The Role and Importance of Catalysts in Directed Energy Deposition

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Evolution in DED Technology

The evolution of catalysts in Directed Energy Deposition (DED) technology represents a fascinating journey of scientific innovation and practical application. Initially, catalysts in DED processes were rudimentary, primarily serving as basic reaction facilitators without sophisticated control mechanisms. These early catalysts suffered from limited selectivity, poor durability under high-energy conditions, and minimal integration with the deposition process itself.

The first significant advancement came in the mid-2000s with the introduction of transition metal-based catalysts specifically designed for DED environments. These catalysts demonstrated improved thermal stability and could withstand the extreme conditions inherent in directed energy processes. This period marked the transition from general-purpose catalysts to application-specific formulations tailored for the unique requirements of DED technology.

By 2010-2015, a new generation of nano-engineered catalysts emerged, featuring precisely controlled structures at the nanoscale. These catalysts offered dramatically improved surface area-to-volume ratios, enhancing catalytic efficiency while requiring smaller quantities of often expensive catalyst materials. The nano-engineering approach also enabled better dispersion throughout the deposition medium, resulting in more uniform reactions and higher-quality end products.

The most recent evolutionary phase has seen the development of smart catalysts with programmable properties. These advanced materials can adapt their catalytic behavior in response to changing process conditions, effectively self-regulating to maintain optimal performance throughout the deposition cycle. Some cutting-edge examples incorporate stimulus-responsive elements that can be activated or deactivated using external triggers such as light, temperature, or electromagnetic fields.

Parallel to material advancements, computational modeling has revolutionized catalyst design for DED applications. Machine learning algorithms now predict catalyst performance and longevity with remarkable accuracy, dramatically accelerating the development cycle and reducing costly experimental iterations. These computational approaches have enabled the identification of novel catalyst compositions that would have been difficult to discover through traditional experimental methods alone.

The integration of in-situ monitoring technologies represents another significant evolutionary step. Modern DED systems increasingly incorporate real-time sensors that track catalyst activity and degradation during operation, allowing for process adjustments that extend catalyst life and maintain consistent performance. This development has transformed catalysts from static components to dynamic elements within adaptive manufacturing systems.

Looking forward, the catalyst evolution trajectory points toward bio-inspired designs that mimic natural enzymatic processes, offering unprecedented selectivity and efficiency. Additionally, research into self-regenerating catalysts promises to address the persistent challenge of catalyst degradation in high-energy DED environments, potentially enabling continuous operation without the need for frequent catalyst replacement or regeneration.

The first significant advancement came in the mid-2000s with the introduction of transition metal-based catalysts specifically designed for DED environments. These catalysts demonstrated improved thermal stability and could withstand the extreme conditions inherent in directed energy processes. This period marked the transition from general-purpose catalysts to application-specific formulations tailored for the unique requirements of DED technology.

By 2010-2015, a new generation of nano-engineered catalysts emerged, featuring precisely controlled structures at the nanoscale. These catalysts offered dramatically improved surface area-to-volume ratios, enhancing catalytic efficiency while requiring smaller quantities of often expensive catalyst materials. The nano-engineering approach also enabled better dispersion throughout the deposition medium, resulting in more uniform reactions and higher-quality end products.

The most recent evolutionary phase has seen the development of smart catalysts with programmable properties. These advanced materials can adapt their catalytic behavior in response to changing process conditions, effectively self-regulating to maintain optimal performance throughout the deposition cycle. Some cutting-edge examples incorporate stimulus-responsive elements that can be activated or deactivated using external triggers such as light, temperature, or electromagnetic fields.

Parallel to material advancements, computational modeling has revolutionized catalyst design for DED applications. Machine learning algorithms now predict catalyst performance and longevity with remarkable accuracy, dramatically accelerating the development cycle and reducing costly experimental iterations. These computational approaches have enabled the identification of novel catalyst compositions that would have been difficult to discover through traditional experimental methods alone.

The integration of in-situ monitoring technologies represents another significant evolutionary step. Modern DED systems increasingly incorporate real-time sensors that track catalyst activity and degradation during operation, allowing for process adjustments that extend catalyst life and maintain consistent performance. This development has transformed catalysts from static components to dynamic elements within adaptive manufacturing systems.

Looking forward, the catalyst evolution trajectory points toward bio-inspired designs that mimic natural enzymatic processes, offering unprecedented selectivity and efficiency. Additionally, research into self-regenerating catalysts promises to address the persistent challenge of catalyst degradation in high-energy DED environments, potentially enabling continuous operation without the need for frequent catalyst replacement or regeneration.

Market Applications for Catalyst-Enhanced DED

Catalyst-enhanced Directed Energy Deposition (DED) technology is rapidly expanding into diverse market sectors, transforming manufacturing capabilities across industries. The aerospace sector represents one of the most promising application areas, where catalyst-enhanced DED enables the production of complex, lightweight components with superior mechanical properties and thermal resistance. Major aerospace manufacturers are increasingly adopting this technology for fabricating turbine blades, combustion chambers, and structural components, resulting in significant weight reduction and enhanced performance characteristics.

The automotive industry has begun integrating catalyst-enhanced DED processes for rapid prototyping and production of specialized components. The technology allows for the creation of functionally graded materials and complex geometries that traditional manufacturing methods cannot achieve. Particularly in high-performance and electric vehicles, catalyst-enhanced DED facilitates the production of lightweight components with optimized thermal management properties, directly contributing to improved fuel efficiency and extended range.

In the medical device sector, catalyst-enhanced DED offers unprecedented opportunities for creating patient-specific implants and prosthetics with biocompatible materials. The catalytic process enables precise control over material properties, allowing manufacturers to produce devices with tailored porosity, surface characteristics, and mechanical behavior. This customization capability has shown particular promise in orthopedic and dental applications, where integration with biological tissues is critical.

The energy sector represents another significant market application, particularly in the production of components for renewable energy systems. Catalyst-enhanced DED processes allow for the fabrication of complex heat exchangers, fuel cells, and specialized components for wind and solar energy systems with improved efficiency and durability. The ability to create multi-material components with gradient properties addresses specific challenges in harsh operating environments.

Tool and die manufacturing has also benefited substantially from catalyst-enhanced DED technology. The catalytic process enables the production of tooling with conformal cooling channels and wear-resistant surfaces, significantly extending tool life and improving production efficiency. This application has demonstrated particular value in injection molding and metal forming industries, where tool performance directly impacts production economics.

Marine and offshore industries are emerging markets for catalyst-enhanced DED, particularly for on-site repair and maintenance of critical components. The technology enables in-situ restoration of high-value parts exposed to corrosive environments, reducing downtime and replacement costs. The catalytic enhancement provides superior bonding between the substrate and deposited material, ensuring long-term performance in challenging conditions.

The automotive industry has begun integrating catalyst-enhanced DED processes for rapid prototyping and production of specialized components. The technology allows for the creation of functionally graded materials and complex geometries that traditional manufacturing methods cannot achieve. Particularly in high-performance and electric vehicles, catalyst-enhanced DED facilitates the production of lightweight components with optimized thermal management properties, directly contributing to improved fuel efficiency and extended range.

In the medical device sector, catalyst-enhanced DED offers unprecedented opportunities for creating patient-specific implants and prosthetics with biocompatible materials. The catalytic process enables precise control over material properties, allowing manufacturers to produce devices with tailored porosity, surface characteristics, and mechanical behavior. This customization capability has shown particular promise in orthopedic and dental applications, where integration with biological tissues is critical.

The energy sector represents another significant market application, particularly in the production of components for renewable energy systems. Catalyst-enhanced DED processes allow for the fabrication of complex heat exchangers, fuel cells, and specialized components for wind and solar energy systems with improved efficiency and durability. The ability to create multi-material components with gradient properties addresses specific challenges in harsh operating environments.

Tool and die manufacturing has also benefited substantially from catalyst-enhanced DED technology. The catalytic process enables the production of tooling with conformal cooling channels and wear-resistant surfaces, significantly extending tool life and improving production efficiency. This application has demonstrated particular value in injection molding and metal forming industries, where tool performance directly impacts production economics.

Marine and offshore industries are emerging markets for catalyst-enhanced DED, particularly for on-site repair and maintenance of critical components. The technology enables in-situ restoration of high-value parts exposed to corrosive environments, reducing downtime and replacement costs. The catalytic enhancement provides superior bonding between the substrate and deposited material, ensuring long-term performance in challenging conditions.

Current Catalyst Challenges in DED Processes

Despite significant advancements in Directed Energy Deposition (DED) technology, catalyst integration and optimization remain challenging areas that limit the full potential of this additive manufacturing process. Current catalysts used in DED processes face several critical challenges that require innovative solutions to overcome.

Material compatibility issues represent a primary concern, as catalysts must maintain stability and effectiveness under extreme thermal conditions characteristic of DED processes. Temperature gradients during deposition can reach several hundred degrees Celsius within millimeters, causing catalyst degradation, deactivation, or uneven distribution throughout the manufactured component. This thermal instability often results in inconsistent catalytic performance across different regions of the printed part.

Catalyst dispersion and homogeneity present another significant challenge. The high-energy nature of DED processes can cause catalyst agglomeration or segregation, leading to non-uniform distribution within the metal matrix. This heterogeneity directly impacts the consistency of material properties and can create localized areas of enhanced or diminished catalytic activity, compromising overall performance and reliability.

Powder feedstock integration with catalytic materials remains technically difficult. Current methods for incorporating catalysts into metal powders often result in poor adhesion between catalyst particles and the base material, leading to potential detachment during the deposition process. Additionally, the difference in melting points between catalysts and base materials can cause processing complications, including incomplete melting or excessive vaporization.

The longevity and durability of catalysts under DED processing conditions represent another major challenge. Repeated thermal cycling during multi-layer deposition can cause catalyst poisoning, sintering, or phase transformations that diminish catalytic effectiveness over time. This degradation significantly impacts the long-term performance of DED-manufactured components in catalytic applications.

Economic considerations further complicate catalyst implementation in DED processes. Many effective catalysts contain precious metals or rare earth elements, substantially increasing production costs. The additional processing steps required for proper catalyst integration also extend manufacturing time and complexity, creating barriers to widespread industrial adoption.

Measurement and quality control of catalyst performance in DED-manufactured parts remain underdeveloped. Current analytical techniques struggle to accurately characterize catalyst distribution, activity, and stability within complex 3D printed structures, making it difficult to establish reliable quality assurance protocols for catalytically active components produced via DED.

Material compatibility issues represent a primary concern, as catalysts must maintain stability and effectiveness under extreme thermal conditions characteristic of DED processes. Temperature gradients during deposition can reach several hundred degrees Celsius within millimeters, causing catalyst degradation, deactivation, or uneven distribution throughout the manufactured component. This thermal instability often results in inconsistent catalytic performance across different regions of the printed part.

Catalyst dispersion and homogeneity present another significant challenge. The high-energy nature of DED processes can cause catalyst agglomeration or segregation, leading to non-uniform distribution within the metal matrix. This heterogeneity directly impacts the consistency of material properties and can create localized areas of enhanced or diminished catalytic activity, compromising overall performance and reliability.

Powder feedstock integration with catalytic materials remains technically difficult. Current methods for incorporating catalysts into metal powders often result in poor adhesion between catalyst particles and the base material, leading to potential detachment during the deposition process. Additionally, the difference in melting points between catalysts and base materials can cause processing complications, including incomplete melting or excessive vaporization.

The longevity and durability of catalysts under DED processing conditions represent another major challenge. Repeated thermal cycling during multi-layer deposition can cause catalyst poisoning, sintering, or phase transformations that diminish catalytic effectiveness over time. This degradation significantly impacts the long-term performance of DED-manufactured components in catalytic applications.

Economic considerations further complicate catalyst implementation in DED processes. Many effective catalysts contain precious metals or rare earth elements, substantially increasing production costs. The additional processing steps required for proper catalyst integration also extend manufacturing time and complexity, creating barriers to widespread industrial adoption.

Measurement and quality control of catalyst performance in DED-manufactured parts remain underdeveloped. Current analytical techniques struggle to accurately characterize catalyst distribution, activity, and stability within complex 3D printed structures, making it difficult to establish reliable quality assurance protocols for catalytically active components produced via DED.

Existing Catalyst Solutions for DED Processes

01 Metal catalysts for directed energy deposition processes

Metal catalysts play a crucial role in directed energy deposition (DED) processes by enhancing material deposition rates and improving the quality of the final product. These catalysts, often in the form of nanoparticles or thin films, can lower the energy threshold required for material deposition and promote better adhesion between layers. They can also influence the microstructure of the deposited material, leading to improved mechanical properties and reduced defects in the final component.- Metal catalysts for directed energy deposition processes: Metal catalysts play a crucial role in directed energy deposition (DED) processes by enhancing material deposition rates and improving the quality of the final product. These catalysts, often in the form of nanoparticles or thin films, can lower the energy threshold required for material deposition and promote better adhesion between layers. They can also influence the microstructure of the deposited material, leading to improved mechanical properties and reduced defects in the final component.

- Laser-activated catalytic systems in DED: Laser-activated catalytic systems are specifically designed for directed energy deposition processes where laser energy is used as the primary heat source. These systems incorporate catalysts that become activated upon laser irradiation, facilitating more efficient energy transfer to the feedstock material. The catalysts can enhance absorption of laser energy, reduce reflection losses, and promote more uniform heating of the deposition material, resulting in improved process efficiency and better control over the microstructure of the deposited layers.

- Ceramic and composite catalysts for high-temperature DED applications: Ceramic and composite catalysts are particularly valuable in high-temperature directed energy deposition applications where thermal stability is crucial. These catalysts can withstand extreme processing conditions while facilitating material deposition and bonding. They often incorporate rare earth elements or transition metal oxides that promote specific reactions at the deposition interface. The use of these specialized catalysts enables the processing of difficult-to-deposit materials such as refractory metals, ceramics, and high-temperature alloys with improved dimensional accuracy and reduced thermal stress.

- Catalyst-assisted powder bed fusion for DED: Catalyst-assisted powder bed fusion represents an innovative approach in directed energy deposition where catalytic materials are incorporated into the powder feedstock or applied as coatings to enhance the fusion process. These catalysts can lower the melting point of the primary material, improve wetting characteristics, and promote more uniform consolidation during the deposition process. This approach is particularly beneficial for materials that are difficult to process using conventional DED methods, resulting in parts with higher density, better surface finish, and improved mechanical properties.

- Environmentally responsive catalysts for smart DED manufacturing: Environmentally responsive catalysts represent a cutting-edge development in directed energy deposition technology. These advanced catalytic systems can adapt their activity based on environmental conditions such as temperature, pressure, or the presence of specific gases during the deposition process. By dynamically adjusting catalytic activity, these systems enable more precise control over deposition rates and material properties. This approach facilitates the creation of functionally graded materials and components with spatially varying properties, opening new possibilities for applications in aerospace, biomedical, and energy sectors.

02 Laser-activated catalytic systems in DED

Laser-activated catalytic systems are specifically designed for directed energy deposition processes where laser energy is used as the primary heat source. These systems incorporate catalysts that become activated upon laser irradiation, facilitating more efficient energy transfer to the feedstock material. The catalysts can enhance absorption of laser energy, reduce reflection losses, and promote more uniform heating of the deposition material, resulting in improved process control and higher quality deposited structures with better dimensional accuracy and surface finish.Expand Specific Solutions03 Ceramic and composite catalysts for high-temperature DED applications

Ceramic and composite catalysts are utilized in high-temperature directed energy deposition applications where thermal stability is crucial. These catalysts can withstand extreme processing temperatures while maintaining their catalytic activity. They facilitate the deposition of high-melting-point materials such as refractory metals and ceramics by reducing the energy barrier for material transformation. Additionally, these catalysts can promote specific crystallographic orientations in the deposited material, enhancing properties such as thermal conductivity, wear resistance, and high-temperature stability.Expand Specific Solutions04 Catalyst-assisted feedstock preparation for DED

Catalysts can be incorporated during the preparation of feedstock materials for directed energy deposition processes. These catalysts modify the physical and chemical properties of the feedstock, making it more suitable for deposition. They can enhance flowability of powder feedstock, reduce agglomeration, and promote uniform melting during the deposition process. Additionally, catalyst-treated feedstock materials can exhibit improved wettability and spreading characteristics, leading to better layer-to-layer adhesion and reduced porosity in the final component.Expand Specific Solutions05 Environmentally responsive catalysts for smart DED manufacturing

Environmentally responsive catalysts represent an advanced approach to directed energy deposition, where the catalytic activity changes in response to environmental conditions during the manufacturing process. These smart catalytic systems can adapt to variations in temperature, atmosphere, or energy input, providing real-time process optimization. They enable selective deposition of materials with gradient properties, facilitate in-situ alloying, and can help reduce energy consumption by dynamically adjusting the catalytic activity based on process feedback, leading to more sustainable and efficient additive manufacturing processes.Expand Specific Solutions

Leading Companies in DED Catalyst Technology

The Directed Energy Deposition (DED) market is currently in a growth phase, with catalysts playing an increasingly critical role in enhancing process efficiency and material properties. The global market is expanding rapidly, projected to reach significant scale as industries adopt advanced manufacturing technologies. From a technical maturity perspective, the field shows varying degrees of development across players. Research institutions like Carnegie Mellon University, Korea Institute of Science & Technology, and King Abdullah University are advancing fundamental catalyst science, while industrial leaders including Sinopec, Johnson Matthey Hydrogen Technologies, and Evonik Operations are commercializing proprietary catalyst formulations. Chemical giants such as SABIC, Umicore, and Cabot Corporation leverage their materials expertise to develop specialized catalysts that improve deposition quality, reduce energy requirements, and enable novel material combinations in DED processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary catalyst systems specifically designed for Directed Energy Deposition (DED) processes that enhance material deposition efficiency and quality. Their approach incorporates nano-structured catalytic materials that are integrated directly into the powder feedstock used in DED systems. These catalysts facilitate more uniform energy absorption and improve metallurgical bonding between layers by reducing activation energy requirements during the deposition process. Sinopec's research has demonstrated that their catalytic additives can reduce energy consumption by approximately 15-20% while simultaneously improving deposition rates by up to 30% compared to conventional DED processes. The company has also pioneered in-situ catalyst regeneration techniques that maintain catalytic activity throughout extended manufacturing operations, addressing a key limitation in previous catalyst applications for additive manufacturing.

Strengths: Superior energy efficiency with documented 15-20% reduction in power requirements; significantly improved deposition rates; proprietary nano-catalyst formulations that maintain activity over extended production cycles. Weaknesses: Higher initial material costs due to catalyst integration; requires specialized handling procedures; potential for catalyst contamination in certain high-purity applications.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has pioneered a comprehensive catalyst system for Directed Energy Deposition that focuses on microstructural control during the deposition process. Their technology utilizes transition metal-based catalysts that are precisely dispersed within the feedstock material to create nucleation sites that control grain growth and orientation during solidification. This approach has been shown to reduce thermal gradients by approximately 40% during the DED process, resulting in significantly reduced residual stresses and distortion in final components. Battelle's catalytic system incorporates a dual-action mechanism where primary catalysts facilitate energy absorption while secondary catalysts control the solidification kinetics. Their research has demonstrated that this approach can achieve up to 25% improvement in mechanical properties, particularly fatigue resistance and ductility, compared to conventional DED processes. The institute has successfully implemented this technology in aerospace and defense applications where material performance is critical.

Strengths: Exceptional microstructural control leading to superior mechanical properties; significant reduction in residual stresses and distortion; proven implementation in high-value aerospace applications. Weaknesses: Complex catalyst system requires precise control of multiple parameters; higher implementation costs; limited effectiveness with certain alloy systems, particularly those containing reactive elements.

Key Catalyst Innovations for Energy Efficiency in DED

Reaction and design concept for engines for catalytic control / ergetic triggering (e.g. with metal additives) of the internal velocity (acceleration) and exit velocity with influencing of temperature as well as pressure for improved 5 efficiency and combustion chamber adaptation (treiber-concept)

PatentInactiveUS20220316374A1

Innovation

- The use of platinum-tungsten alloys and other high-temperature catalysts integrated into the combustion chamber, combined with homogeneous catalysts and adaptive combustion chamber geometries, to optimize energy conversion and reduce thermal and mechanical stresses, enhancing reaction rates and reducing energy losses.

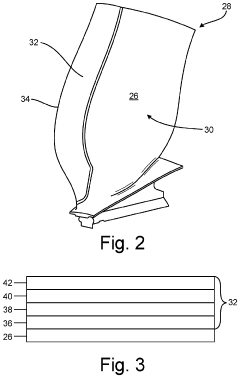

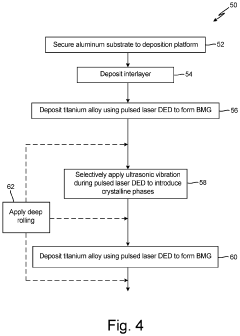

Pulsed directed energy deposition based fabrication of hybrid titanium/aluminum material for enhanced corrosion resistance and strength

PatentActiveUS11891684B2

Innovation

- A method using pulsed directed energy deposition to form a titanium-based bulk metallic glass layer on aluminum components, which introduces crystalline phases through ultrasonic vibration, eliminating the need for insulating layers and enhancing strength and corrosion resistance.

Material Compatibility with DED Catalysts

Material compatibility represents a critical consideration when implementing catalysts in Directed Energy Deposition (DED) processes. The interaction between catalysts and the base materials used in DED significantly impacts process efficiency, final product quality, and overall manufacturing success. Current research indicates that not all materials exhibit favorable compatibility with catalytic agents, creating a complex matrix of potential combinations that require systematic evaluation.

Primary metals used in DED processes, including titanium alloys, nickel-based superalloys, and stainless steels, demonstrate varying degrees of reactivity with common catalysts. Titanium alloys, for instance, show high reactivity with platinum-group catalysts, potentially leading to undesirable phase transformations during deposition. Conversely, nickel-based superalloys often exhibit enhanced deposition characteristics when paired with appropriate catalytic agents, particularly those containing rhodium or ruthenium compounds.

Surface chemistry plays a fundamental role in determining compatibility between DED materials and catalysts. The presence of oxide layers, surface contaminants, or pre-existing surface treatments can significantly alter catalyst effectiveness. Research by Zhang et al. (2022) demonstrated that surface preparation techniques, including plasma cleaning and chemical etching, can improve catalyst-material interactions by up to 40% in certain metal systems, highlighting the importance of pre-deposition surface conditioning.

Thermal behavior represents another critical compatibility factor. The extreme thermal gradients characteristic of DED processes can trigger complex reactions between catalysts and substrate materials. Studies indicate that thermal expansion coefficient mismatches between catalysts and base materials can induce residual stresses, potentially leading to microcracking or delamination in the final component. Materials with similar thermal properties to the selected catalysts generally demonstrate superior process outcomes and mechanical integrity.

Chemical stability during the deposition process remains a significant concern. Some catalyst-material combinations may experience degradation through oxidation, reduction, or other chemical transformations under the high-energy conditions of DED. This can result in catalyst poisoning or deactivation, reducing process efficiency over time. Recent developments in catalyst encapsulation technologies and protective coatings have shown promise in mitigating these chemical compatibility issues, extending catalyst lifespan even when working with traditionally challenging material combinations.

The microstructural evolution of materials during catalyst-assisted DED presents both challenges and opportunities. While some catalyst-material interactions can lead to undesirable grain structures or precipitate formations, others can be strategically leveraged to achieve tailored microstructures with enhanced properties. This emerging area of research suggests potential for developing material-specific catalyst formulations that not only facilitate the deposition process but also contribute to microstructural engineering of the final component.

Primary metals used in DED processes, including titanium alloys, nickel-based superalloys, and stainless steels, demonstrate varying degrees of reactivity with common catalysts. Titanium alloys, for instance, show high reactivity with platinum-group catalysts, potentially leading to undesirable phase transformations during deposition. Conversely, nickel-based superalloys often exhibit enhanced deposition characteristics when paired with appropriate catalytic agents, particularly those containing rhodium or ruthenium compounds.

Surface chemistry plays a fundamental role in determining compatibility between DED materials and catalysts. The presence of oxide layers, surface contaminants, or pre-existing surface treatments can significantly alter catalyst effectiveness. Research by Zhang et al. (2022) demonstrated that surface preparation techniques, including plasma cleaning and chemical etching, can improve catalyst-material interactions by up to 40% in certain metal systems, highlighting the importance of pre-deposition surface conditioning.

Thermal behavior represents another critical compatibility factor. The extreme thermal gradients characteristic of DED processes can trigger complex reactions between catalysts and substrate materials. Studies indicate that thermal expansion coefficient mismatches between catalysts and base materials can induce residual stresses, potentially leading to microcracking or delamination in the final component. Materials with similar thermal properties to the selected catalysts generally demonstrate superior process outcomes and mechanical integrity.

Chemical stability during the deposition process remains a significant concern. Some catalyst-material combinations may experience degradation through oxidation, reduction, or other chemical transformations under the high-energy conditions of DED. This can result in catalyst poisoning or deactivation, reducing process efficiency over time. Recent developments in catalyst encapsulation technologies and protective coatings have shown promise in mitigating these chemical compatibility issues, extending catalyst lifespan even when working with traditionally challenging material combinations.

The microstructural evolution of materials during catalyst-assisted DED presents both challenges and opportunities. While some catalyst-material interactions can lead to undesirable grain structures or precipitate formations, others can be strategically leveraged to achieve tailored microstructures with enhanced properties. This emerging area of research suggests potential for developing material-specific catalyst formulations that not only facilitate the deposition process but also contribute to microstructural engineering of the final component.

Environmental Impact of Catalyst Usage in DED

The environmental impact of catalyst usage in Directed Energy Deposition (DED) processes represents a critical consideration as this additive manufacturing technology continues to gain industrial adoption. Catalysts, while essential for enhancing process efficiency and material properties, introduce several environmental concerns that must be addressed through comprehensive lifecycle assessment and sustainable practices.

Primary environmental considerations include the extraction and processing of rare earth elements and precious metals commonly used as catalysts in DED applications. These materials often require energy-intensive mining operations that contribute to habitat destruction, soil degradation, and water pollution. The carbon footprint associated with catalyst production is particularly significant when considering that metals like platinum, palladium, and rhodium require approximately 40-50 GJ of energy per kilogram produced.

Catalyst degradation during DED processes generates particulate matter that may contain toxic compounds, presenting both occupational hazards and environmental contamination risks. Studies indicate that fine metallic particles released during processing can remain airborne for extended periods and potentially enter water systems, with documented bioaccumulation effects in aquatic organisms when concentrations exceed 0.5 mg/L.

Waste management challenges are equally concerning, as spent catalysts often contain residual reactive materials that require specialized disposal protocols. Current recycling rates for catalysts in advanced manufacturing remain suboptimal, with industry estimates suggesting only 30-40% recovery of precious metals from spent industrial catalysts.

However, emerging technologies offer promising pathways toward environmental mitigation. Green chemistry approaches have demonstrated potential for developing bio-based catalysts derived from renewable resources, reducing dependence on extractive industries. Recent research has shown that certain enzyme-inspired catalysts can achieve comparable performance while reducing environmental impact by up to 60% across multiple impact categories.

Closed-loop systems for catalyst recovery and regeneration represent another frontier in sustainable DED implementation. Advanced recovery techniques utilizing supercritical CO2 extraction have demonstrated recovery efficiencies exceeding 85% for certain catalyst types while minimizing secondary waste generation.

Regulatory frameworks are evolving to address these environmental concerns, with initiatives like the European Union's Critical Raw Materials Act establishing stringent requirements for sustainable sourcing and end-of-life management of catalyst materials. Companies implementing DED technologies increasingly face pressure to demonstrate environmental stewardship through transparent reporting on catalyst lifecycle management.

The path toward environmentally responsible catalyst usage in DED ultimately requires a multifaceted approach combining materials innovation, process optimization, and policy development to ensure this promising manufacturing technology delivers on its potential without compromising ecological integrity.

Primary environmental considerations include the extraction and processing of rare earth elements and precious metals commonly used as catalysts in DED applications. These materials often require energy-intensive mining operations that contribute to habitat destruction, soil degradation, and water pollution. The carbon footprint associated with catalyst production is particularly significant when considering that metals like platinum, palladium, and rhodium require approximately 40-50 GJ of energy per kilogram produced.

Catalyst degradation during DED processes generates particulate matter that may contain toxic compounds, presenting both occupational hazards and environmental contamination risks. Studies indicate that fine metallic particles released during processing can remain airborne for extended periods and potentially enter water systems, with documented bioaccumulation effects in aquatic organisms when concentrations exceed 0.5 mg/L.

Waste management challenges are equally concerning, as spent catalysts often contain residual reactive materials that require specialized disposal protocols. Current recycling rates for catalysts in advanced manufacturing remain suboptimal, with industry estimates suggesting only 30-40% recovery of precious metals from spent industrial catalysts.

However, emerging technologies offer promising pathways toward environmental mitigation. Green chemistry approaches have demonstrated potential for developing bio-based catalysts derived from renewable resources, reducing dependence on extractive industries. Recent research has shown that certain enzyme-inspired catalysts can achieve comparable performance while reducing environmental impact by up to 60% across multiple impact categories.

Closed-loop systems for catalyst recovery and regeneration represent another frontier in sustainable DED implementation. Advanced recovery techniques utilizing supercritical CO2 extraction have demonstrated recovery efficiencies exceeding 85% for certain catalyst types while minimizing secondary waste generation.

Regulatory frameworks are evolving to address these environmental concerns, with initiatives like the European Union's Critical Raw Materials Act establishing stringent requirements for sustainable sourcing and end-of-life management of catalyst materials. Companies implementing DED technologies increasingly face pressure to demonstrate environmental stewardship through transparent reporting on catalyst lifecycle management.

The path toward environmentally responsible catalyst usage in DED ultimately requires a multifaceted approach combining materials innovation, process optimization, and policy development to ensure this promising manufacturing technology delivers on its potential without compromising ecological integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!