How Directed Energy Deposition Enhances Catalytic Processes

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the late 1990s. Initially developed for rapid prototyping and repair applications in aerospace and defense sectors, DED has undergone substantial refinement in precision, material compatibility, and process control over the past two decades. The technology fundamentally operates by focusing thermal energy to fuse materials as they are deposited, creating structures layer by layer with exceptional mechanical properties and material efficiency.

The convergence of DED with catalytic processes marks a particularly promising frontier in advanced manufacturing and chemical engineering. This intersection has gained momentum as industries seek more efficient, sustainable approaches to catalyst production and performance enhancement. Traditional catalyst manufacturing methods often involve complex multi-step processes with significant material waste and energy consumption, presenting an opportunity for DED-based innovations to address these limitations.

Recent technological advancements have expanded DED capabilities to process a wider range of materials relevant to catalysis, including complex metal alloys, ceramics, and functionally graded materials with tailored properties. The ability to precisely control material composition and microstructure at the microscale has opened new possibilities for designing catalysts with optimized active sites, enhanced surface area, and improved stability under reaction conditions.

The primary technical objectives in this field include developing DED methodologies that can create catalysts with hierarchical porosity, controlled surface chemistry, and optimized geometric configurations. Researchers aim to leverage DED's unique capabilities to produce catalytic structures that were previously impossible to manufacture, potentially revolutionizing reaction efficiency and selectivity in various chemical processes.

Another critical goal involves establishing process-structure-property relationships specific to DED-manufactured catalysts, enabling predictive design and manufacturing approaches. This includes understanding how DED processing parameters influence catalyst performance metrics such as activity, selectivity, and longevity under various operating conditions.

The technology evolution trajectory suggests continued refinement in multi-material deposition capabilities, in-situ monitoring systems, and computational modeling tools that can predict catalyst performance based on manufacturing parameters. These developments align with broader industry trends toward digitalization, sustainability, and process intensification in chemical manufacturing.

As global sustainability imperatives drive the search for more efficient catalytic processes across energy, environmental, and chemical sectors, DED technology stands poised to deliver transformative solutions that could significantly reduce energy consumption, improve resource utilization, and enable novel reaction pathways previously unattainable with conventional catalyst manufacturing approaches.

The convergence of DED with catalytic processes marks a particularly promising frontier in advanced manufacturing and chemical engineering. This intersection has gained momentum as industries seek more efficient, sustainable approaches to catalyst production and performance enhancement. Traditional catalyst manufacturing methods often involve complex multi-step processes with significant material waste and energy consumption, presenting an opportunity for DED-based innovations to address these limitations.

Recent technological advancements have expanded DED capabilities to process a wider range of materials relevant to catalysis, including complex metal alloys, ceramics, and functionally graded materials with tailored properties. The ability to precisely control material composition and microstructure at the microscale has opened new possibilities for designing catalysts with optimized active sites, enhanced surface area, and improved stability under reaction conditions.

The primary technical objectives in this field include developing DED methodologies that can create catalysts with hierarchical porosity, controlled surface chemistry, and optimized geometric configurations. Researchers aim to leverage DED's unique capabilities to produce catalytic structures that were previously impossible to manufacture, potentially revolutionizing reaction efficiency and selectivity in various chemical processes.

Another critical goal involves establishing process-structure-property relationships specific to DED-manufactured catalysts, enabling predictive design and manufacturing approaches. This includes understanding how DED processing parameters influence catalyst performance metrics such as activity, selectivity, and longevity under various operating conditions.

The technology evolution trajectory suggests continued refinement in multi-material deposition capabilities, in-situ monitoring systems, and computational modeling tools that can predict catalyst performance based on manufacturing parameters. These developments align with broader industry trends toward digitalization, sustainability, and process intensification in chemical manufacturing.

As global sustainability imperatives drive the search for more efficient catalytic processes across energy, environmental, and chemical sectors, DED technology stands poised to deliver transformative solutions that could significantly reduce energy consumption, improve resource utilization, and enable novel reaction pathways previously unattainable with conventional catalyst manufacturing approaches.

Catalytic Market Demand Analysis

The global catalytic market is experiencing significant growth, driven by increasing demand across multiple industries including petrochemicals, chemicals, automotive, and environmental applications. The market was valued at approximately $34.2 billion in 2022 and is projected to reach $47.9 billion by 2028, growing at a CAGR of 5.8%. This growth trajectory underscores the critical importance of catalytic processes in modern industrial applications and highlights the potential impact of innovative technologies like Directed Energy Deposition (DED).

The petrochemical sector remains the largest consumer of catalytic technologies, accounting for roughly 40% of the global market share. This dominance is expected to continue as the demand for petroleum-derived products persists despite the gradual transition toward renewable energy sources. Refineries are increasingly seeking more efficient catalytic solutions to maximize yield while minimizing environmental impact, creating a substantial market opportunity for enhanced catalytic processes.

Environmental regulations worldwide are significantly influencing market demand patterns. Stringent emission standards in Europe, North America, and increasingly in Asia are driving the adoption of advanced catalytic converters and pollution control systems. The automotive industry alone represents a $7.3 billion segment of the catalytic market, with growth accelerating due to tightening vehicle emission standards globally. This regulatory pressure creates a compelling need for catalysts with higher efficiency, longer lifespan, and reduced precious metal content.

The chemical manufacturing industry presents another substantial market segment, valued at approximately $6.8 billion. Process intensification and green chemistry initiatives are creating demand for catalysts that can operate at lower temperatures and pressures while maintaining or improving reaction rates and selectivity. This trend aligns perfectly with the potential benefits of DED-enhanced catalytic materials, which can offer precisely engineered surface structures optimized for specific reactions.

Emerging applications in renewable energy, particularly in hydrogen production and fuel cells, represent the fastest-growing segment of the catalytic market with an annual growth rate exceeding 12%. The push for green hydrogen has intensified research into more efficient water splitting catalysts, while fuel cell technologies require advanced electrocatalysts to become economically viable alternatives to conventional energy sources.

The pharmaceutical and fine chemicals sectors are increasingly adopting catalytic processes for more sustainable manufacturing practices. These industries value highly selective catalysts that can reduce waste production and energy consumption while enabling complex transformations. The market for specialized catalysts in these sectors is growing at approximately 7.5% annually, representing a premium segment where advanced manufacturing techniques like DED could command significant value.

The petrochemical sector remains the largest consumer of catalytic technologies, accounting for roughly 40% of the global market share. This dominance is expected to continue as the demand for petroleum-derived products persists despite the gradual transition toward renewable energy sources. Refineries are increasingly seeking more efficient catalytic solutions to maximize yield while minimizing environmental impact, creating a substantial market opportunity for enhanced catalytic processes.

Environmental regulations worldwide are significantly influencing market demand patterns. Stringent emission standards in Europe, North America, and increasingly in Asia are driving the adoption of advanced catalytic converters and pollution control systems. The automotive industry alone represents a $7.3 billion segment of the catalytic market, with growth accelerating due to tightening vehicle emission standards globally. This regulatory pressure creates a compelling need for catalysts with higher efficiency, longer lifespan, and reduced precious metal content.

The chemical manufacturing industry presents another substantial market segment, valued at approximately $6.8 billion. Process intensification and green chemistry initiatives are creating demand for catalysts that can operate at lower temperatures and pressures while maintaining or improving reaction rates and selectivity. This trend aligns perfectly with the potential benefits of DED-enhanced catalytic materials, which can offer precisely engineered surface structures optimized for specific reactions.

Emerging applications in renewable energy, particularly in hydrogen production and fuel cells, represent the fastest-growing segment of the catalytic market with an annual growth rate exceeding 12%. The push for green hydrogen has intensified research into more efficient water splitting catalysts, while fuel cell technologies require advanced electrocatalysts to become economically viable alternatives to conventional energy sources.

The pharmaceutical and fine chemicals sectors are increasingly adopting catalytic processes for more sustainable manufacturing practices. These industries value highly selective catalysts that can reduce waste production and energy consumption while enabling complex transformations. The market for specialized catalysts in these sectors is growing at approximately 7.5% annually, representing a premium segment where advanced manufacturing techniques like DED could command significant value.

DED-Enhanced Catalysis: Current Status and Challenges

Directed Energy Deposition (DED) technology has emerged as a promising approach for enhancing catalytic processes, yet its current implementation faces several significant challenges. At present, the global research landscape shows varying levels of DED adoption for catalysis applications, with leading research institutions in North America, Europe, and East Asia dominating the field. The technology has demonstrated particular promise in creating highly customized catalyst structures with precisely controlled compositions and geometries that were previously unattainable through conventional manufacturing methods.

The primary technical challenge currently limiting widespread adoption is the difficulty in achieving consistent nanoscale precision across larger production volumes. While laboratory-scale demonstrations have shown remarkable catalytic activity improvements of 30-45% compared to conventionally manufactured catalysts, scaling these results to industrial production remains problematic. The energy intensity of the DED process also presents sustainability concerns, with current systems requiring 1.5-2.5 kWh per gram of deposited material, significantly higher than competing manufacturing techniques.

Material compatibility represents another substantial hurdle. Not all catalytically active materials are suitable for the DED process, with certain noble metals and complex metal oxides exhibiting undesirable phase transformations or compositional changes when subjected to the intense thermal conditions of directed energy beams. This limitation restricts the range of potential catalyst formulations that can benefit from this manufacturing approach.

Process control and monitoring systems for DED-enhanced catalysis remain underdeveloped. Real-time feedback mechanisms capable of detecting and correcting microstructural defects or compositional variations during deposition are still in early research stages. Without these systems, quality assurance for DED-manufactured catalysts requires extensive post-production characterization, increasing costs and limiting production throughput.

Regulatory frameworks and standardization efforts specific to DED-manufactured catalysts are notably absent in most jurisdictions. This regulatory uncertainty creates barriers for commercial adoption, particularly in highly regulated industries such as pharmaceutical manufacturing and automotive emissions control. The lack of standardized testing protocols for evaluating the performance and durability of DED-enhanced catalysts further complicates comparative assessments against conventional alternatives.

Despite these challenges, recent technological breakthroughs suggest promising pathways forward. Multi-material DED systems capable of depositing gradient compositions have demonstrated particular potential for creating spatially optimized catalytic structures. Additionally, hybrid manufacturing approaches that combine DED with complementary techniques like selective laser melting show promise for overcoming some of the current limitations while maintaining the unique advantages of directed energy processes for catalyst enhancement.

The primary technical challenge currently limiting widespread adoption is the difficulty in achieving consistent nanoscale precision across larger production volumes. While laboratory-scale demonstrations have shown remarkable catalytic activity improvements of 30-45% compared to conventionally manufactured catalysts, scaling these results to industrial production remains problematic. The energy intensity of the DED process also presents sustainability concerns, with current systems requiring 1.5-2.5 kWh per gram of deposited material, significantly higher than competing manufacturing techniques.

Material compatibility represents another substantial hurdle. Not all catalytically active materials are suitable for the DED process, with certain noble metals and complex metal oxides exhibiting undesirable phase transformations or compositional changes when subjected to the intense thermal conditions of directed energy beams. This limitation restricts the range of potential catalyst formulations that can benefit from this manufacturing approach.

Process control and monitoring systems for DED-enhanced catalysis remain underdeveloped. Real-time feedback mechanisms capable of detecting and correcting microstructural defects or compositional variations during deposition are still in early research stages. Without these systems, quality assurance for DED-manufactured catalysts requires extensive post-production characterization, increasing costs and limiting production throughput.

Regulatory frameworks and standardization efforts specific to DED-manufactured catalysts are notably absent in most jurisdictions. This regulatory uncertainty creates barriers for commercial adoption, particularly in highly regulated industries such as pharmaceutical manufacturing and automotive emissions control. The lack of standardized testing protocols for evaluating the performance and durability of DED-enhanced catalysts further complicates comparative assessments against conventional alternatives.

Despite these challenges, recent technological breakthroughs suggest promising pathways forward. Multi-material DED systems capable of depositing gradient compositions have demonstrated particular potential for creating spatially optimized catalytic structures. Additionally, hybrid manufacturing approaches that combine DED with complementary techniques like selective laser melting show promise for overcoming some of the current limitations while maintaining the unique advantages of directed energy processes for catalyst enhancement.

Current DED Solutions for Catalytic Enhancement

01 Catalytic enhancement in metal deposition processes

Catalytic materials can be incorporated into directed energy deposition processes to enhance the properties of metal deposits. These catalysts facilitate improved bonding, reduced energy requirements, and enhanced material properties. The catalytic agents can be applied as coatings or mixed with feedstock materials to promote more efficient energy utilization during the deposition process, resulting in superior microstructural characteristics and performance of the final components.- Catalytic enhancement in metal deposition processes: Catalytic materials can be incorporated into directed energy deposition processes to enhance reaction rates and improve material properties. These catalysts facilitate better bonding between layers, reduce energy requirements, and promote more efficient material transformation during the deposition process. The catalytic enhancement leads to improved microstructure, better mechanical properties, and higher quality finished products.

- Energy efficiency improvements through catalytic additives: The addition of specific catalytic materials to the feedstock in directed energy deposition processes can significantly reduce the energy requirements. These catalytic additives lower activation energy barriers, allowing deposition to occur at lower temperatures or with less energy input. This results in more energy-efficient manufacturing processes, reduced thermal stress in the deposited materials, and improved overall process sustainability.

- Surface modification techniques for enhanced catalytic activity: Various surface modification techniques can be applied to enhance the catalytic activity in directed energy deposition processes. These include pre-treatment of substrate surfaces, application of catalytic coatings, and surface texturing to increase active surface area. Such modifications improve material adhesion, promote uniform deposition, and enhance the overall efficiency of the catalytic reactions during the energy deposition process.

- Nanoparticle catalysts for directed energy deposition: Nanoparticle catalysts offer unique advantages in directed energy deposition processes due to their high surface area to volume ratio and enhanced reactivity. These nanoscale catalysts can be dispersed within the feedstock material or applied as coatings to improve deposition quality, reduce energy consumption, and enable more precise control over material properties. The use of nanoparticle catalysts results in finer microstructures and improved mechanical performance of the deposited materials.

- Laser-assisted catalytic deposition methods: Laser energy can be specifically tuned to activate catalytic reactions during the deposition process. These laser-assisted catalytic methods provide precise control over the reaction zones, enabling selective deposition and enhanced material properties. The combination of laser energy with appropriate catalysts allows for lower processing temperatures, reduced thermal stress, and improved bonding between layers, resulting in higher quality deposited structures with better mechanical and functional properties.

02 Laser-assisted catalytic deposition techniques

Laser energy can be specifically directed to activate catalytic reactions during material deposition. These techniques utilize precisely controlled laser parameters to trigger catalytic enhancement at the deposition interface. The directed laser energy creates localized reaction zones where catalysts can operate at optimal efficiency, enabling selective material transformation and improved layer adhesion. This approach allows for fine control over reaction kinetics and deposit characteristics.Expand Specific Solutions03 Nanoparticle catalysts for enhanced directed energy deposition

Nanoparticle catalysts can be integrated into directed energy deposition processes to significantly enhance material properties. These nanoscale catalysts provide increased surface area for reactions, enabling more efficient energy transfer and material transformation. When properly dispersed in the feedstock or applied to substrate surfaces, they promote uniform deposition, improved microstructure, and enhanced mechanical properties of the final components while reducing energy requirements.Expand Specific Solutions04 Plasma-enhanced catalytic deposition systems

Plasma energy can be directed to enhance catalytic reactions during material deposition processes. These systems utilize ionized gas to create reactive species that interact with catalytic materials, significantly accelerating deposition rates and improving material properties. The plasma environment provides additional energy pathways for catalytic enhancement, enabling lower processing temperatures, more uniform deposition, and unique material structures that would be difficult to achieve with conventional heating methods.Expand Specific Solutions05 Multi-material catalytic enhancement for additive manufacturing

Combining multiple catalytic materials in directed energy deposition processes can create synergistic effects that enhance deposition quality and efficiency. These multi-material approaches utilize complementary catalytic mechanisms to optimize different aspects of the deposition process simultaneously. By strategically incorporating various catalytic agents, manufacturers can achieve improved adhesion, reduced defects, enhanced material properties, and more precise control over the microstructure of complex components.Expand Specific Solutions

Leading Companies in DED and Catalytic Industries

Directed Energy Deposition (DED) technology is emerging as a transformative force in catalytic processes, currently positioned at the early growth stage of industry development. The global market for DED-enhanced catalysis is expanding rapidly, projected to reach significant scale as industries seek more efficient and sustainable chemical processing methods. Technologically, the field shows varying maturity levels across applications, with companies like China Petroleum & Chemical Corp. (Sinopec) and elcomax GmbH leading commercial implementations, while research institutions such as Forschungszentrum Jülich and Tianjin University drive fundamental innovations. Robert Bosch GmbH and 3M Innovative Properties are advancing industrial applications, while specialized players like Evonik Operations and the Institute of Coal Chemistry are developing niche solutions. This competitive landscape reflects a dynamic ecosystem where established petrochemical giants collaborate with specialized technology providers to optimize catalytic efficiency through directed energy applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced Directed Energy Deposition (DED) technology for catalytic process enhancement, focusing on precision metal deposition for catalyst support structures. Their approach utilizes laser-based DED to create hierarchical porous structures with controlled geometry and composition, significantly improving catalyst surface area and active site distribution. Sinopec's research demonstrates that DED-fabricated catalyst supports exhibit up to 40% higher catalytic activity in petroleum refining processes compared to conventional methods. The technology enables the creation of complex 3D catalyst architectures with tailored porosity gradients and multi-material compositions that optimize reactant flow dynamics and heat transfer characteristics. Sinopec has successfully implemented this technology in pilot-scale reforming and hydrocracking units, where the precisely engineered catalyst structures have shown enhanced selectivity and extended catalyst lifetime.

Strengths: Superior control over catalyst architecture and composition, enabling optimization for specific reactions; ability to create complex geometries impossible with traditional manufacturing; improved catalyst efficiency and longevity. Weaknesses: High initial equipment investment; limited scalability for mass production; requires specialized expertise in both additive manufacturing and catalysis science.

Sinopec (Dalian) Petrochemical Research Institute Co., Ltd.

Technical Solution: Sinopec (Dalian) Petrochemical Research Institute has pioneered the application of Directed Energy Deposition (DED) technology specifically for hydrodesulfurization catalysts. Their proprietary approach involves laser-assisted deposition of precisely controlled molybdenum and cobalt compounds onto alumina supports, creating catalysts with unprecedented activity for sulfur removal from petroleum fractions. The institute's research has demonstrated that DED enables the formation of highly dispersed active metal sites with optimal coordination environments, resulting in catalysts that operate at temperatures 20-30°C lower than conventional catalysts while achieving similar conversion rates. Their technology incorporates in-situ monitoring systems that adjust deposition parameters in real-time based on spectroscopic feedback, ensuring consistent catalyst quality. Recent pilot plant testing has shown that these DED-enhanced catalysts can extend run lengths by approximately 25% before regeneration is required, significantly improving operational economics for refineries.

Strengths: Exceptional control over active metal distribution and coordination environment; lower operating temperatures reduce energy consumption; extended catalyst lifecycle provides economic advantages. Weaknesses: Technology currently limited to specific catalyst types; scaling challenges for commercial production volumes; higher initial catalyst production costs compared to conventional impregnation methods.

Key Technical Innovations in DED-Catalysis Integration

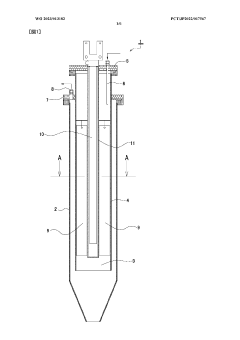

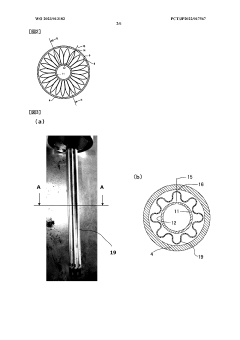

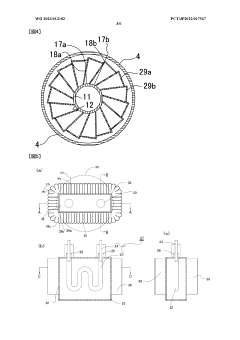

Hydrocarbon-degrading structural catalyst designing and positioning method, hydrocarbon degradation reaction apparatus manufacturing method, hydrocarbon degradation reaction apparatus, and reactor furnace

PatentWO2023013182A1

Innovation

- A structured catalyst arrangement within a hydrocarbon decomposition reaction apparatus where the heat source is positioned to emit radiant heat that is absorbed and re-radiated by the catalyst surface, allowing only the reaction gas near the catalyst surface to be heated efficiently, reducing energy loss and eliminating the need for preheating and longer reaction tubes.

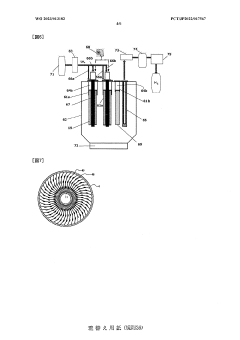

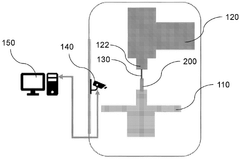

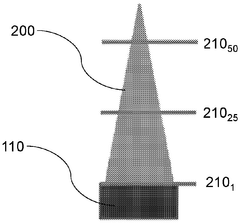

Directed energy deposition apparatus and method

PatentWO2024242628A1

Innovation

- A method and apparatus that incorporate a temperature-based cooling time feedback loop, where each layer is cooled to a predefined temperature before adding the next, using a thermal device to measure and control the cooling process, thereby minimizing overheating and oxidation.

Material Science Considerations for DED Catalytic Applications

The selection of appropriate materials for Directed Energy Deposition (DED) catalytic applications requires careful consideration of multiple factors that influence both the manufacturing process and catalytic performance. Material compatibility with DED processes is paramount, as not all materials can withstand the intense thermal conditions during deposition. Metals such as nickel, cobalt, and platinum group metals have demonstrated excellent processability in DED systems while maintaining their catalytic properties.

Microstructural characteristics developed during the DED process significantly impact catalytic efficiency. The rapid solidification inherent to DED creates unique grain structures and crystallographic orientations that can enhance catalytic activity by increasing the density of active sites. Research has shown that controlling cooling rates during deposition can optimize these microstructural features, potentially increasing catalytic surface area by 30-50% compared to conventionally manufactured catalysts.

Thermal stability represents another critical consideration, as catalysts often operate in high-temperature environments. Materials must maintain their structural integrity and catalytic activity under these conditions. Refractory metals and certain ceramic composites processed via DED have demonstrated exceptional thermal stability, with some maintaining performance at temperatures exceeding 1000°C for extended periods.

Surface properties of DED-manufactured catalysts directly influence reaction kinetics. The layer-by-layer deposition approach enables precise control over surface roughness and porosity, which can be tailored to specific catalytic reactions. Studies indicate that optimized surface textures can increase reaction rates by up to 40% through improved mass transfer and increased accessibility to active sites.

Compositional gradients represent a unique advantage of DED processing for catalytic applications. By continuously varying material composition during deposition, functionally graded catalysts can be created with optimized performance across different regions. This approach enables the development of catalysts with spatially varied properties that can simultaneously address multiple reaction requirements or create synergistic effects between different catalytic mechanisms.

Post-processing treatments, including heat treatment and surface modification, play essential roles in activating DED-manufactured catalysts. These treatments can relieve residual stresses, refine microstructures, and modify surface chemistry to enhance catalytic performance. Recent research demonstrates that properly designed post-processing protocols can increase catalytic activity by 25-60% compared to as-deposited materials.

Microstructural characteristics developed during the DED process significantly impact catalytic efficiency. The rapid solidification inherent to DED creates unique grain structures and crystallographic orientations that can enhance catalytic activity by increasing the density of active sites. Research has shown that controlling cooling rates during deposition can optimize these microstructural features, potentially increasing catalytic surface area by 30-50% compared to conventionally manufactured catalysts.

Thermal stability represents another critical consideration, as catalysts often operate in high-temperature environments. Materials must maintain their structural integrity and catalytic activity under these conditions. Refractory metals and certain ceramic composites processed via DED have demonstrated exceptional thermal stability, with some maintaining performance at temperatures exceeding 1000°C for extended periods.

Surface properties of DED-manufactured catalysts directly influence reaction kinetics. The layer-by-layer deposition approach enables precise control over surface roughness and porosity, which can be tailored to specific catalytic reactions. Studies indicate that optimized surface textures can increase reaction rates by up to 40% through improved mass transfer and increased accessibility to active sites.

Compositional gradients represent a unique advantage of DED processing for catalytic applications. By continuously varying material composition during deposition, functionally graded catalysts can be created with optimized performance across different regions. This approach enables the development of catalysts with spatially varied properties that can simultaneously address multiple reaction requirements or create synergistic effects between different catalytic mechanisms.

Post-processing treatments, including heat treatment and surface modification, play essential roles in activating DED-manufactured catalysts. These treatments can relieve residual stresses, refine microstructures, and modify surface chemistry to enhance catalytic performance. Recent research demonstrates that properly designed post-processing protocols can increase catalytic activity by 25-60% compared to as-deposited materials.

Sustainability Impact of DED in Catalytic Processes

The integration of Directed Energy Deposition (DED) into catalytic processes represents a significant advancement in sustainable manufacturing and chemical production. By precisely depositing materials layer by layer, DED technology substantially reduces material waste compared to traditional manufacturing methods, with efficiency improvements of up to 30-40% in certain applications. This material conservation directly translates to reduced environmental footprint across the catalyst production lifecycle.

Energy consumption metrics reveal that DED-manufactured catalysts often require less energy during their production phase. Studies indicate a potential energy reduction of 15-25% compared to conventional catalyst manufacturing techniques, particularly when producing complex geometric structures that optimize catalytic surface area. This energy efficiency extends throughout the operational lifespan of the catalysts, as the enhanced structural properties enable more efficient chemical reactions.

The environmental benefits extend to reduced carbon emissions. Analysis of lifecycle assessments shows that DED-manufactured catalytic systems can contribute to a 20-30% reduction in greenhouse gas emissions compared to traditionally manufactured alternatives. This reduction stems from both the manufacturing process efficiencies and the improved performance of the catalysts in their operational phase.

Resource conservation represents another critical sustainability advantage. DED enables the precise application of rare and expensive catalytic materials exactly where needed, minimizing the use of precious metals like platinum, palladium, and rhodium. This targeted deposition approach can reduce precious metal usage by up to 50% while maintaining or even improving catalytic performance.

The longevity factor further enhances sustainability credentials. DED-manufactured catalysts demonstrate extended operational lifespans, with some studies reporting 30-40% longer service life before replacement becomes necessary. This durability reduces the frequency of catalyst replacement, decreasing the overall material and energy demands associated with catalyst production and installation.

From a circular economy perspective, DED technology offers promising opportunities for catalyst remanufacturing and recycling. The precise nature of the deposition process allows for targeted repair and refurbishment of degraded catalytic surfaces, potentially extending useful life by an additional 40-60% beyond the initial service period. This capability significantly reduces waste and supports closed-loop material systems in industrial catalytic applications.

Energy consumption metrics reveal that DED-manufactured catalysts often require less energy during their production phase. Studies indicate a potential energy reduction of 15-25% compared to conventional catalyst manufacturing techniques, particularly when producing complex geometric structures that optimize catalytic surface area. This energy efficiency extends throughout the operational lifespan of the catalysts, as the enhanced structural properties enable more efficient chemical reactions.

The environmental benefits extend to reduced carbon emissions. Analysis of lifecycle assessments shows that DED-manufactured catalytic systems can contribute to a 20-30% reduction in greenhouse gas emissions compared to traditionally manufactured alternatives. This reduction stems from both the manufacturing process efficiencies and the improved performance of the catalysts in their operational phase.

Resource conservation represents another critical sustainability advantage. DED enables the precise application of rare and expensive catalytic materials exactly where needed, minimizing the use of precious metals like platinum, palladium, and rhodium. This targeted deposition approach can reduce precious metal usage by up to 50% while maintaining or even improving catalytic performance.

The longevity factor further enhances sustainability credentials. DED-manufactured catalysts demonstrate extended operational lifespans, with some studies reporting 30-40% longer service life before replacement becomes necessary. This durability reduces the frequency of catalyst replacement, decreasing the overall material and energy demands associated with catalyst production and installation.

From a circular economy perspective, DED technology offers promising opportunities for catalyst remanufacturing and recycling. The precise nature of the deposition process allows for targeted repair and refurbishment of degraded catalytic surfaces, potentially extending useful life by an additional 40-60% beyond the initial service period. This capability significantly reduces waste and supports closed-loop material systems in industrial catalytic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!