Sensor Integration in Directed Energy Deposition Manufacturing

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Sensor Integration Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the late 1990s. This metal-based process utilizes focused thermal energy to fuse materials as they are deposited, enabling the creation of complex geometries and functionally graded materials. The technology has progressed from rudimentary systems with limited control capabilities to sophisticated platforms incorporating multiple energy sources, multi-axis deposition systems, and advanced material handling mechanisms.

The integration of sensors within DED systems has become increasingly critical as manufacturing industries demand higher precision, repeatability, and quality assurance. Early DED systems operated primarily in open-loop configurations, relying on pre-programmed parameters without real-time adjustments. This approach resulted in inconsistent build quality and limited the technology's adoption in high-value applications such as aerospace and medical device manufacturing.

Current technological trends indicate a decisive shift toward closed-loop control systems enabled by comprehensive sensor integration. This evolution is driven by the need to address persistent challenges in DED manufacturing, including thermal management, dimensional accuracy, material property consistency, and defect prevention. The industry is witnessing convergence between additive manufacturing technologies and Industry 4.0 principles, where data-driven decision-making and autonomous process control are paramount.

The primary objective of sensor integration in DED manufacturing is to establish robust process monitoring and control capabilities that can detect and respond to process variations in real-time. This includes thermal condition monitoring, melt pool dynamics analysis, layer geometry verification, and material feed rate optimization. By implementing multi-modal sensing approaches, manufacturers aim to create digital twins of the manufacturing process that enable predictive quality control rather than reactive inspection procedures.

Secondary objectives include the development of standardized sensor integration frameworks that can be implemented across different DED platforms, facilitating technology transfer and consistent quality metrics. Additionally, there is growing interest in utilizing sensor data for machine learning applications that can optimize process parameters automatically based on historical performance data and desired part characteristics.

The long-term vision for sensor-integrated DED systems encompasses fully autonomous manufacturing capabilities where the system can self-calibrate, detect anomalies, implement corrective actions, and validate part quality without human intervention. This represents a paradigm shift from traditional manufacturing approaches and aligns with broader industry goals of reducing production costs while enhancing component performance and reliability.

The integration of sensors within DED systems has become increasingly critical as manufacturing industries demand higher precision, repeatability, and quality assurance. Early DED systems operated primarily in open-loop configurations, relying on pre-programmed parameters without real-time adjustments. This approach resulted in inconsistent build quality and limited the technology's adoption in high-value applications such as aerospace and medical device manufacturing.

Current technological trends indicate a decisive shift toward closed-loop control systems enabled by comprehensive sensor integration. This evolution is driven by the need to address persistent challenges in DED manufacturing, including thermal management, dimensional accuracy, material property consistency, and defect prevention. The industry is witnessing convergence between additive manufacturing technologies and Industry 4.0 principles, where data-driven decision-making and autonomous process control are paramount.

The primary objective of sensor integration in DED manufacturing is to establish robust process monitoring and control capabilities that can detect and respond to process variations in real-time. This includes thermal condition monitoring, melt pool dynamics analysis, layer geometry verification, and material feed rate optimization. By implementing multi-modal sensing approaches, manufacturers aim to create digital twins of the manufacturing process that enable predictive quality control rather than reactive inspection procedures.

Secondary objectives include the development of standardized sensor integration frameworks that can be implemented across different DED platforms, facilitating technology transfer and consistent quality metrics. Additionally, there is growing interest in utilizing sensor data for machine learning applications that can optimize process parameters automatically based on historical performance data and desired part characteristics.

The long-term vision for sensor-integrated DED systems encompasses fully autonomous manufacturing capabilities where the system can self-calibrate, detect anomalies, implement corrective actions, and validate part quality without human intervention. This represents a paradigm shift from traditional manufacturing approaches and aligns with broader industry goals of reducing production costs while enhancing component performance and reliability.

Market Analysis for Sensor-Enabled DED Systems

The global market for sensor-enabled Directed Energy Deposition (DED) systems is experiencing robust growth, driven by increasing demand for advanced manufacturing solutions across aerospace, automotive, healthcare, and energy sectors. Current market valuations indicate that the additive manufacturing industry, within which DED technology operates, reached approximately $15 billion in 2022, with sensor-integrated systems representing a rapidly expanding segment projected to grow at a compound annual rate of 25% through 2028.

The aerospace industry remains the primary adopter of sensor-enabled DED technology, accounting for roughly 40% of the market share. This dominance stems from the sector's stringent quality requirements and the need for complex, lightweight components with superior mechanical properties. The automotive industry follows closely, representing about 30% of market demand, particularly as manufacturers transition toward electric vehicle production requiring specialized metal components.

Healthcare applications, especially in medical implant manufacturing, constitute approximately 15% of the market, with significant growth potential as personalized medicine advances. The remaining market share is distributed across energy, defense, and general industrial applications, each contributing to the expanding ecosystem of sensor-integrated additive manufacturing.

Regional analysis reveals North America leading the market with approximately 45% share, bolstered by substantial R&D investments and the presence of major industry players like GE Additive, EOS, and 3D Systems. Europe follows with 30% market share, demonstrating strong adoption in aerospace and automotive manufacturing hubs. The Asia-Pacific region, particularly China, Japan, and South Korea, represents the fastest-growing market at 35% annual growth, driven by aggressive government initiatives to modernize manufacturing capabilities.

Customer segmentation indicates that large enterprises currently dominate adoption rates, accounting for 65% of purchases. However, the mid-market segment is showing accelerated growth as system costs decrease and turnkey solutions become more accessible. Small manufacturers typically access this technology through service bureaus rather than direct acquisition.

The economic value proposition of sensor-enabled DED systems centers on waste reduction, with material utilization rates exceeding 95% compared to 20-30% in traditional subtractive manufacturing. Additionally, real-time quality monitoring reduces scrap rates by an estimated 40%, while decreasing post-processing inspection costs by up to 60%. These efficiency gains translate to an average return on investment period of 18-24 months for high-volume production environments.

The aerospace industry remains the primary adopter of sensor-enabled DED technology, accounting for roughly 40% of the market share. This dominance stems from the sector's stringent quality requirements and the need for complex, lightweight components with superior mechanical properties. The automotive industry follows closely, representing about 30% of market demand, particularly as manufacturers transition toward electric vehicle production requiring specialized metal components.

Healthcare applications, especially in medical implant manufacturing, constitute approximately 15% of the market, with significant growth potential as personalized medicine advances. The remaining market share is distributed across energy, defense, and general industrial applications, each contributing to the expanding ecosystem of sensor-integrated additive manufacturing.

Regional analysis reveals North America leading the market with approximately 45% share, bolstered by substantial R&D investments and the presence of major industry players like GE Additive, EOS, and 3D Systems. Europe follows with 30% market share, demonstrating strong adoption in aerospace and automotive manufacturing hubs. The Asia-Pacific region, particularly China, Japan, and South Korea, represents the fastest-growing market at 35% annual growth, driven by aggressive government initiatives to modernize manufacturing capabilities.

Customer segmentation indicates that large enterprises currently dominate adoption rates, accounting for 65% of purchases. However, the mid-market segment is showing accelerated growth as system costs decrease and turnkey solutions become more accessible. Small manufacturers typically access this technology through service bureaus rather than direct acquisition.

The economic value proposition of sensor-enabled DED systems centers on waste reduction, with material utilization rates exceeding 95% compared to 20-30% in traditional subtractive manufacturing. Additionally, real-time quality monitoring reduces scrap rates by an estimated 40%, while decreasing post-processing inspection costs by up to 60%. These efficiency gains translate to an average return on investment period of 18-24 months for high-volume production environments.

Current Sensor Technologies and Challenges in DED

Directed Energy Deposition (DED) manufacturing processes currently employ a variety of sensor technologies to monitor and control the complex additive manufacturing environment. Thermal sensors, including infrared cameras and pyrometers, represent the most widely implemented sensing technology in DED systems. These sensors provide critical temperature measurements of the melt pool, substrate, and surrounding areas, enabling real-time thermal profile monitoring. However, they face significant challenges including calibration difficulties due to varying material emissivity, limited spatial resolution, and interference from process emissions.

Optical sensors constitute another major category, with high-speed cameras and photodiodes being utilized to capture melt pool geometry, powder flow characteristics, and layer formation. These systems often incorporate specialized filters to reduce noise from plasma emissions and thermal radiation. Despite their utility, optical sensors struggle with obscuration from metal vapor, spatter, and powder particles, which can significantly degrade image quality and measurement accuracy.

Acoustic emission sensors have emerged as valuable tools for detecting defects and process anomalies by monitoring the sound waves generated during material deposition. These sensors can identify issues such as porosity formation, cracking, and delamination through characteristic acoustic signatures. The primary limitations include high sensitivity to environmental noise and the complex signal processing required to extract meaningful data from the acoustic waveforms.

Force and pressure sensors monitor mechanical aspects of the DED process, including nozzle back-pressure and substrate deformation. These measurements provide insights into powder flow consistency and build integrity but are often affected by the harsh thermal conditions of the build environment, leading to drift and calibration issues over extended manufacturing runs.

Integration challenges persist across all sensor types in DED systems. The extreme thermal gradients, electromagnetic interference from power sources, and metal vapor deposition on sensor components significantly reduce sensor lifespan and reliability. Additionally, the high-speed nature of DED processes demands sensors with rapid response times and high sampling rates, which increases system complexity and cost.

Data fusion represents perhaps the most significant challenge in current DED sensor integration. Individual sensors provide limited process information, necessitating multi-sensor approaches that combine thermal, optical, and mechanical measurements. However, synchronizing these diverse data streams and extracting actionable information in real-time remains technically challenging, requiring sophisticated algorithms and computing resources that add complexity to DED systems.

Miniaturization constraints further complicate sensor integration, as the limited space within DED print heads restricts sensor placement options, often forcing compromises between measurement accuracy and practical implementation.

Optical sensors constitute another major category, with high-speed cameras and photodiodes being utilized to capture melt pool geometry, powder flow characteristics, and layer formation. These systems often incorporate specialized filters to reduce noise from plasma emissions and thermal radiation. Despite their utility, optical sensors struggle with obscuration from metal vapor, spatter, and powder particles, which can significantly degrade image quality and measurement accuracy.

Acoustic emission sensors have emerged as valuable tools for detecting defects and process anomalies by monitoring the sound waves generated during material deposition. These sensors can identify issues such as porosity formation, cracking, and delamination through characteristic acoustic signatures. The primary limitations include high sensitivity to environmental noise and the complex signal processing required to extract meaningful data from the acoustic waveforms.

Force and pressure sensors monitor mechanical aspects of the DED process, including nozzle back-pressure and substrate deformation. These measurements provide insights into powder flow consistency and build integrity but are often affected by the harsh thermal conditions of the build environment, leading to drift and calibration issues over extended manufacturing runs.

Integration challenges persist across all sensor types in DED systems. The extreme thermal gradients, electromagnetic interference from power sources, and metal vapor deposition on sensor components significantly reduce sensor lifespan and reliability. Additionally, the high-speed nature of DED processes demands sensors with rapid response times and high sampling rates, which increases system complexity and cost.

Data fusion represents perhaps the most significant challenge in current DED sensor integration. Individual sensors provide limited process information, necessitating multi-sensor approaches that combine thermal, optical, and mechanical measurements. However, synchronizing these diverse data streams and extracting actionable information in real-time remains technically challenging, requiring sophisticated algorithms and computing resources that add complexity to DED systems.

Miniaturization constraints further complicate sensor integration, as the limited space within DED print heads restricts sensor placement options, often forcing compromises between measurement accuracy and practical implementation.

Existing Sensor Integration Approaches for DED

01 Real-time monitoring systems for DED processes

Integration of sensors for real-time monitoring of directed energy deposition processes allows for continuous quality control and process optimization. These systems typically include thermal cameras, optical sensors, and spectrometers that can detect variations in melt pool temperature, geometry, and material composition during deposition. The data collected enables closed-loop control systems to make immediate adjustments to process parameters, ensuring consistent build quality and reducing defects.- Real-time monitoring systems for DED processes: Integration of sensors for real-time monitoring of directed energy deposition processes enables continuous quality control and process optimization. These systems typically include thermal cameras, optical sensors, and spectrometers that track melt pool characteristics, material deposition rates, and thermal gradients. Real-time monitoring allows for immediate detection of defects or process anomalies, enabling automatic adjustments to process parameters such as laser power, feed rate, or deposition path to maintain consistent build quality.

- Closed-loop feedback control systems: Closed-loop feedback control systems in directed energy deposition utilize sensor data to automatically adjust process parameters during fabrication. These systems incorporate multiple sensor types including thermal, optical, and mechanical sensors to measure critical process variables. The sensor data is processed through control algorithms that make real-time adjustments to laser power, material feed rate, and motion control systems. This approach significantly improves dimensional accuracy, material properties, and reduces defects in the final components.

- Multi-sensor fusion for process monitoring: Multi-sensor fusion approaches combine data from various sensor types to provide comprehensive monitoring of directed energy deposition processes. These systems typically integrate thermal imaging, high-speed cameras, pyrometers, and spectrometers to simultaneously monitor multiple process parameters. Advanced data fusion algorithms correlate information from different sensors to create a more complete understanding of the process dynamics. This approach enables more accurate detection of defects, thermal anomalies, and process instabilities than single-sensor solutions.

- In-situ defect detection and quality assurance: Sensor systems for in-situ defect detection in directed energy deposition processes enable real-time quality assurance during manufacturing. These systems employ various sensing technologies including acoustic sensors, optical tomography, and infrared thermography to detect porosity, cracks, lack of fusion, and other common defects. Machine learning algorithms analyze sensor data to identify defect signatures and classify defect types. This capability allows for immediate corrective actions or part rejection decisions during the build process rather than post-build inspection.

- Advanced sensor integration for material property control: Advanced sensor integration in directed energy deposition focuses on controlling material properties through precise monitoring of solidification conditions. These systems incorporate specialized sensors such as high-resolution thermal cameras, spectroscopic sensors, and X-ray detectors to monitor grain structure formation, phase transformations, and chemical composition during deposition. The sensor data guides adjustments to process parameters that influence cooling rates and thermal gradients, enabling tailored microstructures and mechanical properties in the fabricated components.

02 Multi-sensor fusion for process control

Advanced DED systems incorporate multiple sensor types working in concert to provide comprehensive process monitoring. By combining data from various sensors such as infrared cameras, pyrometers, high-speed cameras, and acoustic sensors, these systems can create a more complete picture of the deposition process. Sensor fusion algorithms correlate different data streams to improve detection accuracy and enable more sophisticated control strategies that respond to complex process dynamics.Expand Specific Solutions03 In-situ defect detection and correction

Sensor systems integrated into DED equipment can identify defects as they form during the build process. These systems use machine vision, laser profilometry, and other sensing technologies to detect issues such as porosity, lack of fusion, or geometric inaccuracies. When defects are detected, the system can either adjust process parameters automatically to correct the issue or flag the area for post-process inspection and repair, significantly improving part quality and reducing waste.Expand Specific Solutions04 Layer-by-layer dimensional verification

Dimensional accuracy in DED processes can be maintained through integrated sensor systems that perform layer-by-layer verification. These systems typically employ laser scanning, structured light, or optical measurement technologies to create a 3D map of each deposited layer. The measured geometry is compared to the intended design, allowing for immediate corrections to subsequent layers. This approach ensures that dimensional deviations do not compound throughout the build process and helps maintain tight tolerances in complex parts.Expand Specific Solutions05 Material composition monitoring and control

Sensors integrated into DED systems can monitor material composition during deposition, which is particularly valuable for functionally graded materials or alloy development. Spectroscopic sensors analyze the plasma or melt pool to determine elemental composition in real-time. This data allows the system to adjust powder feed rates or energy input to maintain desired material properties. The technology enables precise control over microstructure development and can create components with spatially varying compositions to meet specific performance requirements.Expand Specific Solutions

Leading Companies in DED Sensor Integration

Sensor Integration in Directed Energy Deposition (DED) Manufacturing is currently in a growth phase, with the market expanding as industries recognize its potential for real-time quality control and process optimization. The global market is projected to reach significant scale as additive manufacturing adoption increases across aerospace, automotive, and medical sectors. Technologically, the field shows varying maturity levels among key players. Applied Materials, Siemens, and Lockheed Martin demonstrate advanced capabilities in sensor fusion and data analytics, while research institutions like Huazhong University and Nanyang Technological University are pioneering next-generation sensing technologies. Companies such as MKS and Robert Bosch are developing specialized sensor solutions specifically optimized for the harsh environments of DED processes, creating a competitive landscape balanced between established industrial giants and specialized technology providers.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed an advanced sensor integration framework for DED manufacturing that leverages their expertise in semiconductor process control. Their solution incorporates in-situ metrology tools adapted from semiconductor manufacturing, including optical emission spectroscopy for plasma monitoring and laser interferometry for precise dimensional control. The system features a modular sensor architecture that allows for customization based on specific material and process requirements. Applied Materials' platform includes specialized thin-film sensors that can be embedded within the build substrate to monitor thermal conditions from below the build surface. Their approach emphasizes high-bandwidth data acquisition systems capable of capturing transient phenomena during the deposition process. The platform incorporates edge computing nodes that perform preliminary data processing near the sensor sources, reducing latency for control decisions. Applied Materials has also developed specialized algorithms for sensor self-calibration and drift compensation, ensuring measurement stability over extended build operations[7][8].

Strengths: Leverages extensive experience in semiconductor process control; high-precision measurement capabilities adapted from microelectronics manufacturing; sophisticated data acquisition and processing infrastructure. Weaknesses: May be optimized for precision rather than the robustness needed in industrial manufacturing environments; potential gaps in adapting semiconductor-focused technologies to metal additive manufacturing conditions.

Siemens AG

Technical Solution: Siemens has developed an integrated sensor ecosystem for Directed Energy Deposition (DED) manufacturing that combines multiple sensor types for real-time process monitoring and control. Their solution incorporates thermal imaging cameras, pyrometers, and high-speed cameras to monitor melt pool dynamics and material deposition. The system utilizes edge computing devices to process sensor data in real-time, enabling closed-loop control of laser power, material feed rate, and deposition path. Siemens' Digital Twin technology creates a virtual representation of the physical process, allowing for predictive quality control and process optimization. Their Industrial Edge platform connects sensor data to cloud-based analytics systems for comprehensive process monitoring and historical data analysis. The system also includes machine learning algorithms that continuously improve process parameters based on sensor feedback and quality inspection results[1][3].

Strengths: Comprehensive integration of multiple sensor types provides redundant monitoring capabilities; advanced digital twin technology enables predictive quality control; established industrial automation expertise ensures robust implementation. Weaknesses: System complexity may require significant initial setup and calibration; proprietary nature of some components could limit interoperability with third-party equipment.

Critical Sensor Technologies for Process Monitoring

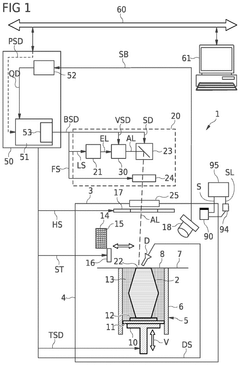

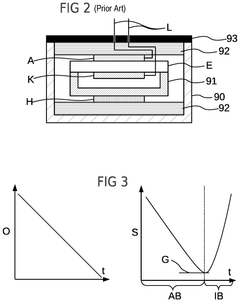

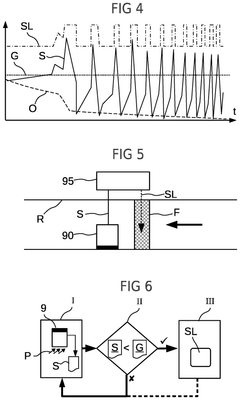

Sensor arrangement for an apparatus for additive manufacturing, and apparatus therefor, and measuring method on the basis thereof

PatentPendingUS20250271381A1

Innovation

- A sensor arrangement with a control module that compares sensor signals to a specified threshold value, initiating countermeasures to maintain the sensor within a stable measurement range by adjusting conditions, such as gas flow or temperature, to compensate for hydrogen and water interference.

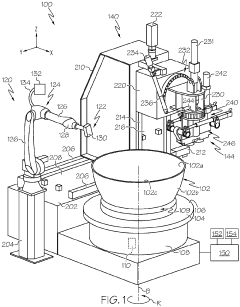

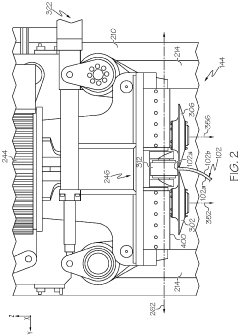

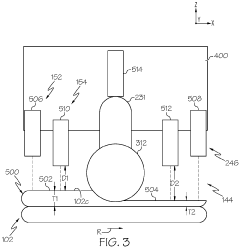

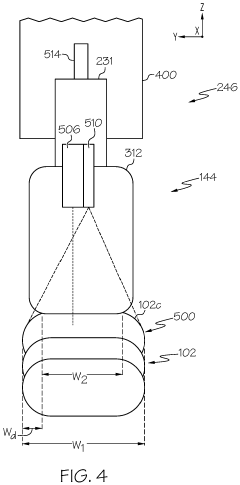

Additive manufacturing system and method for compression of material based on detected temperature

PatentPendingEP4302913A1

Innovation

- The integration of a compression rig with temperature and distance sensors into the DED system allows for simultaneous material deposition and compression, using a compression head with rollers to apply a compressive load during deposition, controlled by a controller that adjusts position and load based on real-time temperature and distance data.

Quality Assurance Standards for Sensor-Integrated DED

Quality assurance standards for sensor-integrated Directed Energy Deposition (DED) manufacturing systems represent a critical framework for ensuring consistent product quality and process reliability. These standards are currently evolving rapidly as sensor integration technologies mature within the additive manufacturing landscape.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have developed preliminary guidelines addressing sensor data acquisition, calibration protocols, and validation methodologies specific to DED processes. ASTM F3187 provides baseline requirements for electronic data records in additive manufacturing, while ISO/ASTM 52901:2021 establishes requirements for purchased AM parts, including those manufactured using sensor-monitored DED systems.

Industry-specific standards have emerged to address unique quality challenges in aerospace, medical, and automotive sectors. For aerospace applications, SAE AMS7003 outlines laser-based powder bed fusion processes with integrated sensing capabilities, providing a reference framework adaptable to DED technologies. The medical device industry follows FDA guidance documents that specifically address real-time monitoring requirements for additive manufacturing processes.

Sensor data quality standards constitute a fundamental component of these frameworks, establishing minimum requirements for data sampling rates, signal-to-noise ratios, and measurement accuracies. For thermal sensors in DED applications, temperature measurement accuracy requirements typically range from ±1°C to ±5°C depending on the application criticality. Melt pool monitoring systems must achieve spatial resolutions of 50-100μm with frame rates exceeding 1kHz to effectively capture process dynamics.

Calibration protocols for integrated sensors represent another critical aspect of quality assurance standards. These protocols typically mandate regular calibration intervals (ranging from daily to monthly depending on sensor type), traceability to national measurement standards, and comprehensive documentation of calibration procedures and results. The National Institute of Standards and Technology (NIST) has published recommended practices for calibrating thermal imaging systems specifically for metal additive manufacturing processes.

Data management standards address the acquisition, storage, and analysis of sensor data throughout the DED manufacturing process. ISO/IEC 27001 provides a framework for information security management that has been adapted for additive manufacturing environments, while the FAIR (Findable, Accessible, Interoperable, Reusable) data principles are increasingly referenced in standards documents to ensure sensor data remains valuable throughout the product lifecycle.

Certification pathways for sensor-integrated DED systems are emerging through organizations like America Makes and the National Additive Manufacturing Innovation Institute, providing manufacturers with clear guidelines for demonstrating compliance with established quality standards and best practices.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have developed preliminary guidelines addressing sensor data acquisition, calibration protocols, and validation methodologies specific to DED processes. ASTM F3187 provides baseline requirements for electronic data records in additive manufacturing, while ISO/ASTM 52901:2021 establishes requirements for purchased AM parts, including those manufactured using sensor-monitored DED systems.

Industry-specific standards have emerged to address unique quality challenges in aerospace, medical, and automotive sectors. For aerospace applications, SAE AMS7003 outlines laser-based powder bed fusion processes with integrated sensing capabilities, providing a reference framework adaptable to DED technologies. The medical device industry follows FDA guidance documents that specifically address real-time monitoring requirements for additive manufacturing processes.

Sensor data quality standards constitute a fundamental component of these frameworks, establishing minimum requirements for data sampling rates, signal-to-noise ratios, and measurement accuracies. For thermal sensors in DED applications, temperature measurement accuracy requirements typically range from ±1°C to ±5°C depending on the application criticality. Melt pool monitoring systems must achieve spatial resolutions of 50-100μm with frame rates exceeding 1kHz to effectively capture process dynamics.

Calibration protocols for integrated sensors represent another critical aspect of quality assurance standards. These protocols typically mandate regular calibration intervals (ranging from daily to monthly depending on sensor type), traceability to national measurement standards, and comprehensive documentation of calibration procedures and results. The National Institute of Standards and Technology (NIST) has published recommended practices for calibrating thermal imaging systems specifically for metal additive manufacturing processes.

Data management standards address the acquisition, storage, and analysis of sensor data throughout the DED manufacturing process. ISO/IEC 27001 provides a framework for information security management that has been adapted for additive manufacturing environments, while the FAIR (Findable, Accessible, Interoperable, Reusable) data principles are increasingly referenced in standards documents to ensure sensor data remains valuable throughout the product lifecycle.

Certification pathways for sensor-integrated DED systems are emerging through organizations like America Makes and the National Additive Manufacturing Innovation Institute, providing manufacturers with clear guidelines for demonstrating compliance with established quality standards and best practices.

Economic Impact of In-Process Monitoring in AM

The integration of in-process monitoring systems in Additive Manufacturing (AM) processes, particularly in Directed Energy Deposition (DED) manufacturing, presents significant economic implications across various industrial sectors. Initial implementation costs for sensor integration typically range from $50,000 to $250,000 depending on the complexity and precision requirements of the monitoring system. However, these investments demonstrate compelling return-on-investment metrics, with most manufacturers reporting breakeven periods of 12-24 months through reduced material waste and quality-related expenses.

Statistical analyses from leading aerospace and medical device manufacturers indicate that comprehensive sensor integration can reduce scrap rates by 30-45% and decrease post-production inspection costs by up to 60%. These efficiency gains translate directly to improved production economics, with case studies from GE Aviation and Siemens Energy documenting annual savings exceeding $2 million in facilities implementing advanced sensor networks for DED processes.

Beyond immediate cost reductions, in-process monitoring enables significant value creation through enhanced product reliability. The economic impact extends to warranty claim reductions, with manufacturers reporting 25-35% decreases in field failures for critical components manufactured under sensor-monitored conditions. This reliability premium often commands price advantages of 5-15% in high-value markets where performance assurance carries substantial economic weight.

Labor economics also transform substantially with sensor integration, as monitoring systems reduce the requirement for specialized quality control personnel by 40-50% while simultaneously increasing throughput. This workforce optimization represents a structural economic shift in manufacturing operations, allowing for reallocation of human resources toward higher-value activities such as process optimization and design innovation.

Supply chain economics benefit through reduced lead times and inventory requirements, with real-time quality verification enabling just-in-time manufacturing approaches previously unattainable in high-precision applications. Market analysis indicates that manufacturers implementing comprehensive sensor integration in DED processes achieve 30-40% reductions in working capital requirements related to buffer inventories and quality holds.

The macroeconomic impact extends to reshoring potential, with enhanced process control enabling cost-competitive manufacturing in higher-wage economies through superior quality outcomes and reduced rework requirements. This reshoring effect creates additional economic value through localized supply chains and reduced transportation costs, estimated at 15-20% of total product cost for complex components.

Statistical analyses from leading aerospace and medical device manufacturers indicate that comprehensive sensor integration can reduce scrap rates by 30-45% and decrease post-production inspection costs by up to 60%. These efficiency gains translate directly to improved production economics, with case studies from GE Aviation and Siemens Energy documenting annual savings exceeding $2 million in facilities implementing advanced sensor networks for DED processes.

Beyond immediate cost reductions, in-process monitoring enables significant value creation through enhanced product reliability. The economic impact extends to warranty claim reductions, with manufacturers reporting 25-35% decreases in field failures for critical components manufactured under sensor-monitored conditions. This reliability premium often commands price advantages of 5-15% in high-value markets where performance assurance carries substantial economic weight.

Labor economics also transform substantially with sensor integration, as monitoring systems reduce the requirement for specialized quality control personnel by 40-50% while simultaneously increasing throughput. This workforce optimization represents a structural economic shift in manufacturing operations, allowing for reallocation of human resources toward higher-value activities such as process optimization and design innovation.

Supply chain economics benefit through reduced lead times and inventory requirements, with real-time quality verification enabling just-in-time manufacturing approaches previously unattainable in high-precision applications. Market analysis indicates that manufacturers implementing comprehensive sensor integration in DED processes achieve 30-40% reductions in working capital requirements related to buffer inventories and quality holds.

The macroeconomic impact extends to reshoring potential, with enhanced process control enabling cost-competitive manufacturing in higher-wage economies through superior quality outcomes and reduced rework requirements. This reshoring effect creates additional economic value through localized supply chains and reduced transportation costs, estimated at 15-20% of total product cost for complex components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!