Applications of Directed Energy Deposition in Renewable Energy

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the late 1990s. Initially developed for rapid prototyping and repair applications in aerospace and defense sectors, DED has undergone substantial technological advancement over the past two decades, expanding its capabilities and potential applications across various industries.

The technology operates on the principle of focused thermal energy that melts materials as they are being deposited, allowing for the creation of complex three-dimensional structures with high precision. Unlike traditional manufacturing methods that often result in material waste, DED offers a more sustainable approach by utilizing materials more efficiently, with material utilization rates often exceeding 90%.

In the context of renewable energy systems, DED technology presents unprecedented opportunities for innovation and advancement. The renewable energy sector faces unique manufacturing challenges, including the need for complex geometries, multi-material components, and high-performance materials capable of withstanding extreme operating conditions. DED's ability to process a wide range of materials—including metals, alloys, and composites—makes it particularly suitable for addressing these challenges.

The evolution of DED technology has been marked by significant improvements in process control, material compatibility, and system integration. Modern DED systems incorporate sophisticated monitoring and control mechanisms that ensure consistent quality and performance, critical factors for renewable energy applications where component reliability directly impacts system efficiency and longevity.

The primary technical objectives for DED in renewable energy applications include enhancing energy conversion efficiency through optimized component design, improving durability and performance in harsh environmental conditions, and enabling cost-effective manufacturing of complex renewable energy system components. Additionally, there is a growing focus on developing DED processes that can incorporate functionally graded materials and smart components, potentially revolutionizing how renewable energy systems are designed and manufactured.

Current research trajectories indicate a convergence of DED technology with other advanced manufacturing techniques and digital technologies, creating hybrid manufacturing approaches that leverage the strengths of multiple processes. This integration is expected to further expand the capabilities and applications of DED in renewable energy manufacturing, potentially enabling entirely new component designs and system architectures that were previously impossible to produce.

As global emphasis on sustainable energy solutions continues to grow, DED technology stands at the forefront of manufacturing innovation, offering pathways to more efficient, durable, and cost-effective renewable energy systems. The continued advancement of this technology will likely play a crucial role in accelerating the transition to renewable energy sources and addressing the pressing challenges of climate change.

The technology operates on the principle of focused thermal energy that melts materials as they are being deposited, allowing for the creation of complex three-dimensional structures with high precision. Unlike traditional manufacturing methods that often result in material waste, DED offers a more sustainable approach by utilizing materials more efficiently, with material utilization rates often exceeding 90%.

In the context of renewable energy systems, DED technology presents unprecedented opportunities for innovation and advancement. The renewable energy sector faces unique manufacturing challenges, including the need for complex geometries, multi-material components, and high-performance materials capable of withstanding extreme operating conditions. DED's ability to process a wide range of materials—including metals, alloys, and composites—makes it particularly suitable for addressing these challenges.

The evolution of DED technology has been marked by significant improvements in process control, material compatibility, and system integration. Modern DED systems incorporate sophisticated monitoring and control mechanisms that ensure consistent quality and performance, critical factors for renewable energy applications where component reliability directly impacts system efficiency and longevity.

The primary technical objectives for DED in renewable energy applications include enhancing energy conversion efficiency through optimized component design, improving durability and performance in harsh environmental conditions, and enabling cost-effective manufacturing of complex renewable energy system components. Additionally, there is a growing focus on developing DED processes that can incorporate functionally graded materials and smart components, potentially revolutionizing how renewable energy systems are designed and manufactured.

Current research trajectories indicate a convergence of DED technology with other advanced manufacturing techniques and digital technologies, creating hybrid manufacturing approaches that leverage the strengths of multiple processes. This integration is expected to further expand the capabilities and applications of DED in renewable energy manufacturing, potentially enabling entirely new component designs and system architectures that were previously impossible to produce.

As global emphasis on sustainable energy solutions continues to grow, DED technology stands at the forefront of manufacturing innovation, offering pathways to more efficient, durable, and cost-effective renewable energy systems. The continued advancement of this technology will likely play a crucial role in accelerating the transition to renewable energy sources and addressing the pressing challenges of climate change.

Renewable Energy Market Demand Analysis

The renewable energy sector has witnessed unprecedented growth over the past decade, with global investments reaching $366 billion in 2021, representing a 6.5% increase from the previous year. This growth trajectory is expected to continue as countries worldwide commit to ambitious carbon reduction targets and energy transition goals. Within this expanding market, advanced manufacturing technologies like Directed Energy Deposition (DED) are finding increasing applications, particularly in the production, maintenance, and innovation of renewable energy infrastructure components.

Wind energy represents one of the most promising markets for DED applications, with the global wind turbine market valued at approximately $90 billion in 2022. The demand for larger, more efficient turbine blades and components has created significant opportunities for advanced manufacturing processes that can produce complex geometries with enhanced material properties. DED's ability to repair and remanufacture high-value components such as turbine blades and gearboxes addresses a critical market need, as maintenance costs constitute up to 25% of the total lifecycle costs for wind energy systems.

Solar energy infrastructure presents another substantial market opportunity, with the global solar panel market expected to reach $200 billion by 2026. The industry's push toward higher efficiency panels and reduced manufacturing costs aligns perfectly with DED's capabilities for producing specialized components and integrating multiple materials. Additionally, the growing demand for building-integrated photovoltaics (BIPV) requires customized solutions that DED can efficiently deliver.

Hydrogen production technologies and fuel cell systems represent emerging markets where DED applications show significant promise. The global hydrogen generation market is projected to grow at a CAGR of 9.2% through 2028, driven by green hydrogen initiatives. DED's ability to work with specialized materials required for electrolyzers and fuel cells positions it as a key enabling technology in this rapidly expanding sector.

Energy storage systems, particularly advanced battery technologies, constitute another high-growth market segment where DED applications can address critical manufacturing challenges. The global battery market for renewable energy storage is expected to grow at a CAGR of 32% through 2025, creating demand for innovative manufacturing solutions that can improve battery performance and reduce production costs.

Regional analysis indicates that Europe leads in renewable energy manufacturing innovation, followed closely by North America and East Asia. Government incentives for clean energy manufacturing, particularly in the EU's Green Deal and the US Inflation Reduction Act, are creating favorable market conditions for advanced manufacturing technologies like DED to gain wider adoption in renewable energy supply chains.

Wind energy represents one of the most promising markets for DED applications, with the global wind turbine market valued at approximately $90 billion in 2022. The demand for larger, more efficient turbine blades and components has created significant opportunities for advanced manufacturing processes that can produce complex geometries with enhanced material properties. DED's ability to repair and remanufacture high-value components such as turbine blades and gearboxes addresses a critical market need, as maintenance costs constitute up to 25% of the total lifecycle costs for wind energy systems.

Solar energy infrastructure presents another substantial market opportunity, with the global solar panel market expected to reach $200 billion by 2026. The industry's push toward higher efficiency panels and reduced manufacturing costs aligns perfectly with DED's capabilities for producing specialized components and integrating multiple materials. Additionally, the growing demand for building-integrated photovoltaics (BIPV) requires customized solutions that DED can efficiently deliver.

Hydrogen production technologies and fuel cell systems represent emerging markets where DED applications show significant promise. The global hydrogen generation market is projected to grow at a CAGR of 9.2% through 2028, driven by green hydrogen initiatives. DED's ability to work with specialized materials required for electrolyzers and fuel cells positions it as a key enabling technology in this rapidly expanding sector.

Energy storage systems, particularly advanced battery technologies, constitute another high-growth market segment where DED applications can address critical manufacturing challenges. The global battery market for renewable energy storage is expected to grow at a CAGR of 32% through 2025, creating demand for innovative manufacturing solutions that can improve battery performance and reduce production costs.

Regional analysis indicates that Europe leads in renewable energy manufacturing innovation, followed closely by North America and East Asia. Government incentives for clean energy manufacturing, particularly in the EU's Green Deal and the US Inflation Reduction Act, are creating favorable market conditions for advanced manufacturing technologies like DED to gain wider adoption in renewable energy supply chains.

DED Technology Status and Challenges

Directed Energy Deposition (DED) technology has evolved significantly over the past decade, establishing itself as a promising additive manufacturing method with applications in renewable energy sectors. Currently, DED technology has reached commercial maturity in certain applications, particularly in repair and remanufacturing of high-value components. However, its specific implementation in renewable energy infrastructure remains in early adoption phases.

The global landscape of DED technology development shows concentration in industrialized nations, with the United States, Germany, China, and Japan leading research efforts. Academic institutions and industrial R&D centers in these regions have established comprehensive research programs focused on expanding DED capabilities for energy applications, particularly in wind turbine component manufacturing and solar energy system production.

Despite its progress, DED technology faces several significant technical challenges when applied to renewable energy manufacturing. Material compatibility issues remain prominent, as renewable energy components often require specialized alloys and composites with specific thermal, mechanical, and corrosion-resistant properties. The deposition of these materials through DED processes frequently results in microstructural inconsistencies and property variations that can compromise component performance.

Process stability and repeatability represent another major hurdle. The complex thermal cycles inherent in DED processes can lead to residual stresses, distortion, and inconsistent material properties across large renewable energy components such as turbine blades or structural supports. This variability undermines the reliability requirements critical for renewable energy infrastructure with expected service lives of 20+ years.

Scale-up challenges are particularly acute in renewable energy applications. Many renewable energy components require large-scale manufacturing capabilities, while current DED systems are limited in build volume and deposition rates. The balance between deposition speed and quality becomes increasingly difficult to maintain as component size increases, creating bottlenecks in production efficiency.

Energy consumption during the DED process itself presents a paradoxical challenge for renewable energy applications. The high-power requirements of DED systems, particularly laser and electron beam variants, create a substantial carbon footprint during manufacturing that must be offset by the renewable energy generated over the component's lifetime to achieve true sustainability.

Quality assurance and certification frameworks for DED-manufactured renewable energy components remain underdeveloped. The lack of standardized testing protocols and certification pathways creates regulatory uncertainty that slows adoption in safety-critical applications like offshore wind or concentrated solar power systems.

The global landscape of DED technology development shows concentration in industrialized nations, with the United States, Germany, China, and Japan leading research efforts. Academic institutions and industrial R&D centers in these regions have established comprehensive research programs focused on expanding DED capabilities for energy applications, particularly in wind turbine component manufacturing and solar energy system production.

Despite its progress, DED technology faces several significant technical challenges when applied to renewable energy manufacturing. Material compatibility issues remain prominent, as renewable energy components often require specialized alloys and composites with specific thermal, mechanical, and corrosion-resistant properties. The deposition of these materials through DED processes frequently results in microstructural inconsistencies and property variations that can compromise component performance.

Process stability and repeatability represent another major hurdle. The complex thermal cycles inherent in DED processes can lead to residual stresses, distortion, and inconsistent material properties across large renewable energy components such as turbine blades or structural supports. This variability undermines the reliability requirements critical for renewable energy infrastructure with expected service lives of 20+ years.

Scale-up challenges are particularly acute in renewable energy applications. Many renewable energy components require large-scale manufacturing capabilities, while current DED systems are limited in build volume and deposition rates. The balance between deposition speed and quality becomes increasingly difficult to maintain as component size increases, creating bottlenecks in production efficiency.

Energy consumption during the DED process itself presents a paradoxical challenge for renewable energy applications. The high-power requirements of DED systems, particularly laser and electron beam variants, create a substantial carbon footprint during manufacturing that must be offset by the renewable energy generated over the component's lifetime to achieve true sustainability.

Quality assurance and certification frameworks for DED-manufactured renewable energy components remain underdeveloped. The lack of standardized testing protocols and certification pathways creates regulatory uncertainty that slows adoption in safety-critical applications like offshore wind or concentrated solar power systems.

Current DED Solutions for Renewable Energy

01 Process and equipment for directed energy deposition

Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits melted material onto a specified surface, where it solidifies. The equipment includes energy sources such as lasers or electron beams, material delivery systems, and motion control systems that enable precise deposition. This technology allows for the creation of complex geometries and can be used for both new part manufacturing and repair applications.- Directed Energy Deposition Process Fundamentals: Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials by melting as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits melted material onto a specified surface, where it solidifies. This technology allows for the creation of complex geometries and can be used with various materials including metals, polymers, and ceramics. The process parameters such as energy source power, material feed rate, and deposition path significantly influence the final product quality.

- Material Considerations for DED Applications: The selection and preparation of materials play a crucial role in Directed Energy Deposition processes. Various metal powders and wire feedstocks can be used, including titanium alloys, nickel-based superalloys, stainless steels, and aluminum alloys. The material properties such as particle size distribution, flowability, and thermal characteristics significantly impact the deposition quality. Pre-processing treatments and post-processing heat treatments are often necessary to achieve desired mechanical properties and microstructure in the final components. Material compatibility with the energy source and substrate is also an important consideration for successful DED applications.

- Energy Source Technologies in DED Systems: Different energy sources can be employed in Directed Energy Deposition systems, including lasers, electron beams, plasma arcs, and other focused heat sources. Laser-based DED systems offer high precision and control over the energy input, while electron beam systems operate in vacuum environments and provide high energy efficiency. Plasma arc-based systems are often more cost-effective but may offer less precision. The selection of an appropriate energy source depends on factors such as the material being processed, required feature resolution, production volume, and economic considerations. Advanced control systems are used to modulate the energy delivery based on real-time process monitoring.

- Process Monitoring and Control Systems: Advanced monitoring and control systems are essential for ensuring quality and consistency in Directed Energy Deposition processes. These systems typically incorporate sensors for measuring melt pool temperature, dimensions, and cooling rates, as well as monitoring the feed material flow and energy source parameters. Closed-loop control algorithms adjust process parameters in real-time based on sensor feedback to maintain optimal deposition conditions. Machine learning and artificial intelligence approaches are increasingly being applied to predict and prevent defects, optimize process parameters, and improve overall part quality. In-situ monitoring enables early detection of anomalies and reduces post-processing inspection requirements.

- Multi-Material and Functionally Graded Components: Directed Energy Deposition enables the fabrication of multi-material and functionally graded components that cannot be produced using conventional manufacturing methods. By controlling the composition of the feedstock material during deposition, it is possible to create components with spatially varying material properties. This capability allows for the optimization of mechanical, thermal, and electrical properties within a single component. Applications include wear-resistant surfaces, thermal barrier coatings, and components with tailored stiffness distributions. The technology enables innovative designs that combine the beneficial properties of different materials while minimizing interfaces that could lead to failure.

02 Materials and powder management in DED processes

Material selection and powder management are critical aspects of directed energy deposition. Various materials can be used in DED processes, including metals, alloys, and composites. The powder characteristics such as particle size distribution, flowability, and chemical composition significantly impact the quality of the final product. Advanced powder delivery systems ensure consistent material flow during the deposition process. Proper handling, storage, and recycling of powders are essential for process efficiency and product quality. Innovations in this area focus on developing specialized materials for specific applications and improving powder management systems.Expand Specific Solutions03 Process control and monitoring systems for DED

Advanced control and monitoring systems are essential for ensuring quality and consistency in directed energy deposition processes. These systems typically include real-time monitoring of process parameters such as temperature, melt pool dimensions, deposition rate, and layer thickness. Closed-loop control systems adjust process parameters dynamically based on sensor feedback to maintain optimal conditions. Machine learning and artificial intelligence algorithms are increasingly being integrated to predict and prevent defects. Vision systems and thermal imaging cameras provide additional data for quality assurance. These monitoring and control technologies significantly improve the reliability and repeatability of DED processes.Expand Specific Solutions04 Multi-material and hybrid manufacturing approaches

Multi-material deposition and hybrid manufacturing approaches combine directed energy deposition with other manufacturing processes to leverage the advantages of each technology. These approaches enable the creation of components with functionally graded materials, where material composition changes gradually throughout the part. Hybrid systems that integrate DED with machining operations allow for in-process finishing, improving dimensional accuracy and surface quality. The ability to deposit different materials in a single build process opens up new design possibilities and enables the creation of components with unique property combinations that cannot be achieved through conventional manufacturing methods.Expand Specific Solutions05 Applications and case studies of DED technology

Directed energy deposition technology has found applications across various industries including aerospace, automotive, medical, and energy sectors. It is particularly valuable for repair and remanufacturing of high-value components, such as turbine blades and tooling. DED enables the restoration of worn or damaged parts by selectively depositing material only where needed. In new part manufacturing, it allows for the creation of large-scale components with complex geometries and internal features. The technology also supports rapid prototyping and the development of functionally graded materials. Case studies demonstrate significant cost savings, reduced lead times, and improved performance characteristics compared to conventional manufacturing methods.Expand Specific Solutions

Key Industry Players and Competitors

The renewable energy sector's adoption of Directed Energy Deposition (DED) technology is currently in an early growth phase, with the market expected to expand significantly as applications mature. The global market size for DED in renewable energy applications is projected to reach substantial value as industries seek more efficient manufacturing methods for complex components. Technologically, companies are at varying stages of maturity: established energy players like Siemens Energy, Vestas Wind Systems, and Shell are investing in DED research for turbine components and specialized equipment, while academic institutions (MIT, Huazhong University) are advancing fundamental research. Technology companies like Stratasys and Enphase Energy are developing practical applications, with GE Avio and Rolls-Royce leading in aerospace-derived energy applications. This competitive landscape reflects a technology transitioning from research to commercial implementation.

Stratasys, Inc.

Technical Solution: Stratasys has developed a specialized Directed Energy Deposition (DED) platform focused on renewable energy applications, particularly for solar and wind power components. Their system combines laser-based DED technology with proprietary material formulations optimized for renewable energy applications. The technology enables the creation of multi-material components with functionally graded properties, allowing for optimized thermal and mechanical performance in solar receivers and wind turbine components. Stratasys' approach incorporates a closed-loop control system that monitors melt pool characteristics in real-time, adjusting laser power and material feed rates to maintain consistent deposition quality. This is particularly valuable for creating components with complex internal cooling channels used in concentrated solar power systems. Their DED technology also supports the use of recycled metal powders, contributing to circular economy principles in renewable energy manufacturing. The system can produce components with wall thicknesses ranging from 0.8mm to 30mm, providing flexibility for various renewable energy applications.

Strengths: Advanced multi-material capabilities allow for optimized component performance; closed-loop control system ensures high quality and repeatability; ability to use recycled materials reduces environmental impact and costs. Weaknesses: Limited build volume compared to some industrial DED systems; higher initial investment costs compared to traditional manufacturing; challenges in scaling production for very large renewable energy components.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed advanced Directed Energy Deposition (DED) applications specifically for renewable energy components manufacturing. Their technology utilizes laser-based DED systems to create complex geometries for wind turbine components and hydrogen electrolyzer parts. The process employs high-power fiber lasers (2-10 kW) coupled with multi-axis robotic arms to deposit specialized metal alloys layer by layer. This approach enables the production of large-scale components with gradient material properties that enhance performance in renewable energy applications. Siemens has particularly focused on using DED for manufacturing heat exchangers for concentrated solar power systems, where the ability to create complex internal cooling channels significantly improves thermal efficiency. Their process incorporates real-time monitoring systems that adjust deposition parameters based on thermal imaging feedback, ensuring consistent material properties throughout large structures.

Strengths: Superior capability to produce large-scale components with complex geometries that traditional manufacturing cannot achieve; ability to create parts with gradient material properties optimized for specific renewable energy applications; reduced material waste compared to subtractive manufacturing. Weaknesses: Higher initial equipment investment compared to conventional manufacturing; process speed limitations for very large components; challenges in maintaining consistent material properties across large structures.

Critical DED Patents and Technical Literature

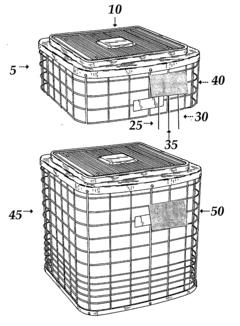

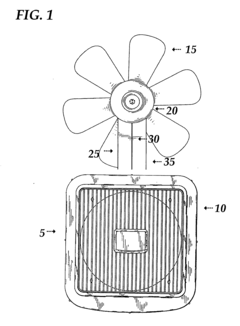

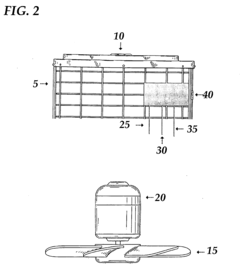

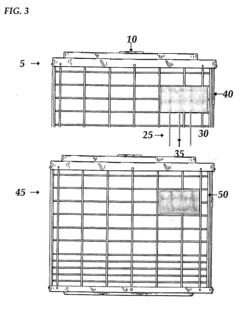

Renewable energy electric power generation system derived from mechanical sources

PatentInactiveUS20100244455A1

Innovation

- A system that integrates turbine generators above mechanical sources like air conditioners to capture exhaust, wind, or discharge energy, eliminating the need for storage and transmission infrastructure by routing energy directly back to the source or grid, using a turbine generator positioned for maximum efficiency and constant energy output.

Directed Energy Deposition to Facilitate High Speed Applications

PatentActiveUS20190003086A1

Innovation

- The method involves impulsively heating a portion of a fluid to create a lower density region surrounded by a higher density region, synchronizing this process with a pulsed propulsion unit to propel an object through the fluid, using techniques like laser-induced filaments and electrical discharges to form and guide energy deposition paths.

Sustainability Impact Assessment

The integration of Directed Energy Deposition (DED) technologies in renewable energy systems presents significant sustainability implications across environmental, economic, and social dimensions. From an environmental perspective, DED manufacturing processes demonstrate considerable advantages over conventional manufacturing methods by reducing material waste by up to 90% in certain applications. This dramatic reduction stems from DED's additive nature, which deposits material only where needed, contrasting sharply with traditional subtractive manufacturing approaches that generate substantial waste.

Energy consumption analysis reveals that DED technologies, when optimized for renewable energy component production, can achieve energy efficiency improvements of 30-45% compared to conventional manufacturing processes. This efficiency gain becomes particularly significant when considering the lifecycle energy requirements of renewable energy infrastructure. The ability to repair and remanufacture components using DED further extends product lifecycles, reducing the environmental burden associated with complete component replacement.

Carbon footprint assessments of DED applications in renewable energy sectors indicate potential emissions reductions of 25-40% when compared to traditional manufacturing methods. These reductions derive from both process efficiencies and the extended service life of components, which distributes embodied carbon costs over longer operational periods. Additionally, DED enables localized manufacturing capabilities, reducing transportation-related emissions in global supply chains.

Resource conservation represents another critical sustainability advantage. DED technologies typically achieve material utilization rates exceeding 95%, significantly higher than conventional manufacturing processes that may waste up to 80% of raw materials in certain applications. This efficiency becomes particularly valuable when working with rare earth elements and specialized materials often required in renewable energy technologies.

From a circular economy perspective, DED facilitates end-of-life strategies by enabling component repair rather than replacement. Studies indicate that DED-based repair approaches can recover 85-95% of a component's original functionality while consuming only 15-30% of the resources required for new production. This capability creates significant opportunities for closed-loop material systems within renewable energy infrastructure.

Water usage analysis shows DED processes typically require 40-60% less water than conventional manufacturing methods for comparable components. This reduction becomes especially valuable in water-stressed regions where renewable energy deployment must balance energy and water security considerations.

Energy consumption analysis reveals that DED technologies, when optimized for renewable energy component production, can achieve energy efficiency improvements of 30-45% compared to conventional manufacturing processes. This efficiency gain becomes particularly significant when considering the lifecycle energy requirements of renewable energy infrastructure. The ability to repair and remanufacture components using DED further extends product lifecycles, reducing the environmental burden associated with complete component replacement.

Carbon footprint assessments of DED applications in renewable energy sectors indicate potential emissions reductions of 25-40% when compared to traditional manufacturing methods. These reductions derive from both process efficiencies and the extended service life of components, which distributes embodied carbon costs over longer operational periods. Additionally, DED enables localized manufacturing capabilities, reducing transportation-related emissions in global supply chains.

Resource conservation represents another critical sustainability advantage. DED technologies typically achieve material utilization rates exceeding 95%, significantly higher than conventional manufacturing processes that may waste up to 80% of raw materials in certain applications. This efficiency becomes particularly valuable when working with rare earth elements and specialized materials often required in renewable energy technologies.

From a circular economy perspective, DED facilitates end-of-life strategies by enabling component repair rather than replacement. Studies indicate that DED-based repair approaches can recover 85-95% of a component's original functionality while consuming only 15-30% of the resources required for new production. This capability creates significant opportunities for closed-loop material systems within renewable energy infrastructure.

Water usage analysis shows DED processes typically require 40-60% less water than conventional manufacturing methods for comparable components. This reduction becomes especially valuable in water-stressed regions where renewable energy deployment must balance energy and water security considerations.

Cost-Benefit Analysis of DED Implementation

Implementing Directed Energy Deposition (DED) technology in renewable energy applications requires thorough cost-benefit analysis to determine economic viability. Initial capital expenditure for DED systems ranges from $500,000 to $2 million, depending on system complexity, power requirements, and auxiliary equipment needs. This substantial investment represents a significant barrier to entry, particularly for smaller enterprises or research institutions exploring renewable energy applications.

Operational costs must also be carefully considered, including material consumption, energy usage, maintenance requirements, and specialized operator training. Material efficiency in DED processes typically ranges between 90-98%, significantly higher than traditional manufacturing methods that often waste 70-80% of raw materials. This efficiency translates to substantial material cost savings over time, especially when working with expensive metals commonly used in renewable energy components.

Energy consumption during DED operations averages 15-25 kWh per kilogram of deposited material, varying based on material properties and deposition parameters. While this represents significant energy input, the ability to repair and remanufacture components rather than replace them entirely creates substantial lifecycle cost advantages.

Maintenance costs typically account for 5-8% of the initial system investment annually, covering laser source maintenance, powder delivery system upkeep, and calibration requirements. These costs can be offset by the reduced downtime achieved through on-site repair capabilities, particularly valuable for remote renewable energy installations like offshore wind farms.

The return on investment timeline for DED implementation in renewable energy applications varies significantly by use case. Component repair applications typically show positive ROI within 2-3 years, while more complex applications like hybrid manufacturing or on-site field repairs may require 3-5 years to achieve financial breakeven. The economic benefits accelerate as system utilization increases and operators gain expertise.

Non-monetary benefits must also factor into comprehensive analysis, including reduced lead times for critical components, decreased supply chain vulnerability, extended component lifecycles, and reduced environmental impact through material conservation. These advantages, while difficult to quantify precisely, contribute significantly to the overall value proposition of DED technology in renewable energy applications.

Risk factors affecting cost-benefit calculations include technology obsolescence, material compatibility limitations, quality assurance challenges, and regulatory compliance requirements. Organizations must develop mitigation strategies for these factors when planning DED implementation to ensure projected benefits materialize as anticipated.

Operational costs must also be carefully considered, including material consumption, energy usage, maintenance requirements, and specialized operator training. Material efficiency in DED processes typically ranges between 90-98%, significantly higher than traditional manufacturing methods that often waste 70-80% of raw materials. This efficiency translates to substantial material cost savings over time, especially when working with expensive metals commonly used in renewable energy components.

Energy consumption during DED operations averages 15-25 kWh per kilogram of deposited material, varying based on material properties and deposition parameters. While this represents significant energy input, the ability to repair and remanufacture components rather than replace them entirely creates substantial lifecycle cost advantages.

Maintenance costs typically account for 5-8% of the initial system investment annually, covering laser source maintenance, powder delivery system upkeep, and calibration requirements. These costs can be offset by the reduced downtime achieved through on-site repair capabilities, particularly valuable for remote renewable energy installations like offshore wind farms.

The return on investment timeline for DED implementation in renewable energy applications varies significantly by use case. Component repair applications typically show positive ROI within 2-3 years, while more complex applications like hybrid manufacturing or on-site field repairs may require 3-5 years to achieve financial breakeven. The economic benefits accelerate as system utilization increases and operators gain expertise.

Non-monetary benefits must also factor into comprehensive analysis, including reduced lead times for critical components, decreased supply chain vulnerability, extended component lifecycles, and reduced environmental impact through material conservation. These advantages, while difficult to quantify precisely, contribute significantly to the overall value proposition of DED technology in renewable energy applications.

Risk factors affecting cost-benefit calculations include technology obsolescence, material compatibility limitations, quality assurance challenges, and regulatory compliance requirements. Organizations must develop mitigation strategies for these factors when planning DED implementation to ensure projected benefits materialize as anticipated.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!