APALD For Gas Barrier Films In Flexible Electronics

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

APALD Technology Background and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, with Plasma-Enhanced ALD (PEALD) emerging as an important variant in the 1990s. The most recent advancement, Atmospheric Pressure ALD (APALD), represents a breakthrough that eliminates the need for vacuum conditions, substantially reducing manufacturing complexity and cost while maintaining the exceptional quality of traditional ALD processes. This evolution has positioned APALD as a transformative technology for creating ultra-thin, highly conformal gas barrier films essential for flexible electronics.

The flexible electronics market has experienced exponential growth, with applications spanning from foldable displays and wearable devices to photovoltaics and medical sensors. These applications demand barrier films with exceptional performance characteristics: water vapor transmission rates (WVTR) below 10^-6 g/m²/day and oxygen transmission rates (OTR) below 10^-3 cm³/m²/day, while maintaining flexibility, transparency, and durability through thousands of bending cycles.

Traditional barrier technologies like metallized films and bulk oxide layers have proven inadequate for next-generation flexible electronics, creating a technological gap that APALD is uniquely positioned to address. By enabling the deposition of nanometer-scale inorganic layers at atmospheric pressure, APALD offers unprecedented precision in creating multi-layer barrier structures without the vacuum equipment traditionally required for high-performance barriers.

The primary objective of APALD technology development for gas barrier films is to achieve industrial-scale, cost-effective production of ultra-high-performance barrier films that can enable the next generation of flexible electronic devices. This includes developing processes capable of high-throughput roll-to-roll manufacturing while maintaining sub-nanometer thickness control and defect-free deposition across large areas.

Secondary objectives include optimizing material combinations for specific applications, such as transparent barriers for displays versus high-temperature resistant barriers for flexible photovoltaics. Additionally, research aims to extend APALD capabilities to create multi-functional barrier layers that provide not only gas impermeability but also additional properties like scratch resistance, anti-reflection, or antimicrobial functionality.

The technology trajectory suggests APALD will continue evolving toward higher deposition rates, greater material versatility, and improved integration with other manufacturing processes. As flexible electronics transition from niche products to mainstream consumer goods, APALD barrier technology represents a critical enabler that could fundamentally transform product design possibilities and manufacturing economics in the electronics industry.

The flexible electronics market has experienced exponential growth, with applications spanning from foldable displays and wearable devices to photovoltaics and medical sensors. These applications demand barrier films with exceptional performance characteristics: water vapor transmission rates (WVTR) below 10^-6 g/m²/day and oxygen transmission rates (OTR) below 10^-3 cm³/m²/day, while maintaining flexibility, transparency, and durability through thousands of bending cycles.

Traditional barrier technologies like metallized films and bulk oxide layers have proven inadequate for next-generation flexible electronics, creating a technological gap that APALD is uniquely positioned to address. By enabling the deposition of nanometer-scale inorganic layers at atmospheric pressure, APALD offers unprecedented precision in creating multi-layer barrier structures without the vacuum equipment traditionally required for high-performance barriers.

The primary objective of APALD technology development for gas barrier films is to achieve industrial-scale, cost-effective production of ultra-high-performance barrier films that can enable the next generation of flexible electronic devices. This includes developing processes capable of high-throughput roll-to-roll manufacturing while maintaining sub-nanometer thickness control and defect-free deposition across large areas.

Secondary objectives include optimizing material combinations for specific applications, such as transparent barriers for displays versus high-temperature resistant barriers for flexible photovoltaics. Additionally, research aims to extend APALD capabilities to create multi-functional barrier layers that provide not only gas impermeability but also additional properties like scratch resistance, anti-reflection, or antimicrobial functionality.

The technology trajectory suggests APALD will continue evolving toward higher deposition rates, greater material versatility, and improved integration with other manufacturing processes. As flexible electronics transition from niche products to mainstream consumer goods, APALD barrier technology represents a critical enabler that could fundamentally transform product design possibilities and manufacturing economics in the electronics industry.

Market Analysis for Gas Barrier Films

The global market for gas barrier films in flexible electronics is experiencing robust growth, driven by the increasing demand for high-performance displays, photovoltaics, and wearable devices. Current market valuations indicate that the gas barrier film sector reached approximately 1.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 12.3% through 2028, potentially reaching 2.4 billion USD by the end of the forecast period.

The Asia-Pacific region dominates the market landscape, accounting for over 60% of global production and consumption, with South Korea, Japan, and China leading manufacturing capabilities. This regional concentration is primarily attributed to the established electronics manufacturing ecosystem and significant investments in advanced display technologies.

Consumer electronics remains the largest application segment, representing nearly 45% of the total market share, followed by flexible displays (30%), photovoltaics (15%), and emerging applications including medical devices and smart packaging (10%). The demand for increasingly thinner, more flexible, and durable electronic devices continues to drive innovation in barrier film technologies.

OLED displays constitute the fastest-growing segment within the application spectrum, with manufacturers seeking ultra-high barrier films with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. This stringent requirement has created a premium market segment where APALD (Atomic and Plasma-Assisted Layer Deposition) technologies offer significant competitive advantages over conventional barrier solutions.

Market analysis reveals a clear correlation between barrier performance and price positioning, with ultra-high barrier films commanding prices 5-8 times higher than standard barrier materials. This price premium underscores the significant value proposition of advanced deposition technologies like APALD in addressing critical performance requirements.

Customer requirements are increasingly focused on multi-functional barrier properties, including not only moisture and oxygen protection but also enhanced optical transparency, flexibility under repeated bending, and resistance to environmental stressors. This trend toward multifunctionality represents a key opportunity for differentiation in an increasingly competitive landscape.

The market structure is characterized by a mix of large materials science corporations and specialized technology providers, with increasing vertical integration observed among major display manufacturers seeking to secure proprietary barrier technologies. Recent strategic partnerships and acquisitions indicate consolidation trends, particularly around technologies that can achieve ultra-high barrier performance at commercially viable production scales.

The Asia-Pacific region dominates the market landscape, accounting for over 60% of global production and consumption, with South Korea, Japan, and China leading manufacturing capabilities. This regional concentration is primarily attributed to the established electronics manufacturing ecosystem and significant investments in advanced display technologies.

Consumer electronics remains the largest application segment, representing nearly 45% of the total market share, followed by flexible displays (30%), photovoltaics (15%), and emerging applications including medical devices and smart packaging (10%). The demand for increasingly thinner, more flexible, and durable electronic devices continues to drive innovation in barrier film technologies.

OLED displays constitute the fastest-growing segment within the application spectrum, with manufacturers seeking ultra-high barrier films with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. This stringent requirement has created a premium market segment where APALD (Atomic and Plasma-Assisted Layer Deposition) technologies offer significant competitive advantages over conventional barrier solutions.

Market analysis reveals a clear correlation between barrier performance and price positioning, with ultra-high barrier films commanding prices 5-8 times higher than standard barrier materials. This price premium underscores the significant value proposition of advanced deposition technologies like APALD in addressing critical performance requirements.

Customer requirements are increasingly focused on multi-functional barrier properties, including not only moisture and oxygen protection but also enhanced optical transparency, flexibility under repeated bending, and resistance to environmental stressors. This trend toward multifunctionality represents a key opportunity for differentiation in an increasingly competitive landscape.

The market structure is characterized by a mix of large materials science corporations and specialized technology providers, with increasing vertical integration observed among major display manufacturers seeking to secure proprietary barrier technologies. Recent strategic partnerships and acquisitions indicate consolidation trends, particularly around technologies that can achieve ultra-high barrier performance at commercially viable production scales.

Current APALD Technical Challenges

Despite significant advancements in Atomic Layer Deposition (ALD) technology, the adaptation of Atmospheric Pressure Atomic Layer Deposition (APALD) for gas barrier films in flexible electronics faces several critical technical challenges. The primary obstacle remains achieving uniform deposition across large surface areas without vacuum conditions. Traditional ALD processes benefit from vacuum environments that ensure precise gas flow control and complete purging between precursor pulses, whereas APALD must overcome gas diffusion limitations in ambient pressure conditions.

The precursor chemistry presents another significant challenge. Many high-performance barrier materials require precursors that are highly reactive with atmospheric components, particularly oxygen and moisture. This reactivity can lead to premature reactions, reduced film quality, and potential safety hazards. Developing precursors that remain stable in atmospheric conditions yet reactive enough for complete surface reactions represents a delicate balance that researchers continue to pursue.

Throughput limitations severely restrict industrial scalability of APALD processes. Current deposition rates typically range from 0.5 to 2 nm per minute, significantly slower than many competing technologies. This slow growth rate becomes particularly problematic for gas barrier applications requiring multi-layer structures or thicker films to achieve adequate protection against oxygen and moisture penetration.

Energy efficiency concerns also plague APALD implementation. The continuous gas flow requirements and thermal management at atmospheric pressure often result in higher energy consumption compared to vacuum-based processes. This inefficiency directly impacts production costs and environmental sustainability, creating barriers to widespread industrial adoption.

Interface quality control between substrate and barrier layers presents unique challenges in atmospheric conditions. Surface contamination from airborne particles and adsorbed species can compromise adhesion and create defect sites that serve as permeation pathways. Current surface preparation techniques developed for vacuum environments often prove inadequate for atmospheric processing conditions.

The spatial separation of precursors—a fundamental requirement for true ALD processes—becomes exceptionally difficult at atmospheric pressure. Gas phase mixing and diffusion can lead to chemical vapor deposition (CVD) growth mechanisms rather than the self-limiting surface reactions characteristic of ALD. This results in less precise thickness control and potentially inferior barrier properties.

Equipment design complexity increases substantially for APALD systems. The need to maintain precursor separation, ensure uniform gas distribution, and manage thermal profiles without vacuum chambers requires sophisticated engineering solutions. Current reactor designs struggle to balance these requirements while maintaining cost-effectiveness and operational simplicity for manufacturing environments.

The precursor chemistry presents another significant challenge. Many high-performance barrier materials require precursors that are highly reactive with atmospheric components, particularly oxygen and moisture. This reactivity can lead to premature reactions, reduced film quality, and potential safety hazards. Developing precursors that remain stable in atmospheric conditions yet reactive enough for complete surface reactions represents a delicate balance that researchers continue to pursue.

Throughput limitations severely restrict industrial scalability of APALD processes. Current deposition rates typically range from 0.5 to 2 nm per minute, significantly slower than many competing technologies. This slow growth rate becomes particularly problematic for gas barrier applications requiring multi-layer structures or thicker films to achieve adequate protection against oxygen and moisture penetration.

Energy efficiency concerns also plague APALD implementation. The continuous gas flow requirements and thermal management at atmospheric pressure often result in higher energy consumption compared to vacuum-based processes. This inefficiency directly impacts production costs and environmental sustainability, creating barriers to widespread industrial adoption.

Interface quality control between substrate and barrier layers presents unique challenges in atmospheric conditions. Surface contamination from airborne particles and adsorbed species can compromise adhesion and create defect sites that serve as permeation pathways. Current surface preparation techniques developed for vacuum environments often prove inadequate for atmospheric processing conditions.

The spatial separation of precursors—a fundamental requirement for true ALD processes—becomes exceptionally difficult at atmospheric pressure. Gas phase mixing and diffusion can lead to chemical vapor deposition (CVD) growth mechanisms rather than the self-limiting surface reactions characteristic of ALD. This results in less precise thickness control and potentially inferior barrier properties.

Equipment design complexity increases substantially for APALD systems. The need to maintain precursor separation, ensure uniform gas distribution, and manage thermal profiles without vacuum chambers requires sophisticated engineering solutions. Current reactor designs struggle to balance these requirements while maintaining cost-effectiveness and operational simplicity for manufacturing environments.

Current Gas Barrier Film Solutions

01 APALD process for gas barrier films

Atmospheric Pressure Atomic Layer Deposition (APALD) can be used to create high-quality gas barrier films without requiring vacuum conditions. This technique allows for the deposition of thin, uniform layers of barrier materials that effectively prevent gas permeation. The process can be optimized for various substrates and can achieve superior barrier properties compared to conventional deposition methods due to the precise layer-by-layer growth mechanism.- APALD process for gas barrier films: Atmospheric Pressure Atomic Layer Deposition (APALD) can be used to create high-quality gas barrier films without requiring vacuum conditions. This technique allows for the deposition of thin, uniform layers of barrier materials that effectively prevent gas permeation. The process can be optimized by controlling parameters such as temperature, precursor exposure time, and purge duration to achieve superior barrier properties while maintaining process efficiency.

- Metal oxide layers as gas barrier materials: Metal oxide layers deposited via APALD, such as aluminum oxide (Al2O3), titanium dioxide (TiO2), and silicon dioxide (SiO2), serve as effective gas barrier materials. These oxides form dense, pinhole-free films that block the diffusion of oxygen, water vapor, and other gases. Multiple layers of different metal oxides can be combined to create multilayer structures with enhanced barrier properties, addressing the limitations of single-layer barriers.

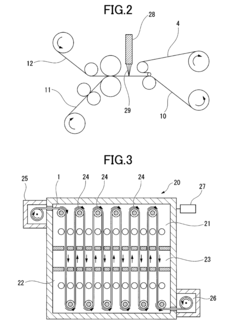

- Flexible substrate applications for APALD barriers: APALD gas barrier technology can be applied to flexible substrates such as polymers, textiles, and thin films, enabling the production of flexible electronics, packaging materials, and displays with excellent barrier properties. The low-temperature nature of APALD processes allows for deposition on temperature-sensitive substrates without causing thermal damage. This approach enables roll-to-roll processing for high-throughput manufacturing of barrier-coated flexible materials.

- Precursor chemistry and delivery systems: The selection and delivery of precursors play crucial roles in APALD gas barrier performance. Various precursor chemistries, including organometallics, halides, and alkoxides, can be used to deposit barrier layers with specific properties. Advanced precursor delivery systems ensure precise dosing and uniform distribution across the substrate surface. Optimization of precursor pulse sequences and carrier gas flow rates enhances the quality and consistency of the deposited barrier layers.

- Nanolaminate structures for enhanced barrier performance: Nanolaminate structures consisting of alternating layers of different materials deposited via APALD can significantly enhance gas barrier performance. These structures disrupt the direct diffusion pathways for gas molecules, forcing them to follow a tortuous path through the barrier. By controlling the thickness and composition of individual layers in the nanolaminate, the barrier properties can be tailored for specific applications. This approach also improves mechanical flexibility and durability of the barrier coating.

02 Metal oxide layers as gas barrier materials

Metal oxide layers, particularly aluminum oxide (Al2O3), titanium oxide (TiO2), and silicon oxide (SiO2), deposited via APALD provide excellent gas barrier properties. These materials form dense, pinhole-free films that effectively block the diffusion of oxygen, water vapor, and other gases. The metal oxide layers can be deposited at relatively low temperatures, making them suitable for temperature-sensitive substrates like polymers and flexible electronics.Expand Specific Solutions03 Multilayer barrier structures

Multilayer structures consisting of alternating organic and inorganic layers deposited via APALD can enhance gas barrier performance. The organic layers provide flexibility and defect decoupling, while the inorganic layers provide the primary barrier function. This multilayer approach creates a tortuous path for gas molecules, significantly reducing permeation rates. The number and thickness of these alternating layers can be optimized for specific barrier requirements.Expand Specific Solutions04 APALD equipment and reactor design

Specialized equipment and reactor designs for APALD enable efficient gas barrier deposition at atmospheric pressure. These systems incorporate precise gas delivery mechanisms, temperature control, and substrate handling capabilities. Roll-to-roll APALD reactors allow for continuous processing of flexible substrates, while spatial APALD systems separate precursor zones physically rather than temporally, increasing throughput. Reactor designs also focus on minimizing precursor waste and ensuring uniform deposition across large areas.Expand Specific Solutions05 Surface treatment and adhesion enhancement

Surface treatments prior to APALD deposition can significantly improve gas barrier performance by enhancing adhesion between the substrate and barrier layers. Plasma treatment, chemical functionalization, and primer layers can modify surface energy and create anchor points for the deposited materials. These pre-treatments help to ensure uniform coverage, reduce defects, and improve the durability of the gas barrier coating, particularly for polymer substrates that may otherwise have poor compatibility with inorganic barrier materials.Expand Specific Solutions

Key Industry Players in APALD Field

The APALD (Atomic Precision Atomic Layer Deposition) technology for gas barrier films in flexible electronics is currently in an early growth phase, with increasing market adoption driven by the expanding flexible electronics sector. The global market is projected to grow significantly as demand for high-performance barrier films increases in OLED displays, photovoltaics, and wearable devices. Technologically, APALD is advancing rapidly with key players demonstrating varied maturity levels. Companies like Lam Research, Tokyo Electron, and ULVAC lead with established equipment solutions, while materials innovators such as DuPont, Sumitomo Chemical, and Konica Minolta are developing specialized precursors and substrates. Chinese entities including NAURA Microelectronics and Leadmicro are emerging as competitive equipment manufacturers, while academic institutions like Nanjing University contribute fundamental research advancing the field's theoretical foundations.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary APALD technology platform called FlexBarrier™ specifically designed for gas barrier applications in flexible electronics. Their approach combines APALD with their expertise in adhesives and multilayer film technologies to create integrated barrier solutions. 3M's process utilizes a unique precursor chemistry that enables faster deposition cycles while maintaining film quality, achieving growth rates up to 2.5nm/minute compared to conventional ALD's typical 0.5-1nm/minute. Their barrier structure incorporates APALD-deposited Al2O3 and TiO2 layers combined with specialized organic interlayers that enhance mechanical durability while maintaining barrier properties. The company has optimized their process for temperatures as low as 60°C, making it compatible with a wide range of polymer substrates including PET, PEN, and polyimide. 3M's barrier films demonstrate WVTR values in the range of 10^-5 to 10^-6 g/m²/day depending on the specific structure, with excellent retention of properties after environmental aging tests including temperature/humidity cycling and UV exposure. Their manufacturing approach is scalable to roll-to-roll production with web widths up to 1.4 meters.

Strengths: Comprehensive barrier solution incorporating both deposition technology and materials science expertise; excellent environmental stability of barrier properties; established manufacturing infrastructure for scale-up. Weaknesses: Moderate barrier performance compared to some competitors' highest-end solutions; technology optimized for moderate barrier requirements rather than ultra-high barriers needed for some OLED applications.

ULVAC, Inc.

Technical Solution: ULVAC has developed advanced APALD (Atomic Layer Deposition with Plasma Assistance) systems specifically designed for creating high-performance gas barrier films for flexible electronics. Their technology utilizes a unique plasma-enhanced process that enables the deposition of ultra-thin, pinhole-free aluminum oxide (Al2O3) and silicon nitride (SiNx) layers at lower temperatures (below 100°C) compared to conventional thermal ALD. This makes it particularly suitable for temperature-sensitive flexible substrates like PET and PEN. ULVAC's APALD systems feature multi-chamber configurations that allow for sequential deposition of different barrier materials to create multilayer structures with water vapor transmission rates (WVTR) below 10^-6 g/m²/day. Their equipment incorporates proprietary plasma source designs that ensure uniform plasma distribution across large substrate areas, enabling the production of barrier films with consistent properties for displays up to Gen 8 size.

Strengths: Superior plasma uniformity technology enabling consistent barrier performance across large areas; specialized in equipment for mass production with high throughput; extensive experience in vacuum coating technologies. Weaknesses: Higher initial equipment investment compared to conventional barrier coating methods; process complexity requiring specialized technical expertise for operation and maintenance.

Critical APALD Patents and Innovations

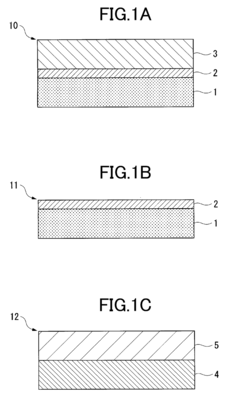

Barrier films for plastic substrates fabricated by atomic layer deposition

PatentInactiveEP1629543A1

Innovation

- Atomic layer deposition (ALD) is used to create thin, defect-free, and highly conformal gas permeation barriers on plastic or glass substrates, employing materials like SiO2 and Al2O3, with adhesion layers to ensure effective protection, and multiple layers are laminated for enhanced barrier properties.

Gas barrier film and method of manufacturing the same

PatentActiveUS20190032208A1

Innovation

- A curable resin overcoat layer is laminated onto the atomic layer deposition film using a transfer process, which cushions the film from mechanical stresses and prevents defects, maintaining gas barrier properties and adhesion strength.

Material Compatibility and Integration Issues

The integration of APALD (Atmospheric Pressure Atomic Layer Deposition) technology for gas barrier films in flexible electronics presents significant material compatibility challenges that must be addressed for successful implementation. The interface between the barrier layer and substrate materials is particularly critical, as poor adhesion can lead to delamination during flexing or thermal cycling, compromising the barrier properties.

Substrate selection represents a primary compatibility concern, as APALD processes must accommodate temperature-sensitive materials common in flexible electronics. Traditional polymeric substrates like polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and polyimide exhibit varying thermal stability profiles, with maximum processing temperatures ranging from 120°C to 350°C. This thermal constraint necessitates careful optimization of APALD parameters to ensure effective deposition without substrate degradation.

Surface chemistry interactions between precursors and substrate materials significantly impact film quality and adhesion. Hydrophilic or hydrophobic surface characteristics can affect nucleation behavior during initial deposition stages. Pre-treatments such as plasma activation, UV-ozone cleaning, or chemical functionalization are often required to modify surface properties and promote uniform film growth with strong interfacial bonding.

Mechanical stress management represents another critical integration challenge. The significant difference in elastic moduli between inorganic barrier layers (typically 70-300 GPa) and flexible substrates (2-5 GPa) creates inherent strain during flexing operations. This mismatch can induce cracking in the barrier layer, creating pathways for gas permeation. Multilayer approaches incorporating organic interlayers have demonstrated improved stress distribution and crack resistance.

Chemical compatibility issues arise from potential reactions between precursor chemicals and substrate materials or functional layers in the device stack. Reactive precursors used in APALD processes may cause degradation of underlying organic materials or functional components. Careful selection of precursor chemistry and implementation of buffer layers can mitigate these adverse interactions.

Integration with existing manufacturing processes presents additional challenges. APALD must be compatible with roll-to-roll processing techniques to maintain economic viability for large-scale production. This requires precise control of deposition parameters across large areas and at speeds compatible with industrial throughput requirements. The development of spatial APALD systems has addressed some of these integration challenges by enabling continuous processing.

Defect management across the substrate-barrier interface remains particularly challenging. Particulate contamination, surface irregularities, and chemical inhomogeneities can create localized defects that compromise barrier performance. Advanced in-line monitoring techniques and quality control protocols are essential to maintain consistent barrier properties across large-area flexible substrates.

Substrate selection represents a primary compatibility concern, as APALD processes must accommodate temperature-sensitive materials common in flexible electronics. Traditional polymeric substrates like polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and polyimide exhibit varying thermal stability profiles, with maximum processing temperatures ranging from 120°C to 350°C. This thermal constraint necessitates careful optimization of APALD parameters to ensure effective deposition without substrate degradation.

Surface chemistry interactions between precursors and substrate materials significantly impact film quality and adhesion. Hydrophilic or hydrophobic surface characteristics can affect nucleation behavior during initial deposition stages. Pre-treatments such as plasma activation, UV-ozone cleaning, or chemical functionalization are often required to modify surface properties and promote uniform film growth with strong interfacial bonding.

Mechanical stress management represents another critical integration challenge. The significant difference in elastic moduli between inorganic barrier layers (typically 70-300 GPa) and flexible substrates (2-5 GPa) creates inherent strain during flexing operations. This mismatch can induce cracking in the barrier layer, creating pathways for gas permeation. Multilayer approaches incorporating organic interlayers have demonstrated improved stress distribution and crack resistance.

Chemical compatibility issues arise from potential reactions between precursor chemicals and substrate materials or functional layers in the device stack. Reactive precursors used in APALD processes may cause degradation of underlying organic materials or functional components. Careful selection of precursor chemistry and implementation of buffer layers can mitigate these adverse interactions.

Integration with existing manufacturing processes presents additional challenges. APALD must be compatible with roll-to-roll processing techniques to maintain economic viability for large-scale production. This requires precise control of deposition parameters across large areas and at speeds compatible with industrial throughput requirements. The development of spatial APALD systems has addressed some of these integration challenges by enabling continuous processing.

Defect management across the substrate-barrier interface remains particularly challenging. Particulate contamination, surface irregularities, and chemical inhomogeneities can create localized defects that compromise barrier performance. Advanced in-line monitoring techniques and quality control protocols are essential to maintain consistent barrier properties across large-area flexible substrates.

Scalability and Cost Optimization Strategies

The scalability of APALD (Atmospheric Pressure Atomic Layer Deposition) technology for gas barrier films represents a critical challenge for widespread industrial adoption in flexible electronics. Current APALD processes demonstrate excellent barrier properties at laboratory scale but face significant hurdles when transitioning to high-volume manufacturing environments. The primary cost drivers include expensive precursor materials, lengthy deposition cycles, and specialized equipment requirements.

To address these challenges, several cost optimization strategies are emerging in the industry. Roll-to-roll (R2R) APALD systems have shown promising results by enabling continuous processing of flexible substrates, dramatically increasing throughput compared to batch processes. Recent advancements in R2R systems have achieved processing speeds of up to 10 meters per minute while maintaining barrier performance below 10^-3 g/m²/day water vapor transmission rates.

Precursor efficiency improvements represent another vital optimization pathway. Novel delivery systems utilizing pulsed injection techniques have demonstrated up to 40% reduction in precursor consumption without compromising film quality. Additionally, research into alternative, lower-cost precursor materials such as trimethylaluminum replacements shows potential for reducing material costs by 25-30% for aluminum oxide barrier layers.

Spatial APALD represents a paradigm shift in deposition methodology, separating reaction zones physically rather than temporally. This approach eliminates the purge steps between precursor exposures, potentially reducing cycle times by 60-70%. Companies implementing spatial APALD have reported throughput increases of 3-5x compared to conventional temporal ALD processes.

Energy consumption optimization through improved reactor designs and thermal management systems has yielded significant cost benefits. Recent innovations in low-temperature APALD processes enable deposition on temperature-sensitive substrates while reducing energy requirements by approximately 35%. These advancements make the technology more compatible with existing manufacturing infrastructure.

Integration with existing production lines presents another opportunity for cost reduction. Modular APALD systems designed to retrofit into conventional coating lines minimize capital expenditure while leveraging existing infrastructure. This approach has shown potential to reduce implementation costs by 40-50% compared to standalone systems.

For mass production scenarios, economies of scale will play a crucial role in cost reduction. Industry projections suggest that at production volumes exceeding 10 million square meters annually, the cost per square meter of APALD barrier films could decrease by 60-70% compared to current small-batch production costs, making them competitive with conventional barrier technologies while offering superior performance.

To address these challenges, several cost optimization strategies are emerging in the industry. Roll-to-roll (R2R) APALD systems have shown promising results by enabling continuous processing of flexible substrates, dramatically increasing throughput compared to batch processes. Recent advancements in R2R systems have achieved processing speeds of up to 10 meters per minute while maintaining barrier performance below 10^-3 g/m²/day water vapor transmission rates.

Precursor efficiency improvements represent another vital optimization pathway. Novel delivery systems utilizing pulsed injection techniques have demonstrated up to 40% reduction in precursor consumption without compromising film quality. Additionally, research into alternative, lower-cost precursor materials such as trimethylaluminum replacements shows potential for reducing material costs by 25-30% for aluminum oxide barrier layers.

Spatial APALD represents a paradigm shift in deposition methodology, separating reaction zones physically rather than temporally. This approach eliminates the purge steps between precursor exposures, potentially reducing cycle times by 60-70%. Companies implementing spatial APALD have reported throughput increases of 3-5x compared to conventional temporal ALD processes.

Energy consumption optimization through improved reactor designs and thermal management systems has yielded significant cost benefits. Recent innovations in low-temperature APALD processes enable deposition on temperature-sensitive substrates while reducing energy requirements by approximately 35%. These advancements make the technology more compatible with existing manufacturing infrastructure.

Integration with existing production lines presents another opportunity for cost reduction. Modular APALD systems designed to retrofit into conventional coating lines minimize capital expenditure while leveraging existing infrastructure. This approach has shown potential to reduce implementation costs by 40-50% compared to standalone systems.

For mass production scenarios, economies of scale will play a crucial role in cost reduction. Industry projections suggest that at production volumes exceeding 10 million square meters annually, the cost per square meter of APALD barrier films could decrease by 60-70% compared to current small-batch production costs, making them competitive with conventional barrier technologies while offering superior performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!