Adaptive Systems for Real-time Turbine Engine Efficiency Monitoring

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Monitoring Technology Evolution and Objectives

The evolution of turbine engine monitoring technologies has undergone significant transformation over the past decades, shifting from basic mechanical gauges to sophisticated digital systems. Initially, turbine monitoring relied on manual inspections and rudimentary measurements of parameters such as temperature and pressure. The 1970s marked the introduction of electronic sensors, enabling more accurate data collection but still limited to periodic assessments rather than continuous monitoring.

The 1990s witnessed a paradigm shift with the integration of computerized systems capable of recording and analyzing operational data. This period established the foundation for condition-based maintenance, moving away from scheduled maintenance toward more efficient need-based approaches. By the early 2000s, the implementation of networked sensors and real-time data transmission capabilities revolutionized monitoring practices, allowing engineers to observe turbine performance remotely and respond promptly to anomalies.

Recent technological advancements have propelled turbine monitoring into the era of intelligent systems. Machine learning algorithms now analyze vast quantities of operational data to identify patterns indicative of potential failures before they occur. Edge computing capabilities have reduced latency in data processing, enabling truly real-time monitoring even in remote installations. The integration of digital twin technology has further enhanced predictive capabilities by creating virtual replicas of physical turbines for simulation and analysis.

The primary objective of modern adaptive systems for turbine monitoring is to maximize operational efficiency while minimizing downtime and maintenance costs. These systems aim to detect efficiency degradation in its earliest stages, allowing for timely interventions that prevent cascading failures and extend equipment lifespan. Additionally, they seek to optimize fuel consumption and reduce emissions through precise performance tuning based on real-time operational data.

Future technological goals include developing self-healing systems capable of automatic adjustments to maintain optimal efficiency without human intervention. Research is also focused on enhancing sensor durability in extreme operating conditions and reducing the energy consumption of monitoring systems themselves. The ultimate vision encompasses fully autonomous monitoring networks that leverage artificial intelligence to continuously improve their predictive accuracy and adapt to changing operational parameters.

The trajectory of turbine monitoring technology continues to move toward greater integration with broader industrial systems, particularly as Industry 4.0 principles become more widely implemented. This evolution represents not merely incremental improvement but a fundamental reconceptualization of how turbine efficiency is understood, measured, and optimized in real-time operational environments.

The 1990s witnessed a paradigm shift with the integration of computerized systems capable of recording and analyzing operational data. This period established the foundation for condition-based maintenance, moving away from scheduled maintenance toward more efficient need-based approaches. By the early 2000s, the implementation of networked sensors and real-time data transmission capabilities revolutionized monitoring practices, allowing engineers to observe turbine performance remotely and respond promptly to anomalies.

Recent technological advancements have propelled turbine monitoring into the era of intelligent systems. Machine learning algorithms now analyze vast quantities of operational data to identify patterns indicative of potential failures before they occur. Edge computing capabilities have reduced latency in data processing, enabling truly real-time monitoring even in remote installations. The integration of digital twin technology has further enhanced predictive capabilities by creating virtual replicas of physical turbines for simulation and analysis.

The primary objective of modern adaptive systems for turbine monitoring is to maximize operational efficiency while minimizing downtime and maintenance costs. These systems aim to detect efficiency degradation in its earliest stages, allowing for timely interventions that prevent cascading failures and extend equipment lifespan. Additionally, they seek to optimize fuel consumption and reduce emissions through precise performance tuning based on real-time operational data.

Future technological goals include developing self-healing systems capable of automatic adjustments to maintain optimal efficiency without human intervention. Research is also focused on enhancing sensor durability in extreme operating conditions and reducing the energy consumption of monitoring systems themselves. The ultimate vision encompasses fully autonomous monitoring networks that leverage artificial intelligence to continuously improve their predictive accuracy and adapt to changing operational parameters.

The trajectory of turbine monitoring technology continues to move toward greater integration with broader industrial systems, particularly as Industry 4.0 principles become more widely implemented. This evolution represents not merely incremental improvement but a fundamental reconceptualization of how turbine efficiency is understood, measured, and optimized in real-time operational environments.

Market Demand for Real-time Engine Efficiency Solutions

The global market for real-time turbine engine efficiency monitoring solutions has experienced significant growth over the past decade, driven primarily by increasing demands for operational cost reduction and environmental compliance. Aviation, power generation, and maritime industries have emerged as the primary sectors seeking advanced monitoring capabilities to optimize fuel consumption and reduce emissions.

In the aviation sector, airlines face mounting pressure to minimize operational costs while adhering to stringent environmental regulations. With fuel expenses representing approximately 25% of operational costs for commercial airlines, even marginal improvements in engine efficiency can translate to substantial financial savings. Major carriers have reported that real-time monitoring systems have enabled fuel savings between 2-5%, representing tens of millions in annual cost reduction for large fleet operators.

The power generation industry similarly demonstrates strong demand for these technologies. As grid operators increasingly integrate renewable energy sources, traditional turbine-based power plants must operate with greater flexibility and efficiency. Market research indicates that the power generation sector's investment in real-time monitoring technologies has grown at a compound annual rate of 14% since 2018, reflecting the urgent need for solutions that can optimize performance during variable load conditions.

Maritime shipping, responsible for transporting over 80% of global trade by volume, has also become a significant market for engine efficiency monitoring. International Maritime Organization (IMO) regulations mandating reduced sulfur emissions and carbon intensity have accelerated adoption of these technologies. The maritime sector's demand for real-time monitoring solutions is projected to double by 2027 as shipping companies seek compliance with environmental regulations while maintaining competitive operational costs.

Industrial applications beyond transportation and power generation represent an expanding market segment. Manufacturing facilities utilizing turbine technologies for on-site power generation have increasingly implemented real-time monitoring to optimize energy usage and reduce costs. This segment has shown particular growth in regions with high energy costs or unreliable grid infrastructure.

Market analysis reveals geographic variations in demand patterns. North America and Europe lead in adoption rates, driven by stringent regulatory frameworks and higher fuel costs. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India making substantial investments in monitoring technologies for their rapidly expanding power generation and industrial sectors.

Customer requirements across these markets consistently emphasize several key features: seamless integration with existing systems, predictive maintenance capabilities, user-friendly interfaces for non-technical operators, and demonstrable return on investment through quantifiable efficiency improvements. Solutions offering these capabilities command premium pricing and enjoy higher adoption rates across all sectors.

In the aviation sector, airlines face mounting pressure to minimize operational costs while adhering to stringent environmental regulations. With fuel expenses representing approximately 25% of operational costs for commercial airlines, even marginal improvements in engine efficiency can translate to substantial financial savings. Major carriers have reported that real-time monitoring systems have enabled fuel savings between 2-5%, representing tens of millions in annual cost reduction for large fleet operators.

The power generation industry similarly demonstrates strong demand for these technologies. As grid operators increasingly integrate renewable energy sources, traditional turbine-based power plants must operate with greater flexibility and efficiency. Market research indicates that the power generation sector's investment in real-time monitoring technologies has grown at a compound annual rate of 14% since 2018, reflecting the urgent need for solutions that can optimize performance during variable load conditions.

Maritime shipping, responsible for transporting over 80% of global trade by volume, has also become a significant market for engine efficiency monitoring. International Maritime Organization (IMO) regulations mandating reduced sulfur emissions and carbon intensity have accelerated adoption of these technologies. The maritime sector's demand for real-time monitoring solutions is projected to double by 2027 as shipping companies seek compliance with environmental regulations while maintaining competitive operational costs.

Industrial applications beyond transportation and power generation represent an expanding market segment. Manufacturing facilities utilizing turbine technologies for on-site power generation have increasingly implemented real-time monitoring to optimize energy usage and reduce costs. This segment has shown particular growth in regions with high energy costs or unreliable grid infrastructure.

Market analysis reveals geographic variations in demand patterns. North America and Europe lead in adoption rates, driven by stringent regulatory frameworks and higher fuel costs. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and India making substantial investments in monitoring technologies for their rapidly expanding power generation and industrial sectors.

Customer requirements across these markets consistently emphasize several key features: seamless integration with existing systems, predictive maintenance capabilities, user-friendly interfaces for non-technical operators, and demonstrable return on investment through quantifiable efficiency improvements. Solutions offering these capabilities command premium pricing and enjoy higher adoption rates across all sectors.

Current Adaptive Monitoring Systems and Challenges

Current adaptive monitoring systems for turbine engine efficiency have evolved significantly over the past decade, integrating advanced sensor technologies, real-time data processing capabilities, and sophisticated analytical algorithms. These systems typically employ a network of sensors strategically positioned throughout the engine to capture critical parameters such as temperature, pressure, vibration, fuel flow, and exhaust gas composition. Modern systems utilize wireless sensor networks that reduce installation complexity while increasing data collection points, enabling more comprehensive monitoring coverage.

The data acquisition layer of these systems has seen substantial improvements, with high-temperature resistant sensors capable of operating reliably in extreme engine environments. These sensors now feature enhanced durability and precision, with sampling rates reaching up to 100,000 samples per second for vibration monitoring. This high-frequency data capture enables the detection of subtle anomalies that might indicate efficiency degradation or impending failures.

Signal processing techniques have become increasingly sophisticated, employing adaptive filtering methods that automatically adjust to changing engine operating conditions. These systems utilize machine learning algorithms, particularly deep neural networks and recurrent neural networks, to establish baseline performance models and detect deviations in real-time. Some advanced implementations incorporate digital twin technology, creating virtual replicas of physical engines to simulate performance under various conditions.

Despite these advancements, significant challenges persist in the field. Sensor degradation remains a critical issue, as the harsh operating environment of turbine engines—with temperatures exceeding 1,500°C in some components—accelerates sensor wear and reduces reliability over time. This degradation introduces measurement drift that can lead to false alarms or missed detection of efficiency losses.

Data integration presents another substantial challenge, as monitoring systems must reconcile information from heterogeneous sensors operating at different sampling rates and with varying levels of precision. The volume of data generated—often exceeding several gigabytes per hour of operation—creates computational bottlenecks that limit real-time processing capabilities, particularly in edge computing environments with restricted resources.

Interpretation complexity further complicates monitoring efforts, as efficiency losses can result from multiple interacting factors that create ambiguous diagnostic signatures. Current systems struggle to differentiate between normal operational variations and genuine efficiency degradation, especially during transient operating conditions such as startup, shutdown, or rapid power adjustments.

Regulatory compliance and certification requirements impose additional constraints on adaptive monitoring systems, necessitating extensive validation processes that slow the deployment of innovative technologies. These challenges collectively highlight the need for continued research and development to enhance the reliability, accuracy, and interpretability of real-time turbine engine efficiency monitoring systems.

The data acquisition layer of these systems has seen substantial improvements, with high-temperature resistant sensors capable of operating reliably in extreme engine environments. These sensors now feature enhanced durability and precision, with sampling rates reaching up to 100,000 samples per second for vibration monitoring. This high-frequency data capture enables the detection of subtle anomalies that might indicate efficiency degradation or impending failures.

Signal processing techniques have become increasingly sophisticated, employing adaptive filtering methods that automatically adjust to changing engine operating conditions. These systems utilize machine learning algorithms, particularly deep neural networks and recurrent neural networks, to establish baseline performance models and detect deviations in real-time. Some advanced implementations incorporate digital twin technology, creating virtual replicas of physical engines to simulate performance under various conditions.

Despite these advancements, significant challenges persist in the field. Sensor degradation remains a critical issue, as the harsh operating environment of turbine engines—with temperatures exceeding 1,500°C in some components—accelerates sensor wear and reduces reliability over time. This degradation introduces measurement drift that can lead to false alarms or missed detection of efficiency losses.

Data integration presents another substantial challenge, as monitoring systems must reconcile information from heterogeneous sensors operating at different sampling rates and with varying levels of precision. The volume of data generated—often exceeding several gigabytes per hour of operation—creates computational bottlenecks that limit real-time processing capabilities, particularly in edge computing environments with restricted resources.

Interpretation complexity further complicates monitoring efforts, as efficiency losses can result from multiple interacting factors that create ambiguous diagnostic signatures. Current systems struggle to differentiate between normal operational variations and genuine efficiency degradation, especially during transient operating conditions such as startup, shutdown, or rapid power adjustments.

Regulatory compliance and certification requirements impose additional constraints on adaptive monitoring systems, necessitating extensive validation processes that slow the deployment of innovative technologies. These challenges collectively highlight the need for continued research and development to enhance the reliability, accuracy, and interpretability of real-time turbine engine efficiency monitoring systems.

Existing Real-time Monitoring Methodologies

01 Real-time adaptive monitoring systems

Advanced systems that continuously adapt to changing engine conditions for real-time monitoring of turbine performance. These systems use dynamic algorithms to adjust monitoring parameters based on operational conditions, enabling more efficient detection of anomalies and potential failures. The adaptive nature allows for optimization of monitoring resources while maintaining high reliability in diverse operating environments.- Real-time monitoring and adaptive control systems: Advanced systems that continuously monitor turbine engine parameters in real-time and adaptively adjust control parameters to optimize performance. These systems use sensors to collect data on various engine parameters such as temperature, pressure, and fuel flow, and then employ algorithms to analyze this data and make automatic adjustments to maintain optimal engine efficiency. The adaptive nature allows the system to respond to changing operating conditions and environmental factors.

- Sensor-based diagnostic systems for turbine efficiency: Specialized sensor networks deployed throughout the turbine engine that collect comprehensive data for diagnostic purposes. These systems utilize various types of sensors to monitor critical parameters affecting engine efficiency, including vibration, temperature gradients, exhaust gas composition, and fuel consumption. The collected data is processed through diagnostic algorithms that can identify inefficiencies, predict potential failures, and recommend maintenance actions to maintain optimal engine performance.

- Machine learning algorithms for predictive maintenance: Implementation of advanced machine learning and artificial intelligence techniques to analyze turbine engine data and predict maintenance needs. These systems learn from historical operational data to identify patterns that precede component failures or efficiency degradation. By predicting maintenance requirements before actual failures occur, these systems help optimize maintenance scheduling, reduce downtime, and maintain peak engine efficiency throughout the operational lifecycle.

- Integrated fuel efficiency optimization systems: Comprehensive systems designed specifically to monitor and optimize fuel consumption in turbine engines. These systems analyze multiple parameters including air-fuel ratio, combustion efficiency, and thrust output to make real-time adjustments that minimize fuel usage while maintaining required power output. The systems incorporate adaptive algorithms that can account for variations in fuel quality, altitude, ambient conditions, and operational demands to continuously optimize the engine's fuel efficiency.

- Distributed monitoring networks with edge computing: Advanced monitoring architectures that utilize distributed sensor networks combined with edge computing capabilities for more efficient data processing. These systems process critical data directly at or near the sensor location, reducing data transmission requirements and enabling faster response times. The edge computing nodes can perform preliminary analysis and filtering of data before transmission to central systems, allowing for more efficient use of communication bandwidth and computing resources while maintaining comprehensive monitoring capabilities.

02 Sensor optimization and data fusion techniques

Methods for optimizing sensor placement and integrating data from multiple sensors to enhance monitoring efficiency. These techniques involve strategic positioning of sensors throughout the turbine engine and sophisticated data fusion algorithms that combine inputs from various sensor types. By reducing redundancy and enhancing signal quality, these approaches minimize data processing requirements while maximizing the accuracy of condition assessments.Expand Specific Solutions03 Machine learning for predictive maintenance

Implementation of machine learning algorithms to predict potential failures and optimize maintenance schedules. These systems analyze historical and real-time data to identify patterns indicative of developing issues, allowing for preemptive maintenance actions. By continuously learning from operational data, these systems improve their predictive accuracy over time, reducing unnecessary inspections while preventing unexpected failures.Expand Specific Solutions04 Adaptive control systems for performance optimization

Systems that dynamically adjust engine parameters based on monitoring data to optimize performance and efficiency. These adaptive control mechanisms respond to changing operational conditions and engine health status by modifying fuel flow, combustion parameters, and other variables. The integration of monitoring and control functions creates a closed-loop system that continuously maximizes efficiency while maintaining safe operation parameters.Expand Specific Solutions05 Distributed monitoring architectures

Network-based monitoring systems that distribute processing across multiple nodes for enhanced efficiency and reliability. These architectures employ strategically placed monitoring units that communicate with central systems, allowing for localized processing of critical data while reducing bandwidth requirements. The distributed approach provides redundancy, scalability, and the ability to continue monitoring even if individual components fail.Expand Specific Solutions

Leading Companies in Adaptive Engine Monitoring

The real-time turbine engine efficiency monitoring market is currently in a growth phase, with adaptive systems representing an emerging technological frontier. The global market is expanding rapidly, driven by increasing demands for fuel efficiency and emissions reduction in aerospace and power generation sectors. Technologically, the field shows varying maturity levels across players. Industry leaders like General Electric, Rolls-Royce, and Pratt & Whitney demonstrate advanced capabilities through established monitoring platforms, while companies such as Safran Aircraft Engines and RTX Corp are making significant R&D investments. Siemens and Honeywell are leveraging their industrial automation expertise to develop competitive solutions. Academic institutions like Nanjing University of Aeronautics & Astronautics are contributing fundamental research, creating a dynamic ecosystem where commercial implementation increasingly focuses on AI-driven predictive analytics and real-time optimization.

General Electric Company

Technical Solution: GE's adaptive monitoring system for turbine engines employs a multi-layered approach combining physics-based models with machine learning algorithms. Their Digital Twin technology creates virtual replicas of physical turbine engines that continuously update based on real-time sensor data. The system utilizes over 300 sensors per engine collecting data at millisecond intervals, processing approximately 10TB of data per day. GE's AutoTune technology automatically adjusts control parameters based on real-time performance metrics, enabling proactive maintenance decisions. Their system incorporates advanced anomaly detection algorithms that can identify potential failures up to 60 days before they occur, reducing unplanned downtime by approximately 25%. The adaptive nature of GE's system allows it to continuously improve prediction accuracy through reinforcement learning techniques that optimize for changing environmental conditions and engine wear patterns.

Strengths: Comprehensive sensor integration with industry-leading Digital Twin technology; extensive historical data for training models; seamless integration with GE's broader maintenance ecosystem. Weaknesses: High implementation costs; significant computational requirements; potential vendor lock-in for customers.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell's adaptive monitoring solution for turbine engines leverages their Connected Plant technology to deliver real-time efficiency insights. Their system employs a distributed architecture with edge computing capabilities that process sensor data directly at the turbine, reducing latency to under 10 milliseconds for critical parameters. Honeywell's approach incorporates over 50 different sensor types measuring temperature, pressure, vibration, and emissions, creating a comprehensive operational profile. Their proprietary Forge analytics platform applies machine learning algorithms that adapt to changing operational conditions, automatically adjusting baseline parameters to maintain monitoring accuracy. The system features self-calibrating virtual sensors that can infer hard-to-measure parameters from available data points, expanding monitoring capabilities without additional hardware. Honeywell's solution includes adaptive alarm thresholds that automatically adjust based on operational context, reducing false positives by approximately 30% compared to static monitoring systems.

Strengths: Strong integration with industrial control systems; robust edge computing capabilities reducing dependency on cloud connectivity; extensive experience across multiple industries including aerospace and power generation. Weaknesses: More complex configuration requirements; higher initial implementation costs; potential challenges in legacy system integration.

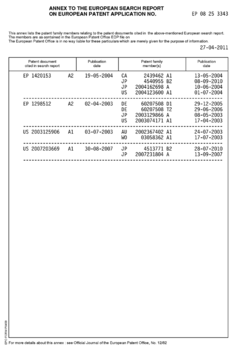

Key Innovations in Adaptive Monitoring Algorithms

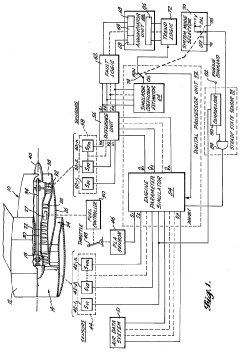

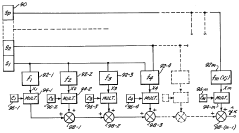

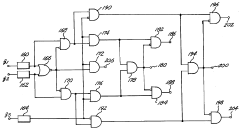

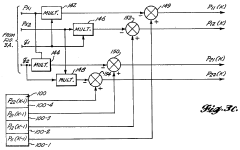

Real time performance monitoring of gas turbine engines

PatentInactiveUS4215412A

Innovation

- A gas turbine performance monitoring system that employs engine modeling techniques adaptable to specific engines, using digital processors to predict performance parameters through linear regression analysis and Kalman filtering, minimizing the impact of manufacturing and installation variations and sensor inaccuracies.

A method of monitoring a gas turbine engine

PatentInactiveEP2078995A3

Innovation

- A method that adjusts engine performance parameter values using a computer model to account for operational deterioration, specifically using a relationship involving changes in core and bypass pressure ratios to determine engine efficiency, allowing for more accurate fuel flow measurements and correcting for engine wear effects.

Energy Efficiency Standards and Compliance

Energy efficiency standards for turbine engines have evolved significantly over the past decades, driven by environmental concerns, regulatory pressures, and economic incentives. For adaptive systems focused on real-time turbine engine efficiency monitoring, compliance with these standards represents both a challenge and an opportunity. Current international frameworks such as ISO 50001 for energy management systems provide baseline requirements that monitoring systems must address, while industry-specific standards like those from the International Civil Aviation Organization (ICAO) for aircraft engines and the International Electrotechnical Commission (IEC) for power generation turbines establish more detailed performance metrics.

The regulatory landscape varies considerably across regions, with the European Union's Ecodesign Directive imposing stringent efficiency requirements for industrial turbines, while the U.S. Department of Energy's standards focus on performance benchmarking and reporting mechanisms. In emerging markets, particularly China and India, rapidly evolving standards are creating new compliance challenges for global turbine manufacturers and operators. These regional variations necessitate adaptive monitoring systems capable of adjusting to different compliance regimes.

Compliance verification methodologies have become increasingly sophisticated, moving beyond simple performance testing to continuous monitoring requirements. Modern standards increasingly mandate real-time efficiency data collection, automated reporting capabilities, and predictive maintenance features. This shift aligns perfectly with the capabilities of adaptive monitoring systems, which can provide continuous validation of compliance parameters while simultaneously optimizing performance.

The economic implications of standards compliance are substantial, with non-compliance penalties in some jurisdictions reaching millions of dollars. However, the implementation of advanced monitoring systems typically delivers return on investment through efficiency improvements that exceed minimum standards. Case studies from major power utilities demonstrate that real-time adaptive monitoring systems can improve turbine efficiency by 2-5% beyond compliance requirements, representing significant operational cost savings.

Future regulatory trends point toward more dynamic standards frameworks that will likely incorporate carbon intensity metrics, lifecycle assessment requirements, and potentially carbon pricing mechanisms. These developments suggest that next-generation adaptive monitoring systems will need to incorporate broader environmental impact parameters beyond simple efficiency metrics. Industry consortia are already developing voluntary standards that anticipate these regulatory developments, creating early-adoption opportunities for advanced monitoring technologies.

The regulatory landscape varies considerably across regions, with the European Union's Ecodesign Directive imposing stringent efficiency requirements for industrial turbines, while the U.S. Department of Energy's standards focus on performance benchmarking and reporting mechanisms. In emerging markets, particularly China and India, rapidly evolving standards are creating new compliance challenges for global turbine manufacturers and operators. These regional variations necessitate adaptive monitoring systems capable of adjusting to different compliance regimes.

Compliance verification methodologies have become increasingly sophisticated, moving beyond simple performance testing to continuous monitoring requirements. Modern standards increasingly mandate real-time efficiency data collection, automated reporting capabilities, and predictive maintenance features. This shift aligns perfectly with the capabilities of adaptive monitoring systems, which can provide continuous validation of compliance parameters while simultaneously optimizing performance.

The economic implications of standards compliance are substantial, with non-compliance penalties in some jurisdictions reaching millions of dollars. However, the implementation of advanced monitoring systems typically delivers return on investment through efficiency improvements that exceed minimum standards. Case studies from major power utilities demonstrate that real-time adaptive monitoring systems can improve turbine efficiency by 2-5% beyond compliance requirements, representing significant operational cost savings.

Future regulatory trends point toward more dynamic standards frameworks that will likely incorporate carbon intensity metrics, lifecycle assessment requirements, and potentially carbon pricing mechanisms. These developments suggest that next-generation adaptive monitoring systems will need to incorporate broader environmental impact parameters beyond simple efficiency metrics. Industry consortia are already developing voluntary standards that anticipate these regulatory developments, creating early-adoption opportunities for advanced monitoring technologies.

Data Security in Industrial Monitoring Systems

Data security in industrial monitoring systems for adaptive turbine engine efficiency monitoring presents unique challenges due to the sensitive nature of operational data and the critical importance of system integrity. The implementation of real-time monitoring systems creates multiple attack vectors that must be addressed through comprehensive security frameworks. These systems collect vast amounts of proprietary performance data, operational parameters, and efficiency metrics that represent significant intellectual property and competitive advantages for turbine manufacturers and operators.

Primary security concerns include unauthorized access to monitoring systems, data interception during transmission, and potential manipulation of efficiency readings that could lead to suboptimal engine performance or premature maintenance interventions. The integration of adaptive systems, which continuously learn and adjust based on operational data, introduces additional vulnerabilities as these systems may be susceptible to adversarial attacks designed to corrupt the learning algorithms.

Encryption protocols specifically designed for industrial control systems must be implemented to protect data both at rest and in transit. These protocols must balance robust security with the low-latency requirements of real-time monitoring applications. Industry standards such as IEC 62351 for power systems management and associated data exchange provide frameworks for securing communications in industrial environments, while the NIST Cybersecurity Framework offers guidance for protecting critical infrastructure.

Authentication mechanisms represent another critical security layer, with multi-factor authentication becoming increasingly important for access to monitoring dashboards and control interfaces. Role-based access control systems ensure that personnel can only access data relevant to their specific responsibilities, limiting exposure of sensitive efficiency metrics and proprietary algorithms.

Network segmentation strategies are essential for isolating monitoring systems from broader corporate networks, creating security zones that contain potential breaches. Implementing unidirectional security gateways can allow efficiency data to flow from turbine systems to monitoring platforms while preventing return traffic that could potentially carry malicious commands.

Regular security audits and penetration testing must be conducted to identify vulnerabilities in adaptive monitoring systems before they can be exploited. As these systems evolve through machine learning processes, security assessments must be performed after significant learning phases to ensure that adaptations haven't introduced new vulnerabilities or compromised data integrity mechanisms.

Primary security concerns include unauthorized access to monitoring systems, data interception during transmission, and potential manipulation of efficiency readings that could lead to suboptimal engine performance or premature maintenance interventions. The integration of adaptive systems, which continuously learn and adjust based on operational data, introduces additional vulnerabilities as these systems may be susceptible to adversarial attacks designed to corrupt the learning algorithms.

Encryption protocols specifically designed for industrial control systems must be implemented to protect data both at rest and in transit. These protocols must balance robust security with the low-latency requirements of real-time monitoring applications. Industry standards such as IEC 62351 for power systems management and associated data exchange provide frameworks for securing communications in industrial environments, while the NIST Cybersecurity Framework offers guidance for protecting critical infrastructure.

Authentication mechanisms represent another critical security layer, with multi-factor authentication becoming increasingly important for access to monitoring dashboards and control interfaces. Role-based access control systems ensure that personnel can only access data relevant to their specific responsibilities, limiting exposure of sensitive efficiency metrics and proprietary algorithms.

Network segmentation strategies are essential for isolating monitoring systems from broader corporate networks, creating security zones that contain potential breaches. Implementing unidirectional security gateways can allow efficiency data to flow from turbine systems to monitoring platforms while preventing return traffic that could potentially carry malicious commands.

Regular security audits and penetration testing must be conducted to identify vulnerabilities in adaptive monitoring systems before they can be exploited. As these systems evolve through machine learning processes, security assessments must be performed after significant learning phases to ensure that adaptations haven't introduced new vulnerabilities or compromised data integrity mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!