Process Window Mapping For APALD On Polymer Substrates

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

APALD Process Evolution and Objectives

Atomic Layer Deposition (ALD) has evolved significantly since its inception in the 1970s, with Atomic Precision ALD (APALD) representing one of the most advanced iterations of this technology. The evolution of APALD specifically for polymer substrates has been driven by increasing demands in flexible electronics, biomedical devices, and advanced packaging solutions where traditional deposition methods face significant limitations due to the temperature sensitivity and surface chemistry of polymers.

The journey of APALD began with conventional thermal ALD processes, which typically required temperatures exceeding 200°C—unsuitable for most polymer substrates. The development of plasma-enhanced ALD (PEALD) in the early 2000s marked a critical advancement, allowing lower temperature processing while maintaining film quality. However, plasma damage to sensitive polymer surfaces remained problematic, leading to the exploration of alternative approaches.

APALD emerged as a refined technique around 2010, characterized by precise control over precursor delivery, purge cycles, and reaction parameters. This technique enables conformal coating at temperatures as low as 50°C while achieving atomic-level precision in film thickness and composition—critical factors when working with temperature-sensitive polymer substrates.

The primary objective of Process Window Mapping for APALD on polymer substrates is to establish comprehensive parameter relationships that optimize film quality while preserving substrate integrity. This involves identifying the critical process variables including temperature ranges (typically 50-150°C), precursor exposure times, purge durations, and potential surface activation methods specific to different polymer chemistries.

Another key objective is to develop standardized methodologies for characterizing the APALD process window across diverse polymer substrates, ranging from commodity polymers like PET and PMMA to high-performance materials such as polyimide and liquid crystal polymers. This standardization aims to accelerate industrial adoption by providing predictable outcomes across various material combinations.

Looking forward, the technology roadmap for APALD on polymers focuses on expanding the temperature window downward (targeting room temperature deposition), increasing throughput without sacrificing precision, and developing specialized precursors designed specifically for polymer surface interactions. The ultimate goal is to establish APALD as the definitive method for creating high-quality functional thin films on polymer substrates with atomic-level control, enabling next-generation flexible electronics, barrier films, and biocompatible coatings.

The journey of APALD began with conventional thermal ALD processes, which typically required temperatures exceeding 200°C—unsuitable for most polymer substrates. The development of plasma-enhanced ALD (PEALD) in the early 2000s marked a critical advancement, allowing lower temperature processing while maintaining film quality. However, plasma damage to sensitive polymer surfaces remained problematic, leading to the exploration of alternative approaches.

APALD emerged as a refined technique around 2010, characterized by precise control over precursor delivery, purge cycles, and reaction parameters. This technique enables conformal coating at temperatures as low as 50°C while achieving atomic-level precision in film thickness and composition—critical factors when working with temperature-sensitive polymer substrates.

The primary objective of Process Window Mapping for APALD on polymer substrates is to establish comprehensive parameter relationships that optimize film quality while preserving substrate integrity. This involves identifying the critical process variables including temperature ranges (typically 50-150°C), precursor exposure times, purge durations, and potential surface activation methods specific to different polymer chemistries.

Another key objective is to develop standardized methodologies for characterizing the APALD process window across diverse polymer substrates, ranging from commodity polymers like PET and PMMA to high-performance materials such as polyimide and liquid crystal polymers. This standardization aims to accelerate industrial adoption by providing predictable outcomes across various material combinations.

Looking forward, the technology roadmap for APALD on polymers focuses on expanding the temperature window downward (targeting room temperature deposition), increasing throughput without sacrificing precision, and developing specialized precursors designed specifically for polymer surface interactions. The ultimate goal is to establish APALD as the definitive method for creating high-quality functional thin films on polymer substrates with atomic-level control, enabling next-generation flexible electronics, barrier films, and biocompatible coatings.

Market Analysis for APALD on Polymer Applications

The Atomic Layer Deposition (ALD) market has been experiencing significant growth, with the global market valued at approximately $2.2 billion in 2022 and projected to reach $4.7 billion by 2028, representing a compound annual growth rate (CAGR) of 13.5%. Within this broader market, Plasma-Enhanced ALD (PEALD) and specifically Atmospheric Pressure ALD (APALD) on polymer substrates represent emerging segments with substantial growth potential.

The application of APALD on polymer substrates addresses several critical market needs across multiple industries. In the electronics sector, flexible displays, wearable devices, and flexible circuits require thin-film deposition techniques that can operate at lower temperatures compatible with temperature-sensitive polymer materials. The global flexible electronics market is expected to grow from $31.6 billion in 2021 to over $73 billion by 2027, creating significant demand for advanced deposition technologies like APALD.

In the packaging industry, barrier films produced using APALD technology offer superior protection against oxygen and moisture penetration, extending shelf life for food, pharmaceuticals, and electronic components. The high-barrier packaging market is projected to reach $36.4 billion by 2026, growing at a CAGR of 8.2%, with APALD processes potentially capturing a significant portion of this growth.

Medical device manufacturing represents another promising application area, with the global medical polymer market expected to reach $24.8 billion by 2025. APALD coatings on polymer-based medical devices can enhance biocompatibility, provide antimicrobial properties, and improve durability, addressing key requirements in this highly regulated industry.

The automotive and aerospace sectors are increasingly incorporating polymer components that require protective coatings with precise thickness control. APALD processes offer advantages in creating uniform, conformal coatings on complex geometries, addressing the $9.3 billion automotive coatings market and the specialized aerospace coatings segment valued at $1.8 billion.

Regional analysis indicates that Asia-Pacific dominates the ALD market with approximately 45% share, driven by semiconductor and electronics manufacturing. North America and Europe follow with 28% and 20% respectively, with growing applications in medical devices and advanced packaging. The most rapid growth is expected in emerging economies where electronics manufacturing is expanding, particularly in countries like Vietnam, India, and Mexico.

Customer demand is increasingly focused on processes that can operate at atmospheric pressure and lower temperatures, reducing energy consumption and enabling integration with existing manufacturing lines. This market trend aligns perfectly with the development of process window mapping for APALD on polymer substrates, positioning this technology to capture significant market share as it matures.

The application of APALD on polymer substrates addresses several critical market needs across multiple industries. In the electronics sector, flexible displays, wearable devices, and flexible circuits require thin-film deposition techniques that can operate at lower temperatures compatible with temperature-sensitive polymer materials. The global flexible electronics market is expected to grow from $31.6 billion in 2021 to over $73 billion by 2027, creating significant demand for advanced deposition technologies like APALD.

In the packaging industry, barrier films produced using APALD technology offer superior protection against oxygen and moisture penetration, extending shelf life for food, pharmaceuticals, and electronic components. The high-barrier packaging market is projected to reach $36.4 billion by 2026, growing at a CAGR of 8.2%, with APALD processes potentially capturing a significant portion of this growth.

Medical device manufacturing represents another promising application area, with the global medical polymer market expected to reach $24.8 billion by 2025. APALD coatings on polymer-based medical devices can enhance biocompatibility, provide antimicrobial properties, and improve durability, addressing key requirements in this highly regulated industry.

The automotive and aerospace sectors are increasingly incorporating polymer components that require protective coatings with precise thickness control. APALD processes offer advantages in creating uniform, conformal coatings on complex geometries, addressing the $9.3 billion automotive coatings market and the specialized aerospace coatings segment valued at $1.8 billion.

Regional analysis indicates that Asia-Pacific dominates the ALD market with approximately 45% share, driven by semiconductor and electronics manufacturing. North America and Europe follow with 28% and 20% respectively, with growing applications in medical devices and advanced packaging. The most rapid growth is expected in emerging economies where electronics manufacturing is expanding, particularly in countries like Vietnam, India, and Mexico.

Customer demand is increasingly focused on processes that can operate at atmospheric pressure and lower temperatures, reducing energy consumption and enabling integration with existing manufacturing lines. This market trend aligns perfectly with the development of process window mapping for APALD on polymer substrates, positioning this technology to capture significant market share as it matures.

Technical Challenges in APALD-Polymer Integration

The integration of Atomic Layer Deposition (ALD) processes with polymer substrates presents significant technical challenges due to the fundamental differences in material properties and processing requirements. Traditional ALD processes typically operate at elevated temperatures (200-350°C) that exceed the thermal stability limits of most polymers, which begin to degrade or deform at much lower temperatures (often below 150°C).

Plasma-enhanced ALD (PEALD) and specifically Atmospheric Pressure ALD (APALD) have emerged as potential solutions for low-temperature deposition on temperature-sensitive substrates. However, these approaches introduce their own set of technical hurdles. The plasma component in PEALD can cause surface damage to polymers through ion bombardment, UV radiation, and radical-induced degradation, potentially compromising the structural integrity and functional properties of the polymer substrate.

Surface chemistry compatibility represents another major challenge. Polymers often have low surface energy and limited reactive sites compared to traditional semiconductor substrates, resulting in poor nucleation and growth during the initial ALD cycles. This leads to extended incubation periods before continuous film formation begins, affecting the quality and uniformity of the deposited layers.

Moisture and gas permeation through polymers create additional complications. Polymers can absorb and desorb water and other gases during the ALD process, which may interfere with precursor reactions and cause unwanted side reactions. This phenomenon can lead to non-uniform film growth and compromised barrier properties in the resulting films.

The mechanical mismatch between rigid inorganic films deposited by ALD and flexible polymer substrates introduces stress at the interface, potentially causing delamination, cracking, or other mechanical failures when the composite structure is subjected to bending or stretching. This is particularly problematic for flexible electronics applications where mechanical durability is essential.

Process window mapping for APALD on polymers is further complicated by the diverse range of polymer types, each with unique thermal properties, surface chemistries, and degradation mechanisms. A process optimized for one polymer may be completely unsuitable for another, necessitating extensive characterization and customization for each polymer-film combination.

The atmospheric pressure environment in APALD introduces additional variables such as oxygen and moisture contamination from ambient air, which can interfere with precursor chemistry and film growth mechanisms. Controlling these variables while maintaining the benefits of atmospheric processing requires sophisticated engineering solutions and precise process control strategies.

Plasma-enhanced ALD (PEALD) and specifically Atmospheric Pressure ALD (APALD) have emerged as potential solutions for low-temperature deposition on temperature-sensitive substrates. However, these approaches introduce their own set of technical hurdles. The plasma component in PEALD can cause surface damage to polymers through ion bombardment, UV radiation, and radical-induced degradation, potentially compromising the structural integrity and functional properties of the polymer substrate.

Surface chemistry compatibility represents another major challenge. Polymers often have low surface energy and limited reactive sites compared to traditional semiconductor substrates, resulting in poor nucleation and growth during the initial ALD cycles. This leads to extended incubation periods before continuous film formation begins, affecting the quality and uniformity of the deposited layers.

Moisture and gas permeation through polymers create additional complications. Polymers can absorb and desorb water and other gases during the ALD process, which may interfere with precursor reactions and cause unwanted side reactions. This phenomenon can lead to non-uniform film growth and compromised barrier properties in the resulting films.

The mechanical mismatch between rigid inorganic films deposited by ALD and flexible polymer substrates introduces stress at the interface, potentially causing delamination, cracking, or other mechanical failures when the composite structure is subjected to bending or stretching. This is particularly problematic for flexible electronics applications where mechanical durability is essential.

Process window mapping for APALD on polymers is further complicated by the diverse range of polymer types, each with unique thermal properties, surface chemistries, and degradation mechanisms. A process optimized for one polymer may be completely unsuitable for another, necessitating extensive characterization and customization for each polymer-film combination.

The atmospheric pressure environment in APALD introduces additional variables such as oxygen and moisture contamination from ambient air, which can interfere with precursor chemistry and film growth mechanisms. Controlling these variables while maintaining the benefits of atmospheric processing requires sophisticated engineering solutions and precise process control strategies.

Current Process Window Mapping Methodologies

01 Temperature and pressure control in ALD process window

Controlling temperature and pressure parameters is critical for optimizing the ALD process window. Precise temperature regulation affects precursor adsorption, reaction kinetics, and film quality. Operating within specific pressure ranges ensures proper gas flow dynamics and uniform precursor distribution. These parameters directly impact film growth rate, conformality, and purity, with optimal settings varying based on precursor chemistry and substrate characteristics.- Temperature and pressure control in ALD process window: Controlling temperature and pressure parameters is critical for optimizing the ALD process window. Specific temperature ranges affect precursor adsorption, reaction kinetics, and film quality. Pressure control ensures proper gas flow dynamics and uniform deposition across substrates. These parameters must be precisely maintained to achieve self-limiting surface reactions characteristic of ALD processes, resulting in conformal thin films with precise thickness control.

- Precursor pulse and purge optimization: Optimizing precursor pulse durations and purge times is essential for defining the ALD process window. Sufficient precursor exposure ensures complete surface saturation, while adequate purge cycles prevent chemical vapor deposition and parasitic reactions. The timing sequence directly impacts film growth rate, uniformity, and purity. Advanced precursor delivery systems with precise flow control help maintain consistent deposition conditions and expand the viable process window.

- Substrate surface preparation and modification: Substrate surface conditions significantly influence the ALD process window. Surface preparation techniques such as cleaning, hydroxylation, or functionalization affect initial nucleation and growth behavior. Plasma treatments can activate surfaces to enhance precursor adsorption. Surface roughness and composition impact film adhesion and conformality. Proper surface preparation expands the process window by enabling more uniform nucleation and reducing incubation periods.

- Reactor design and gas flow dynamics: Reactor configuration and gas flow dynamics are crucial factors in determining the ALD process window. Chamber geometry affects precursor distribution and residence time. Flow patterns influence deposition uniformity across large substrates. Advanced reactor designs incorporate features like showerheads, rotating substrates, or spatial ALD concepts to optimize precursor utilization and throughput. Proper reactor design expands the process window by enabling more uniform deposition conditions.

- In-situ monitoring and process control systems: In-situ monitoring and advanced process control systems enable real-time optimization of the ALD process window. Techniques like quartz crystal microbalance, optical emission spectroscopy, or mass spectrometry provide immediate feedback on deposition rate and film properties. Automated control systems can adjust process parameters to maintain optimal conditions despite equipment drift or batch variations. These monitoring capabilities allow for process window expansion through adaptive control strategies.

02 Precursor delivery and pulse optimization

Optimizing precursor delivery and pulse timing is essential for defining the ALD process window. This includes controlling precursor dose, pulse duration, and purge times between pulses to ensure complete surface reactions while preventing CVD-like growth. Advanced delivery systems can maintain precursor stability and consistent vapor pressure, while pulse sequence optimization prevents precursor overlap and enables self-limiting reactions characteristic of true ALD processes.Expand Specific Solutions03 Substrate surface preparation and modification

Substrate surface conditions significantly affect the ALD process window. Surface preparation techniques including cleaning, hydroxylation, and activation treatments create optimal nucleation sites for precursor adsorption. Surface modifications can expand the process window by enhancing initial growth, improving adhesion, and enabling selective deposition. These preparations help achieve uniform film coverage and consistent properties across different substrate materials and geometries.Expand Specific Solutions04 Plasma-enhanced ALD process window expansion

Plasma-enhanced ALD (PEALD) techniques can significantly expand the conventional ALD process window. By introducing plasma energy, PEALD enables lower deposition temperatures, faster reaction kinetics, and improved film properties. The plasma parameters, including power, duration, and gas composition, must be carefully optimized to maintain the self-limiting nature of ALD while benefiting from enhanced reactivity. This approach allows deposition on temperature-sensitive substrates and access to a wider range of materials.Expand Specific Solutions05 In-situ monitoring and process control systems

Advanced in-situ monitoring and control systems enable real-time optimization of the ALD process window. These systems use sensors to track film growth, chamber conditions, and precursor behavior during deposition. Feedback mechanisms can automatically adjust process parameters to maintain optimal conditions despite variations in precursor delivery or chamber status. This approach improves reproducibility, enables precise thickness control, and facilitates process window mapping for new material systems.Expand Specific Solutions

Industry Leaders in APALD Processing Technology

The atomic layer deposition (ALD) on polymer substrates market is in a growth phase, characterized by increasing adoption across semiconductor, display, and medical device industries. The global ALD equipment market is projected to expand significantly, driven by demand for precise thin-film deposition technologies. Technologically, the field is advancing rapidly with major players like Applied Materials, Tokyo Electron, and Lam Research leading innovation in high-volume manufacturing solutions. Specialized companies such as Beneq, Picosun, and Nanexa are developing polymer-specific ALD processes, while research institutions like Imec and TNO contribute fundamental advancements. The competitive landscape shows established semiconductor equipment manufacturers expanding their polymer ALD capabilities while niche players focus on specialized applications, creating a dynamic ecosystem of innovation.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed the Endura® Volta™ APALD system specifically optimized for polymer substrates processing. Their technology utilizes a unique spatial ALD approach with separated precursor zones and plasma treatment capabilities. The system operates at temperatures as low as 50°C, making it suitable for temperature-sensitive polymers. Their process window mapping methodology incorporates in-situ monitoring tools that track film growth in real-time, allowing precise control of deposition parameters. The company has implemented machine learning algorithms to analyze the complex relationship between plasma parameters, precursor exposure time, and substrate temperature to automatically identify optimal process windows for different polymer types. Their solution includes specialized gas delivery systems that ensure uniform precursor distribution across large-area polymer substrates, addressing one of the key challenges in APALD processing.

Strengths: Industry-leading plasma control technology allowing for precise energy delivery without substrate damage; extensive material library for various polymer-compatible chemistries; advanced in-situ monitoring capabilities. Weaknesses: Higher capital equipment cost compared to competitors; complex system integration requirements; limited flexibility for rapid process changes during production.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron has pioneered the FlexAL™ APALD system designed specifically for polymer substrate applications. Their approach focuses on a comprehensive process window mapping methodology that systematically evaluates critical parameters including temperature (30-120°C range), plasma power (5-300W), precursor dose, and purge times. The system incorporates a proprietary "soft plasma" technology that minimizes damage to sensitive polymer surfaces while maintaining effective surface activation. TEL's solution includes specialized substrate handling mechanisms that accommodate the dimensional instability of polymers during thermal cycling. Their process window mapping utilizes automated Design of Experiments (DoE) software that can rapidly identify optimal processing conditions for various polymer types including PET, PEN, PI, and PMMA. The system also features real-time thickness monitoring capabilities through integrated ellipsometry to ensure precise thickness control across large substrate areas.

Strengths: Exceptional temperature uniformity control (±1°C) across large substrates; advanced plasma source design minimizing ion bombardment damage; comprehensive automation software for process optimization. Weaknesses: Limited precursor compatibility compared to some competitors; higher operational costs; more complex maintenance requirements for the plasma generation system.

Key Patents in APALD Polymer Substrate Processing

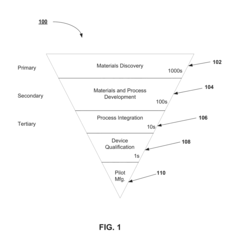

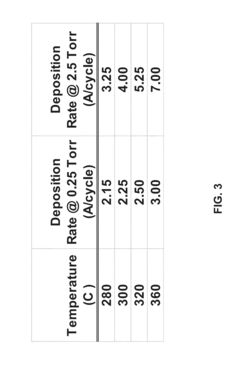

ALD Process Window Combinatorial Screening Tool

PatentInactiveUS20140174540A1

Innovation

- A system and apparatus that facilitate combinatorial processing to evaluate ALD processes at different pressures, using an orthogonal array of intersecting flow channels to create site-isolated regions on a substrate, allowing for characterization across a range of pressures and process parameters.

Method for self-limiting deposition of one or more monolayers

PatentActiveUS8114480B2

Innovation

- The method involves using organometallic compounds as starting materials, accompanied by a limiter introduced at a separate process step to ensure self-limiting deposition of monolayers, expanding the spectrum of available materials and allowing for precise control of layer growth, even on complex substrates, by using hydrocarbons like ruthenium and octane or isooctane as limiters, and reactive gases like oxygen, to achieve conformal deposition.

Thermal Management Strategies for Polymer Substrates

Thermal management represents a critical challenge in Atomic Layer Deposition (ALD) processes on polymer substrates due to their inherently low thermal conductivity and temperature sensitivity. Effective thermal management strategies must balance the need for sufficient thermal energy to drive ALD reactions while preventing substrate degradation or deformation.

Temperature distribution control systems have emerged as essential components in APALD (Atmospheric Pressure ALD) equipment designed for polymer processing. These systems typically incorporate multi-zone heating elements with independent temperature controllers that create precisely managed thermal gradients across the substrate. Real-time thermal imaging and feedback mechanisms allow for dynamic adjustments during the deposition process, maintaining optimal conditions as reactions progress.

Thermal buffer layers represent another innovative approach, where thermally conductive but chemically inert materials are temporarily applied to polymer surfaces. These buffers help distribute heat more evenly across the substrate while protecting temperature-sensitive regions. Materials such as aluminum nitride and boron nitride have demonstrated particular promise in this application due to their excellent thermal conductivity and chemical stability.

Pulsed heating methodologies offer a temporal solution to thermal management challenges. Rather than maintaining constant elevated temperatures, these techniques deliver precisely timed thermal energy pulses synchronized with precursor introduction. This approach minimizes the total thermal exposure of polymer substrates while ensuring sufficient energy for complete surface reactions. Advanced algorithms optimize pulse duration, intensity, and frequency based on specific polymer characteristics.

Substrate cooling systems have also proven effective, particularly in continuous roll-to-roll APALD processes. These systems incorporate targeted cooling elements positioned strategically to extract excess heat immediately following reaction zones. Liquid-based cooling channels embedded within substrate support structures provide efficient thermal extraction without introducing contamination risks.

Computational fluid dynamics (CFD) modeling has become instrumental in designing thermal management strategies for specific polymer-precursor combinations. These models simulate heat transfer dynamics throughout the deposition chamber, enabling process engineers to identify potential hotspots or thermal gradients before physical implementation. Machine learning algorithms increasingly enhance these models by incorporating empirical data from previous deposition runs.

Recent developments in selective surface heating technologies, including laser-assisted and microwave-enhanced APALD, demonstrate promising results for thermally challenging polymers. These approaches deliver energy directly to reaction sites rather than heating the entire substrate, dramatically reducing thermal stress on temperature-sensitive materials while maintaining deposition efficiency.

Temperature distribution control systems have emerged as essential components in APALD (Atmospheric Pressure ALD) equipment designed for polymer processing. These systems typically incorporate multi-zone heating elements with independent temperature controllers that create precisely managed thermal gradients across the substrate. Real-time thermal imaging and feedback mechanisms allow for dynamic adjustments during the deposition process, maintaining optimal conditions as reactions progress.

Thermal buffer layers represent another innovative approach, where thermally conductive but chemically inert materials are temporarily applied to polymer surfaces. These buffers help distribute heat more evenly across the substrate while protecting temperature-sensitive regions. Materials such as aluminum nitride and boron nitride have demonstrated particular promise in this application due to their excellent thermal conductivity and chemical stability.

Pulsed heating methodologies offer a temporal solution to thermal management challenges. Rather than maintaining constant elevated temperatures, these techniques deliver precisely timed thermal energy pulses synchronized with precursor introduction. This approach minimizes the total thermal exposure of polymer substrates while ensuring sufficient energy for complete surface reactions. Advanced algorithms optimize pulse duration, intensity, and frequency based on specific polymer characteristics.

Substrate cooling systems have also proven effective, particularly in continuous roll-to-roll APALD processes. These systems incorporate targeted cooling elements positioned strategically to extract excess heat immediately following reaction zones. Liquid-based cooling channels embedded within substrate support structures provide efficient thermal extraction without introducing contamination risks.

Computational fluid dynamics (CFD) modeling has become instrumental in designing thermal management strategies for specific polymer-precursor combinations. These models simulate heat transfer dynamics throughout the deposition chamber, enabling process engineers to identify potential hotspots or thermal gradients before physical implementation. Machine learning algorithms increasingly enhance these models by incorporating empirical data from previous deposition runs.

Recent developments in selective surface heating technologies, including laser-assisted and microwave-enhanced APALD, demonstrate promising results for thermally challenging polymers. These approaches deliver energy directly to reaction sites rather than heating the entire substrate, dramatically reducing thermal stress on temperature-sensitive materials while maintaining deposition efficiency.

Environmental Impact of APALD Manufacturing

The environmental impact of Atomic Layer Deposition (APALD) manufacturing on polymer substrates represents a critical consideration in the advancement of this technology. APALD processes typically operate at lower temperatures compared to conventional ALD, which significantly reduces energy consumption during deposition cycles. This temperature reduction, essential for polymer substrate compatibility, translates to approximately 30-40% less energy usage than traditional high-temperature deposition methods, contributing to a smaller carbon footprint.

Chemical precursor utilization in APALD systems demonstrates remarkable efficiency, with material utilization rates often exceeding 90%. This high efficiency stems from the self-limiting nature of ALD reactions, where precursors react only with available surface sites. However, certain metal-organic precursors used in APALD processes may contain environmentally concerning elements or require energy-intensive synthesis methods, necessitating careful selection and handling protocols.

Waste management presents both challenges and opportunities in APALD manufacturing. The process generates minimal solid waste compared to solution-based coating methods, but unreacted precursors and byproducts require proper abatement systems. Modern APALD facilities increasingly implement closed-loop precursor recovery systems, reducing emissions by up to 80% compared to earlier generation equipment. Additionally, the extended lifetime of APALD-coated products often offsets initial manufacturing impacts through reduced replacement frequency.

Water consumption in APALD manufacturing remains relatively modest compared to wet chemical processes. A typical APALD production line consumes approximately 70-80% less water than equivalent wet chemical coating operations. This reduction becomes particularly significant when scaling to industrial production volumes, where water conservation translates to substantial environmental and economic benefits.

The polymer substrates themselves introduce environmental considerations. Biodegradable polymers paired with APALD coatings can create environmentally responsible composite materials, while petroleum-based polymers present end-of-life disposal challenges. Research indicates that APALD coatings can be designed to maintain recyclability of the underlying polymer substrate when process parameters are carefully optimized within specific temperature and chemistry windows.

Lifecycle assessment studies suggest that the environmental benefits of APALD-coated polymer products often outweigh manufacturing impacts when considering extended product lifespans and enhanced performance characteristics. The precise mapping of process windows for APALD on polymers enables manufacturers to minimize environmental impact while maintaining coating quality, representing a crucial balance in sustainable manufacturing development.

Chemical precursor utilization in APALD systems demonstrates remarkable efficiency, with material utilization rates often exceeding 90%. This high efficiency stems from the self-limiting nature of ALD reactions, where precursors react only with available surface sites. However, certain metal-organic precursors used in APALD processes may contain environmentally concerning elements or require energy-intensive synthesis methods, necessitating careful selection and handling protocols.

Waste management presents both challenges and opportunities in APALD manufacturing. The process generates minimal solid waste compared to solution-based coating methods, but unreacted precursors and byproducts require proper abatement systems. Modern APALD facilities increasingly implement closed-loop precursor recovery systems, reducing emissions by up to 80% compared to earlier generation equipment. Additionally, the extended lifetime of APALD-coated products often offsets initial manufacturing impacts through reduced replacement frequency.

Water consumption in APALD manufacturing remains relatively modest compared to wet chemical processes. A typical APALD production line consumes approximately 70-80% less water than equivalent wet chemical coating operations. This reduction becomes particularly significant when scaling to industrial production volumes, where water conservation translates to substantial environmental and economic benefits.

The polymer substrates themselves introduce environmental considerations. Biodegradable polymers paired with APALD coatings can create environmentally responsible composite materials, while petroleum-based polymers present end-of-life disposal challenges. Research indicates that APALD coatings can be designed to maintain recyclability of the underlying polymer substrate when process parameters are carefully optimized within specific temperature and chemistry windows.

Lifecycle assessment studies suggest that the environmental benefits of APALD-coated polymer products often outweigh manufacturing impacts when considering extended product lifespans and enhanced performance characteristics. The precise mapping of process windows for APALD on polymers enables manufacturers to minimize environmental impact while maintaining coating quality, representing a crucial balance in sustainable manufacturing development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!