Accuracy and Precision in Directed Energy Deposition Technologies

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) emerged in the late 1990s as an advanced additive manufacturing technology capable of producing complex metal components directly from digital models. This technology evolved from earlier laser cladding and direct metal deposition processes, representing a significant advancement in metal additive manufacturing capabilities. DED utilizes focused thermal energy, typically from a laser, electron beam, or plasma arc, to melt feedstock material (powder or wire) as it is being deposited layer by layer, creating fully dense metal structures.

The evolution of DED technology has been marked by continuous improvements in energy source precision, material delivery systems, and process control mechanisms. Early systems suffered from significant dimensional inaccuracies and inconsistent material properties, limiting their industrial applications. However, recent technological advancements have dramatically enhanced the precision and repeatability of DED processes, expanding their potential applications across various industries.

The primary technical objective in DED development is achieving superior accuracy and precision in the fabrication process. Accuracy refers to the dimensional conformity of the produced part to its design specifications, while precision relates to the consistency and repeatability of the manufacturing process. These factors are critical for DED's adoption in high-value industries such as aerospace, defense, and medical device manufacturing, where component performance and reliability are paramount.

Current research and development efforts focus on several key areas: enhancing deposition resolution to enable finer feature creation, improving surface finish quality to reduce post-processing requirements, and developing advanced in-situ monitoring systems for real-time quality control. Additionally, significant attention is being directed toward multi-material deposition capabilities and functionally graded materials, which represent the next frontier in DED technology.

The trajectory of DED technology development is increasingly oriented toward closed-loop control systems that integrate advanced sensors, machine learning algorithms, and predictive modeling to achieve unprecedented levels of accuracy and precision. These systems aim to detect and correct process deviations in real-time, compensating for thermal distortions, material variations, and other factors that impact dimensional accuracy.

As DED technology continues to mature, the ultimate goal is to establish it as a reliable, high-precision manufacturing process capable of producing components with complex geometries, optimized material properties, and minimal post-processing requirements. This evolution will likely transform traditional manufacturing paradigms, enabling more agile, sustainable, and cost-effective production methodologies across multiple industrial sectors.

The evolution of DED technology has been marked by continuous improvements in energy source precision, material delivery systems, and process control mechanisms. Early systems suffered from significant dimensional inaccuracies and inconsistent material properties, limiting their industrial applications. However, recent technological advancements have dramatically enhanced the precision and repeatability of DED processes, expanding their potential applications across various industries.

The primary technical objective in DED development is achieving superior accuracy and precision in the fabrication process. Accuracy refers to the dimensional conformity of the produced part to its design specifications, while precision relates to the consistency and repeatability of the manufacturing process. These factors are critical for DED's adoption in high-value industries such as aerospace, defense, and medical device manufacturing, where component performance and reliability are paramount.

Current research and development efforts focus on several key areas: enhancing deposition resolution to enable finer feature creation, improving surface finish quality to reduce post-processing requirements, and developing advanced in-situ monitoring systems for real-time quality control. Additionally, significant attention is being directed toward multi-material deposition capabilities and functionally graded materials, which represent the next frontier in DED technology.

The trajectory of DED technology development is increasingly oriented toward closed-loop control systems that integrate advanced sensors, machine learning algorithms, and predictive modeling to achieve unprecedented levels of accuracy and precision. These systems aim to detect and correct process deviations in real-time, compensating for thermal distortions, material variations, and other factors that impact dimensional accuracy.

As DED technology continues to mature, the ultimate goal is to establish it as a reliable, high-precision manufacturing process capable of producing components with complex geometries, optimized material properties, and minimal post-processing requirements. This evolution will likely transform traditional manufacturing paradigms, enabling more agile, sustainable, and cost-effective production methodologies across multiple industrial sectors.

Market Demand Analysis for High-Precision DED

The global market for high-precision Directed Energy Deposition (DED) technologies has witnessed substantial growth in recent years, driven primarily by increasing demand across aerospace, defense, medical, and automotive sectors. These industries require components with exceptional dimensional accuracy, surface finish, and mechanical properties that traditional manufacturing methods struggle to deliver consistently.

Market research indicates that the aerospace industry represents the largest segment for high-precision DED applications, accounting for approximately 35% of the total market share. This dominance stems from the need for complex, lightweight components with superior performance characteristics in extreme operating conditions. The ability of DED to produce parts with intricate internal geometries while maintaining tight tolerances has made it particularly valuable for manufacturing turbine blades, combustion chambers, and structural components.

The medical device industry has emerged as the fastest-growing market segment for high-precision DED technologies, with a compound annual growth rate exceeding 20%. This rapid expansion is fueled by increasing demand for patient-specific implants, prosthetics, and surgical instruments that require biocompatible materials and complex geometries. The ability to create porous structures with controlled density gradients has proven especially valuable for orthopedic implants that promote osseointegration.

Regional analysis reveals that North America currently leads the high-precision DED market, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to experience the highest growth rate over the next five years due to significant investments in advanced manufacturing capabilities in China, Japan, and South Korea. Government initiatives supporting Industry 4.0 transformation are accelerating adoption across these regions.

End-user surveys highlight that precision requirements continue to become more stringent, with many applications now demanding tolerances below ±0.05mm. This trend is particularly evident in industries producing high-value, mission-critical components where performance and reliability cannot be compromised. Consequently, manufacturers are increasingly willing to invest in premium DED solutions that can deliver superior accuracy and repeatability.

Market forecasts suggest that the global high-precision DED market will reach approximately $2.3 billion by 2027, representing a significant portion of the overall additive manufacturing landscape. This growth trajectory is supported by ongoing technological advancements in process monitoring, feedback control systems, and multi-material capabilities that continue to expand the application scope of DED technologies.

Market research indicates that the aerospace industry represents the largest segment for high-precision DED applications, accounting for approximately 35% of the total market share. This dominance stems from the need for complex, lightweight components with superior performance characteristics in extreme operating conditions. The ability of DED to produce parts with intricate internal geometries while maintaining tight tolerances has made it particularly valuable for manufacturing turbine blades, combustion chambers, and structural components.

The medical device industry has emerged as the fastest-growing market segment for high-precision DED technologies, with a compound annual growth rate exceeding 20%. This rapid expansion is fueled by increasing demand for patient-specific implants, prosthetics, and surgical instruments that require biocompatible materials and complex geometries. The ability to create porous structures with controlled density gradients has proven especially valuable for orthopedic implants that promote osseointegration.

Regional analysis reveals that North America currently leads the high-precision DED market, followed closely by Europe and Asia-Pacific. However, the Asia-Pacific region is projected to experience the highest growth rate over the next five years due to significant investments in advanced manufacturing capabilities in China, Japan, and South Korea. Government initiatives supporting Industry 4.0 transformation are accelerating adoption across these regions.

End-user surveys highlight that precision requirements continue to become more stringent, with many applications now demanding tolerances below ±0.05mm. This trend is particularly evident in industries producing high-value, mission-critical components where performance and reliability cannot be compromised. Consequently, manufacturers are increasingly willing to invest in premium DED solutions that can deliver superior accuracy and repeatability.

Market forecasts suggest that the global high-precision DED market will reach approximately $2.3 billion by 2027, representing a significant portion of the overall additive manufacturing landscape. This growth trajectory is supported by ongoing technological advancements in process monitoring, feedback control systems, and multi-material capabilities that continue to expand the application scope of DED technologies.

Current State and Technical Challenges in DED

Directed Energy Deposition (DED) technology has evolved significantly over the past decade, establishing itself as a prominent additive manufacturing method for metal components. Currently, the global landscape shows varying levels of technological maturity, with North America and Europe leading in research and industrial implementation, while Asia is rapidly closing the gap with substantial investments in research infrastructure.

The current state of DED technology demonstrates considerable progress in material compatibility, with capabilities now extending beyond traditional metals to include specialized alloys, functionally graded materials, and multi-material structures. Process parameters have been refined through extensive empirical studies, resulting in improved deposition rates that can reach up to 10 kg/h for certain applications, significantly outpacing many competing additive manufacturing technologies.

Despite these advancements, DED faces persistent technical challenges that limit its broader industrial adoption. Accuracy and precision remain primary concerns, with typical dimensional tolerances ranging from ±0.2mm to ±0.5mm depending on the specific DED variant and process parameters. This level of precision falls short of requirements for high-precision applications in aerospace and medical industries, where tolerances below ±0.1mm are often necessary.

Thermal management represents another significant challenge. The high-energy input characteristic of DED processes creates substantial thermal gradients that lead to residual stresses, distortion, and inconsistent microstructural properties throughout the built component. Current thermal monitoring systems offer limited real-time control capabilities, resulting in part-to-part variability that undermines reproducibility.

Surface finish quality continues to be problematic, with as-deposited surfaces typically exhibiting Ra values between 15-40μm, necessitating extensive post-processing operations that reduce the economic viability of the technology. This limitation is particularly pronounced in powder-based DED systems where powder catchment efficiency rarely exceeds 70%, leading to material waste and potential contamination issues.

Process monitoring and control systems have advanced but remain insufficient for closed-loop quality assurance. Current sensor technologies can detect major process deviations but lack the sensitivity and response time needed for real-time adjustments to maintain consistent quality throughout complex builds. This gap in process control capability directly impacts the repeatability of mechanical properties, with variations in tensile strength and fatigue resistance observed both within and between builds.

Standardization efforts are underway through organizations like ASTM and ISO, but the industry still lacks comprehensive standards for process qualification, material certification, and quality assurance specific to DED technologies. This regulatory gap creates barriers to adoption in highly regulated industries where certification pathways must be clearly defined.

The current state of DED technology demonstrates considerable progress in material compatibility, with capabilities now extending beyond traditional metals to include specialized alloys, functionally graded materials, and multi-material structures. Process parameters have been refined through extensive empirical studies, resulting in improved deposition rates that can reach up to 10 kg/h for certain applications, significantly outpacing many competing additive manufacturing technologies.

Despite these advancements, DED faces persistent technical challenges that limit its broader industrial adoption. Accuracy and precision remain primary concerns, with typical dimensional tolerances ranging from ±0.2mm to ±0.5mm depending on the specific DED variant and process parameters. This level of precision falls short of requirements for high-precision applications in aerospace and medical industries, where tolerances below ±0.1mm are often necessary.

Thermal management represents another significant challenge. The high-energy input characteristic of DED processes creates substantial thermal gradients that lead to residual stresses, distortion, and inconsistent microstructural properties throughout the built component. Current thermal monitoring systems offer limited real-time control capabilities, resulting in part-to-part variability that undermines reproducibility.

Surface finish quality continues to be problematic, with as-deposited surfaces typically exhibiting Ra values between 15-40μm, necessitating extensive post-processing operations that reduce the economic viability of the technology. This limitation is particularly pronounced in powder-based DED systems where powder catchment efficiency rarely exceeds 70%, leading to material waste and potential contamination issues.

Process monitoring and control systems have advanced but remain insufficient for closed-loop quality assurance. Current sensor technologies can detect major process deviations but lack the sensitivity and response time needed for real-time adjustments to maintain consistent quality throughout complex builds. This gap in process control capability directly impacts the repeatability of mechanical properties, with variations in tensile strength and fatigue resistance observed both within and between builds.

Standardization efforts are underway through organizations like ASTM and ISO, but the industry still lacks comprehensive standards for process qualification, material certification, and quality assurance specific to DED technologies. This regulatory gap creates barriers to adoption in highly regulated industries where certification pathways must be clearly defined.

Current Accuracy Enhancement Solutions

01 Process parameter optimization for DED accuracy

Optimizing process parameters such as laser power, scanning speed, powder feed rate, and layer thickness is crucial for improving the accuracy and precision of Directed Energy Deposition (DED) technologies. Proper calibration and control of these parameters can significantly reduce dimensional errors and improve surface finish. Advanced control systems that monitor and adjust these parameters in real-time can further enhance the precision of the deposition process.- Process parameter optimization for DED accuracy: Optimizing process parameters such as laser power, scanning speed, powder feed rate, and layer thickness is crucial for improving the accuracy and precision of Directed Energy Deposition (DED) technologies. Proper calibration and control of these parameters can significantly reduce dimensional errors and enhance surface finish quality. Advanced control systems that monitor and adjust parameters in real-time can compensate for variations during the deposition process, resulting in more precise fabricated components.

- Advanced monitoring and feedback systems: Implementation of sophisticated monitoring and feedback systems enables real-time quality control during the DED process. These systems utilize sensors, cameras, and other measurement devices to track critical parameters such as melt pool geometry, temperature distribution, and deposition height. The collected data is processed through algorithms that can detect deviations from desired specifications and automatically adjust the process parameters to maintain accuracy and precision. This closed-loop approach significantly improves the dimensional accuracy and repeatability of DED-manufactured parts.

- Multi-axis deposition strategies: Advanced multi-axis deposition strategies enhance the geometric accuracy of complex parts manufactured using DED technologies. By utilizing 5-axis or 6-axis motion systems, the deposition head can maintain optimal orientation relative to the build surface, ensuring consistent material delivery and reducing the need for support structures. Path planning algorithms optimize the deposition trajectory to minimize stress accumulation and geometric distortion. These strategies are particularly effective for producing complex geometries with overhangs, internal features, and variable cross-sections while maintaining high dimensional precision.

- Material-specific calibration techniques: Different materials require specific calibration techniques to achieve optimal accuracy and precision in DED processes. Parameters must be adjusted based on the thermal properties, particle size distribution, and flow characteristics of the feedstock material. Pre-process material characterization and testing help establish optimal processing windows for each material type. Post-deposition heat treatment protocols can also be tailored to specific materials to relieve internal stresses and improve dimensional stability. These material-specific approaches significantly enhance the repeatability and precision of DED-manufactured components.

- Hybrid manufacturing approaches: Combining DED with subtractive manufacturing processes in hybrid systems offers significant improvements in accuracy and precision. These systems integrate additive deposition capabilities with in-process machining operations, allowing for periodic surface finishing and dimensional correction during the build process. The integration enables the production of components with tight tolerances and excellent surface finish that would be difficult to achieve with DED alone. Advanced software solutions coordinate the transition between additive and subtractive operations to optimize the manufacturing sequence and ensure dimensional accuracy of the final part.

02 Advanced monitoring and feedback systems

Implementation of real-time monitoring and feedback systems is essential for maintaining high accuracy in DED processes. These systems utilize sensors to track melt pool characteristics, deposition height, temperature distribution, and other critical parameters. The collected data is used to make immediate adjustments to the process, ensuring consistent quality and dimensional accuracy. Machine learning algorithms can be integrated to predict and prevent potential defects before they occur.Expand Specific Solutions03 Multi-axis deposition strategies

Advanced multi-axis deposition strategies significantly improve the accuracy and precision of DED technologies. By utilizing 5-axis or 6-axis motion systems, complex geometries can be built with minimal support structures and improved surface quality. These strategies enable the deposition head to maintain optimal orientation relative to the build surface, ensuring consistent material properties and reducing geometric distortions, particularly for overhanging features and intricate designs.Expand Specific Solutions04 Material-specific calibration techniques

Different materials require specific calibration techniques to achieve optimal accuracy and precision in DED processes. Developing material-specific process parameters and calibration methods is essential for consistent results across various alloys and composites. This includes adjusting energy input, cooling rates, and deposition strategies based on the thermal and mechanical properties of the material being processed. Proper material handling and preparation also contribute significantly to the final dimensional accuracy of printed parts.Expand Specific Solutions05 Post-processing methods for improved precision

Various post-processing methods can be employed to enhance the final precision of DED-manufactured components. These include machining, heat treatment, surface finishing, and stress relief processes. Hybrid manufacturing systems that combine DED with in-situ machining capabilities allow for immediate correction of dimensional inaccuracies during the build process. Advanced metrology techniques enable precise measurement and verification of the final parts, ensuring they meet the required specifications and tolerances.Expand Specific Solutions

Key Industry Players in DED Manufacturing

Directed Energy Deposition (DED) technology is currently in a growth phase, with the market expected to expand significantly due to increasing applications in aerospace, automotive, and industrial sectors. The global market size for DED is projected to reach several billion dollars by 2030, driven by demand for complex metal components with reduced material waste. Technologically, DED is maturing rapidly with key players advancing precision capabilities. Companies like GE Avio and Rolls-Royce are pioneering aerospace applications, while Relativity Space leads in large-scale 3D printing integration. Applied Materials and Mitsubishi Electric are developing enhanced control systems for improved accuracy, and research institutions including Karlsruhe Institute of Technology and Oregon State University are pushing boundaries in multi-material deposition. Toyota, Nissan, and DENSO are exploring automotive applications, indicating cross-industry adoption potential.

GE Avio Srl

Technical Solution: GE Avio has developed a comprehensive directed energy deposition (DED) technology platform specifically optimized for aerospace propulsion components requiring exceptional precision. Their approach integrates laser-based DED with sophisticated multi-physics modeling and real-time monitoring systems to achieve unprecedented accuracy in complex geometries. GE Avio's technology incorporates proprietary thermal management strategies that precisely control heat input and dissipation throughout the build process, minimizing distortion in thin-walled structures and maintaining dimensional tolerances within ±0.1mm. Their system utilizes advanced optical monitoring with high-speed cameras and spectroscopic sensors that analyze melt pool dynamics in real-time, enabling adaptive control of laser parameters and material feed rates. GE Avio has also implemented machine learning algorithms that continuously analyze process data to identify optimal parameter combinations for specific geometries and materials, creating a self-improving manufacturing system. Additionally, their technology features integrated non-destructive testing capabilities that verify component integrity layer-by-layer, ensuring consistent mechanical properties throughout the build.

Strengths: Exceptional precision for complex aerospace components with internal cooling channels; comprehensive digital thread from design to verification ensures repeatability; advanced material capabilities including functionally graded structures and proprietary superalloys. Weaknesses: Requires substantial capital investment and specialized expertise; process optimization is time-intensive for new materials; system complexity creates maintenance challenges in production environments.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed an advanced directed energy deposition (DED) technology platform focused on high-precision manufacturing of complex aerospace components. Their approach combines laser-based DED with sophisticated process monitoring and control systems to achieve exceptional dimensional accuracy and material consistency. Safran's technology incorporates multi-sensor arrays that provide real-time feedback on melt pool dynamics, thermal gradients, and build geometry, enabling adaptive control of process parameters. Their system utilizes a proprietary closed-loop control algorithm that continuously adjusts laser power, travel speed, and material feed rate based on thermal imaging data, ensuring consistent energy input regardless of geometry variations. Safran has also implemented advanced path planning strategies that optimize deposition patterns based on thermal history and structural requirements, minimizing residual stresses and distortion. Additionally, their technology features in-situ defect detection capabilities that can identify and remediate anomalies during the build process, significantly enhancing the reliability and precision of manufactured components.

Strengths: Exceptional precision for critical aerospace components with complex internal features; comprehensive process monitoring enables consistent quality across production runs; ability to process specialized high-temperature alloys with tight control of microstructure. Weaknesses: Relatively slower deposition rates compared to less precise DED methods; requires extensive parameter optimization for each new material or geometry; high implementation and operational costs.

Core Patents and Innovations in DED Precision

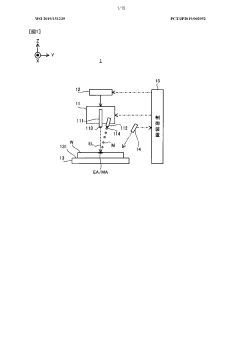

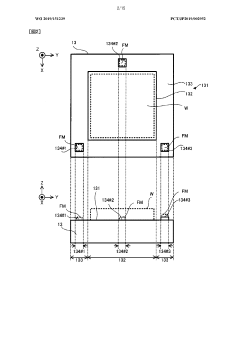

Processing system, processing method, computer program, recording medium, and control device

PatentWO2019151239A1

Innovation

- A processing system that includes a support device for the workpiece, a processing device for irradiating an energy beam, and a position changing device to adjust the relative positional relationship between the energy beam and the workpiece, controlled by a control device using reference models to ensure precise alignment and processing.

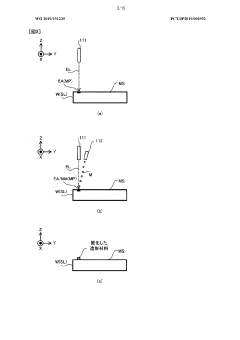

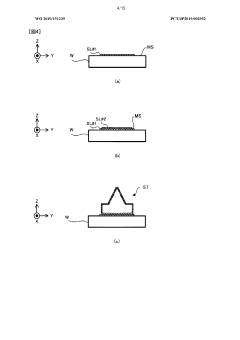

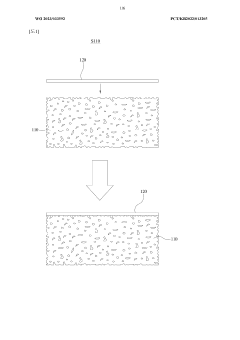

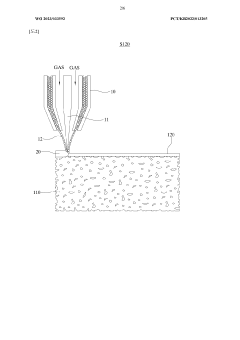

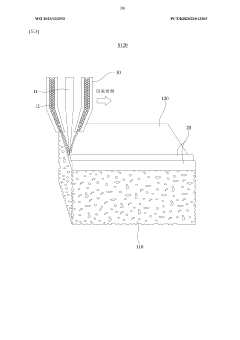

Method for manufacturing lightweight component having porous metal combined with non-porous metal

PatentWO2023033592A1

Innovation

- A method using direct energy deposition (DED) technology where a metal plate is flattened on a porous metal base, and a laser beam is used to melt the metal plate and powder, forming overlapping molten pools that are rapidly solidified to create a flat metal layer, allowing for the stacking of multiple layers with improved density and strength by varying the nozzle movement direction.

Material Compatibility and Process Parameters

Material compatibility represents a critical factor in achieving high accuracy and precision in Directed Energy Deposition (DED) technologies. Different materials exhibit varying thermal properties, melting points, and solidification behaviors, which significantly influence the deposition process. For instance, titanium alloys require specific process parameters due to their high reactivity with oxygen at elevated temperatures, while nickel-based superalloys demand precise heat input control to prevent cracking and maintain microstructural integrity.

Process parameters must be meticulously calibrated for each material system to ensure optimal deposition quality. Laser power density, typically ranging from 10^2 to 10^4 W/mm², directly affects melt pool dynamics and subsequent solidification patterns. Higher power densities may increase deposition rates but often at the expense of dimensional accuracy and surface finish. Experimental studies have demonstrated that maintaining power density within material-specific optimal ranges can reduce geometric deviations by up to 40%.

Powder feed rate constitutes another crucial parameter, with typical values between 2-15 g/min for most metal powders. The correlation between feed rate and deposition accuracy follows a non-linear relationship, where excessive feed rates lead to powder waste and dimensional inaccuracies, while insufficient rates result in incomplete layer formation. Advanced systems now incorporate closed-loop control mechanisms that adjust feed rates in real-time based on melt pool monitoring data.

Travel speed, commonly ranging from 5-30 mm/s, determines layer thickness and cooling rates. Research indicates that optimizing travel speed can improve surface roughness by up to 60% compared to non-optimized parameters. The interaction between travel speed and laser power creates a processing window that must be precisely maintained to achieve desired microstructural characteristics and mechanical properties.

Environmental factors, including shielding gas composition and flow rate, significantly impact oxidation levels and cooling dynamics. Argon remains the most widely used shielding gas, though helium mixtures offer enhanced thermal conductivity beneficial for certain high-temperature alloys. Studies have shown that proper gas flow configuration can reduce oxygen content in the build chamber to below 10 ppm, minimizing oxide inclusion defects that compromise structural integrity.

The development of material-specific parameter databases has emerged as a critical research direction, with several institutions creating comprehensive libraries that correlate material properties with optimal process parameters. These databases increasingly incorporate machine learning algorithms to predict parameter adjustments needed for novel material compositions, potentially reducing parameter optimization time by up to 70%.

Process parameters must be meticulously calibrated for each material system to ensure optimal deposition quality. Laser power density, typically ranging from 10^2 to 10^4 W/mm², directly affects melt pool dynamics and subsequent solidification patterns. Higher power densities may increase deposition rates but often at the expense of dimensional accuracy and surface finish. Experimental studies have demonstrated that maintaining power density within material-specific optimal ranges can reduce geometric deviations by up to 40%.

Powder feed rate constitutes another crucial parameter, with typical values between 2-15 g/min for most metal powders. The correlation between feed rate and deposition accuracy follows a non-linear relationship, where excessive feed rates lead to powder waste and dimensional inaccuracies, while insufficient rates result in incomplete layer formation. Advanced systems now incorporate closed-loop control mechanisms that adjust feed rates in real-time based on melt pool monitoring data.

Travel speed, commonly ranging from 5-30 mm/s, determines layer thickness and cooling rates. Research indicates that optimizing travel speed can improve surface roughness by up to 60% compared to non-optimized parameters. The interaction between travel speed and laser power creates a processing window that must be precisely maintained to achieve desired microstructural characteristics and mechanical properties.

Environmental factors, including shielding gas composition and flow rate, significantly impact oxidation levels and cooling dynamics. Argon remains the most widely used shielding gas, though helium mixtures offer enhanced thermal conductivity beneficial for certain high-temperature alloys. Studies have shown that proper gas flow configuration can reduce oxygen content in the build chamber to below 10 ppm, minimizing oxide inclusion defects that compromise structural integrity.

The development of material-specific parameter databases has emerged as a critical research direction, with several institutions creating comprehensive libraries that correlate material properties with optimal process parameters. These databases increasingly incorporate machine learning algorithms to predict parameter adjustments needed for novel material compositions, potentially reducing parameter optimization time by up to 70%.

Quality Control and Certification Standards

Quality control frameworks for Directed Energy Deposition (DED) technologies have evolved significantly in response to the growing industrial adoption of these advanced manufacturing processes. The establishment of comprehensive certification standards is crucial for ensuring consistent accuracy and precision in DED-produced components, particularly in high-consequence sectors such as aerospace, medical devices, and automotive industries.

International standards organizations including ISO, ASTM, and AWS have developed specific guidelines addressing the unique challenges of DED processes. ASTM F3187 provides standard terminology for DED systems, while ISO/ASTM 52901 outlines requirements for purchased parts made via additive manufacturing. These standards establish baseline requirements for material properties, dimensional tolerances, and surface finish characteristics that directly impact the accuracy and precision of final components.

In-process monitoring systems represent a critical advancement in quality assurance for DED technologies. These systems employ various sensing technologies including thermal imaging cameras, high-speed photography, and spectroscopic analysis to provide real-time feedback on process parameters. The data collected enables automated adjustments to laser power, material feed rate, and deposition path to maintain optimal accuracy throughout the build process.

Post-process verification methods complement in-process monitoring by providing definitive assessment of component quality. Non-destructive testing techniques such as X-ray computed tomography, ultrasonic testing, and laser scanning metrology have been adapted specifically for DED-manufactured parts. These methods can detect internal defects, verify dimensional accuracy, and confirm material integrity with micron-level precision.

Certification pathways for DED processes typically involve a multi-tiered approach. This begins with equipment qualification to verify that the DED system meets manufacturer specifications, followed by process qualification to establish optimal parameters for specific material-geometry combinations. The final tier involves part qualification, where representative components undergo rigorous testing to validate performance characteristics.

Digital certification frameworks are emerging as next-generation quality control solutions for DED technologies. These systems create comprehensive digital records that document the entire manufacturing process, from raw material characteristics through process parameters to final inspection results. This digital thread enables traceability throughout the component lifecycle and facilitates regulatory compliance in regulated industries.

International standards organizations including ISO, ASTM, and AWS have developed specific guidelines addressing the unique challenges of DED processes. ASTM F3187 provides standard terminology for DED systems, while ISO/ASTM 52901 outlines requirements for purchased parts made via additive manufacturing. These standards establish baseline requirements for material properties, dimensional tolerances, and surface finish characteristics that directly impact the accuracy and precision of final components.

In-process monitoring systems represent a critical advancement in quality assurance for DED technologies. These systems employ various sensing technologies including thermal imaging cameras, high-speed photography, and spectroscopic analysis to provide real-time feedback on process parameters. The data collected enables automated adjustments to laser power, material feed rate, and deposition path to maintain optimal accuracy throughout the build process.

Post-process verification methods complement in-process monitoring by providing definitive assessment of component quality. Non-destructive testing techniques such as X-ray computed tomography, ultrasonic testing, and laser scanning metrology have been adapted specifically for DED-manufactured parts. These methods can detect internal defects, verify dimensional accuracy, and confirm material integrity with micron-level precision.

Certification pathways for DED processes typically involve a multi-tiered approach. This begins with equipment qualification to verify that the DED system meets manufacturer specifications, followed by process qualification to establish optimal parameters for specific material-geometry combinations. The final tier involves part qualification, where representative components undergo rigorous testing to validate performance characteristics.

Digital certification frameworks are emerging as next-generation quality control solutions for DED technologies. These systems create comprehensive digital records that document the entire manufacturing process, from raw material characteristics through process parameters to final inspection results. This digital thread enables traceability throughout the component lifecycle and facilitates regulatory compliance in regulated industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!