methods such as casting, forging, and machining. However, increasing demands for lightweight structures, complex geometries, and rapid prototyping capabilities have driven interest in advanced manufacturing technologies. DED emerges as a promising solution to address these evolving requirements, offering unprecedented design freedom and material efficiency.

Recent technological advancements have significantly enhanced DED's capabilities, particularly in multi-material deposition, in-situ monitoring, and process control systems. These improvements have expanded the range of applicable materials to include high-performance alloys critical for automotive applications, such as titanium alloys, tool steels, and nickel-based superalloys. The technology's ability to create functionally graded materials represents a particularly valuable attribute for automotive components subject to varying mechanical and thermal stresses.

The primary objective of DED implementation in automotive manufacturing is to revolutionize production paradigms by enabling rapid prototyping, efficient repairs, and on-demand manufacturing of complex components. This approach aims to significantly reduce lead times, minimize material waste, and optimize supply chain logistics. Additionally, DED technology seeks to facilitate weight reduction through topology optimization and the strategic use of high-performance materials, directly contributing to improved fuel efficiency and reduced emissions.

Looking forward, the technology trajectory indicates continued refinement in process stability, surface finish quality, and dimensional accuracy. Research efforts are increasingly focused on expanding material compatibility, enhancing deposition rates, and developing sophisticated control algorithms to ensure consistent quality. The integration of artificial intelligence and machine learning approaches promises to further optimize process parameters and predict material behaviors with unprecedented precision.

The convergence of DED technology with digital manufacturing ecosystems represents another significant trend, enabling seamless integration with design software, simulation tools, and quality control systems. This digital thread approach aims to create a continuous information flow from design to production, supporting agile manufacturing strategies essential for the rapidly evolving automotive market.

The automotive industry has historically relied on conventional manufacturing methods such as casting, forging, and machining. However, increasing demands for lightweight structures, complex geometries, and rapid prototyping capabilities have driven interest in advanced manufacturing technologies. DED emerges as a promising solution to address these evolving requirements, offering unprecedented design freedom and material efficiency.

Recent technological advancements have significantly enhanced DED's capabilities, particularly in multi-material deposition, in-situ monitoring, and process control systems. These improvements have expanded the range of applicable materials to include high-performance alloys critical for automotive applications, such as titanium alloys, tool steels, and nickel-based superalloys. The technology's ability to create functionally graded materials represents a particularly valuable attribute for automotive components subject to varying mechanical and thermal stresses.

The primary objective of DED implementation in automotive manufacturing is to revolutionize production paradigms by enabling rapid prototyping, efficient repairs, and on-demand manufacturing of complex components. This approach aims to significantly reduce lead times, minimize material waste, and optimize supply chain logistics. Additionally, DED technology seeks to facilitate weight reduction through topology optimization and the strategic use of high-performance materials, directly contributing to improved fuel efficiency and reduced emissions.

Looking forward, the technology trajectory indicates continued refinement in process stability, surface finish quality, and dimensional accuracy. Research efforts are increasingly focused on expanding material compatibility, enhancing deposition rates, and developing sophisticated control algorithms to ensure consistent quality. The integration of artificial intelligence and machine learning approaches promises to further optimize process parameters and predict material behaviors with unprecedented precision.

The convergence of DED technology with digital manufacturing ecosystems represents another significant trend, enabling seamless integration with design software, simulation tools, and quality control systems. This digital thread approach aims to create a continuous information flow from design to production, supporting agile manufacturing strategies essential for the rapidly evolving automotive market.

Automotive Market Demand Analysis

The automotive industry is witnessing a significant shift toward advanced manufacturing technologies, with Directed Energy Deposition (DED) emerging as a transformative additive manufacturing process. Market analysis indicates that the global automotive additive manufacturing market is projected to grow at a CAGR of 14.5% through 2028, with DED technologies representing an increasingly important segment within this space.

The demand for DED in automotive applications is primarily driven by the industry's push toward lightweighting vehicles to meet stringent fuel efficiency standards and reduce carbon emissions. Automotive manufacturers are seeking technologies that can produce complex, high-strength components while reducing material waste and production time. DED addresses these needs by enabling the creation of near-net-shape parts with superior mechanical properties.

Another significant market driver is the growing trend toward vehicle customization and limited production runs. Traditional manufacturing methods often require expensive tooling and setup costs that become prohibitive for small batch production. DED technology offers a cost-effective alternative for producing customized components or replacement parts for luxury and performance vehicles, where volumes are lower but value is higher.

The electric vehicle (EV) segment represents a particularly promising market for DED applications. As EV production accelerates globally, manufacturers are seeking innovative solutions for battery enclosures, motor housings, and thermal management systems. DED's ability to work with multiple materials and create functionally graded components makes it especially valuable for these applications.

Repair and remanufacturing represent another substantial market opportunity. The automotive aftermarket sector values technologies that can extend component lifecycles through repair rather than replacement. DED's capability to add material to existing parts and restore worn surfaces aligns perfectly with this need, potentially creating a significant service-based revenue stream for adopters of the technology.

Regional analysis shows varying levels of DED adoption, with North America and Europe leading implementation in premium vehicle manufacturing, while Asian markets are rapidly increasing investments in this technology as part of broader manufacturing modernization initiatives. The technology adoption curve indicates that DED will likely move from high-end applications toward more mainstream vehicle production over the next five years.

Supply chain considerations are also driving interest in DED technology. The recent global disruptions have highlighted vulnerabilities in traditional manufacturing networks, prompting automotive companies to explore technologies that enable more localized, flexible production capabilities. DED systems offer this flexibility, allowing manufacturers to reduce dependency on complex supply chains for specialized components.

The demand for DED in automotive applications is primarily driven by the industry's push toward lightweighting vehicles to meet stringent fuel efficiency standards and reduce carbon emissions. Automotive manufacturers are seeking technologies that can produce complex, high-strength components while reducing material waste and production time. DED addresses these needs by enabling the creation of near-net-shape parts with superior mechanical properties.

Another significant market driver is the growing trend toward vehicle customization and limited production runs. Traditional manufacturing methods often require expensive tooling and setup costs that become prohibitive for small batch production. DED technology offers a cost-effective alternative for producing customized components or replacement parts for luxury and performance vehicles, where volumes are lower but value is higher.

The electric vehicle (EV) segment represents a particularly promising market for DED applications. As EV production accelerates globally, manufacturers are seeking innovative solutions for battery enclosures, motor housings, and thermal management systems. DED's ability to work with multiple materials and create functionally graded components makes it especially valuable for these applications.

Repair and remanufacturing represent another substantial market opportunity. The automotive aftermarket sector values technologies that can extend component lifecycles through repair rather than replacement. DED's capability to add material to existing parts and restore worn surfaces aligns perfectly with this need, potentially creating a significant service-based revenue stream for adopters of the technology.

Regional analysis shows varying levels of DED adoption, with North America and Europe leading implementation in premium vehicle manufacturing, while Asian markets are rapidly increasing investments in this technology as part of broader manufacturing modernization initiatives. The technology adoption curve indicates that DED will likely move from high-end applications toward more mainstream vehicle production over the next five years.

Supply chain considerations are also driving interest in DED technology. The recent global disruptions have highlighted vulnerabilities in traditional manufacturing networks, prompting automotive companies to explore technologies that enable more localized, flexible production capabilities. DED systems offer this flexibility, allowing manufacturers to reduce dependency on complex supply chains for specialized components.

Global DED Technology Landscape and Challenges

Directed Energy Deposition (DED) technology has evolved significantly over the past decade, with global adoption varying across regions. North America currently leads in DED implementation within automotive manufacturing, particularly in the United States where companies like General Motors and Ford have established dedicated additive manufacturing centers incorporating DED technologies for rapid prototyping and repair applications.

In Europe, countries such as Germany and the United Kingdom demonstrate strong research foundations in DED technology, with automotive manufacturers like BMW and Volkswagen actively exploring DED for lightweight component production. The European landscape is characterized by strong university-industry collaborations, creating innovation hubs that accelerate technology transfer to production environments.

The Asia-Pacific region, particularly China and Japan, has shown remarkable growth in DED adoption rates, with significant government investments supporting industrial implementation. Japanese automotive manufacturers have focused on DED for high-precision components, while Chinese manufacturers leverage the technology primarily for cost-effective production of large structural parts.

Despite global progress, DED technology faces several critical challenges in automotive applications. Material compatibility remains a significant hurdle, as not all automotive-grade alloys perform consistently under DED processing conditions. This limitation restricts the range of components that can be manufactured using this technology, particularly for safety-critical applications.

Process stability and repeatability present another major challenge, with variations in build quality still occurring between identical production runs. This inconsistency hampers widespread adoption for high-volume automotive manufacturing, where strict quality standards must be maintained across thousands of components.

Surface finish quality from DED processes typically requires secondary operations, adding cost and time to production cycles. The relatively slow deposition rates compared to traditional manufacturing methods also limit throughput for larger automotive components, creating production bottlenecks.

Regulatory frameworks for DED-manufactured automotive parts remain underdeveloped globally, with certification standards varying significantly between regions. This regulatory uncertainty creates barriers for automotive manufacturers seeking to implement DED across global production networks.

Energy consumption represents another challenge, as DED processes typically require substantial power input, potentially offsetting sustainability benefits in other areas. Research into more energy-efficient DED systems is ongoing but has yet to yield commercially viable solutions for automotive-scale production.

In Europe, countries such as Germany and the United Kingdom demonstrate strong research foundations in DED technology, with automotive manufacturers like BMW and Volkswagen actively exploring DED for lightweight component production. The European landscape is characterized by strong university-industry collaborations, creating innovation hubs that accelerate technology transfer to production environments.

The Asia-Pacific region, particularly China and Japan, has shown remarkable growth in DED adoption rates, with significant government investments supporting industrial implementation. Japanese automotive manufacturers have focused on DED for high-precision components, while Chinese manufacturers leverage the technology primarily for cost-effective production of large structural parts.

Despite global progress, DED technology faces several critical challenges in automotive applications. Material compatibility remains a significant hurdle, as not all automotive-grade alloys perform consistently under DED processing conditions. This limitation restricts the range of components that can be manufactured using this technology, particularly for safety-critical applications.

Process stability and repeatability present another major challenge, with variations in build quality still occurring between identical production runs. This inconsistency hampers widespread adoption for high-volume automotive manufacturing, where strict quality standards must be maintained across thousands of components.

Surface finish quality from DED processes typically requires secondary operations, adding cost and time to production cycles. The relatively slow deposition rates compared to traditional manufacturing methods also limit throughput for larger automotive components, creating production bottlenecks.

Regulatory frameworks for DED-manufactured automotive parts remain underdeveloped globally, with certification standards varying significantly between regions. This regulatory uncertainty creates barriers for automotive manufacturers seeking to implement DED across global production networks.

Energy consumption represents another challenge, as DED processes typically require substantial power input, potentially offsetting sustainability benefits in other areas. Research into more energy-efficient DED systems is ongoing but has yet to yield commercially viable solutions for automotive-scale production.

Current DED Implementation Solutions

01 Directed Energy Deposition Process Fundamentals

Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits melted material onto a specified surface, where it solidifies. This technology allows for the creation of complex geometries and can be used with various materials including metals, polymers, and ceramics. The process parameters such as energy source power, material feed rate, and deposition path significantly influence the quality of the final product.- Process and equipment for directed energy deposition: Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The process involves specialized equipment including energy sources (lasers, electron beams), material delivery systems, and motion control mechanisms. These systems are designed to precisely control the deposition of material layer by layer, allowing for the creation of complex three-dimensional structures with high accuracy and repeatability.

- Materials and powder management in DED: Various materials can be used in directed energy deposition processes, including metals, alloys, and composites. The management of these materials, particularly in powder form, is critical for successful deposition. This includes powder feeding systems, powder recycling mechanisms, and methods to ensure consistent powder quality and flow. Proper material handling contributes to the structural integrity and mechanical properties of the final product.

- Process control and monitoring systems: Advanced control and monitoring systems are essential for directed energy deposition to ensure quality and consistency. These systems include real-time monitoring of process parameters such as temperature, deposition rate, and material flow. Feedback mechanisms adjust parameters during the build process to maintain optimal conditions. Monitoring technologies may include thermal imaging, optical sensors, and machine learning algorithms to detect and correct anomalies during fabrication.

- Multi-material and hybrid manufacturing approaches: Directed energy deposition enables the fabrication of components with multiple materials or functionally graded properties. Hybrid manufacturing approaches combine DED with other processes such as machining or heat treatment to enhance efficiency and part quality. These approaches allow for the creation of complex components with varying material compositions throughout the structure, optimizing mechanical properties for specific applications.

- Applications and industry-specific implementations: Directed energy deposition has diverse applications across industries including aerospace, automotive, medical, and energy sectors. Industry-specific implementations focus on particular requirements such as repair of high-value components, rapid prototyping, or production of specialized parts with unique geometries or material properties. The technology enables on-demand manufacturing, reduced material waste, and the ability to create parts that would be difficult or impossible to produce using traditional manufacturing methods.

02 Material Considerations for DED Applications

The selection of materials for Directed Energy Deposition significantly impacts the properties of the manufactured components. Various metal powders and wire feedstocks can be used, including titanium alloys, nickel-based superalloys, stainless steels, and aluminum alloys. The material properties such as thermal conductivity, melting point, and powder flowability affect the deposition process and final part quality. Multi-material deposition is also possible, allowing for functionally graded materials and components with varying properties throughout their structure.Expand Specific Solutions03 Energy Sources and Delivery Systems

Different energy sources can be employed in Directed Energy Deposition systems, including lasers, electron beams, plasma arcs, and other focused heat sources. The energy delivery system is crucial for controlling the melt pool size, temperature distribution, and solidification rate. Advanced systems incorporate real-time monitoring and closed-loop control to adjust energy input based on process conditions. The selection of an appropriate energy source depends on the material being processed, desired feature resolution, and production requirements.Expand Specific Solutions04 Process Monitoring and Quality Control

Effective monitoring and control systems are essential for ensuring the quality of parts produced using Directed Energy Deposition. These systems may include thermal cameras, high-speed imaging, pyrometers, and other sensors to monitor the melt pool dynamics, layer height, and overall build progress. Advanced systems incorporate machine learning algorithms to detect anomalies and make real-time adjustments to process parameters. Post-process inspection techniques such as CT scanning, ultrasonic testing, and mechanical testing are also employed to verify part integrity and performance.Expand Specific Solutions05 Hybrid Manufacturing and Industry Applications

Directed Energy Deposition is increasingly being integrated with traditional manufacturing processes to create hybrid manufacturing systems. These systems combine the advantages of additive manufacturing with those of subtractive processes like CNC machining. DED technology finds applications in various industries including aerospace, automotive, medical, and energy sectors. It is particularly valuable for component repair, part restoration, and the production of large-scale metal components. The ability to deposit material onto existing parts makes it suitable for adding features to previously manufactured components or repairing high-value parts.Expand Specific Solutions

Key Industry Players in Automotive DED Applications

Directed Energy Deposition (DED) in automotive innovation is currently in a growth phase, with the market expanding as manufacturers seek advanced manufacturing solutions. The technology is maturing rapidly, with key players demonstrating varying levels of expertise. Major automotive OEMs like GM, Volkswagen, Toyota, BMW, and Mercedes-Benz are investing in DED applications, while specialized technology providers such as GE Avio and Rolls-Royce are advancing technical capabilities. Academic institutions including Jilin University and Beihang University contribute significant research. The competitive landscape is characterized by collaboration between traditional automotive manufacturers and technology specialists, with companies like Bosch and Hitachi bridging the gap between automotive requirements and additive manufacturing capabilities. The technology shows promising applications in rapid prototyping, repair, and lightweight component manufacturing.

GE Avio Srl

Technical Solution: GE Avio has developed a sophisticated DED platform specifically for automotive and aerospace applications, focusing on high-temperature alloys and complex geometries. Their DMLM (Direct Metal Laser Melting) technology integrates with DED processes to create hybrid manufacturing solutions for automotive components. The company's proprietary powder delivery system ensures precise material deposition with minimal waste, achieving material utilization rates exceeding 90%. GE Avio's DED technology incorporates multi-axis deposition capabilities, allowing for the creation of complex overhanging features without support structures. Their system includes advanced thermal management to control residual stresses and microstructure development during deposition, resulting in parts with superior mechanical properties. The company has successfully implemented DED for manufacturing lightweight structural components for next-generation vehicles.

Strengths: Exceptional capability for processing high-temperature alloys and creating complex geometries impossible with traditional manufacturing. Excellent material efficiency. Weaknesses: Process speed limitations for large components and challenges with surface finish requiring post-processing operations.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has pioneered advanced DED applications in automotive and aerospace components manufacturing. Their proprietary BLISK (Bladed Disk) repair technology utilizes DED to restore high-value engine components with precision metal deposition. The company has developed a hybrid manufacturing approach combining DED with traditional machining in a single setup, allowing for both additive and subtractive processes. Their DED systems employ multiple powder feeders to create functionally graded materials with varying compositions throughout a single component, enabling optimized performance characteristics in different areas of the same part. Rolls-Royce has also implemented closed-loop monitoring systems that adjust deposition parameters in real-time based on thermal imaging and melt pool analysis, ensuring consistent material properties.

Strengths: Superior capability for repairing high-value components rather than replacement, reducing costs and waste. Excellent material utilization with near-net shape manufacturing. Weaknesses: Higher initial equipment investment compared to conventional manufacturing. Process requires significant expertise and parameter optimization for each application.

Critical Patents and Technical Literature Review

Multi-material components and methods of making the same

PatentWO2019040509A1

Innovation

- The method involves additively manufacturing multi-material components, where high stress regions are made from one material and high temperature regions from another, followed by forging to create a monolithic, integral component with tailored properties, using techniques like direct metal laser sintering and selective laser melting, and incorporating thermal treatments to achieve desired microstructures.

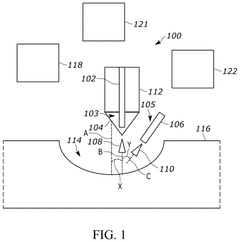

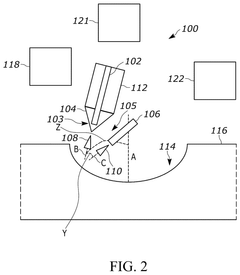

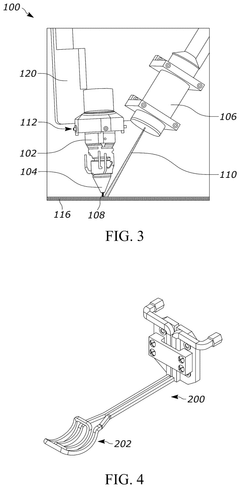

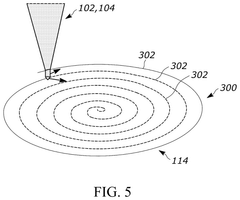

Directed energy deposition system and methods for component repairs

PatentPendingUS20250276379A1

Innovation

- A DED system employing multiple energy sources and a bi-directional spiral deposition pattern, combined with induction heating, to melt and uniformly fill concave cavities in jet engine components, using titanium aluminide powder, ensuring thermal distribution and adhesion to angled surfaces.

Material Science Advancements for DED in Automotive

The evolution of material science specifically for Directed Energy Deposition (DED) in automotive applications has witnessed significant advancements in recent years. Traditional automotive manufacturing has relied heavily on conventional materials like steel and aluminum alloys, but DED technology has expanded the material palette considerably, enabling the use of high-performance alloys, composites, and functionally graded materials that were previously impractical for automotive applications.

Powder-based materials have undergone substantial refinement to meet the specific requirements of DED processes in automotive manufacturing. These improvements include enhanced flowability, controlled particle size distribution, and increased purity levels, all contributing to more consistent deposition quality. Particularly noteworthy are the developments in nickel-based superalloys and titanium alloys that offer exceptional strength-to-weight ratios and thermal resistance properties critical for high-performance automotive components.

Wire-feed DED systems have similarly benefited from material science innovations, with new wire formulations designed specifically for automotive applications. These materials demonstrate improved deposition characteristics and reduced susceptibility to defects such as porosity and lack of fusion, which are critical factors in meeting automotive quality standards.

Multi-material capabilities represent perhaps the most transformative advancement in DED material science for automotive applications. Researchers have developed novel approaches for creating functionally graded materials that transition smoothly between different compositions, allowing for components with location-specific properties. This capability enables automotive engineers to design parts with wear resistance in high-friction areas while maintaining ductility and impact resistance elsewhere.

Surface engineering has emerged as another crucial area of material science advancement for automotive DED applications. Specialized coating materials have been developed that can be precisely deposited onto existing components, enhancing surface properties such as wear resistance, corrosion protection, and thermal barrier capabilities without affecting the bulk material properties.

Post-processing treatments have evolved in parallel with material developments, with heat treatment protocols specifically optimized for DED-manufactured automotive components. These treatments address the unique microstructural characteristics of additively manufactured materials, ensuring consistent mechanical properties throughout complex geometries.

The sustainability aspect of materials for automotive DED has gained increasing attention, with research focusing on recyclable powders and wires that minimize material waste while maintaining performance characteristics. This aligns with the automotive industry's broader sustainability goals and represents a significant advancement in responsible manufacturing practices.

Powder-based materials have undergone substantial refinement to meet the specific requirements of DED processes in automotive manufacturing. These improvements include enhanced flowability, controlled particle size distribution, and increased purity levels, all contributing to more consistent deposition quality. Particularly noteworthy are the developments in nickel-based superalloys and titanium alloys that offer exceptional strength-to-weight ratios and thermal resistance properties critical for high-performance automotive components.

Wire-feed DED systems have similarly benefited from material science innovations, with new wire formulations designed specifically for automotive applications. These materials demonstrate improved deposition characteristics and reduced susceptibility to defects such as porosity and lack of fusion, which are critical factors in meeting automotive quality standards.

Multi-material capabilities represent perhaps the most transformative advancement in DED material science for automotive applications. Researchers have developed novel approaches for creating functionally graded materials that transition smoothly between different compositions, allowing for components with location-specific properties. This capability enables automotive engineers to design parts with wear resistance in high-friction areas while maintaining ductility and impact resistance elsewhere.

Surface engineering has emerged as another crucial area of material science advancement for automotive DED applications. Specialized coating materials have been developed that can be precisely deposited onto existing components, enhancing surface properties such as wear resistance, corrosion protection, and thermal barrier capabilities without affecting the bulk material properties.

Post-processing treatments have evolved in parallel with material developments, with heat treatment protocols specifically optimized for DED-manufactured automotive components. These treatments address the unique microstructural characteristics of additively manufactured materials, ensuring consistent mechanical properties throughout complex geometries.

The sustainability aspect of materials for automotive DED has gained increasing attention, with research focusing on recyclable powders and wires that minimize material waste while maintaining performance characteristics. This aligns with the automotive industry's broader sustainability goals and represents a significant advancement in responsible manufacturing practices.

Sustainability and Cost-Efficiency Analysis

The sustainability and cost-efficiency aspects of Directed Energy Deposition (DED) technology in automotive applications represent critical factors for industry adoption. When evaluating DED against traditional manufacturing methods, material utilization rates demonstrate significant advantages, with DED achieving up to 90-95% material efficiency compared to conventional subtractive manufacturing's typical 20-40% efficiency. This dramatic reduction in material waste translates directly to cost savings and environmental benefits.

Energy consumption analysis reveals that DED processes, while energy-intensive during operation, offer lifecycle energy savings through reduced raw material processing requirements and streamlined production workflows. Quantitative assessments indicate potential energy reductions of 25-30% across the complete manufacturing chain when implementing DED for appropriate automotive components.

The economic model for DED implementation shows a distinct pattern: higher initial capital investment offset by reduced operational costs over time. Current market data indicates that automotive manufacturers implementing DED technology typically reach return on investment within 2-3 years for high-value, low-volume production scenarios. This timeline continues to improve as the technology matures and equipment costs decrease.

From an environmental perspective, DED contributes to sustainability through multiple pathways. The localized production capability reduces transportation emissions associated with complex supply chains. Additionally, the ability to repair and remanufacture components rather than replace them entirely extends product lifecycles significantly, with case studies demonstrating up to 70% reduction in replacement part requirements for certain applications.

Lifecycle assessment (LCA) studies comparing DED to conventional manufacturing for automotive components show reduced carbon footprints ranging from 15-40%, depending on component complexity and production volume. These environmental benefits become particularly pronounced when considering the entire product lifecycle, including maintenance and end-of-life considerations.

Cost modeling reveals that while DED currently presents higher per-unit production costs for simple, high-volume components, it offers substantial economic advantages for complex geometries, customized parts, and repair operations. The break-even point continues to shift toward higher production volumes as technology costs decrease and process efficiencies improve.

Future cost trajectories indicate accelerating economic viability as equipment costs decline approximately 8-12% annually while material and energy efficiencies continue to improve. This trend suggests DED will reach cost parity with traditional methods for an expanding range of automotive applications within the next 3-5 years.

Energy consumption analysis reveals that DED processes, while energy-intensive during operation, offer lifecycle energy savings through reduced raw material processing requirements and streamlined production workflows. Quantitative assessments indicate potential energy reductions of 25-30% across the complete manufacturing chain when implementing DED for appropriate automotive components.

The economic model for DED implementation shows a distinct pattern: higher initial capital investment offset by reduced operational costs over time. Current market data indicates that automotive manufacturers implementing DED technology typically reach return on investment within 2-3 years for high-value, low-volume production scenarios. This timeline continues to improve as the technology matures and equipment costs decrease.

From an environmental perspective, DED contributes to sustainability through multiple pathways. The localized production capability reduces transportation emissions associated with complex supply chains. Additionally, the ability to repair and remanufacture components rather than replace them entirely extends product lifecycles significantly, with case studies demonstrating up to 70% reduction in replacement part requirements for certain applications.

Lifecycle assessment (LCA) studies comparing DED to conventional manufacturing for automotive components show reduced carbon footprints ranging from 15-40%, depending on component complexity and production volume. These environmental benefits become particularly pronounced when considering the entire product lifecycle, including maintenance and end-of-life considerations.

Cost modeling reveals that while DED currently presents higher per-unit production costs for simple, high-volume components, it offers substantial economic advantages for complex geometries, customized parts, and repair operations. The break-even point continues to shift toward higher production volumes as technology costs decrease and process efficiencies improve.

Future cost trajectories indicate accelerating economic viability as equipment costs decline approximately 8-12% annually while material and energy efficiencies continue to improve. This trend suggests DED will reach cost parity with traditional methods for an expanding range of automotive applications within the next 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!