Plasma Source Design For Plasma-Enhanced SALD Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasma SALD Technology Evolution and Objectives

Plasma-Enhanced Spatial Atomic Layer Deposition (PE-SALD) represents a significant advancement in thin film deposition technology, combining the precision of ALD with enhanced deposition rates through plasma activation. The evolution of this technology can be traced back to the early 2000s when conventional ALD faced limitations in industrial applications due to its inherently slow deposition rates. The introduction of plasma sources to SALD systems around 2010 marked a pivotal moment, enabling faster reactions and lower processing temperatures.

The technological progression of plasma sources for PE-SALD has followed several distinct phases. Initially, simple direct plasma configurations were employed, where plasma was generated directly above the substrate. This approach, while effective for enhancing reaction rates, often resulted in film damage due to ion bombardment. By 2015, remote plasma configurations emerged as a superior alternative, separating plasma generation from the deposition zone and thereby reducing substrate damage while maintaining enhanced reactivity.

Recent years have witnessed the development of more sophisticated plasma source designs, including atmospheric pressure plasma jets, dielectric barrier discharges (DBDs), and microwave-induced plasmas. Each configuration offers unique advantages in terms of plasma density, uniformity, and energy efficiency. The integration of these advanced plasma sources with high-throughput spatial ALD systems represents the current technological frontier.

The primary objectives of plasma source design for PE-SALD systems center around several key parameters. First, achieving uniform plasma distribution across large substrate areas remains crucial for industrial-scale applications, particularly in sectors like photovoltaics and display manufacturing. Second, precise control over plasma characteristics—including electron temperature, ion density, and radical species concentration—is essential for optimizing film properties and deposition kinetics.

Energy efficiency constitutes another critical objective, as plasma generation typically accounts for a significant portion of the overall energy consumption in PE-SALD processes. Innovations in power delivery systems and plasma confinement mechanisms have shown promising results in reducing energy requirements while maintaining process effectiveness.

Compatibility with various precursors and substrates represents an ongoing challenge and objective in plasma source design. Different materials may require specific plasma conditions to achieve optimal deposition results without causing thermal or radiation damage to sensitive substrates. This has driven research toward tunable plasma sources that can adapt to diverse processing requirements.

Looking forward, the evolution of plasma sources for PE-SALD systems is expected to focus on intelligent plasma control systems incorporating real-time monitoring and feedback mechanisms. These developments aim to enable adaptive processing conditions that respond to changing deposition parameters, ultimately leading to more robust and versatile deposition systems capable of addressing the increasingly complex requirements of advanced electronic and energy devices.

The technological progression of plasma sources for PE-SALD has followed several distinct phases. Initially, simple direct plasma configurations were employed, where plasma was generated directly above the substrate. This approach, while effective for enhancing reaction rates, often resulted in film damage due to ion bombardment. By 2015, remote plasma configurations emerged as a superior alternative, separating plasma generation from the deposition zone and thereby reducing substrate damage while maintaining enhanced reactivity.

Recent years have witnessed the development of more sophisticated plasma source designs, including atmospheric pressure plasma jets, dielectric barrier discharges (DBDs), and microwave-induced plasmas. Each configuration offers unique advantages in terms of plasma density, uniformity, and energy efficiency. The integration of these advanced plasma sources with high-throughput spatial ALD systems represents the current technological frontier.

The primary objectives of plasma source design for PE-SALD systems center around several key parameters. First, achieving uniform plasma distribution across large substrate areas remains crucial for industrial-scale applications, particularly in sectors like photovoltaics and display manufacturing. Second, precise control over plasma characteristics—including electron temperature, ion density, and radical species concentration—is essential for optimizing film properties and deposition kinetics.

Energy efficiency constitutes another critical objective, as plasma generation typically accounts for a significant portion of the overall energy consumption in PE-SALD processes. Innovations in power delivery systems and plasma confinement mechanisms have shown promising results in reducing energy requirements while maintaining process effectiveness.

Compatibility with various precursors and substrates represents an ongoing challenge and objective in plasma source design. Different materials may require specific plasma conditions to achieve optimal deposition results without causing thermal or radiation damage to sensitive substrates. This has driven research toward tunable plasma sources that can adapt to diverse processing requirements.

Looking forward, the evolution of plasma sources for PE-SALD systems is expected to focus on intelligent plasma control systems incorporating real-time monitoring and feedback mechanisms. These developments aim to enable adaptive processing conditions that respond to changing deposition parameters, ultimately leading to more robust and versatile deposition systems capable of addressing the increasingly complex requirements of advanced electronic and energy devices.

Market Analysis for Plasma-Enhanced SALD Applications

The global market for Plasma-Enhanced Spatial Atomic Layer Deposition (PE-SALD) systems is experiencing significant growth, driven by increasing demand for high-performance thin film coatings across multiple industries. Current market valuations indicate that the PE-SALD segment is growing at approximately 12% annually, outpacing the broader ALD market which grows at 8-9% per year.

The semiconductor industry remains the primary consumer of PE-SALD technology, accounting for roughly 65% of market share. This dominance stems from the critical need for precise, uniform, and defect-free thin films in advanced node manufacturing. The continuous miniaturization of semiconductor devices, following Moore's Law, necessitates atomic-level precision that PE-SALD uniquely provides.

Display manufacturing represents the second largest application sector, comprising about 18% of the market. The transition to flexible OLED displays and next-generation display technologies has intensified demand for high-quality barrier films and transparent conductive oxides that PE-SALD can efficiently deposit.

Photovoltaics is emerging as a rapidly growing application area, currently at 8% market share but projected to reach 15% by 2027. PE-SALD enables the deposition of passivation layers and transparent conducting oxides critical for high-efficiency solar cells, particularly in heterojunction and perovskite architectures.

Energy storage applications, specifically for battery technology, constitute approximately 5% of current market demand but show the highest growth potential at 25% annually. PE-SALD's ability to create uniform coatings on high-aspect-ratio structures makes it valuable for next-generation battery electrode and electrolyte interface engineering.

Geographically, East Asia dominates the market with 58% share, followed by North America (22%) and Europe (17%). China's aggressive semiconductor and display manufacturing expansion is creating substantial new demand for advanced deposition technologies including PE-SALD systems.

Customer requirements are evolving toward larger substrate capabilities, higher throughput, and enhanced process control. Market research indicates that 85% of potential customers rank plasma source reliability and uniformity as their top technical concerns when evaluating PE-SALD systems.

The market shows increasing preference for modular plasma source designs that can be integrated into existing production lines, with 70% of new installations following this approach rather than standalone systems. This trend underscores the importance of developing plasma sources that offer flexibility in configuration while maintaining performance specifications.

The semiconductor industry remains the primary consumer of PE-SALD technology, accounting for roughly 65% of market share. This dominance stems from the critical need for precise, uniform, and defect-free thin films in advanced node manufacturing. The continuous miniaturization of semiconductor devices, following Moore's Law, necessitates atomic-level precision that PE-SALD uniquely provides.

Display manufacturing represents the second largest application sector, comprising about 18% of the market. The transition to flexible OLED displays and next-generation display technologies has intensified demand for high-quality barrier films and transparent conductive oxides that PE-SALD can efficiently deposit.

Photovoltaics is emerging as a rapidly growing application area, currently at 8% market share but projected to reach 15% by 2027. PE-SALD enables the deposition of passivation layers and transparent conducting oxides critical for high-efficiency solar cells, particularly in heterojunction and perovskite architectures.

Energy storage applications, specifically for battery technology, constitute approximately 5% of current market demand but show the highest growth potential at 25% annually. PE-SALD's ability to create uniform coatings on high-aspect-ratio structures makes it valuable for next-generation battery electrode and electrolyte interface engineering.

Geographically, East Asia dominates the market with 58% share, followed by North America (22%) and Europe (17%). China's aggressive semiconductor and display manufacturing expansion is creating substantial new demand for advanced deposition technologies including PE-SALD systems.

Customer requirements are evolving toward larger substrate capabilities, higher throughput, and enhanced process control. Market research indicates that 85% of potential customers rank plasma source reliability and uniformity as their top technical concerns when evaluating PE-SALD systems.

The market shows increasing preference for modular plasma source designs that can be integrated into existing production lines, with 70% of new installations following this approach rather than standalone systems. This trend underscores the importance of developing plasma sources that offer flexibility in configuration while maintaining performance specifications.

Current Plasma Source Technologies and Limitations

Plasma sources for Plasma-Enhanced Spatial Atomic Layer Deposition (PE-SALD) systems currently employ several key technologies, each with distinct operational principles and limitations. Direct plasma sources, particularly those utilizing radio frequency (RF) power, represent the most widely adopted technology in industrial applications. These systems typically operate at 13.56 MHz and generate high-density plasmas through capacitive or inductive coupling mechanisms. While offering excellent control over plasma parameters, RF sources often struggle with uniformity across large substrate areas and may cause ion bombardment damage to sensitive surfaces.

Atmospheric pressure plasma jets (APPJs) have emerged as an alternative solution, particularly valuable for open-air PE-SALD processes. These sources generate non-equilibrium plasmas at atmospheric pressure, eliminating the need for vacuum systems and enabling integration with roll-to-roll manufacturing. However, APPJs face challenges in scaling to wider deposition areas and maintaining consistent plasma characteristics across the treatment zone.

Dielectric barrier discharge (DBD) plasma sources represent another significant technology, operating through the application of high voltage across dielectric-covered electrodes. DBD systems excel in generating uniform plasmas over large areas at atmospheric pressure, making them suitable for industrial-scale applications. Their primary limitations include lower plasma densities compared to RF sources and challenges in precise control of reactive species generation.

Microwave plasma sources operating at 2.45 GHz offer advantages in creating high-density plasmas with minimal ion bombardment. These systems can achieve efficient precursor activation without substrate damage, but they typically require complex waveguide designs and face difficulties in achieving uniform plasma distribution across large areas.

Remote plasma sources, which physically separate plasma generation from the deposition zone, have gained attention for sensitive applications. By reducing direct ion bombardment while delivering activated species to the substrate, these systems minimize surface damage. However, the separation distance introduces challenges in maintaining reactive species concentration at the substrate surface due to recombination losses during transport.

Each plasma source technology presents inherent trade-offs between plasma density, uniformity, process control, and scalability. Current limitations across all technologies include challenges in precise spatial control of plasma characteristics, difficulties in maintaining consistent plasma parameters during long process runs, and limited understanding of plasma-precursor interactions specific to SALD chemistry. Additionally, energy efficiency remains a concern, with most systems converting only a small fraction of input power into useful chemical activation.

Atmospheric pressure plasma jets (APPJs) have emerged as an alternative solution, particularly valuable for open-air PE-SALD processes. These sources generate non-equilibrium plasmas at atmospheric pressure, eliminating the need for vacuum systems and enabling integration with roll-to-roll manufacturing. However, APPJs face challenges in scaling to wider deposition areas and maintaining consistent plasma characteristics across the treatment zone.

Dielectric barrier discharge (DBD) plasma sources represent another significant technology, operating through the application of high voltage across dielectric-covered electrodes. DBD systems excel in generating uniform plasmas over large areas at atmospheric pressure, making them suitable for industrial-scale applications. Their primary limitations include lower plasma densities compared to RF sources and challenges in precise control of reactive species generation.

Microwave plasma sources operating at 2.45 GHz offer advantages in creating high-density plasmas with minimal ion bombardment. These systems can achieve efficient precursor activation without substrate damage, but they typically require complex waveguide designs and face difficulties in achieving uniform plasma distribution across large areas.

Remote plasma sources, which physically separate plasma generation from the deposition zone, have gained attention for sensitive applications. By reducing direct ion bombardment while delivering activated species to the substrate, these systems minimize surface damage. However, the separation distance introduces challenges in maintaining reactive species concentration at the substrate surface due to recombination losses during transport.

Each plasma source technology presents inherent trade-offs between plasma density, uniformity, process control, and scalability. Current limitations across all technologies include challenges in precise spatial control of plasma characteristics, difficulties in maintaining consistent plasma parameters during long process runs, and limited understanding of plasma-precursor interactions specific to SALD chemistry. Additionally, energy efficiency remains a concern, with most systems converting only a small fraction of input power into useful chemical activation.

Contemporary Plasma Source Design Solutions

01 Plasma source configuration and electrode design

The design of plasma sources often involves specific electrode configurations to optimize plasma generation and control. These designs may include various electrode shapes, materials, and arrangements to enhance plasma stability, uniformity, and energy efficiency. Advanced electrode designs can incorporate cooling mechanisms, specialized coatings, or geometric optimizations to improve performance in different applications such as semiconductor processing or materials treatment.- Plasma source configuration and electrode design: The design of plasma source configurations and electrode arrangements significantly impacts plasma generation efficiency and stability. Various electrode geometries, including planar, cylindrical, and helical designs, can be optimized for specific applications. The spacing, material, and shape of electrodes affect plasma density, uniformity, and energy distribution. Advanced designs incorporate multiple electrodes with precise positioning to control plasma characteristics and enable selective processing in semiconductor manufacturing and materials treatment.

- RF power delivery and impedance matching systems: Efficient RF power delivery systems are crucial for plasma source design, incorporating impedance matching networks to maximize power transfer to the plasma. These systems typically include variable capacitors and inductors that automatically adjust to changing plasma conditions. Advanced designs feature multi-frequency power delivery capabilities, allowing for independent control of ion energy and plasma density. Proper impedance matching reduces reflected power, prevents damage to RF generators, and ensures stable plasma operation across varying process conditions.

- Gas distribution and flow control mechanisms: Gas distribution systems in plasma sources are designed to deliver process gases uniformly across the plasma generation region. These systems incorporate specialized nozzles, showerheads, and flow controllers to regulate gas composition and pressure. Advanced designs feature multiple gas injection points with independent flow control to create customized plasma chemistry profiles. Proper gas distribution enhances plasma stability, improves process uniformity, and enables precise control of reaction kinetics for applications in thin film deposition and surface modification.

- Thermal management and cooling systems: Effective thermal management is essential in plasma source design to prevent overheating of components and maintain process stability. Cooling systems typically incorporate water channels, heat exchangers, or thermoelectric coolers strategically positioned near heat-generating components. Advanced designs feature temperature sensors and feedback control systems to maintain optimal operating temperatures. Proper thermal management extends component lifetime, ensures consistent plasma characteristics, and enables high-power operation for industrial applications requiring intense plasma processing.

- Plasma confinement and magnetic field configurations: Magnetic field configurations are used to confine and control plasma behavior within the source. These designs incorporate permanent magnets or electromagnets arranged in specific geometries to create magnetic field lines that trap charged particles. Advanced configurations include rotating magnetic fields, cusped magnetic fields, and multipole arrangements to enhance plasma density and uniformity. Proper magnetic confinement reduces wall losses, increases ionization efficiency, and enables the generation of high-density plasmas at lower pressures for applications in semiconductor etching, deposition, and surface modification.

02 Radio frequency (RF) plasma generation systems

RF-based plasma generation systems utilize radio frequency power to create and sustain plasma discharges. These systems typically include RF power supplies, impedance matching networks, and specialized transmission components. The design focuses on efficient power coupling to the plasma, frequency optimization, and control systems to maintain stable plasma conditions. RF plasma sources are widely used in semiconductor manufacturing, thin film deposition, and surface modification applications.Expand Specific Solutions03 Plasma chamber and confinement designs

The design of plasma chambers and confinement systems is critical for controlling plasma properties and process outcomes. These designs include considerations for gas flow dynamics, pressure control, thermal management, and plasma confinement techniques. Specialized chamber geometries, magnetic confinement systems, and material selections are employed to optimize plasma density, uniformity, and interaction with substrates or materials being processed.Expand Specific Solutions04 Plasma source control and monitoring systems

Advanced control and monitoring systems are essential components of plasma source design. These systems incorporate sensors, feedback loops, and control algorithms to maintain precise plasma conditions. Real-time monitoring of parameters such as plasma density, temperature, and composition allows for process optimization and repeatability. Computer modeling and simulation tools are often used in the design phase to predict plasma behavior and optimize source configurations before physical implementation.Expand Specific Solutions05 Specialized plasma sources for specific applications

Various specialized plasma source designs are developed for specific industrial and research applications. These include atmospheric pressure plasma sources, microplasma arrays, inductively coupled plasma sources, and plasma jet configurations. Each design addresses particular requirements such as processing temperature, gas composition, power density, or treatment area. Application-specific designs may focus on features like portability, scalability, or integration with existing manufacturing processes.Expand Specific Solutions

Industry Leaders in Plasma-Enhanced SALD Equipment

The plasma source design for Plasma-Enhanced SALD systems market is in its growth phase, with increasing adoption across semiconductor manufacturing and display industries. The market is projected to expand significantly due to rising demand for high-precision thin film deposition technologies. Leading players include Applied Materials and Tokyo Electron, who leverage their established semiconductor equipment expertise, while specialized companies like Picosun and Nfinite Nanotechnology focus on ALD innovations. Research institutions such as Naval Research Laboratory and universities collaborate with industry to advance plasma source technology. The competitive landscape features both established equipment manufacturers and emerging players developing proprietary plasma source designs to achieve higher deposition rates, improved film quality, and larger processing areas.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced plasma source designs for Spatial Atomic Layer Deposition (SALD) systems that utilize a multi-zone plasma configuration. Their technology incorporates radio frequency (RF) powered electrodes with independent power control for each plasma zone, enabling precise plasma density distribution across the deposition area. The system employs a unique gas distribution design that separates precursor and plasma regions while maintaining laminar flow conditions, critical for SALD processes. Applied Materials' plasma sources feature impedance matching networks that automatically adjust to changing process conditions, ensuring plasma stability during continuous operation. Their designs also incorporate advanced thermal management systems that prevent overheating of plasma components while maintaining substrate temperature uniformity within ±1°C, essential for high-quality film deposition in high-throughput SALD applications.

Strengths: Superior plasma uniformity control across large substrate areas; excellent integration with existing semiconductor manufacturing infrastructure; advanced thermal management capabilities. Weaknesses: Higher system complexity requiring specialized maintenance; relatively higher capital investment compared to simpler plasma sources.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has pioneered a compact atmospheric pressure plasma source specifically optimized for SALD applications. Their design utilizes a dielectric barrier discharge (DBD) configuration that generates uniform plasma at atmospheric pressure, eliminating the need for vacuum systems. The plasma source incorporates a novel electrode geometry that creates a stable glow discharge with minimal arcing, even at atmospheric conditions. TEL's system features a proprietary gas delivery system that enables rapid switching between reactive species, with gas residence times below 100 milliseconds. The plasma source is designed with a modular architecture that allows for easy scaling to accommodate different substrate sizes, from small wafers to large panels for display applications. Their technology also incorporates real-time plasma monitoring using optical emission spectroscopy to ensure process consistency and enable closed-loop control of plasma parameters during continuous SALD operation.

Strengths: Atmospheric pressure operation reduces system complexity and cost; excellent scalability for various substrate sizes; integrated process monitoring capabilities. Weaknesses: Potential challenges with plasma uniformity over very large areas; limited to certain types of precursors compatible with atmospheric processing.

Critical Patents in Plasma Source Technology

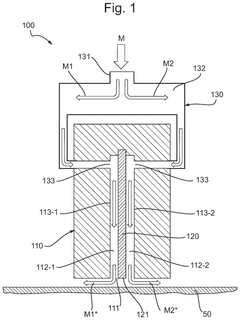

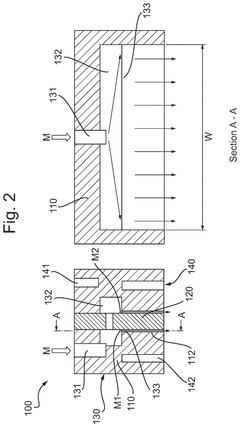

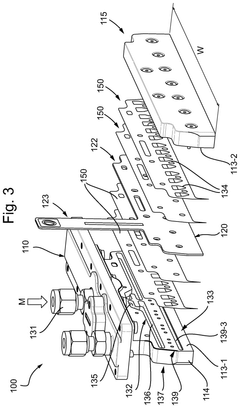

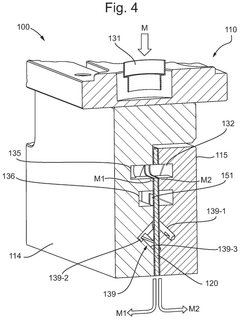

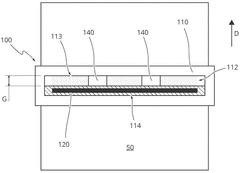

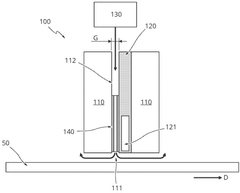

Plasma source and apparatus for atomic layer deposition

PatentPendingUS20250122618A1

Innovation

- The plasma source design incorporates a gas supply system with divided mass flow channels on opposing sides of the electrode plate, which compensates for geometrical variations and thermal effects, ensuring a uniform mass flow of gas.

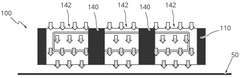

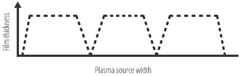

Plasma source for patterned deposition

PatentWO2025053756A1

Innovation

- A plasma source with a removable insert that patterns the flow of atmospheric plasma by locally blocking sections of the slotted cavity, creating distinct channels that minimize radical diffusion and allow for interchangeable patterns without modifying the electrode plate or deposition head.

Materials Compatibility and Process Integration

The integration of plasma sources with SALD systems presents significant materials compatibility challenges that must be addressed for successful implementation. Plasma-enhanced SALD processes expose various materials to reactive plasma species, potentially causing degradation, contamination, or undesired modifications. Substrate materials, particularly temperature-sensitive polymers and flexible electronics components, require careful consideration as plasma exposure may induce thermal damage or structural changes even at nominally low process temperatures.

Electrode materials used in plasma generation systems must withstand continuous exposure to reactive species without significant erosion or contamination. Noble metals like platinum and gold offer excellent resistance but at prohibitive costs for large-scale implementation. Alternative materials such as carbon-based electrodes or specialized ceramic coatings have shown promising durability while maintaining cost-effectiveness in recent industrial applications.

Precursor compatibility represents another critical consideration, as plasma interaction may cause premature decomposition or unwanted side reactions. The chemical pathways of precursor activation must be thoroughly understood to prevent the formation of non-volatile byproducts that could compromise film quality. Recent studies have demonstrated that tailoring plasma parameters specifically to precursor chemistry can significantly improve process yields and film characteristics.

Process integration challenges extend beyond materials to include equipment design considerations. Plasma sources must be positioned to ensure uniform activation across the substrate while avoiding localized "hot spots" that could damage sensitive areas. The spatial distribution of plasma species must align with precursor delivery patterns to achieve consistent film properties across the entire deposition area.

Sequential integration of plasma steps with precursor dosing requires precise timing control systems. The residence time of reactive species must be carefully managed to prevent cross-contamination between process cycles. Advanced gas flow management systems have been developed to rapidly purge reaction zones, enabling clean interfaces between deposited layers even at atmospheric pressure conditions.

Scaling considerations present additional integration challenges as plasma uniformity becomes increasingly difficult to maintain over larger substrate areas. Multi-source plasma configurations have emerged as a promising solution, though they introduce complexity in synchronization and control. Recent developments in computational fluid dynamics modeling have significantly improved the ability to predict and optimize plasma distribution across industrial-scale substrates.

Electrode materials used in plasma generation systems must withstand continuous exposure to reactive species without significant erosion or contamination. Noble metals like platinum and gold offer excellent resistance but at prohibitive costs for large-scale implementation. Alternative materials such as carbon-based electrodes or specialized ceramic coatings have shown promising durability while maintaining cost-effectiveness in recent industrial applications.

Precursor compatibility represents another critical consideration, as plasma interaction may cause premature decomposition or unwanted side reactions. The chemical pathways of precursor activation must be thoroughly understood to prevent the formation of non-volatile byproducts that could compromise film quality. Recent studies have demonstrated that tailoring plasma parameters specifically to precursor chemistry can significantly improve process yields and film characteristics.

Process integration challenges extend beyond materials to include equipment design considerations. Plasma sources must be positioned to ensure uniform activation across the substrate while avoiding localized "hot spots" that could damage sensitive areas. The spatial distribution of plasma species must align with precursor delivery patterns to achieve consistent film properties across the entire deposition area.

Sequential integration of plasma steps with precursor dosing requires precise timing control systems. The residence time of reactive species must be carefully managed to prevent cross-contamination between process cycles. Advanced gas flow management systems have been developed to rapidly purge reaction zones, enabling clean interfaces between deposited layers even at atmospheric pressure conditions.

Scaling considerations present additional integration challenges as plasma uniformity becomes increasingly difficult to maintain over larger substrate areas. Multi-source plasma configurations have emerged as a promising solution, though they introduce complexity in synchronization and control. Recent developments in computational fluid dynamics modeling have significantly improved the ability to predict and optimize plasma distribution across industrial-scale substrates.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in the design and operation of Plasma-Enhanced Spatial Atomic Layer Deposition (PE-SALD) systems. The plasma source, as a key component, significantly impacts the overall environmental footprint and operational costs of these systems. Current plasma sources in PE-SALD typically consume substantial electrical power, with energy efficiency rates often below 30%, representing a major opportunity for improvement.

Recent advancements in plasma source design have focused on reducing energy consumption while maintaining process performance. Pulsed plasma technologies have emerged as promising solutions, allowing for intermittent high-power plasma generation rather than continuous operation. Studies indicate that optimized pulsed plasma systems can reduce energy consumption by 25-40% compared to conventional continuous wave plasma sources, while achieving comparable deposition quality and rates.

Thermal management represents another crucial aspect of energy efficiency in plasma source design. Excessive heat generation not only wastes energy but also necessitates additional cooling systems that further increase power consumption. Novel cooling strategies, including microfluidic channels and advanced heat sink designs, have demonstrated potential to improve thermal efficiency by up to 35% in laboratory settings.

Material selection for plasma source components also plays a vital role in sustainability considerations. Traditional materials often include rare earth elements and precious metals with significant environmental extraction impacts. Research into alternative materials, such as advanced ceramics and composite structures, shows promise for reducing environmental impact while maintaining or even enhancing performance characteristics.

The power supply and control systems for plasma sources present additional opportunities for efficiency improvements. Smart power management systems that dynamically adjust power delivery based on real-time process requirements have demonstrated energy savings of 15-30% in industrial implementations. Integration of renewable energy sources and energy recovery systems further enhances the sustainability profile of PE-SALD operations.

Life cycle assessment (LCA) studies of plasma sources reveal that operational energy consumption typically accounts for over 70% of lifetime environmental impact. This underscores the importance of efficiency-focused design approaches that consider not only initial performance but long-term operational sustainability. Extended equipment lifespan through modular design and serviceable components can significantly reduce the embodied energy and material consumption associated with manufacturing replacement parts.

Industry benchmarking indicates that the most energy-efficient plasma source designs for PE-SALD currently achieve energy utilization efficiencies of 45-55%, representing the target threshold for next-generation systems. Achieving these efficiency levels while maintaining or improving process performance remains a key challenge for researchers and equipment manufacturers in this field.

Recent advancements in plasma source design have focused on reducing energy consumption while maintaining process performance. Pulsed plasma technologies have emerged as promising solutions, allowing for intermittent high-power plasma generation rather than continuous operation. Studies indicate that optimized pulsed plasma systems can reduce energy consumption by 25-40% compared to conventional continuous wave plasma sources, while achieving comparable deposition quality and rates.

Thermal management represents another crucial aspect of energy efficiency in plasma source design. Excessive heat generation not only wastes energy but also necessitates additional cooling systems that further increase power consumption. Novel cooling strategies, including microfluidic channels and advanced heat sink designs, have demonstrated potential to improve thermal efficiency by up to 35% in laboratory settings.

Material selection for plasma source components also plays a vital role in sustainability considerations. Traditional materials often include rare earth elements and precious metals with significant environmental extraction impacts. Research into alternative materials, such as advanced ceramics and composite structures, shows promise for reducing environmental impact while maintaining or even enhancing performance characteristics.

The power supply and control systems for plasma sources present additional opportunities for efficiency improvements. Smart power management systems that dynamically adjust power delivery based on real-time process requirements have demonstrated energy savings of 15-30% in industrial implementations. Integration of renewable energy sources and energy recovery systems further enhances the sustainability profile of PE-SALD operations.

Life cycle assessment (LCA) studies of plasma sources reveal that operational energy consumption typically accounts for over 70% of lifetime environmental impact. This underscores the importance of efficiency-focused design approaches that consider not only initial performance but long-term operational sustainability. Extended equipment lifespan through modular design and serviceable components can significantly reduce the embodied energy and material consumption associated with manufacturing replacement parts.

Industry benchmarking indicates that the most energy-efficient plasma source designs for PE-SALD currently achieve energy utilization efficiencies of 45-55%, representing the target threshold for next-generation systems. Achieving these efficiency levels while maintaining or improving process performance remains a key challenge for researchers and equipment manufacturers in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!