Adhesion And Interfacial Engineering For SALD Films

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SALD Film Adhesion Background and Objectives

Spatial Atomic Layer Deposition (SALD) technology has evolved significantly over the past two decades as an extension of conventional Atomic Layer Deposition (ALD). While traditional ALD processes operate in vacuum environments with sequential precursor exposures, SALD enables atmospheric pressure deposition with continuous precursor flows separated in space rather than time. This technological evolution has opened new possibilities for high-throughput manufacturing of thin films with precise thickness control at the nanometer scale.

The adhesion properties of SALD films represent a critical aspect of their industrial applicability. Historically, interfacial engineering for thin films has been extensively studied in vacuum-based deposition techniques, but the unique deposition environment of SALD introduces new challenges and opportunities for adhesion control. The transition from vacuum to atmospheric processing fundamentally alters surface chemistry dynamics, gas-phase reactions, and film nucleation mechanisms, necessitating a reevaluation of established adhesion principles.

Current technological trends indicate growing interest in SALD for applications requiring large-area coatings on temperature-sensitive substrates, including flexible electronics, photovoltaics, and barrier films. The ability to deposit conformal thin films at atmospheric pressure without vacuum equipment represents a significant cost advantage, but only if adhesion challenges can be overcome. Recent developments have focused on precursor chemistry optimization and surface pretreatment methods specifically designed for atmospheric deposition conditions.

The primary technical objectives for SALD film adhesion engineering include developing robust methodologies for quantifying adhesion strength under various environmental conditions, identifying optimal surface preparation techniques compatible with atmospheric processing, and establishing fundamental understanding of interfacial chemistry at the SALD film-substrate boundary. Additionally, there is significant interest in creating predictive models that can accelerate the development of new SALD processes with enhanced adhesion properties.

Long-term goals in this field encompass the creation of standardized protocols for SALD film adhesion testing, development of universal adhesion promotion strategies applicable across diverse substrate materials, and integration of in-situ adhesion monitoring capabilities into SALD equipment. The ultimate aim is to enable widespread industrial adoption of SALD technology by ensuring reliable, reproducible adhesion performance that meets or exceeds the standards established by conventional vacuum-based deposition methods.

Understanding the complex interplay between deposition parameters, film microstructure, and interfacial bonding mechanisms represents the cornerstone of advancing SALD film adhesion engineering. This requires multidisciplinary approaches combining surface science, materials characterization, computational modeling, and process engineering to develop comprehensive solutions for next-generation thin film applications.

The adhesion properties of SALD films represent a critical aspect of their industrial applicability. Historically, interfacial engineering for thin films has been extensively studied in vacuum-based deposition techniques, but the unique deposition environment of SALD introduces new challenges and opportunities for adhesion control. The transition from vacuum to atmospheric processing fundamentally alters surface chemistry dynamics, gas-phase reactions, and film nucleation mechanisms, necessitating a reevaluation of established adhesion principles.

Current technological trends indicate growing interest in SALD for applications requiring large-area coatings on temperature-sensitive substrates, including flexible electronics, photovoltaics, and barrier films. The ability to deposit conformal thin films at atmospheric pressure without vacuum equipment represents a significant cost advantage, but only if adhesion challenges can be overcome. Recent developments have focused on precursor chemistry optimization and surface pretreatment methods specifically designed for atmospheric deposition conditions.

The primary technical objectives for SALD film adhesion engineering include developing robust methodologies for quantifying adhesion strength under various environmental conditions, identifying optimal surface preparation techniques compatible with atmospheric processing, and establishing fundamental understanding of interfacial chemistry at the SALD film-substrate boundary. Additionally, there is significant interest in creating predictive models that can accelerate the development of new SALD processes with enhanced adhesion properties.

Long-term goals in this field encompass the creation of standardized protocols for SALD film adhesion testing, development of universal adhesion promotion strategies applicable across diverse substrate materials, and integration of in-situ adhesion monitoring capabilities into SALD equipment. The ultimate aim is to enable widespread industrial adoption of SALD technology by ensuring reliable, reproducible adhesion performance that meets or exceeds the standards established by conventional vacuum-based deposition methods.

Understanding the complex interplay between deposition parameters, film microstructure, and interfacial bonding mechanisms represents the cornerstone of advancing SALD film adhesion engineering. This requires multidisciplinary approaches combining surface science, materials characterization, computational modeling, and process engineering to develop comprehensive solutions for next-generation thin film applications.

Market Analysis for SALD Technology Applications

The Spatial Atomic Layer Deposition (SALD) technology market is experiencing significant growth, driven by increasing demand for high-performance thin films across multiple industries. Current market valuations place the global ALD equipment market at approximately 1.8 billion USD, with SALD representing an emerging segment poised for accelerated adoption due to its throughput advantages over conventional ALD.

The electronics sector remains the primary market for SALD applications, accounting for roughly 65% of current implementation. Semiconductor manufacturers are increasingly adopting SALD for high-k dielectrics, barrier layers, and gate oxides as device architectures continue to shrink below 5nm nodes. The improved throughput of SALD compared to traditional ALD makes it particularly attractive for high-volume manufacturing environments.

Renewable energy represents the fastest-growing application segment for SALD technology, with an estimated annual growth rate of 27%. Solar cell manufacturers are implementing SALD for passivation layers and transparent conductive oxides, achieving efficiency improvements of 0.5-1.2% absolute through superior interface quality and reduced recombination losses. The ability to process temperature-sensitive substrates opens new opportunities in flexible photovoltaics and building-integrated solar solutions.

Display technologies constitute another significant market segment, particularly for transparent conductive oxides and encapsulation layers in OLED and microLED applications. The market demand for improved adhesion and interface engineering in this sector is driven by requirements for flexible displays and improved device lifetimes under mechanical stress.

Medical and biomedical applications represent an emerging opportunity, with SALD films being explored for biocompatible coatings, controlled drug release systems, and antimicrobial surfaces. The precise control over film thickness and composition enables tailored surface properties for specific biological interactions.

Geographical analysis reveals Asia-Pacific as the dominant market region, accounting for approximately 58% of global SALD implementation, followed by North America (22%) and Europe (17%). China and South Korea are experiencing the most rapid adoption rates, driven by substantial investments in semiconductor and display manufacturing infrastructure.

Market forecasts project the SALD-specific equipment market to grow at a compound annual rate of 18-22% over the next five years, outpacing traditional ALD growth. This acceleration is contingent upon continued improvements in adhesion and interfacial engineering to ensure film quality and reliability across diverse substrate materials and operating conditions.

The electronics sector remains the primary market for SALD applications, accounting for roughly 65% of current implementation. Semiconductor manufacturers are increasingly adopting SALD for high-k dielectrics, barrier layers, and gate oxides as device architectures continue to shrink below 5nm nodes. The improved throughput of SALD compared to traditional ALD makes it particularly attractive for high-volume manufacturing environments.

Renewable energy represents the fastest-growing application segment for SALD technology, with an estimated annual growth rate of 27%. Solar cell manufacturers are implementing SALD for passivation layers and transparent conductive oxides, achieving efficiency improvements of 0.5-1.2% absolute through superior interface quality and reduced recombination losses. The ability to process temperature-sensitive substrates opens new opportunities in flexible photovoltaics and building-integrated solar solutions.

Display technologies constitute another significant market segment, particularly for transparent conductive oxides and encapsulation layers in OLED and microLED applications. The market demand for improved adhesion and interface engineering in this sector is driven by requirements for flexible displays and improved device lifetimes under mechanical stress.

Medical and biomedical applications represent an emerging opportunity, with SALD films being explored for biocompatible coatings, controlled drug release systems, and antimicrobial surfaces. The precise control over film thickness and composition enables tailored surface properties for specific biological interactions.

Geographical analysis reveals Asia-Pacific as the dominant market region, accounting for approximately 58% of global SALD implementation, followed by North America (22%) and Europe (17%). China and South Korea are experiencing the most rapid adoption rates, driven by substantial investments in semiconductor and display manufacturing infrastructure.

Market forecasts project the SALD-specific equipment market to grow at a compound annual rate of 18-22% over the next five years, outpacing traditional ALD growth. This acceleration is contingent upon continued improvements in adhesion and interfacial engineering to ensure film quality and reliability across diverse substrate materials and operating conditions.

Current Challenges in SALD Interfacial Engineering

Spatial Atomic Layer Deposition (SALD) technology faces significant interfacial challenges that currently limit its broader industrial adoption. The primary challenge lies in achieving strong adhesion between SALD films and various substrate materials. Unlike conventional ALD processes, SALD operates at atmospheric pressure and often at lower temperatures, which can result in reduced film density and compromised interfacial bonding strength. This is particularly problematic when depositing films on polymers, flexible substrates, or materials with complex surface chemistries.

Surface preparation protocols for SALD remain inconsistent across different applications, creating reproducibility issues in film quality and adhesion properties. Current surface activation methods, including plasma treatments and chemical functionalization, often lack the precision required for nanoscale interfacial engineering. Additionally, the rapid processing nature of SALD can lead to insufficient surface reaction time, resulting in incomplete chemical bonding at interfaces.

Thermal management at the interface presents another significant challenge. The temperature gradient between the deposition zone and substrate can induce thermal stress, leading to delamination or cracking of films during or after deposition. This is especially critical for temperature-sensitive substrates where the processing window is narrow.

Contamination control at atmospheric pressure conditions poses unique difficulties for SALD processes. Airborne particles, moisture, and other contaminants can become trapped at interfaces, creating weak points in the film structure. Current purging and gas flow management systems have not fully addressed this issue, particularly for high-throughput manufacturing environments.

The characterization of SALD interfaces remains technically challenging. Conventional analytical techniques often lack the spatial resolution or in-situ capabilities needed to monitor interfacial formation during the high-speed SALD process. This knowledge gap hampers the development of predictive models for interface engineering.

Chemical compatibility between precursors and substrate surfaces represents another obstacle. Many SALD precursors designed for specific film materials may interact unfavorably with certain substrate chemistries, creating unwanted interfacial compounds that compromise adhesion. The development of universal precursor systems or targeted surface modification approaches has not kept pace with the expanding application scope of SALD technology.

Scale-up of interfacial engineering solutions from laboratory to industrial implementation remains problematic. Techniques that work well for small-area substrates often fail to deliver consistent results across large-area applications, limiting the commercial viability of SALD for next-generation electronic devices, energy storage systems, and barrier films.

Surface preparation protocols for SALD remain inconsistent across different applications, creating reproducibility issues in film quality and adhesion properties. Current surface activation methods, including plasma treatments and chemical functionalization, often lack the precision required for nanoscale interfacial engineering. Additionally, the rapid processing nature of SALD can lead to insufficient surface reaction time, resulting in incomplete chemical bonding at interfaces.

Thermal management at the interface presents another significant challenge. The temperature gradient between the deposition zone and substrate can induce thermal stress, leading to delamination or cracking of films during or after deposition. This is especially critical for temperature-sensitive substrates where the processing window is narrow.

Contamination control at atmospheric pressure conditions poses unique difficulties for SALD processes. Airborne particles, moisture, and other contaminants can become trapped at interfaces, creating weak points in the film structure. Current purging and gas flow management systems have not fully addressed this issue, particularly for high-throughput manufacturing environments.

The characterization of SALD interfaces remains technically challenging. Conventional analytical techniques often lack the spatial resolution or in-situ capabilities needed to monitor interfacial formation during the high-speed SALD process. This knowledge gap hampers the development of predictive models for interface engineering.

Chemical compatibility between precursors and substrate surfaces represents another obstacle. Many SALD precursors designed for specific film materials may interact unfavorably with certain substrate chemistries, creating unwanted interfacial compounds that compromise adhesion. The development of universal precursor systems or targeted surface modification approaches has not kept pace with the expanding application scope of SALD technology.

Scale-up of interfacial engineering solutions from laboratory to industrial implementation remains problematic. Techniques that work well for small-area substrates often fail to deliver consistent results across large-area applications, limiting the commercial viability of SALD for next-generation electronic devices, energy storage systems, and barrier films.

Current Interfacial Engineering Solutions for SALD Films

01 Surface treatment methods for improving SALD film adhesion

Various surface treatment methods can be employed to enhance the adhesion of Spatial Atomic Layer Deposition (SALD) films to substrates. These include plasma treatment, chemical etching, and surface activation techniques that modify the substrate surface to create stronger bonds with the deposited films. These treatments remove contaminants, increase surface energy, and create functional groups that promote better film adhesion.- Surface treatment methods for improving SALD film adhesion: Various surface treatment methods can be employed to enhance the adhesion of Spatial Atomic Layer Deposition (SALD) films to substrates. These include plasma treatment, chemical etching, and surface activation techniques that modify the substrate surface to create stronger bonds with the deposited films. Such treatments remove contaminants, increase surface energy, and create functional groups that promote better adhesion of the SALD films.

- Interlayer materials for enhancing SALD film adhesion: Introducing interlayer materials between the substrate and SALD films can significantly improve adhesion. These interlayers, which may include metal oxides, nitrides, or organic compounds, act as adhesion promoters by providing compatible interfaces between the substrate and the film. They can compensate for differences in thermal expansion coefficients and create chemical bonds that strengthen the overall adhesion of the film structure.

- Thermal processing techniques for SALD film adhesion: Thermal processing techniques, such as annealing and heat treatment, can be applied before, during, or after SALD film deposition to enhance adhesion. These processes promote interdiffusion at interfaces, crystallization, and chemical bonding between the film and substrate. Controlled temperature cycles can reduce internal stresses and improve the mechanical stability of the film-substrate interface.

- Composition modifications for improved SALD film adhesion: Modifying the chemical composition of SALD films can enhance their adhesion properties. By incorporating specific elements or compounds into the film structure, the interfacial bonding with the substrate can be strengthened. Gradient composition layers, doping, and co-deposition techniques can create films with customized adhesion characteristics suited to specific substrate materials.

- Equipment and process optimization for SALD film adhesion: Specialized equipment designs and process parameter optimization can significantly impact SALD film adhesion. This includes precise control of precursor delivery, substrate temperature, gas flow dynamics, and deposition sequence. Advanced reactor designs with improved spatial control of the deposition zone and in-situ monitoring capabilities allow for real-time adjustments that enhance film uniformity and adhesion properties.

02 Adhesion promotion layers for SALD films

Intermediate layers can be deposited between the substrate and the SALD film to improve adhesion. These adhesion promotion layers typically consist of materials that have good bonding characteristics with both the substrate and the SALD film. Examples include metal oxides, nitrides, and organic compounds that create a gradual transition between different materials, reducing stress and improving overall film adhesion.Expand Specific Solutions03 Process parameter optimization for enhanced SALD film adhesion

The adhesion of SALD films can be significantly improved by optimizing various process parameters during deposition. These parameters include substrate temperature, precursor exposure time, purge duration, and reactor pressure. Careful control of these parameters ensures complete surface reactions, reduces impurities, and promotes the formation of strong interfacial bonds between the film and substrate.Expand Specific Solutions04 Post-deposition treatments for improving SALD film adhesion

After SALD film deposition, various post-treatment methods can be applied to enhance film adhesion. These include thermal annealing, laser treatment, and chemical treatments that promote interfacial mixing and strengthen the bond between the film and substrate. Post-deposition treatments can reduce internal stress, eliminate defects, and improve the mechanical properties of the film-substrate interface.Expand Specific Solutions05 Substrate material selection and preparation for optimal SALD film adhesion

The choice of substrate material and its preparation significantly impact SALD film adhesion. Proper cleaning protocols, surface roughness control, and substrate composition are critical factors. Certain substrate materials naturally form stronger bonds with specific SALD films. Preparation techniques such as solvent cleaning, ultrasonic treatment, and mechanical polishing help remove contaminants and create an ideal surface for film deposition.Expand Specific Solutions

Leading Companies and Research Institutions in SALD Field

The Spatial Atomic Layer Deposition (SALD) films adhesion and interfacial engineering market is in a growth phase, with increasing applications across semiconductor, display, and energy sectors. The global market is expanding rapidly due to demand for high-performance thin films in miniaturized electronics. Technologically, the field shows varying maturity levels, with established players like Applied Materials, ASM International, and Tokyo Electron leading commercial development through advanced deposition techniques. Emerging companies like Nfinite Nanotechnology are innovating with open-air ALD systems that significantly increase processing speeds. Research institutions including CNRS and universities collaborate with industry leaders like Samsung and TSMC to address fundamental adhesion challenges, indicating the field's continued evolution toward industrial-scale implementation.

ASM International NV

Technical Solution: ASM International has developed a comprehensive SALD film adhesion solution centered around their proprietary "InterfaceEngineering" technology suite. This approach combines pre-deposition surface treatments with carefully designed nucleation layers to maximize adhesion across diverse substrate materials. Their SALD systems incorporate multi-step surface activation processes using controlled plasma exposure and chemical functionalization to create optimal binding sites[2]. ASM's technology employs precise gas flow dynamics in their spatial ALD reactors to ensure uniform precursor distribution, which directly impacts interface quality and adhesion performance. The company has pioneered gradient composition interfaces where film composition gradually transitions from substrate to final film chemistry, eliminating abrupt interfaces that often lead to adhesion failures[4]. Their systems also feature real-time monitoring of film growth and interface formation using in-situ ellipsometry and quartz crystal microbalance techniques[7].

Strengths: Exceptional control over interface chemistry through proprietary precursor delivery systems; demonstrated success with challenging substrate materials including polymers and flexible substrates; industry-leading throughput while maintaining adhesion quality. Weaknesses: Higher initial capital investment compared to conventional batch ALD systems; requires specialized precursors optimized for spatial delivery; more complex process integration into existing manufacturing lines.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced SALD (Spatial Atomic Layer Deposition) film adhesion technologies focusing on interface engineering through plasma-enhanced pre-treatment processes. Their approach utilizes controlled plasma exposure to create reactive surface sites that promote strong chemical bonding between SALD films and various substrates. The company's proprietary "Endura" platform incorporates in-situ surface modification capabilities that can tailor interface properties without breaking vacuum, significantly enhancing adhesion quality[1]. Applied Materials has also pioneered selective area deposition techniques using self-assembled monolayers (SAMs) as adhesion promoters for SALD films, allowing precise control over where films adhere[3]. Their recent innovations include temperature-controlled deposition sequences that minimize thermal stress at interfaces, reducing delamination risks in high-aspect-ratio structures common in advanced semiconductor devices[5].

Strengths: Industry-leading in-situ surface modification capabilities that maintain pristine interfaces; extensive materials expertise across multiple substrate types; integrated metrology for real-time adhesion quality monitoring. Weaknesses: Higher implementation costs compared to conventional ALD systems; process complexity requiring specialized expertise; potential throughput limitations when implementing multiple interface engineering steps.

Key Patents and Innovations in SALD Adhesion Technology

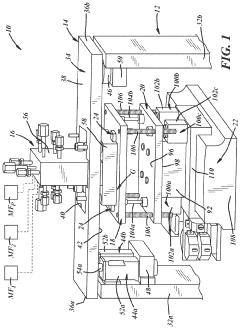

Deposition system with vacuum pre-loaded deposition head

PatentWO2018169688A1

Innovation

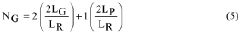

- A vacuum-preloaded gas bearing deposition head is used in an external environment at ambient pressure, with a motion control system that moves the substrate over the deposition head in a specified motion profile, allowing for a net force on the substrate and maintaining gas separation, enabling the coating of substrates larger than the deposition head without vacuum preloading.

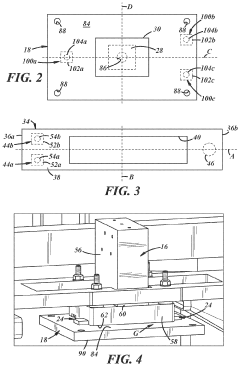

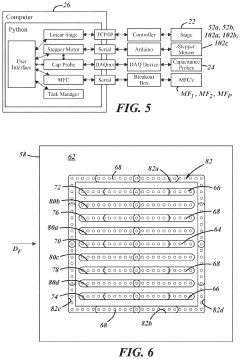

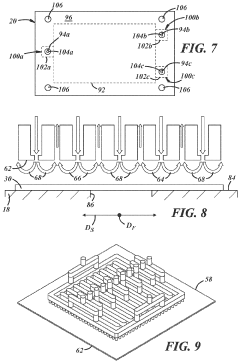

Mechatronic spatial atomic layer deposition system with closed-loop feedback control of parallelism and component alignment

PatentPendingUS20230097272A1

Innovation

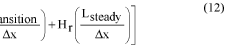

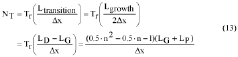

- The integration of gap detection sensors and linear actuators with a controller allows for real-time monitoring and adjustment of the gap between the depositor head and the substrate plate, ensuring precise control over the positioning and maintaining the desired gap size and parallelism, thereby preventing gas intermixing and maintaining the integrity of the SALD process.

Materials Compatibility and Substrate Selection Considerations

The selection of appropriate substrate materials is a critical factor in the successful implementation of Spatial Atomic Layer Deposition (SALD) technology. Material compatibility between the substrate and deposited films directly impacts adhesion quality, film uniformity, and overall device performance. Different substrate materials exhibit varying surface energies, chemical reactivities, and thermal expansion coefficients, all of which influence the interfacial bonding mechanisms with SALD films.

For rigid applications, silicon wafers remain the gold standard due to their atomically smooth surfaces and well-understood surface chemistry. However, glass substrates offer cost advantages for large-area applications while maintaining good thermal stability. Metal substrates such as aluminum, stainless steel, and titanium present unique challenges due to native oxide layers that can either enhance or impede adhesion depending on the target film composition.

The emerging trend toward flexible electronics has expanded substrate options to include polymeric materials like polyethylene terephthalate (PET), polyimide, and polydimethylsiloxane (PDMS). These materials introduce additional considerations regarding thermal budget limitations, with maximum processing temperatures typically restricted to 150-200°C for PET and up to 350°C for polyimide. Surface modification techniques such as plasma treatment, UV-ozone exposure, or chemical functionalization are often necessary to improve wettability and adhesion on these low-surface-energy substrates.

Thermal expansion mismatch between substrate and film materials represents a significant challenge, particularly for applications involving temperature cycling. This mismatch can induce mechanical stress at the interface, potentially leading to delamination or cracking. Computational modeling of thermal stress distributions can help predict and mitigate these effects through careful materials selection or the introduction of buffer layers with intermediate expansion coefficients.

Chemical compatibility must also be considered, as substrate materials may react with precursors or by-products during the SALD process. For example, certain metal substrates may catalyze unwanted side reactions, while some polymers may absorb precursors, leading to contamination or degraded film properties. Pre-deposition surface treatments and careful process parameter optimization can help address these challenges.

Substrate topography and roughness significantly impact film nucleation and growth mechanisms. While atomically flat surfaces generally promote uniform film formation, controlled surface roughness can sometimes enhance mechanical interlocking and improve adhesion strength. Advanced characterization techniques such as atomic force microscopy (AFM) and X-ray photoelectron spectroscopy (XPS) are essential for understanding substrate surface properties and their influence on interfacial engineering.

For rigid applications, silicon wafers remain the gold standard due to their atomically smooth surfaces and well-understood surface chemistry. However, glass substrates offer cost advantages for large-area applications while maintaining good thermal stability. Metal substrates such as aluminum, stainless steel, and titanium present unique challenges due to native oxide layers that can either enhance or impede adhesion depending on the target film composition.

The emerging trend toward flexible electronics has expanded substrate options to include polymeric materials like polyethylene terephthalate (PET), polyimide, and polydimethylsiloxane (PDMS). These materials introduce additional considerations regarding thermal budget limitations, with maximum processing temperatures typically restricted to 150-200°C for PET and up to 350°C for polyimide. Surface modification techniques such as plasma treatment, UV-ozone exposure, or chemical functionalization are often necessary to improve wettability and adhesion on these low-surface-energy substrates.

Thermal expansion mismatch between substrate and film materials represents a significant challenge, particularly for applications involving temperature cycling. This mismatch can induce mechanical stress at the interface, potentially leading to delamination or cracking. Computational modeling of thermal stress distributions can help predict and mitigate these effects through careful materials selection or the introduction of buffer layers with intermediate expansion coefficients.

Chemical compatibility must also be considered, as substrate materials may react with precursors or by-products during the SALD process. For example, certain metal substrates may catalyze unwanted side reactions, while some polymers may absorb precursors, leading to contamination or degraded film properties. Pre-deposition surface treatments and careful process parameter optimization can help address these challenges.

Substrate topography and roughness significantly impact film nucleation and growth mechanisms. While atomically flat surfaces generally promote uniform film formation, controlled surface roughness can sometimes enhance mechanical interlocking and improve adhesion strength. Advanced characterization techniques such as atomic force microscopy (AFM) and X-ray photoelectron spectroscopy (XPS) are essential for understanding substrate surface properties and their influence on interfacial engineering.

Environmental Impact and Sustainability of SALD Processes

Spatial Atomic Layer Deposition (SALD) processes have gained significant attention for their potential to deliver high-quality thin films with precise control at atmospheric pressure. When evaluating the environmental impact and sustainability of SALD processes, several critical factors emerge that differentiate this technology from conventional vacuum-based ALD methods.

SALD processes operate at atmospheric pressure, eliminating the need for energy-intensive vacuum systems that traditional ALD requires. This fundamental difference results in substantially reduced energy consumption, with some studies indicating energy savings of up to 60-70% compared to conventional vacuum ALD systems. The elimination of vacuum pumps not only reduces direct energy usage but also decreases the associated carbon footprint of manufacturing operations.

Precursor utilization efficiency represents another significant environmental advantage of SALD technology. The spatial separation of precursors in SALD systems enables more efficient chemical delivery and utilization, reducing chemical waste by approximately 30-40% compared to temporal ALD processes. This improved efficiency directly translates to decreased environmental impact through reduced chemical synthesis requirements and waste disposal needs.

Water consumption in SALD processes deserves particular attention when assessing environmental impact. While SALD systems typically require water cooling for temperature management, innovative designs incorporating closed-loop cooling systems have emerged, reducing fresh water requirements by up to 80% in advanced implementations. These water conservation measures significantly enhance the sustainability profile of SALD technology.

The atmospheric operation of SALD also eliminates the need for certain greenhouse gases commonly used in vacuum systems, such as perfluorocarbons and sulfur hexafluoride. These gases, when used in semiconductor manufacturing, can have global warming potentials thousands of times greater than CO2. Their elimination represents a substantial environmental benefit of SALD technology.

Life cycle assessment (LCA) studies comparing SALD to conventional deposition techniques have demonstrated 25-45% reductions in overall environmental impact across multiple categories, including global warming potential, acidification, and resource depletion. These comprehensive analyses account for raw material extraction, manufacturing processes, use phase, and end-of-life considerations.

The scalability of SALD processes to roll-to-roll manufacturing further enhances sustainability by enabling continuous production with minimal material waste. This capability proves particularly valuable for applications in flexible electronics and solar cells, where large-area, uniform coatings are required without the environmental burden of batch processing.

SALD processes operate at atmospheric pressure, eliminating the need for energy-intensive vacuum systems that traditional ALD requires. This fundamental difference results in substantially reduced energy consumption, with some studies indicating energy savings of up to 60-70% compared to conventional vacuum ALD systems. The elimination of vacuum pumps not only reduces direct energy usage but also decreases the associated carbon footprint of manufacturing operations.

Precursor utilization efficiency represents another significant environmental advantage of SALD technology. The spatial separation of precursors in SALD systems enables more efficient chemical delivery and utilization, reducing chemical waste by approximately 30-40% compared to temporal ALD processes. This improved efficiency directly translates to decreased environmental impact through reduced chemical synthesis requirements and waste disposal needs.

Water consumption in SALD processes deserves particular attention when assessing environmental impact. While SALD systems typically require water cooling for temperature management, innovative designs incorporating closed-loop cooling systems have emerged, reducing fresh water requirements by up to 80% in advanced implementations. These water conservation measures significantly enhance the sustainability profile of SALD technology.

The atmospheric operation of SALD also eliminates the need for certain greenhouse gases commonly used in vacuum systems, such as perfluorocarbons and sulfur hexafluoride. These gases, when used in semiconductor manufacturing, can have global warming potentials thousands of times greater than CO2. Their elimination represents a substantial environmental benefit of SALD technology.

Life cycle assessment (LCA) studies comparing SALD to conventional deposition techniques have demonstrated 25-45% reductions in overall environmental impact across multiple categories, including global warming potential, acidification, and resource depletion. These comprehensive analyses account for raw material extraction, manufacturing processes, use phase, and end-of-life considerations.

The scalability of SALD processes to roll-to-roll manufacturing further enhances sustainability by enabling continuous production with minimal material waste. This capability proves particularly valuable for applications in flexible electronics and solar cells, where large-area, uniform coatings are required without the environmental burden of batch processing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!