Directed Energy Deposition: Energy Parameters and Assessment

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology since its inception in the late 1990s. Initially developed as a repair technology for high-value components in aerospace and defense sectors, DED has evolved significantly over the past two decades to become a versatile manufacturing process capable of producing complex metal parts with exceptional material properties.

The technology operates on the principle of simultaneously depositing material (typically metal powder or wire) and energy (laser, electron beam, or plasma arc) to create three-dimensional structures layer by layer. This direct approach distinguishes DED from other additive manufacturing methods, allowing for the production of fully dense parts with minimal post-processing requirements.

Historical development of DED technology shows a clear trajectory from rudimentary systems with limited control parameters to today's sophisticated machines featuring multi-axis movement, closed-loop monitoring, and precise energy delivery systems. The evolution has been driven by increasing demands for material efficiency, geometric complexity, and mechanical performance in critical applications.

Current technological trends in DED focus on expanding material compatibility, enhancing deposition rates, improving surface finish quality, and developing more sophisticated process monitoring and control systems. The integration of machine learning algorithms for real-time process optimization represents a particularly promising direction in recent research efforts.

The primary technical objectives in DED advancement center around energy parameter optimization - specifically understanding and controlling the complex relationships between energy input, material properties, and resulting component characteristics. This includes investigating the effects of laser power density, beam focus, scanning speed, and energy distribution patterns on microstructure formation, residual stress development, and mechanical properties.

Additional objectives include developing standardized methodologies for energy parameter assessment across different DED systems, establishing correlations between energy inputs and material-specific outcomes, and creating predictive models that can accelerate process parameter optimization for new material systems.

The ultimate goal of current DED research is to establish a comprehensive framework for energy parameter selection and assessment that enables consistent, repeatable manufacturing outcomes while maximizing material efficiency and minimizing energy consumption. This would significantly enhance the industrial adoption of DED technology across sectors including aerospace, medical, automotive, and energy production.

The technology operates on the principle of simultaneously depositing material (typically metal powder or wire) and energy (laser, electron beam, or plasma arc) to create three-dimensional structures layer by layer. This direct approach distinguishes DED from other additive manufacturing methods, allowing for the production of fully dense parts with minimal post-processing requirements.

Historical development of DED technology shows a clear trajectory from rudimentary systems with limited control parameters to today's sophisticated machines featuring multi-axis movement, closed-loop monitoring, and precise energy delivery systems. The evolution has been driven by increasing demands for material efficiency, geometric complexity, and mechanical performance in critical applications.

Current technological trends in DED focus on expanding material compatibility, enhancing deposition rates, improving surface finish quality, and developing more sophisticated process monitoring and control systems. The integration of machine learning algorithms for real-time process optimization represents a particularly promising direction in recent research efforts.

The primary technical objectives in DED advancement center around energy parameter optimization - specifically understanding and controlling the complex relationships between energy input, material properties, and resulting component characteristics. This includes investigating the effects of laser power density, beam focus, scanning speed, and energy distribution patterns on microstructure formation, residual stress development, and mechanical properties.

Additional objectives include developing standardized methodologies for energy parameter assessment across different DED systems, establishing correlations between energy inputs and material-specific outcomes, and creating predictive models that can accelerate process parameter optimization for new material systems.

The ultimate goal of current DED research is to establish a comprehensive framework for energy parameter selection and assessment that enables consistent, repeatable manufacturing outcomes while maximizing material efficiency and minimizing energy consumption. This would significantly enhance the industrial adoption of DED technology across sectors including aerospace, medical, automotive, and energy production.

Market Applications and Demand Analysis

The Directed Energy Deposition (DED) market has experienced significant growth in recent years, driven by increasing demand across multiple industrial sectors. The global market for DED technology was valued at approximately $500 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 15.7%. This growth trajectory is supported by the technology's unique capabilities in additive manufacturing, particularly for large-scale components and repair applications.

The aerospace industry remains the primary adopter of DED technology, accounting for roughly 35% of the total market share. Major aerospace manufacturers utilize DED for fabricating complex titanium components, repairing high-value parts such as turbine blades, and producing specialized structural elements. The ability to work with superalloys and create gradient materials has positioned DED as a critical technology for next-generation aircraft development.

Automotive manufacturing represents the second-largest market segment at 22%, with applications focused on rapid prototyping, tooling production, and repair of molds and dies. The industry's push toward lightweight materials and complex geometries has accelerated DED adoption, particularly for components requiring specific mechanical properties that can be achieved through precise energy parameter control.

The medical device sector has emerged as a rapidly growing market for DED technology, currently representing 15% of applications but expanding at 18% annually. Custom implants, orthopedic devices, and dental prosthetics benefit from DED's ability to create patient-specific geometries with biocompatible materials. The precise control of energy parameters enables manufacturers to achieve the surface characteristics and mechanical properties required for medical applications.

Energy sector applications constitute approximately 18% of the market, with oil and gas companies implementing DED for on-site repair of drilling equipment and pipeline components. The technology's portability and ability to deposit materials with high corrosion resistance make it particularly valuable in remote operations where component replacement would be costly and time-consuming.

Market analysis indicates growing demand for DED systems with enhanced energy parameter control capabilities. End users increasingly require systems that can automatically adjust laser power, feed rate, and other parameters in real-time based on feedback from monitoring systems. This trend is driving development of more sophisticated control algorithms and sensor integration, with 78% of surveyed manufacturers citing improved energy parameter management as a critical factor in purchasing decisions.

The aerospace industry remains the primary adopter of DED technology, accounting for roughly 35% of the total market share. Major aerospace manufacturers utilize DED for fabricating complex titanium components, repairing high-value parts such as turbine blades, and producing specialized structural elements. The ability to work with superalloys and create gradient materials has positioned DED as a critical technology for next-generation aircraft development.

Automotive manufacturing represents the second-largest market segment at 22%, with applications focused on rapid prototyping, tooling production, and repair of molds and dies. The industry's push toward lightweight materials and complex geometries has accelerated DED adoption, particularly for components requiring specific mechanical properties that can be achieved through precise energy parameter control.

The medical device sector has emerged as a rapidly growing market for DED technology, currently representing 15% of applications but expanding at 18% annually. Custom implants, orthopedic devices, and dental prosthetics benefit from DED's ability to create patient-specific geometries with biocompatible materials. The precise control of energy parameters enables manufacturers to achieve the surface characteristics and mechanical properties required for medical applications.

Energy sector applications constitute approximately 18% of the market, with oil and gas companies implementing DED for on-site repair of drilling equipment and pipeline components. The technology's portability and ability to deposit materials with high corrosion resistance make it particularly valuable in remote operations where component replacement would be costly and time-consuming.

Market analysis indicates growing demand for DED systems with enhanced energy parameter control capabilities. End users increasingly require systems that can automatically adjust laser power, feed rate, and other parameters in real-time based on feedback from monitoring systems. This trend is driving development of more sophisticated control algorithms and sensor integration, with 78% of surveyed manufacturers citing improved energy parameter management as a critical factor in purchasing decisions.

Current State and Technical Challenges

Directed Energy Deposition (DED) technology has evolved significantly over the past decade, with current global development showing varied maturity levels across different regions. North America and Europe lead in research and industrial implementation, with China rapidly closing the gap through substantial investments in additive manufacturing technologies. The current state of DED technology demonstrates promising capabilities in producing complex metal components with reasonable mechanical properties, but several technical challenges persist.

Energy parameter optimization remains one of the most critical challenges in DED processes. Current systems struggle with precise control of energy distribution, leading to inconsistent material properties across built parts. Research indicates that variations in laser power density can cause up to 15% fluctuation in mechanical properties within the same component, significantly impacting product reliability and performance predictability.

Thermal management presents another substantial hurdle. The high-energy input characteristic of DED processes creates steep thermal gradients that induce residual stresses and potential distortion in fabricated components. Recent studies have documented distortion rates of 0.5-2mm per 100mm of build length, necessitating post-processing operations that reduce the economic viability of the technology for certain applications.

Material compatibility limitations further constrain widespread adoption. While DED shows excellent results with titanium alloys and certain steels, processing of aluminum alloys, copper, and refractory metals remains problematic due to reflectivity issues, oxidation sensitivity, and thermal conductivity challenges. Current material portfolios typically encompass only 15-20 well-characterized alloys, representing a fraction of materials used in conventional manufacturing.

Process monitoring and quality assurance systems for DED lack the sophistication found in other manufacturing technologies. Real-time monitoring capabilities are primarily limited to thermal imaging and basic geometric verification, with limited feedback control mechanisms. This deficiency results in approximately 8-12% rejection rates for critical components, significantly higher than traditional manufacturing methods.

Standardization efforts remain fragmented across different regions and industries. The absence of universally accepted testing protocols and certification pathways creates barriers to adoption in highly regulated sectors such as aerospace and medical device manufacturing. Currently, only about 30% of DED processes have corresponding international standards, creating significant uncertainty for potential industrial adopters.

Energy efficiency of current DED systems presents both environmental and economic challenges. Typical energy utilization rates hover between 15-30%, with substantial energy losses occurring through reflection, radiation, and cooling requirements. This inefficiency contributes to higher operational costs and carbon footprints compared to some conventional manufacturing methods.

Energy parameter optimization remains one of the most critical challenges in DED processes. Current systems struggle with precise control of energy distribution, leading to inconsistent material properties across built parts. Research indicates that variations in laser power density can cause up to 15% fluctuation in mechanical properties within the same component, significantly impacting product reliability and performance predictability.

Thermal management presents another substantial hurdle. The high-energy input characteristic of DED processes creates steep thermal gradients that induce residual stresses and potential distortion in fabricated components. Recent studies have documented distortion rates of 0.5-2mm per 100mm of build length, necessitating post-processing operations that reduce the economic viability of the technology for certain applications.

Material compatibility limitations further constrain widespread adoption. While DED shows excellent results with titanium alloys and certain steels, processing of aluminum alloys, copper, and refractory metals remains problematic due to reflectivity issues, oxidation sensitivity, and thermal conductivity challenges. Current material portfolios typically encompass only 15-20 well-characterized alloys, representing a fraction of materials used in conventional manufacturing.

Process monitoring and quality assurance systems for DED lack the sophistication found in other manufacturing technologies. Real-time monitoring capabilities are primarily limited to thermal imaging and basic geometric verification, with limited feedback control mechanisms. This deficiency results in approximately 8-12% rejection rates for critical components, significantly higher than traditional manufacturing methods.

Standardization efforts remain fragmented across different regions and industries. The absence of universally accepted testing protocols and certification pathways creates barriers to adoption in highly regulated sectors such as aerospace and medical device manufacturing. Currently, only about 30% of DED processes have corresponding international standards, creating significant uncertainty for potential industrial adopters.

Energy efficiency of current DED systems presents both environmental and economic challenges. Typical energy utilization rates hover between 15-30%, with substantial energy losses occurring through reflection, radiation, and cooling requirements. This inefficiency contributes to higher operational costs and carbon footprints compared to some conventional manufacturing methods.

Energy Parameter Optimization Solutions

01 Laser power and energy density optimization

Optimization of laser power and energy density is critical in directed energy deposition processes. Proper calibration of these parameters ensures optimal material deposition, minimizes defects, and achieves desired microstructural properties. The energy input must be carefully controlled to ensure sufficient melting without excessive heat that could cause distortion or undesirable phase transformations in the deposited material.- Laser power and energy density optimization: Optimization of laser power and energy density is critical in directed energy deposition processes. These parameters directly influence material deposition rate, melt pool characteristics, and resulting microstructure. Proper calibration of energy input ensures adequate melting without excessive heat that could cause defects. Adjusting power levels based on material properties and desired build characteristics helps achieve optimal mechanical properties and dimensional accuracy in the final parts.

- Feed rate and powder flow control: The control of material feed rate and powder flow is essential for consistent deposition quality in directed energy deposition. These parameters must be synchronized with the energy source movement to ensure uniform material distribution. Precise powder delivery systems with adjustable flow rates allow for optimization based on part geometry and material characteristics. Advanced systems incorporate real-time monitoring and feedback control to maintain consistent powder flow despite variations in process conditions.

- Scanning strategy and path planning: Scanning strategy and path planning significantly impact energy distribution during directed energy deposition. Different scanning patterns (zigzag, spiral, contour) affect thermal gradients, residual stress, and microstructural development. Path planning algorithms optimize travel distance, minimize start/stop events, and ensure appropriate overlap between adjacent tracks. Advanced strategies incorporate variable energy parameters based on geometric features to maintain consistent melt pool characteristics throughout complex builds.

- Thermal management and cooling parameters: Thermal management is crucial for controlling microstructure and preventing defects in directed energy deposition. Parameters such as substrate preheating temperature, interlayer cooling time, and ambient temperature control affect solidification rates and thermal gradients. Active cooling strategies can be implemented to manage heat accumulation in specific regions. Monitoring and controlling thermal history throughout the build process helps minimize distortion, cracking, and ensures consistent material properties throughout the deposited structure.

- Multi-parameter process monitoring and adaptive control: Advanced directed energy deposition systems employ multi-parameter monitoring and adaptive control to optimize energy parameters in real-time. Sensors track melt pool geometry, temperature distribution, and build quality during fabrication. Machine learning algorithms analyze this data to make dynamic adjustments to laser power, scan speed, and material feed rate. This closed-loop approach compensates for process variations, material inconsistencies, and thermal accumulation, resulting in improved part quality and reproducibility across different geometries and materials.

02 Scanning speed and pattern parameters

The scanning speed and pattern parameters significantly influence the quality of directed energy deposition builds. These parameters determine the time of interaction between the energy source and the material, affecting cooling rates, layer adhesion, and overall build quality. Optimized scanning strategies can reduce residual stresses, prevent warping, and improve surface finish of the fabricated components.Expand Specific Solutions03 Powder feed rate and material-specific energy requirements

The powder feed rate must be synchronized with energy parameters to achieve consistent material deposition. Different materials require specific energy parameters due to their unique thermal properties, melting points, and absorption characteristics. Tailoring energy parameters to material properties ensures optimal fusion, minimizes porosity, and achieves desired mechanical properties in the final component.Expand Specific Solutions04 Multi-parameter process monitoring and adaptive control

Advanced directed energy deposition systems incorporate real-time monitoring and adaptive control of energy parameters. These systems use sensors to track melt pool characteristics, temperature gradients, and build geometry, allowing for dynamic adjustment of energy parameters during fabrication. This adaptive approach compensates for variations in thermal conditions and material properties, ensuring consistent quality throughout complex builds.Expand Specific Solutions05 Environmental and substrate temperature effects

Environmental conditions and substrate temperature significantly impact energy parameter requirements in directed energy deposition. Preheating substrates can reduce thermal gradients and minimize residual stresses. Controlling the build chamber atmosphere (inert gas flow, oxygen content) affects energy absorption and oxidation behavior. These factors must be considered when establishing energy parameters to ensure consistent material properties and dimensional accuracy.Expand Specific Solutions

Key Industry Players and Competition

Directed Energy Deposition (DED) technology is currently in a growth phase, with the market expanding due to increasing applications in aerospace, automotive, and medical sectors. The global DED market is estimated to reach $1.2 billion by 2027, growing at approximately 14% CAGR. Technologically, DED is advancing toward maturity with key players driving innovation across different segments. Companies like Nanjing University of Science & Technology and Xi'an Jiaotong University are leading academic research, while industrial players such as Rolls-Royce Corp. and Boeing Co. are implementing practical applications. Energy parameter optimization remains a critical focus area, with SolarEdge Technologies, Enphase Energy, and Fronius International developing advanced energy control systems that enhance DED process efficiency and material quality. The technology is progressing from experimental to commercial implementation, though standardization of energy parameters assessment methods remains a challenge.

Nanjing University of Science & Technology

Technical Solution: Nanjing University of Science & Technology has developed an innovative Directed Energy Deposition research program centered on energy parameter optimization for specialized metal alloys. Their approach incorporates advanced laser beam shaping technologies that enable precise control of energy distribution within the melt pool, resulting in enhanced microstructural control. The university's research team has established detailed correlations between energy density metrics (including volumetric energy density and linear heat input) and resulting material properties for various engineering alloys. Their DED platform features multi-sensor monitoring systems that provide real-time assessment of energy absorption efficiency, thermal gradients, and cooling rates during deposition. The university has pioneered adaptive control algorithms that continuously adjust energy parameters based on in-process measurements, ensuring consistent material quality regardless of geometry complexity.

Strengths: Strong materials science foundation; innovative beam shaping technologies; sophisticated energy-microstructure correlation databases. Weaknesses: Limited large-scale manufacturing experience; primarily focused on research applications; requires further development for industrial implementation.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed a sophisticated Directed Energy Deposition research platform focused on fundamental energy parameter relationships and their effects on material properties. Their approach employs multi-physics modeling to predict thermal gradients, solidification rates, and residual stress distributions based on various energy input parameters. The university's research team has established comprehensive energy parameter maps for various metal alloys, correlating laser power density, scan speed, and powder feed rate with resulting microstructure and mechanical properties. Their DED system incorporates advanced in-situ monitoring tools including thermal imaging, melt pool visualization, and acoustic emission sensors to provide real-time assessment of energy absorption and material consolidation. The university has pioneered novel energy distribution strategies that minimize thermal stresses while maximizing deposition efficiency.

Strengths: Strong fundamental research capabilities; comprehensive multi-physics modeling expertise; innovative energy parameter optimization approaches. Weaknesses: Limited industrial-scale implementation experience; research-focused rather than production-oriented; requires further development for commercial applications.

Critical Patents and Research in Energy Control

Purification and Sanitization Using Directed Energy

PatentInactiveUS20210346559A1

Innovation

- The use of directed energy systems that emit electromagnetic radiation and other waves at specific wavelengths and frequencies to treat surfaces, air, and objects, eliminating pathogens without chemicals, by controlling parameters such as wavelength, frequency, amplitude, and temperature to effectively sanitize and promote health.

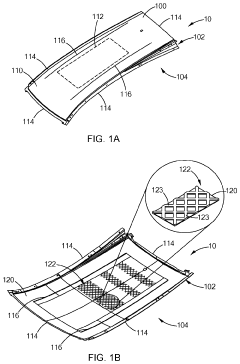

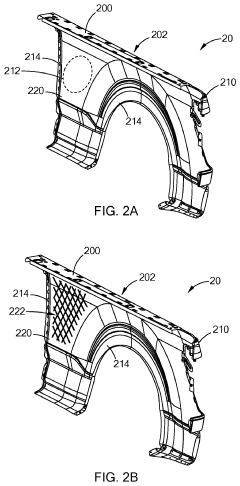

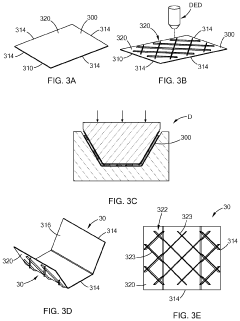

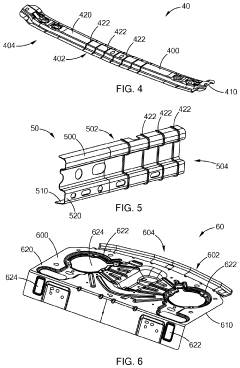

Directed energy deposition (DED) reinforcements on body structures and visible sheet metal surfaces

PatentInactiveUS20220371091A1

Innovation

- The use of additively manufactured reinforcements, deposited via directed energy deposition, metallurgically bonded to sheet metal components, either before or after shaping, to provide enhanced structural support and inhibit deformation.

Material Compatibility Assessment

Material compatibility is a critical factor in the successful implementation of Directed Energy Deposition (DED) processes. The interaction between energy parameters and material properties significantly influences the quality, integrity, and performance of fabricated components. Different materials exhibit varying responses to energy inputs during DED processing, necessitating careful assessment and optimization of parameters for each specific material system.

Metallic materials commonly used in DED include titanium alloys, nickel-based superalloys, stainless steels, and aluminum alloys. Each material category presents unique challenges regarding energy absorption characteristics, thermal conductivity, melting point, and oxidation behavior. For instance, titanium alloys require stringent atmospheric control due to their high reactivity with oxygen at elevated temperatures, while nickel-based superalloys demand higher energy inputs due to their superior thermal resistance properties.

The microstructural evolution during DED processing is heavily dependent on the material-energy interaction. Higher energy densities typically result in larger melt pools, affecting cooling rates and subsequently influencing grain structure, phase formation, and residual stress distribution. Materials with high thermal conductivity, such as aluminum alloys, dissipate heat rapidly, potentially leading to insufficient fusion between layers if energy parameters are not properly calibrated.

Compatibility assessment must also consider the substrate-deposit interface, where metallurgical bonding occurs. The thermal expansion coefficient mismatch between substrate and deposited material can induce significant residual stresses, potentially leading to delamination or cracking. Energy parameter optimization can mitigate these effects by controlling heat input and cooling rates at the interface region.

Multi-material deposition represents an advanced application of DED technology, enabling functionally graded components with tailored properties. However, this approach introduces additional compatibility challenges, including the formation of brittle intermetallic compounds, differences in melting temperatures, and potential immiscibility between certain material combinations. Energy parameter modulation throughout the deposition process becomes essential to accommodate these material transitions.

Comprehensive material compatibility assessment requires systematic characterization of microstructure, mechanical properties, and defect formation across various energy parameter combinations. Advanced techniques such as in-situ monitoring of melt pool dynamics, thermal imaging, and real-time spectroscopy provide valuable insights into material-energy interactions during processing, enabling more precise parameter optimization for specific material systems.

Metallic materials commonly used in DED include titanium alloys, nickel-based superalloys, stainless steels, and aluminum alloys. Each material category presents unique challenges regarding energy absorption characteristics, thermal conductivity, melting point, and oxidation behavior. For instance, titanium alloys require stringent atmospheric control due to their high reactivity with oxygen at elevated temperatures, while nickel-based superalloys demand higher energy inputs due to their superior thermal resistance properties.

The microstructural evolution during DED processing is heavily dependent on the material-energy interaction. Higher energy densities typically result in larger melt pools, affecting cooling rates and subsequently influencing grain structure, phase formation, and residual stress distribution. Materials with high thermal conductivity, such as aluminum alloys, dissipate heat rapidly, potentially leading to insufficient fusion between layers if energy parameters are not properly calibrated.

Compatibility assessment must also consider the substrate-deposit interface, where metallurgical bonding occurs. The thermal expansion coefficient mismatch between substrate and deposited material can induce significant residual stresses, potentially leading to delamination or cracking. Energy parameter optimization can mitigate these effects by controlling heat input and cooling rates at the interface region.

Multi-material deposition represents an advanced application of DED technology, enabling functionally graded components with tailored properties. However, this approach introduces additional compatibility challenges, including the formation of brittle intermetallic compounds, differences in melting temperatures, and potential immiscibility between certain material combinations. Energy parameter modulation throughout the deposition process becomes essential to accommodate these material transitions.

Comprehensive material compatibility assessment requires systematic characterization of microstructure, mechanical properties, and defect formation across various energy parameter combinations. Advanced techniques such as in-situ monitoring of melt pool dynamics, thermal imaging, and real-time spectroscopy provide valuable insights into material-energy interactions during processing, enabling more precise parameter optimization for specific material systems.

Quality Control and Process Monitoring

Quality control and process monitoring are critical components in Directed Energy Deposition (DED) manufacturing processes, particularly when evaluating energy parameters. Effective monitoring systems enable real-time assessment of build quality and provide opportunities for immediate process adjustments, significantly reducing waste and improving part reliability.

Current state-of-the-art monitoring approaches for DED processes include thermal imaging cameras, high-speed photography, and spectroscopic analysis. Thermal imaging systems track melt pool dynamics and temperature gradients, providing crucial data on energy absorption and heat distribution. These systems typically operate in the near-infrared or mid-infrared spectrum to accurately capture thermal signatures across various metal powders and energy levels.

Melt pool monitoring represents a particularly valuable quality control method, as melt pool geometry and stability directly correlate with part microstructure and mechanical properties. Advanced systems can detect anomalies such as overheating, insufficient melting, or powder feed inconsistencies within milliseconds, allowing for immediate parameter adjustments.

Acoustic emission monitoring has emerged as a complementary technique, detecting ultrasonic waves generated during material deposition. The acoustic signature can reveal defects like porosity or cracking that may not be immediately visible through other monitoring methods. When combined with machine learning algorithms, these systems demonstrate increasing accuracy in defect prediction and classification.

In-process metrology using laser scanning or structured light systems enables dimensional verification during builds. This approach compares the as-built geometry against the intended design, identifying deviations that may result from inappropriate energy parameters or material feed rates. The integration of these systems with closed-loop control mechanisms represents a significant advancement in DED process stability.

Post-process quality assessment remains essential despite advances in in-situ monitoring. Techniques including X-ray computed tomography, ultrasonic testing, and metallographic analysis provide comprehensive evaluation of internal structures and material properties. These methods validate the effectiveness of energy parameter selections and process monitoring systems.

The development of standardized quality metrics specifically for DED processes represents an ongoing challenge. Current efforts focus on establishing correlations between monitored parameters (melt pool dimensions, thermal history, cooling rates) and resultant material properties. This work is essential for industry-wide adoption of consistent quality control protocols and certification standards for DED-manufactured components.

Current state-of-the-art monitoring approaches for DED processes include thermal imaging cameras, high-speed photography, and spectroscopic analysis. Thermal imaging systems track melt pool dynamics and temperature gradients, providing crucial data on energy absorption and heat distribution. These systems typically operate in the near-infrared or mid-infrared spectrum to accurately capture thermal signatures across various metal powders and energy levels.

Melt pool monitoring represents a particularly valuable quality control method, as melt pool geometry and stability directly correlate with part microstructure and mechanical properties. Advanced systems can detect anomalies such as overheating, insufficient melting, or powder feed inconsistencies within milliseconds, allowing for immediate parameter adjustments.

Acoustic emission monitoring has emerged as a complementary technique, detecting ultrasonic waves generated during material deposition. The acoustic signature can reveal defects like porosity or cracking that may not be immediately visible through other monitoring methods. When combined with machine learning algorithms, these systems demonstrate increasing accuracy in defect prediction and classification.

In-process metrology using laser scanning or structured light systems enables dimensional verification during builds. This approach compares the as-built geometry against the intended design, identifying deviations that may result from inappropriate energy parameters or material feed rates. The integration of these systems with closed-loop control mechanisms represents a significant advancement in DED process stability.

Post-process quality assessment remains essential despite advances in in-situ monitoring. Techniques including X-ray computed tomography, ultrasonic testing, and metallographic analysis provide comprehensive evaluation of internal structures and material properties. These methods validate the effectiveness of energy parameter selections and process monitoring systems.

The development of standardized quality metrics specifically for DED processes represents an ongoing challenge. Current efforts focus on establishing correlations between monitored parameters (melt pool dimensions, thermal history, cooling rates) and resultant material properties. This work is essential for industry-wide adoption of consistent quality control protocols and certification standards for DED-manufactured components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!